Etching solution

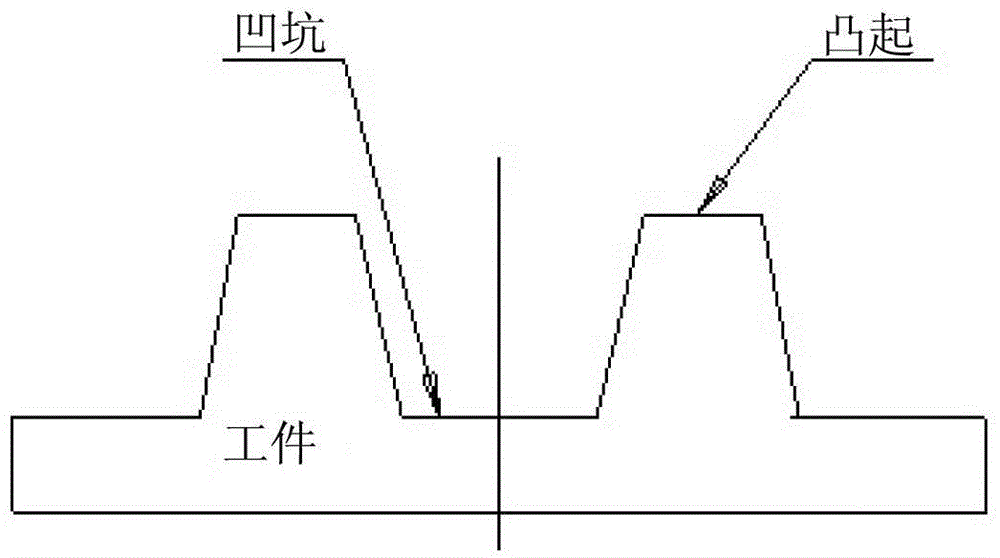

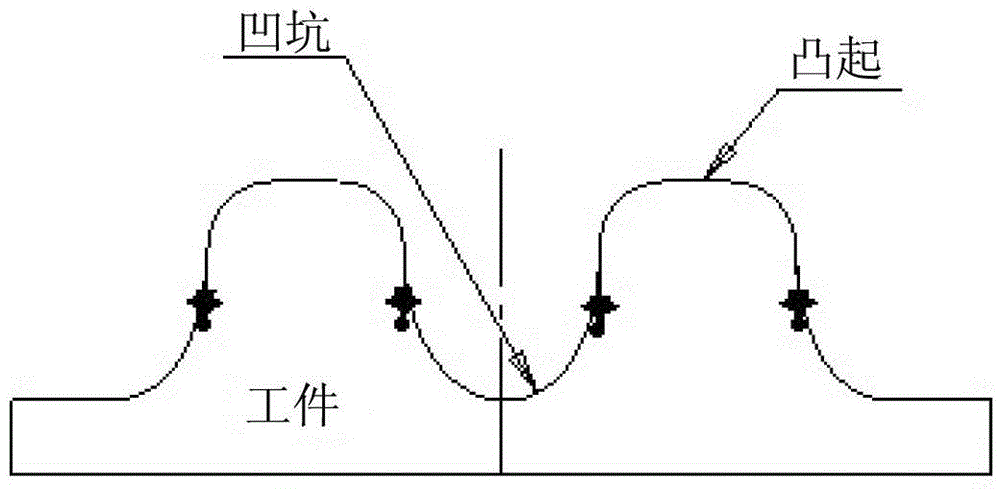

A technology of etching solution and content, applied in the field of chemical etching process, can solve the problems of large surface opening, affecting visual effect, and poor touch feeling of processed workpieces.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0028] In example 1, adopt following method to prepare etching solution: first, take by weight 15% iron trichloride, 30% hydrofluoric acid, 2% phosphoric acid and 53% water respectively; Dissolve ferric chloride in water to obtain a premixed solution; when the obtained premixed solution is cooled to room temperature, add hydrofluoric acid and phosphoric acid, and mix well to obtain an etching solution.

example 2

[0030] In example 2, adopt following method to prepare etching solution: first, take by weight 20% iron trichloride, 35% hydrofluoric acid, 3% phosphoric acid and 42% water respectively; Dissolve ferric chloride in water to obtain a premixed solution; when the obtained premixed solution is cooled to room temperature, add hydrofluoric acid and phosphoric acid, and mix well to obtain an etching solution.

example 3

[0032] In example 3, adopt following method to prepare etching solution: first, take by weight 25% iron trichloride, 50% hydrofluoric acid, 5% phosphoric acid and 20% water respectively; Dissolve ferric chloride in water to obtain a premixed solution; when the obtained premixed solution is cooled to room temperature, add hydrofluoric acid and phosphoric acid, and mix well to obtain an etching solution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com