Electroplating solution for enhancing electrical conductivity of electronic copper foil, preparation method and electroplating process

A technology of electronic copper foil and electroplating solution, applied in the field of copper foil manufacturing, can solve the problems of long production cycle, environmental pollution, complicated equipment, etc., and achieve the effects of low cost, no environmental pollution, and little pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

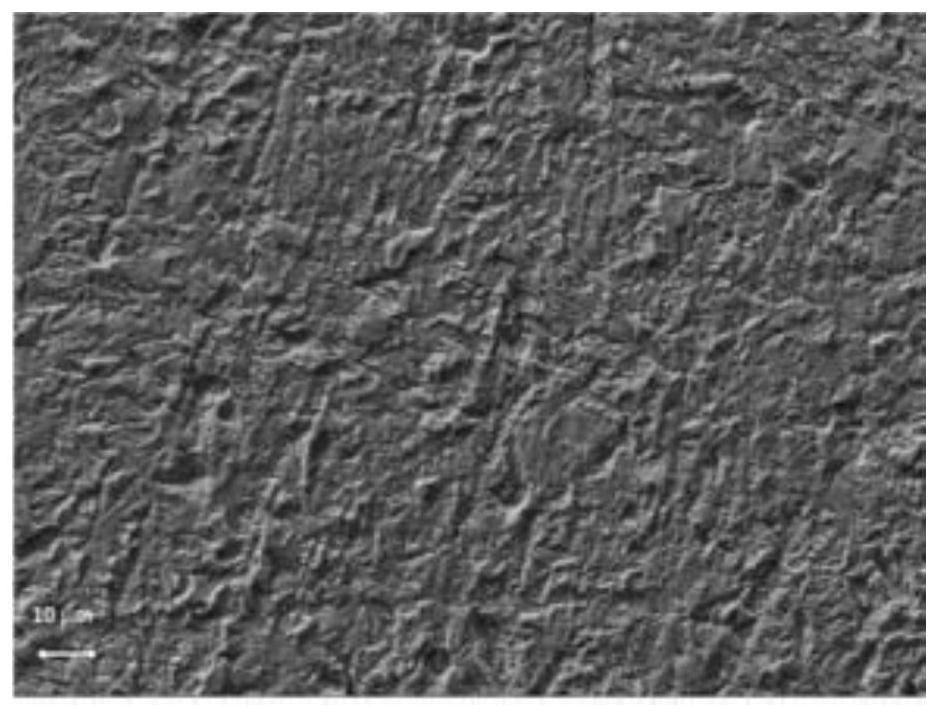

Image

Examples

preparation example Construction

[0025] A preparation method according to the above-mentioned electroplating solution, in an inert gas environment, a solution mixed with 100 to 150 parts of EMIMCl and 63 to 95 parts of absolute ethanol is put into an electrolytic cell, and no Arsenic trichloride (AsCl) for water treatment 3 ) 1 to 6 parts, anhydrous niobium pentachloride (NbCl 5 ) 2 to 9 parts, 0.3 to 0.8 parts of propylene carbonate, 10 to 20 parts of cationic cellulose, 0.1 to 0.5 parts of 8-hydroxyquinoline, mechanically stirred and ultrasonically stirred for 4 to 12 hours to obtain an electroplating solution.

[0026] A kind of electroplating process according to above-mentioned electroplating solution, comprises the following steps:

[0027] S1: Use electronic copper foil as the cathode, platinum sheet or graphite as the anode, wash with acetone, activate with dilute hydrochloric acid, rinse with deionized water, degrease with acetone, and air dry;

[0028] S2: In an inert gas environment, prepare the ...

Embodiment 1

[0031] The electroplating solution provided by the present embodiment, in parts by mass, 146 parts of EMIMCl, 94 parts of absolute ethanol, 4 parts of anhydrous AsCl 3 , 6 parts of anhydrous NbCl 5 , 12.6 parts of cosolvent, 0.4 part of additive;

[0032] Wherein the co-solvent is 12 parts of cationic cellulose and 0.6 part of propylene carbonate;

[0033] Wherein the additive is 0.4 part of 8-hydroxyquinoline.

[0034] The electroplating solution is prepared according to the following steps: put the mixed solution of EMIMCl and absolute ethanol in the self-made electrolytic cell, and then add anhydrous AsCl to the mixed solution 3 , anhydrous NbCl 5, cationic cellulose, 8-hydroxyquinoline and propylene carbonate, mechanically stirred and ultrasonically stirred for 10 hours to mix uniformly to obtain an electroplating solution.

[0035] The electroplating process of electroplating using this electroplating solution is carried out according to the following steps:

[0036]...

Embodiment 2

[0040] The electroplating solution preparation method and electroplating process steps used in this example are the same as in Example 1, the difference is that the proportions of the components used in this example are different, and the electroplating solution provided in this example is calculated in parts by mass, 100 parts EMIMCl, 63 parts absolute ethanol, 1 part absolute AsCl 3 , 2 parts anhydrous NbCl 5 , 10.3 parts of cosolvent, 0.1 part of additive;

[0041] Wherein the co-solvent is 10 parts of cationic cellulose and 0.3 part of propylene carbonate;

[0042] Wherein the additive is 0.1 part of 8-hydroxyquinoline.

[0043] The preparation method and the electroplating process of the electroplating solution in this embodiment are the same as those in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com