Patents

Literature

44 results about "Contact duration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

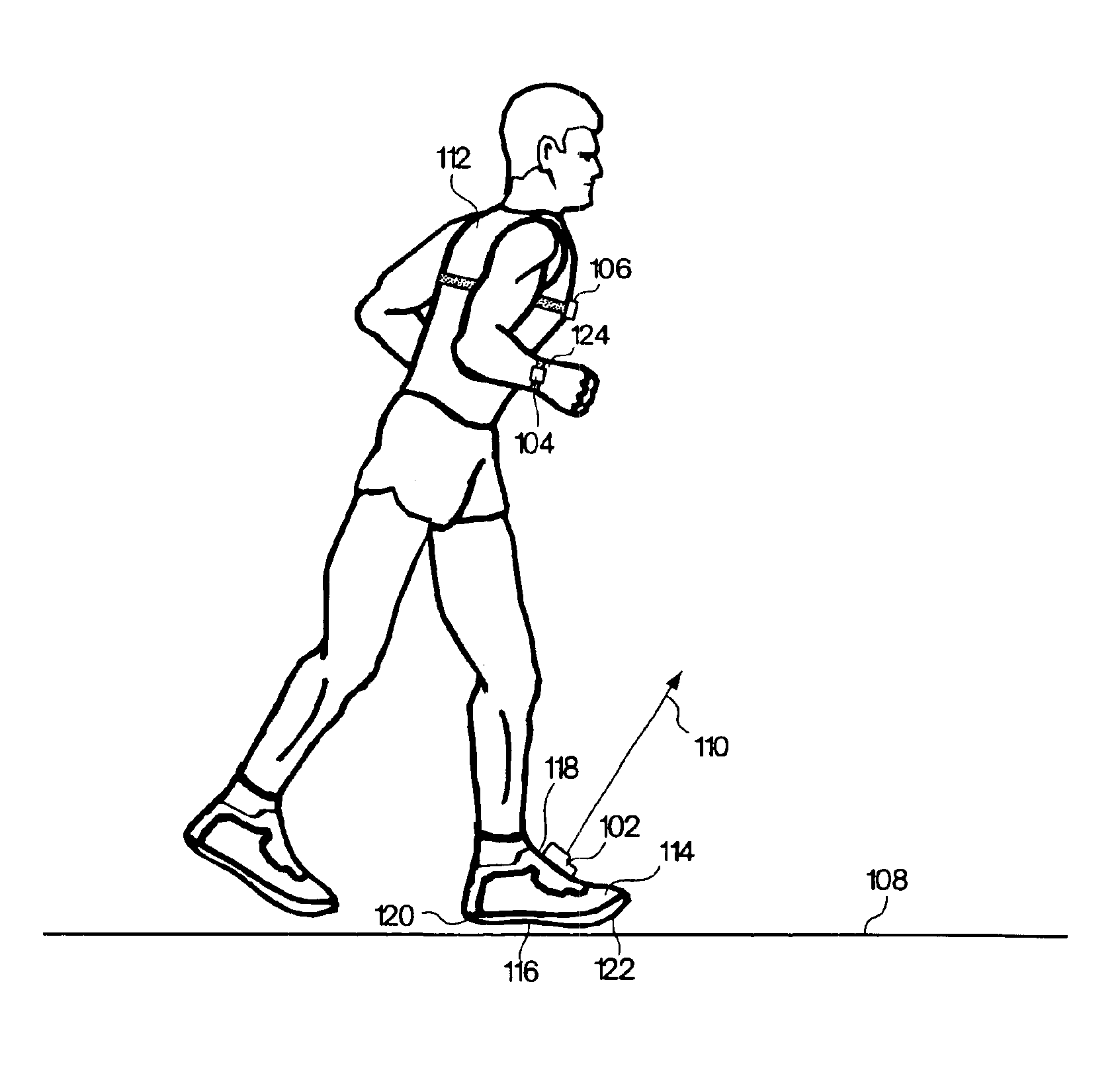

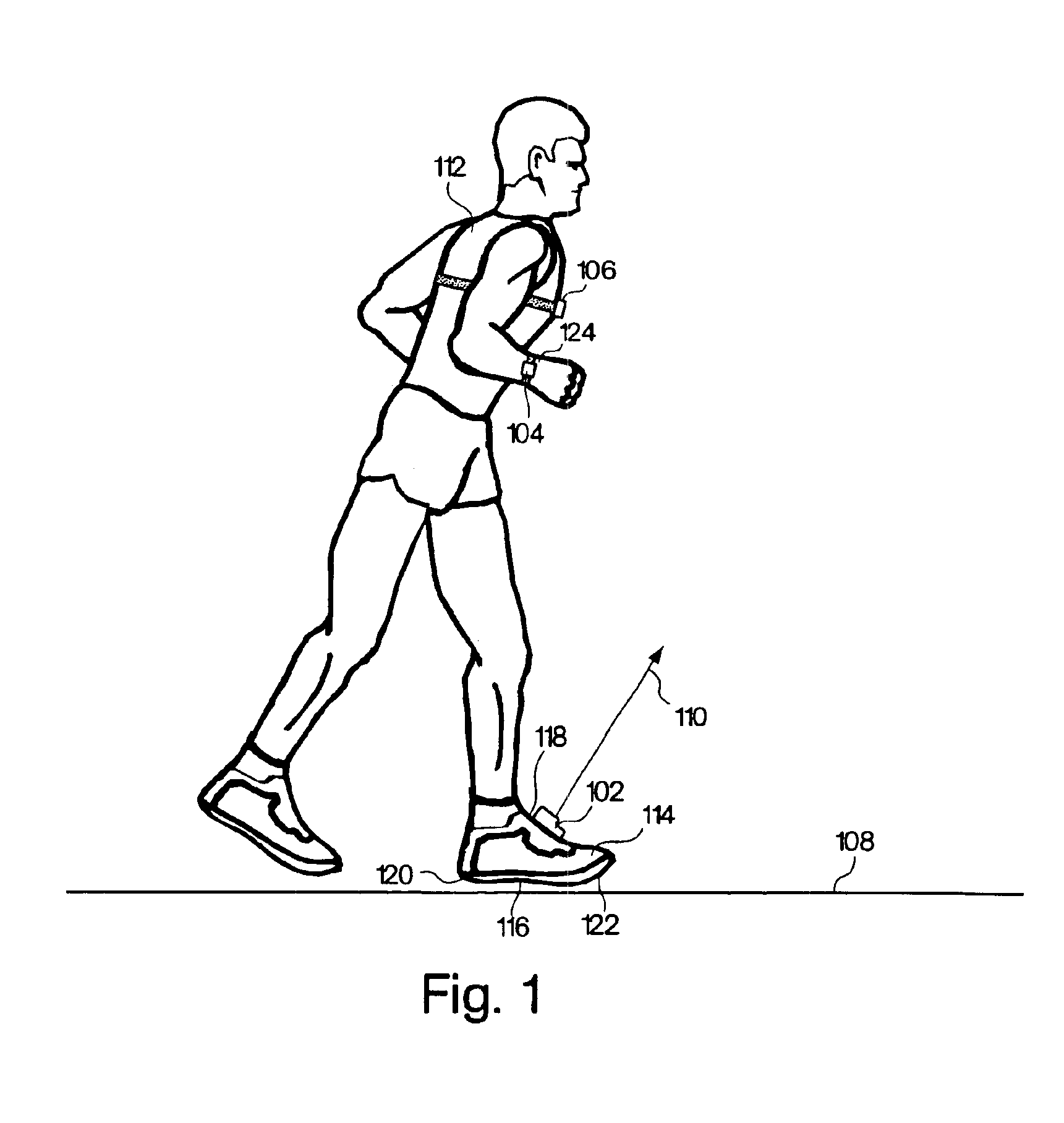

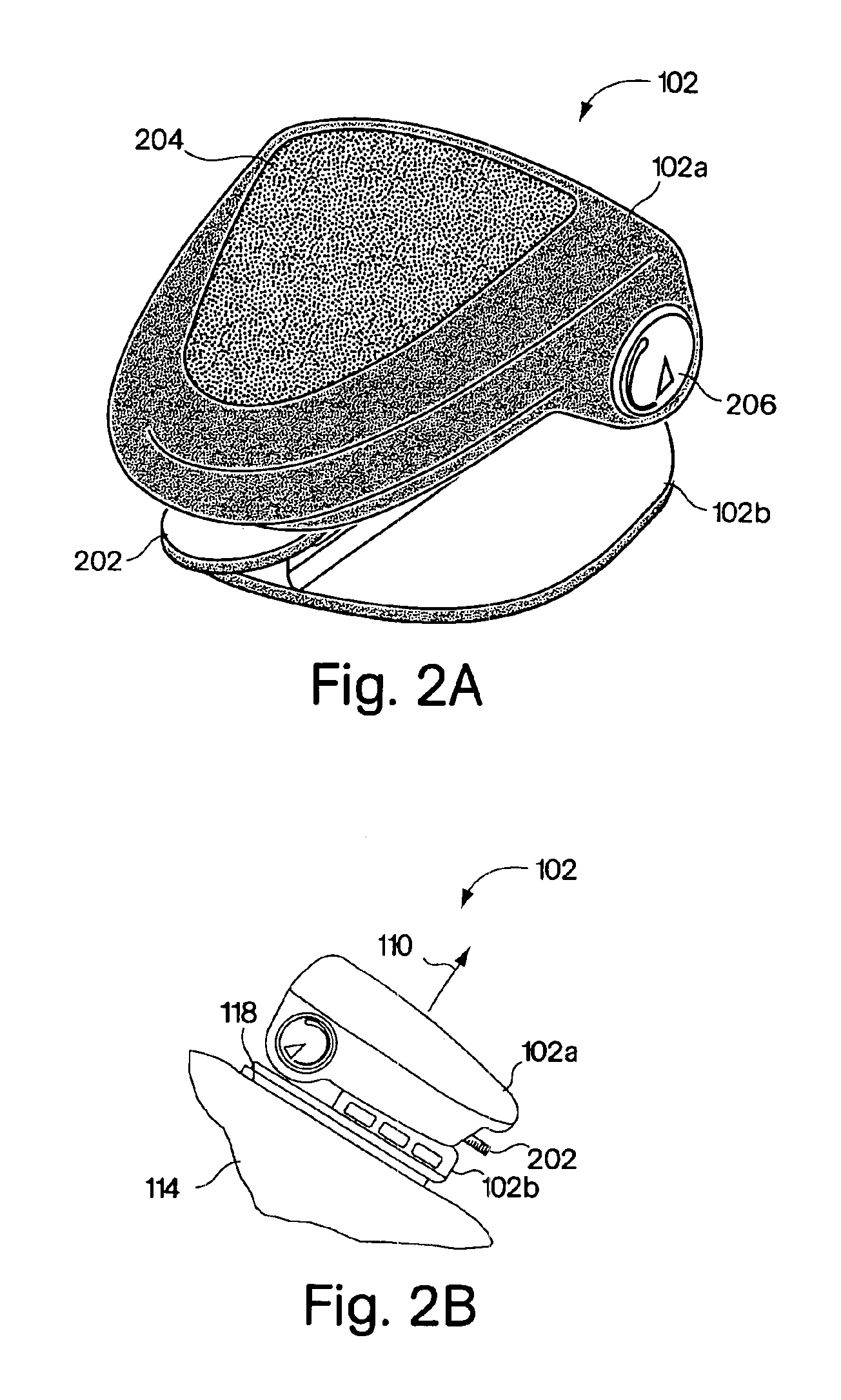

Monitoring activity of a user in locomotion on foot

InactiveUS6876947B1Physical therapies and activitiesTime indicationPacePhysical medicine and rehabilitation

In one embodiment, a method includes steps of: (a) identifying an average foot contact time of a user during a first outing; (b) identifying an average pace of the user during the first outing; (c) defining a relationship between foot contact times of the user and corresponding paces of the user, wherein the relationship is based upon the average foot contact time and the average pace identified during the first outing, and wherein no other average foot contact times and no other average paces identified during any different outings by the user are used to define the relationship; and (d) calibrating at least one device that monitors activity of the user in locomotion on foot based upon the defined relationship between foot contact times of the user and corresponding paces of the user. In another embodiment, a method includes steps of: (a) determining a single user-specific calibration constant that defines a relationship between foot contact times of a user and corresponding paces of the user, wherein no other user-specific calibration constants are used to define the relationship; and (b) calibrating at least one device that monitors activity of the user in locomotion on foot based upon the relationship between foot contact times of the user and corresponding paces of the user that is defined by the single user-specific calibration constant.

