Ferric fluoride/conducting polymer composite material, preparation method thereof and lithium secondary battery

A technology of conductive polymer and conductive polymer layer, used in secondary batteries, battery electrodes, circuits, etc., can solve the problems of low electronic conductivity and volume expansion of iron trifluoride

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0051] The present invention also provides a preparation method of ferric fluoride / conductive polymer composite material, comprising the following steps:

[0052] A) After mixing and reacting ferric fluoride powder, ferric chloride solution, conductive polymer monomer, anionic surfactant and organic solvent, ferric fluoride / conductive polymer composite material is obtained.

[0053] The selection, source and ratio of the raw materials in the present invention are consistent with those in the aforementioned ferric fluoride / conductive polymer composite material unless otherwise specified, and will not be repeated here.

[0054] The present invention has no special restrictions on the specific selection of the ferric chloride solution, and those skilled in the art can select according to actual production conditions, composite conditions and product performance. The ferric chloride solution of the present invention is preferably acid trichloride iron solution. The concentration ...

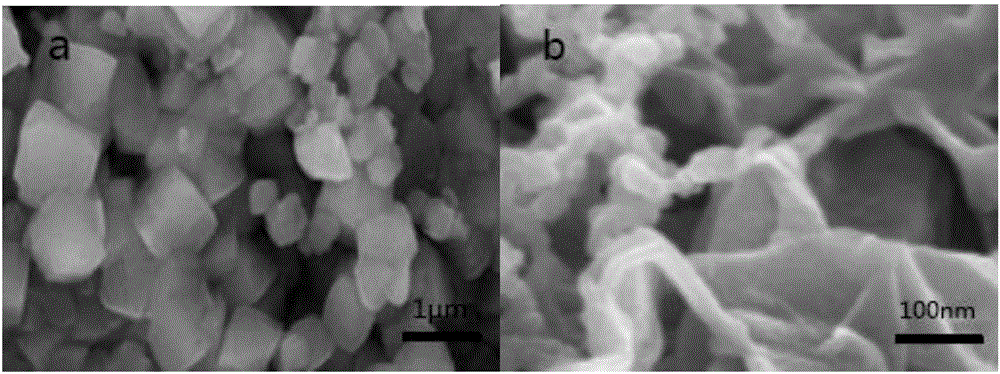

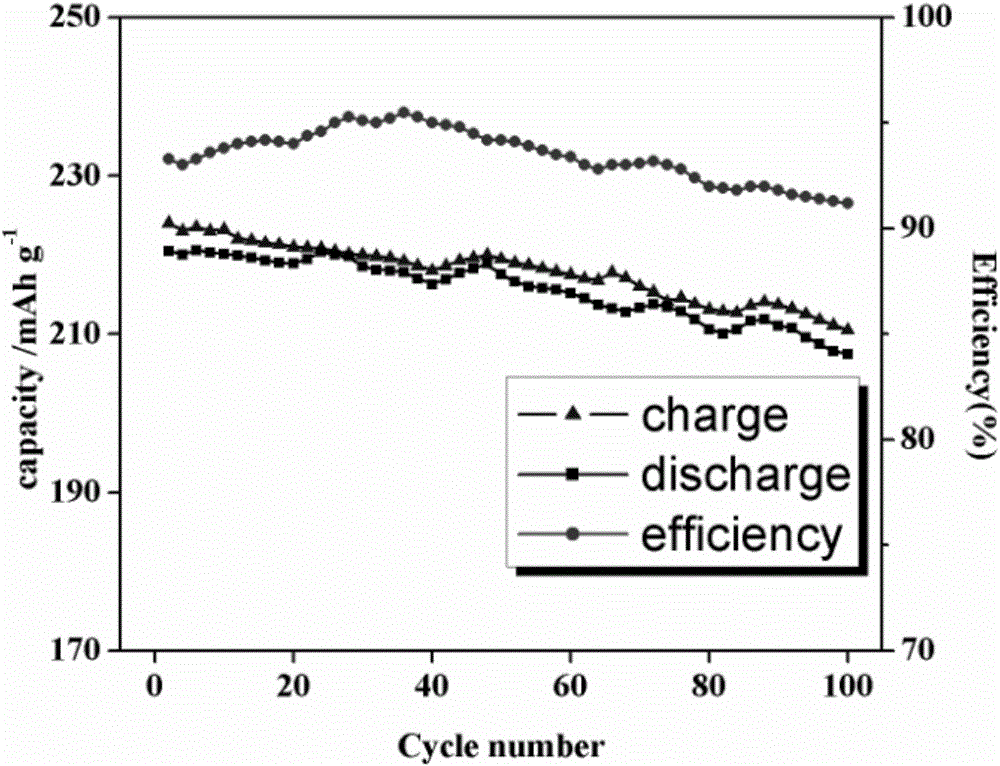

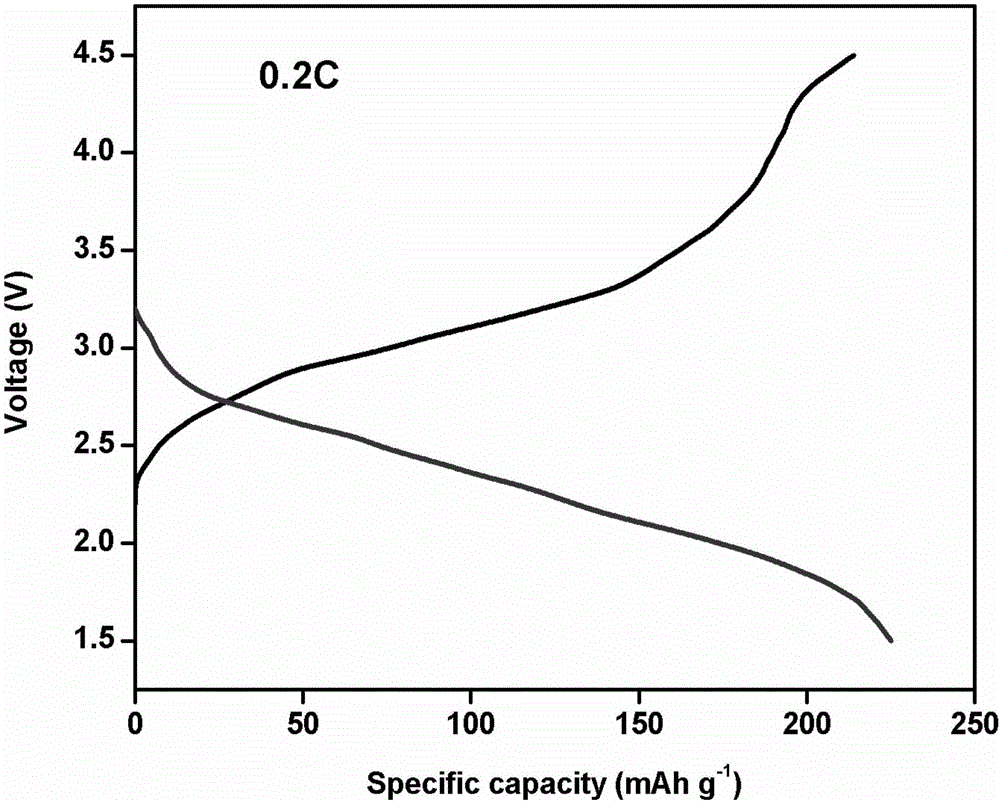

Embodiment 1

[0070] First configure the iron source FeCl with a concentration of 0.35M 3 solution with a concentration of 1.2M fluorine source NH 4 F solution, then add a small amount of lauryltrimethylammonium bromide (DTAB) powder in the polytetrafluoroethylene reactor (PTFE) equipped with iron source, and put PTFE