Preparation method of high-purity arsenic

A high-purity arsenic and arsenic trichloride technology, which is applied in the field of high-purity material preparation, can solve environmental pollution and other problems, and achieve the effect of low impurity content and lower requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

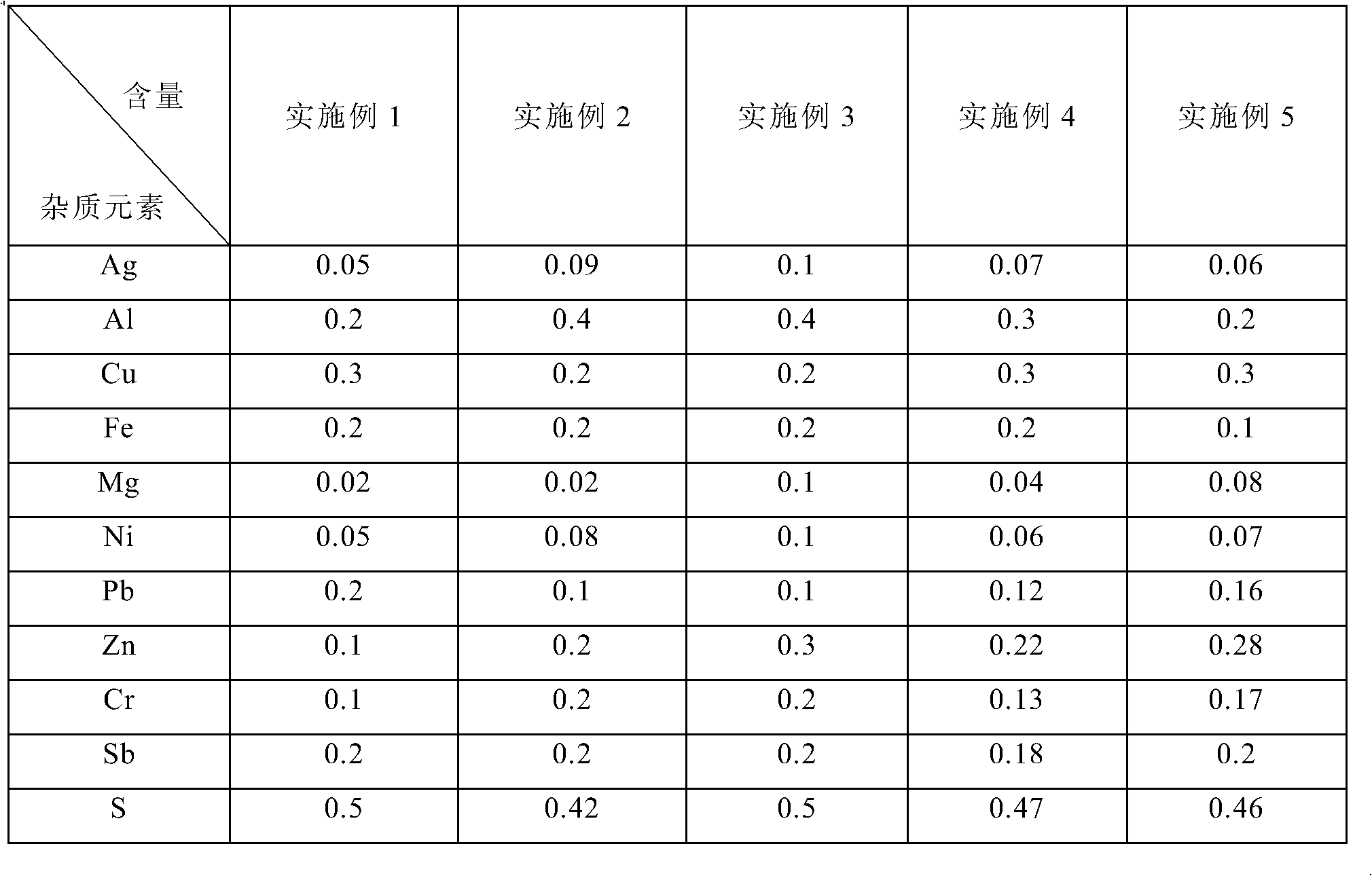

Examples

preparation example Construction

[0015] The preparation method of high-purity arsenic according to the present invention will be described in detail below.

[0016] The preparation method of high-purity arsenic according to the present invention comprises the steps of: loading the arsenic raw material into a sublimation furnace, sublimating the arsenic in the arsenic raw material at a specified vacuum degree and sublimation temperature, condensing the sublimated arsenic vapor at a specified condensation temperature, To obtain purified arsenic; put the purified arsenic into a chlorination furnace, feed chlorine gas and heat up, so that the purified arsenic reacts with chlorine gas to generate arsenic trichloride; feed arsenic trichloride into a dechlorination tower, heat up the three The arsenic chloride is steamed out, and the arsenic trichloride is steamed to obtain the impurity-removing arsenic trichloride after passing through the heat preservation section of the dechlorination tower; Evaporation, the evap...

Embodiment 1

[0028] The arsenic raw material is broken into 2~3cm, in the sublimation furnace: the specified vacuum degree is 10 -2 Pa, the sublimation temperature is 400°C, the sublimation time is 15h, and the specified condensation temperature is 200°C;

[0029] Purified arsenic is broken into small pieces of 1-3cm. In the chlorination furnace: the flow rate of chlorine gas is 800ml / min, and the heating temperature is 200°C;

[0030] In the dechlorination tower: the heating temperature is 300°C, and the temperature of the holding section is 260°C;

[0031] In the rectification kettle: the temperature of the heating is 180°C, and the temperature of the heat preservation section is 130°C;

[0032] In the reduction furnace: the flow rate of hydrogen is 500ml / min, and the heating temperature is 300°C;

[0033] In another sublimation furnace: the given vacuum is 7×10 -3 Pa, the sublimation temperature is 640°C, the sublimation time is 10h, and the given condensation temperature is 330°C. ...

Embodiment 2

[0035] The arsenic raw material is broken into 2~3cm, in the sublimation furnace: the specified vacuum degree is 1.5×10 -3 , the sublimation temperature is 450°C, the sublimation time is 14h, and the specified condensation temperature is 250°C;

[0036] The purified arsenic is broken into small pieces of 1-3cm. In the chlorination furnace: the flow rate of chlorine gas is 1200mL / min, and the heating temperature is 160°C;

[0037] In the dechlorination tower: the heating temperature is 120°C, and the temperature of the holding section is 90°C;

[0038] In the rectification kettle: the heating temperature is 120°C, and the temperature of the heat preservation section is 90°C;

[0039] In the reduction furnace: the flow rate of hydrogen is 400ml / min, and the heating temperature is 400°C;

[0040] In another sublimation furnace: Given a vacuum of 10 -2 Pa, the sublimation temperature is 700°C, the sublimation time is 5h, and the given condensation temperature is 400°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com