Owner:NIKE INC +1

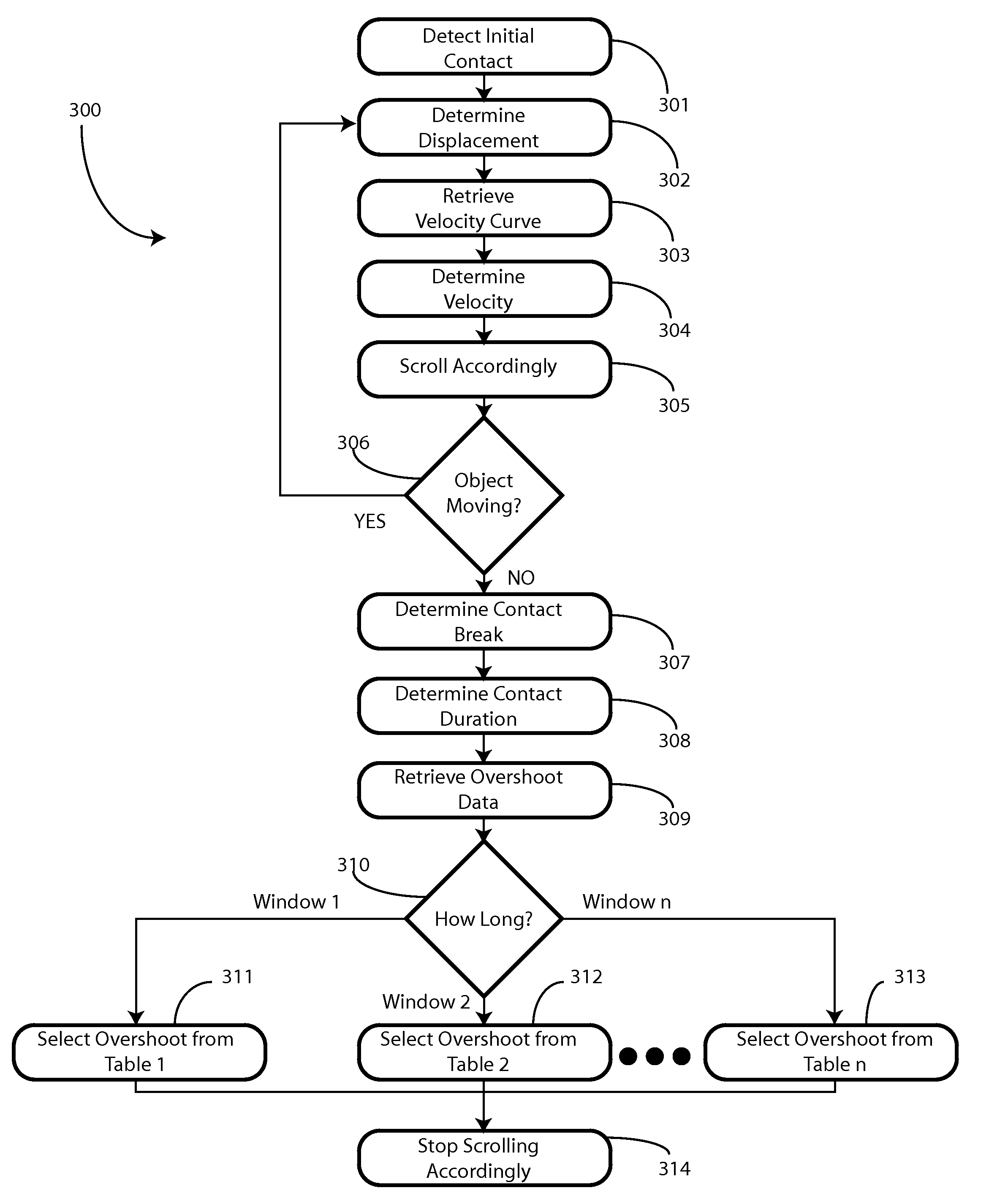

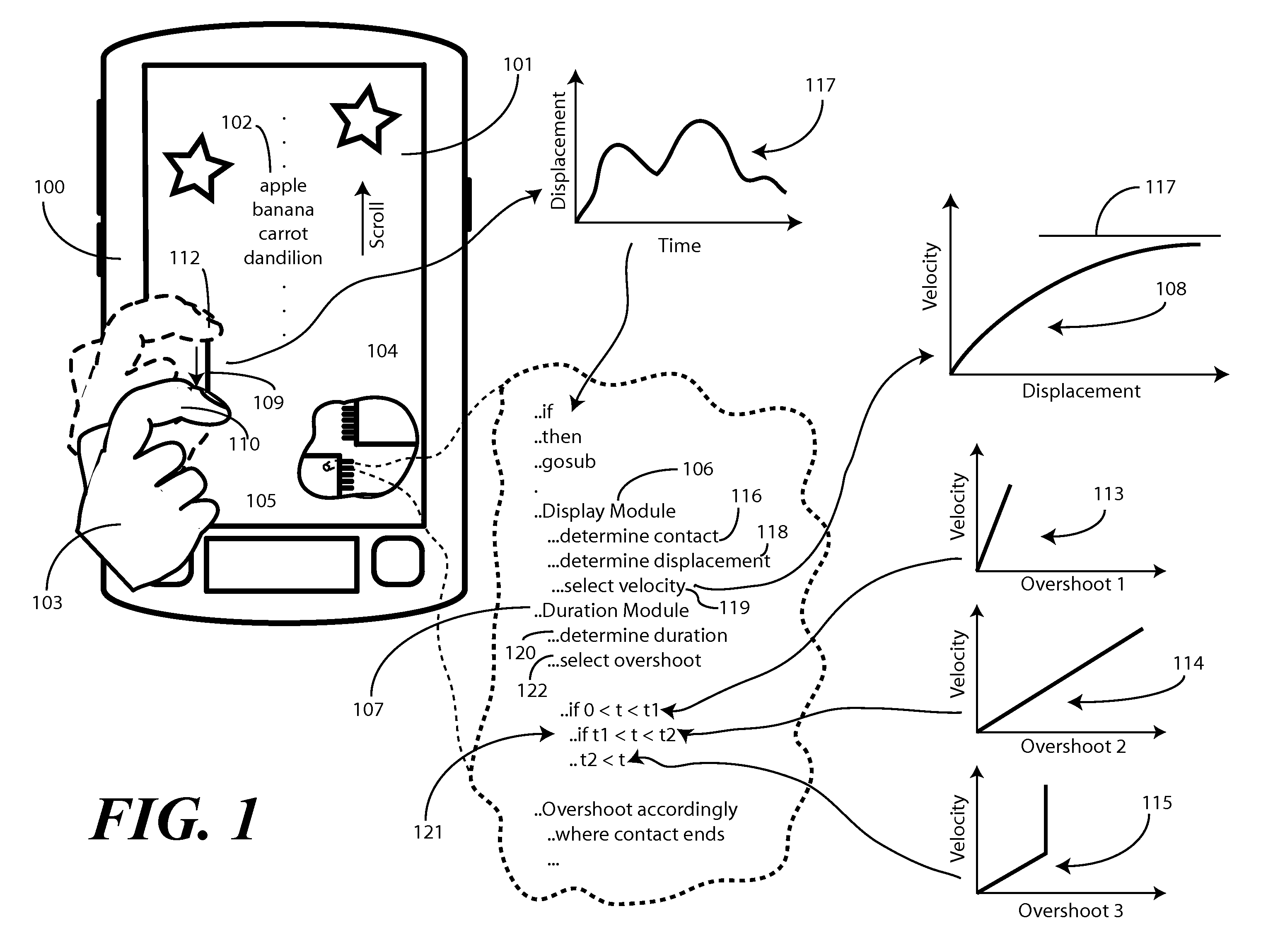

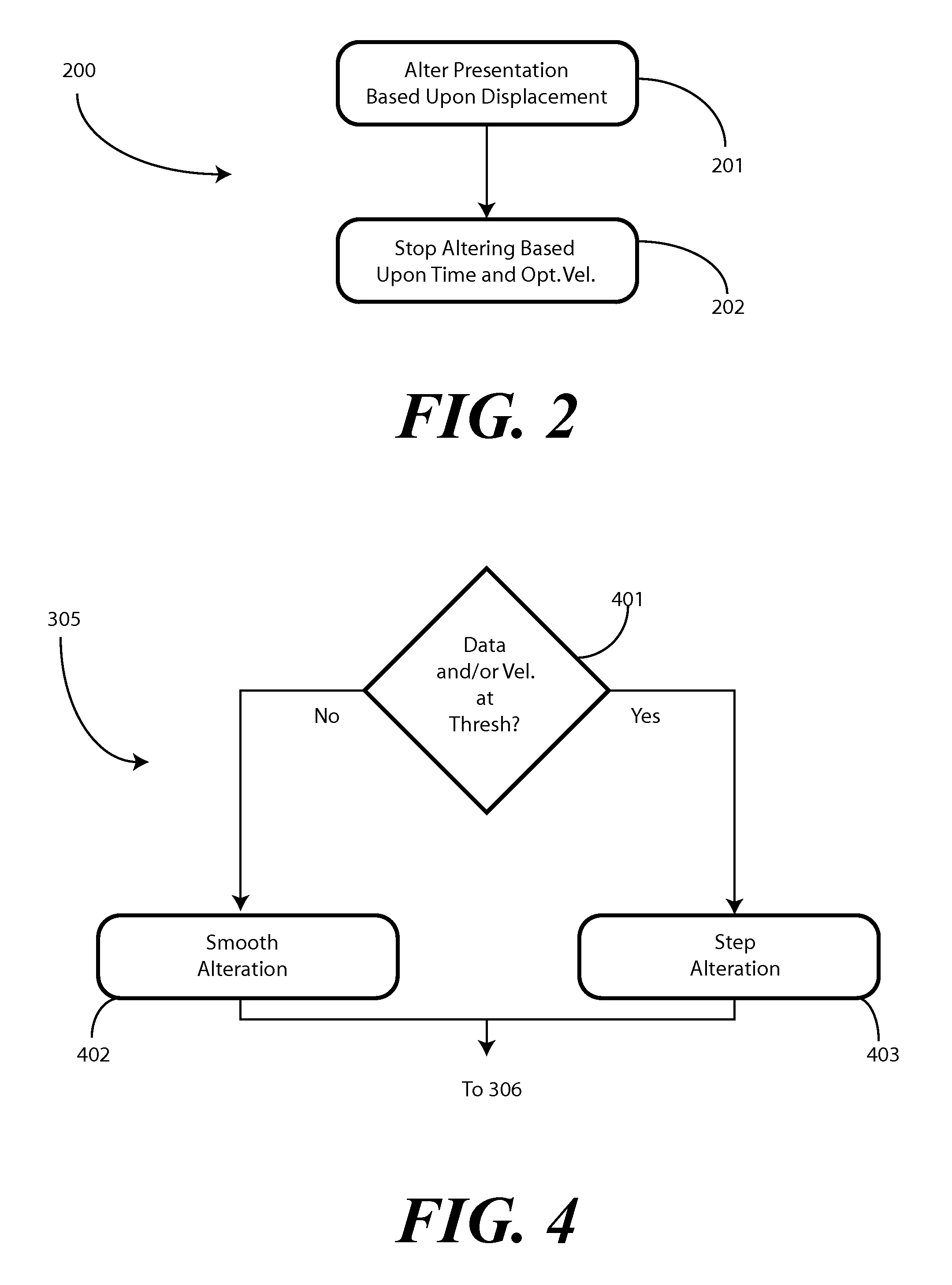

Method and Apparatus for Altering the Presentation Data Based Upon Displacement and Duration of Contact

A method (300) and apparatus (900) for altering the presentation of data (102) on a user interface such as a touch sensitive display (101) of an electronic device (100) are described. Alteration of the presentation of data (102) can include scrolling, paging, and so forth. Scrolling velocity can be selected based upon predetermined velocity data (108) stored in a memory (105). Velocity selection can be dependent upon displacement (109) of a user's finger (110) or stylus along a user interface. Deceleration of the data presentation alteration can be based upon contact duration and the velocity at which the data presentation is being altered when the user's finger (110) or stylus breaks contact with the user interface, as determined from predetermined deceleration data or overshoot curves (113,114,115) stored in memory (105).