in the DF-101S type with a rotating speed of 200r / min at the same time Stir on a magnetic stirrer at constant temperature for 2 hours; then add the fluorine source dropwise to the PTFE under stirring at a molar ratio of 4:1 to the iron source, and seal the reaction for 4 hours at room temperature; put the reaction kettle into the stirrer, Stir at 300r / min and react in an oil bath at 70°C for 22 hours to obtain a precipitate containing crystal water; wash the precipitate with absolute ethanol for 3 times, then transfer it to a 75°C drying oven with Ar for drying After cooling to room temperature for 12 hours, put it into an Ar-protected tube atmosphere furnace and dry it at 30...

Embodiment 2

[0077] First configure the iron source FeCl with a concentration of 0.5M 3 solution with a concentration of 1.5M fluorine source NH 4 F solution, then add a small amount of lauryltrimethylammonium bromide (DTAB) powder in the polytetrafluoroethylene reactor (PTFE) equipped with iron source, and put PTFE in the DF-101S type with a rotating speed of 200r / min at the same time Stir on a magnetic stirrer at constant temperature for 2 hours; then add the fluorine source dropwise to the PTFE under stirring at a molar ratio of 3.5:1 to the iron source, and seal the reaction for 3 hours at room temperature; put the reaction kettle into the stirrer, Stir at 300r / min and react in an oil bath at 75°C for 24 hours to obtain a precipitate containing crystal water; wash the precipitate with absolute ethanol for 3 times, then transfer it to a 65°C drying oven with Ar for drying After cooling to room temperature for 13 hours, put it into an Ar-protected tube atmosphere furnace and dry it at 4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Initial discharge capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com