Owner:GOOGLE TECH HLDG LLC

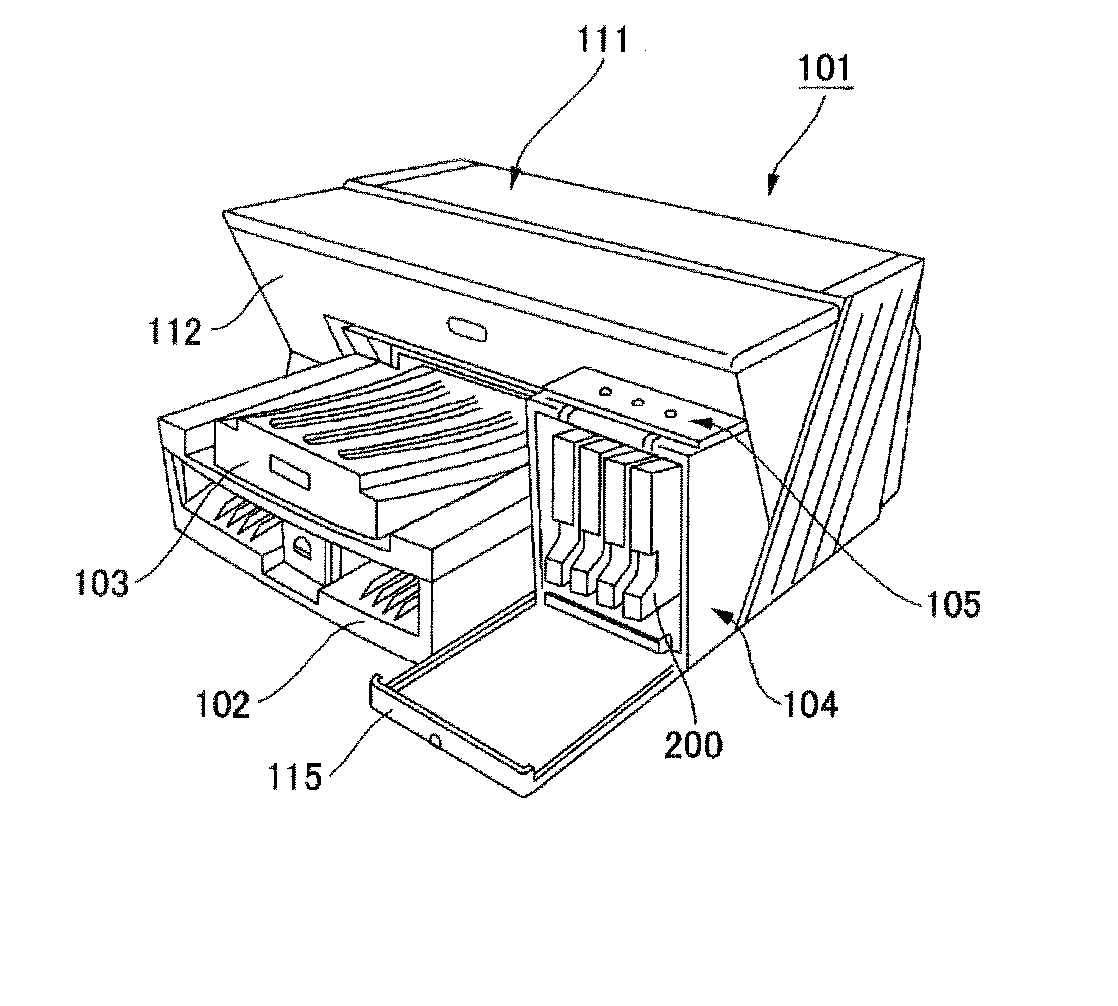

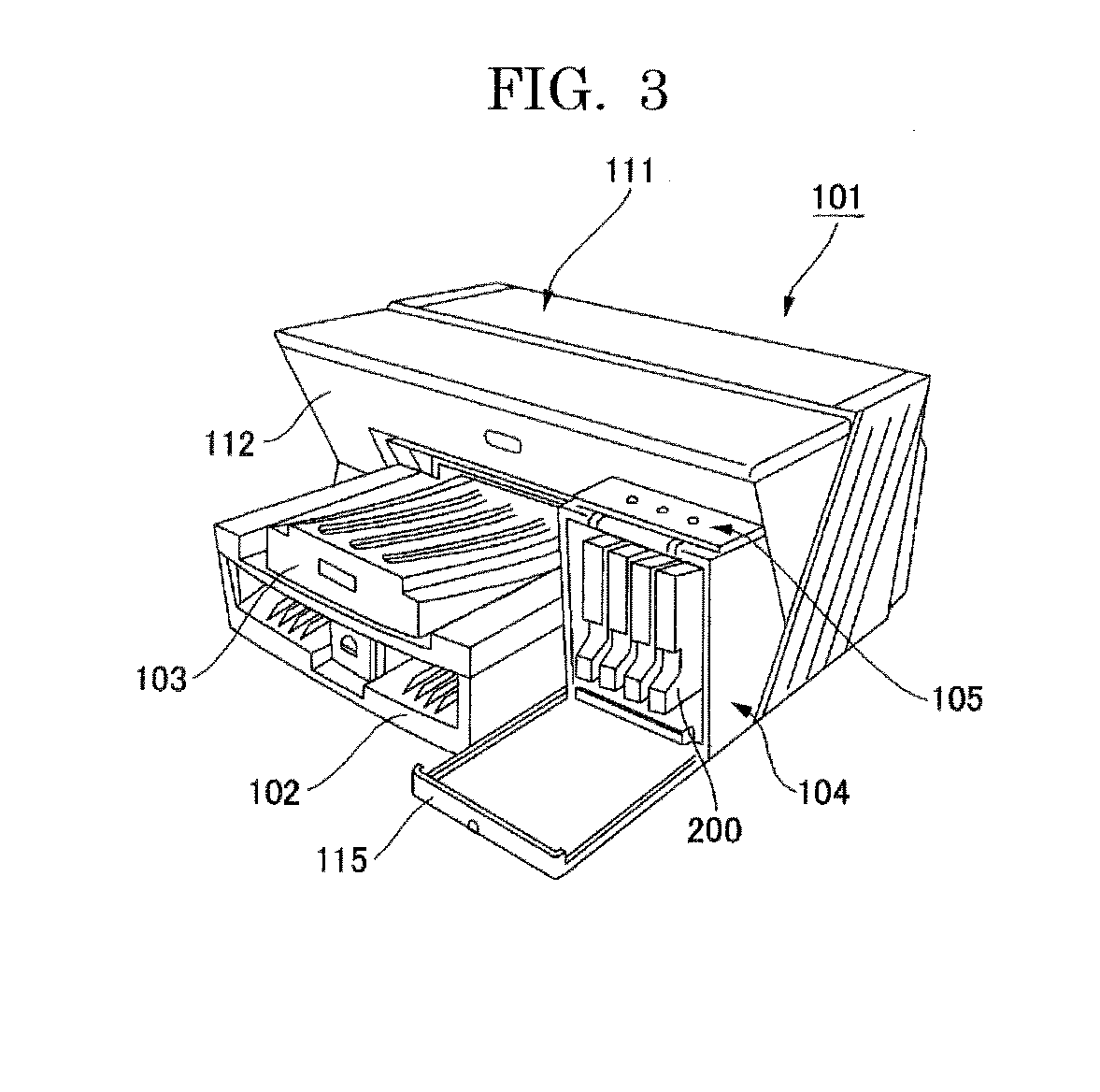

Inkjet recording method and inkjet recording device

ActiveUS20140204156A1High image densityExcellent glossinessMeasurement apparatus componentsDuplicating/marking methodsWater dispersibleMass ratio

An inkjet recording method, including applying stimulus to recording ink to allow the ink to jet to record image on recording medium, wherein the recording medium includes support and surface layer on at least one surface thereof, and has transferred amount of pure water on surface thereof at side of the surface layer of 1 to 10 mL / m2 with contact duration of 100 ms as measured by dynamic scanning absorptometer, wherein the recording medium is surface-modified with corona discharge treatment or plasma treatment, the ink contains water-dispersible colorant, organic solvent, surfactant, water-dispersible resin, and water, the organic solvent contains polyhydric alcohol(s) having equilibrium moisture content ≧30 mass % at 23° C. / 80% RH, certain amide compound, and at least one of certain compounds, and total of solid content of the water dispersible colorant (A) and solid content of the water dispersible resin (B) is 8 to 35 mass %, and mass ratio (A / B) is 2 to 8.

Owner:RICOH KK

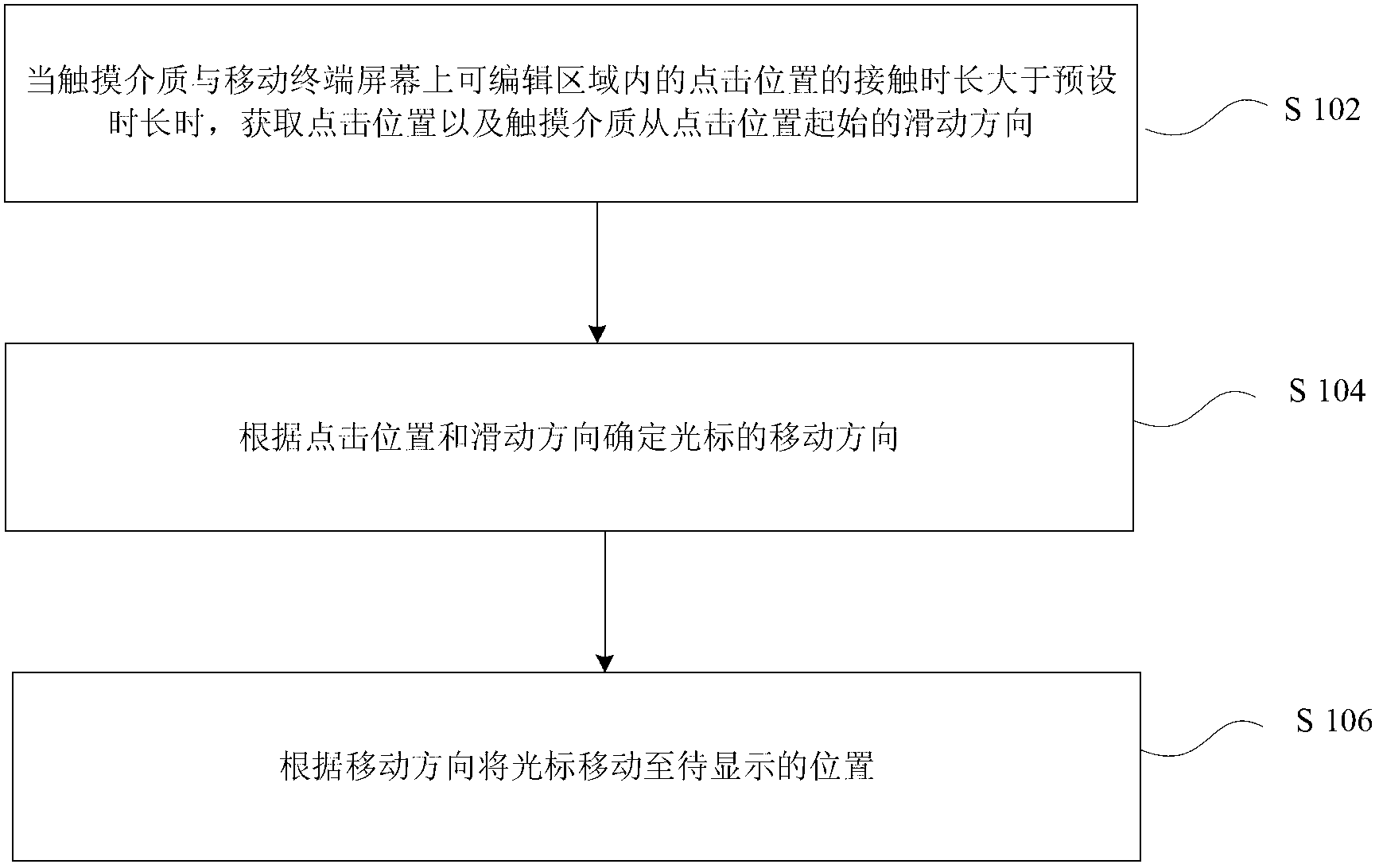

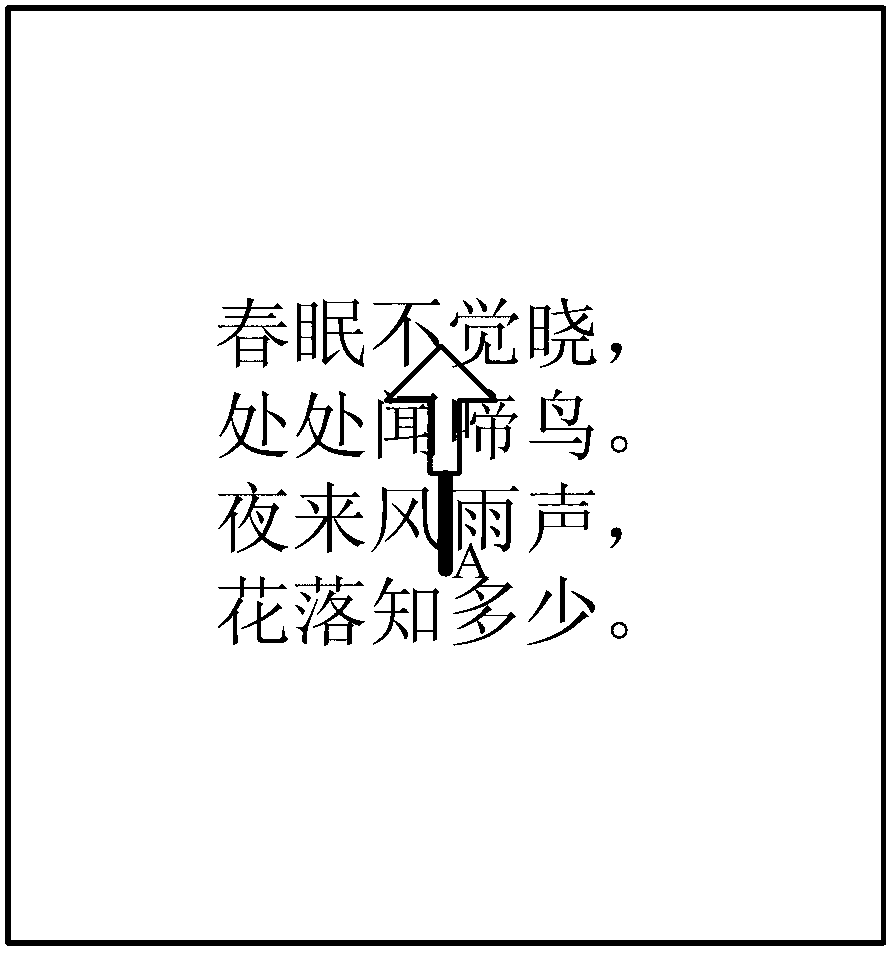

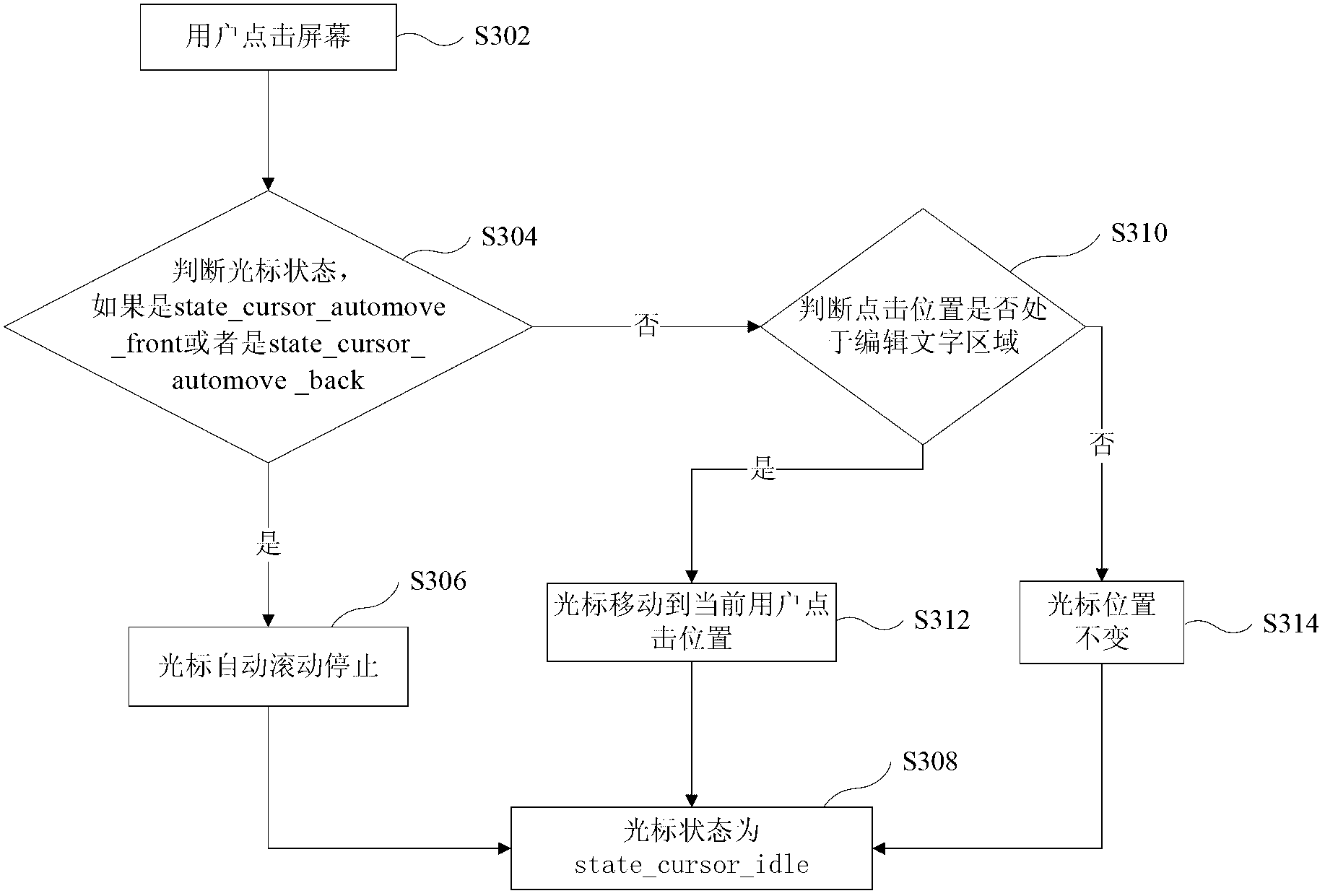

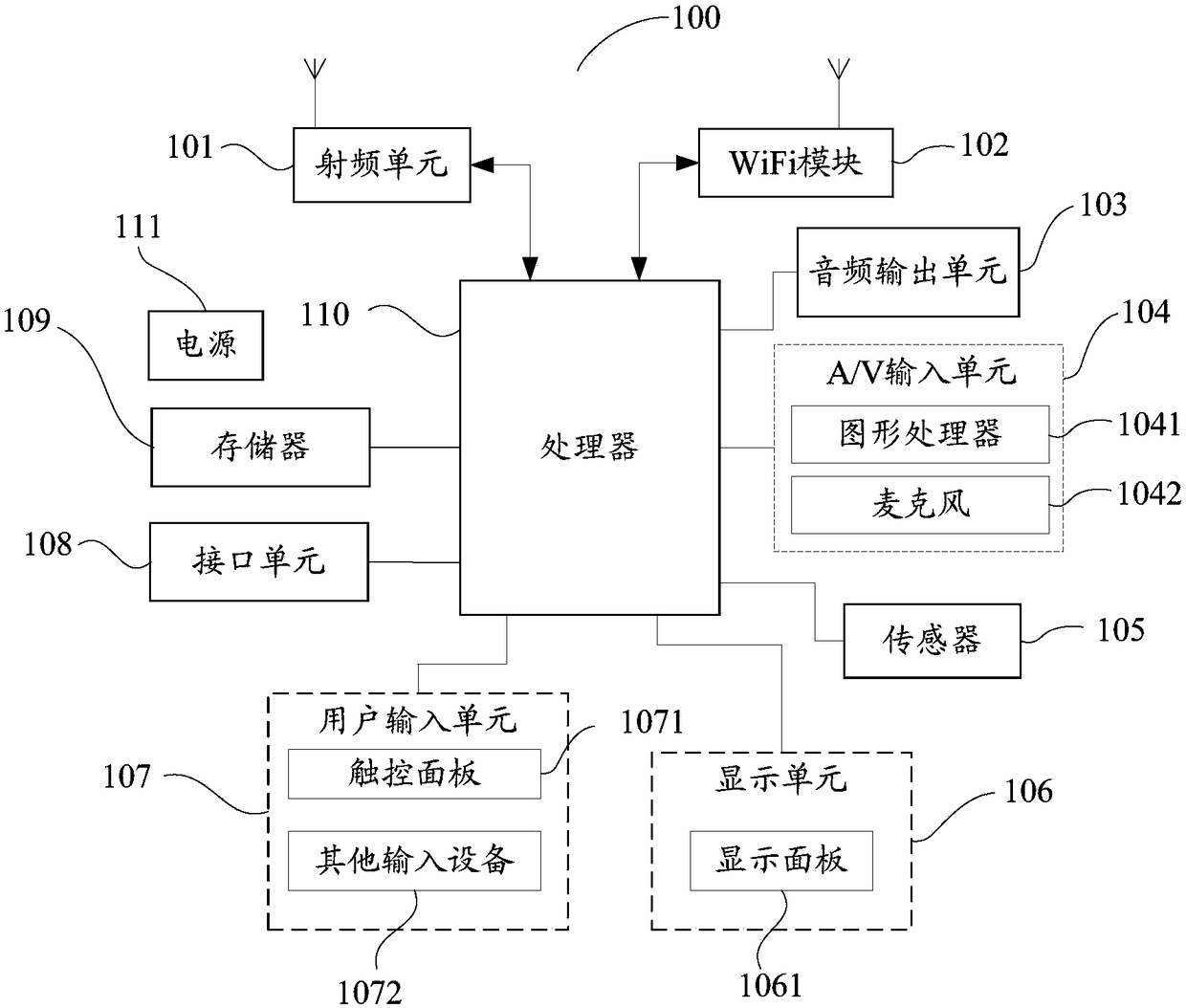

Method and device for determining display position of cursor

ActiveCN102799358ASolve complex operationsPrecise positioningInput/output processes for data processingComputer graphics (images)Text editing

The invention discloses a method and a device for determining a display position of a cursor. The method comprises the following steps of: when contact duration of a touch medium and a clicking position in an editable area on a mobile terminal screen is longer than a pre-set duration, obtaining the clicking position and the initial sliding direction of the touch medium from the clicking position; determining the movement direction of the cursor according to the clicking position and the sliding direction; and moving the cursor to be at a position to be displayed according to the movement direction. By utilizing the technical scheme provided by the invention, the entire text editing interface is effectively viewed by automatic movement of the cursor, the cursor is relatively convenient to position, and the operation is simple.

Owner:ZTE CORP

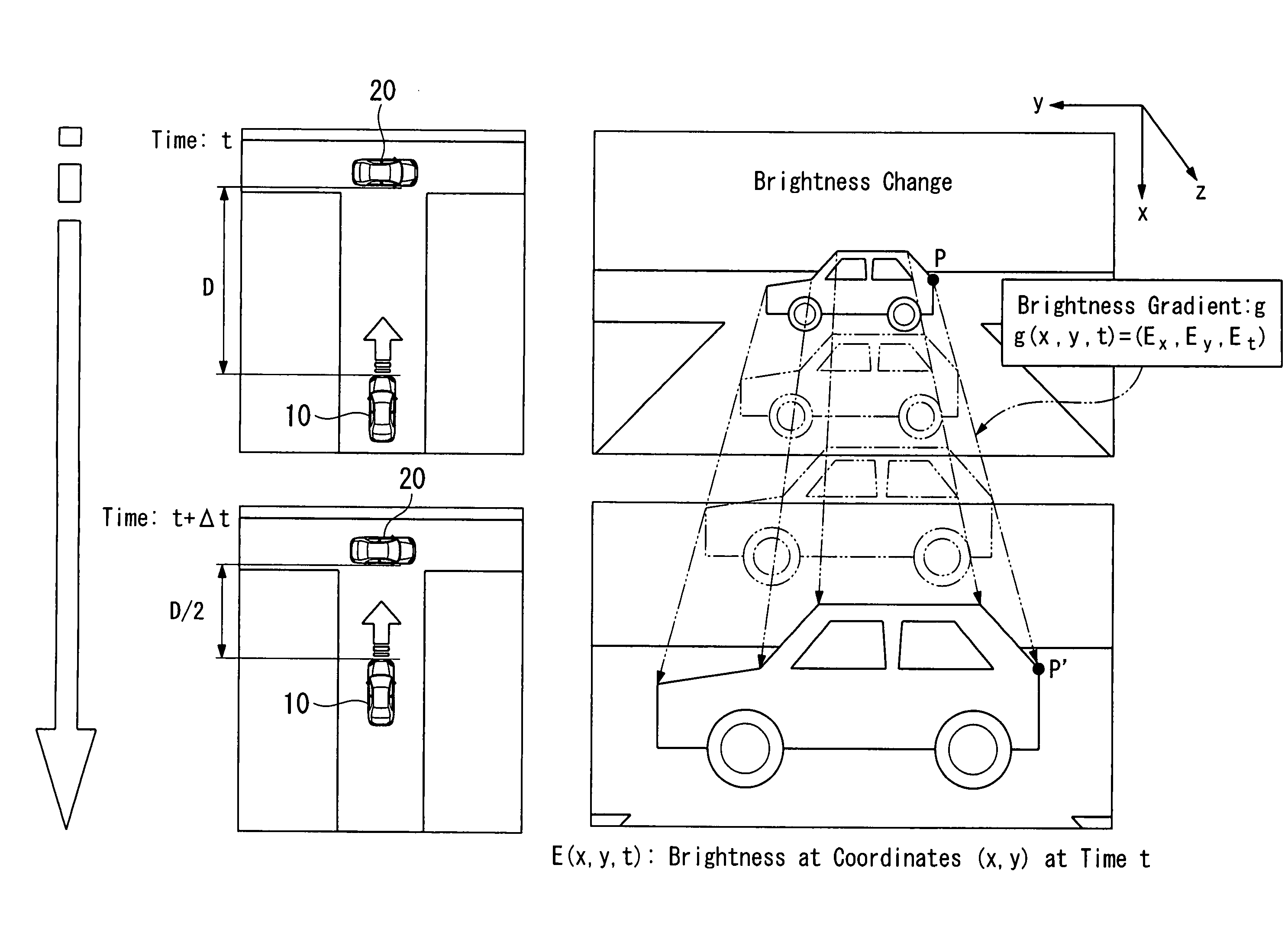

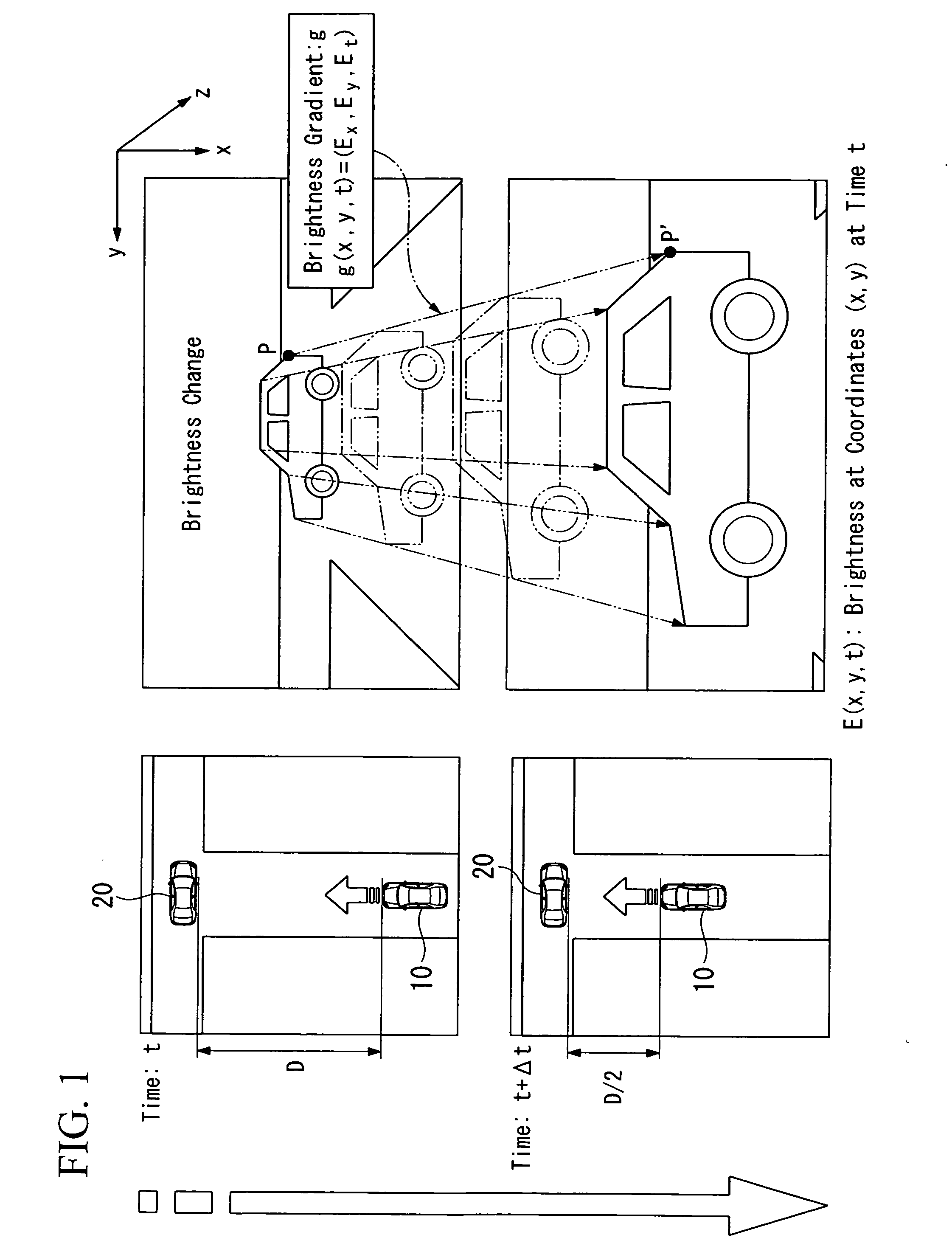

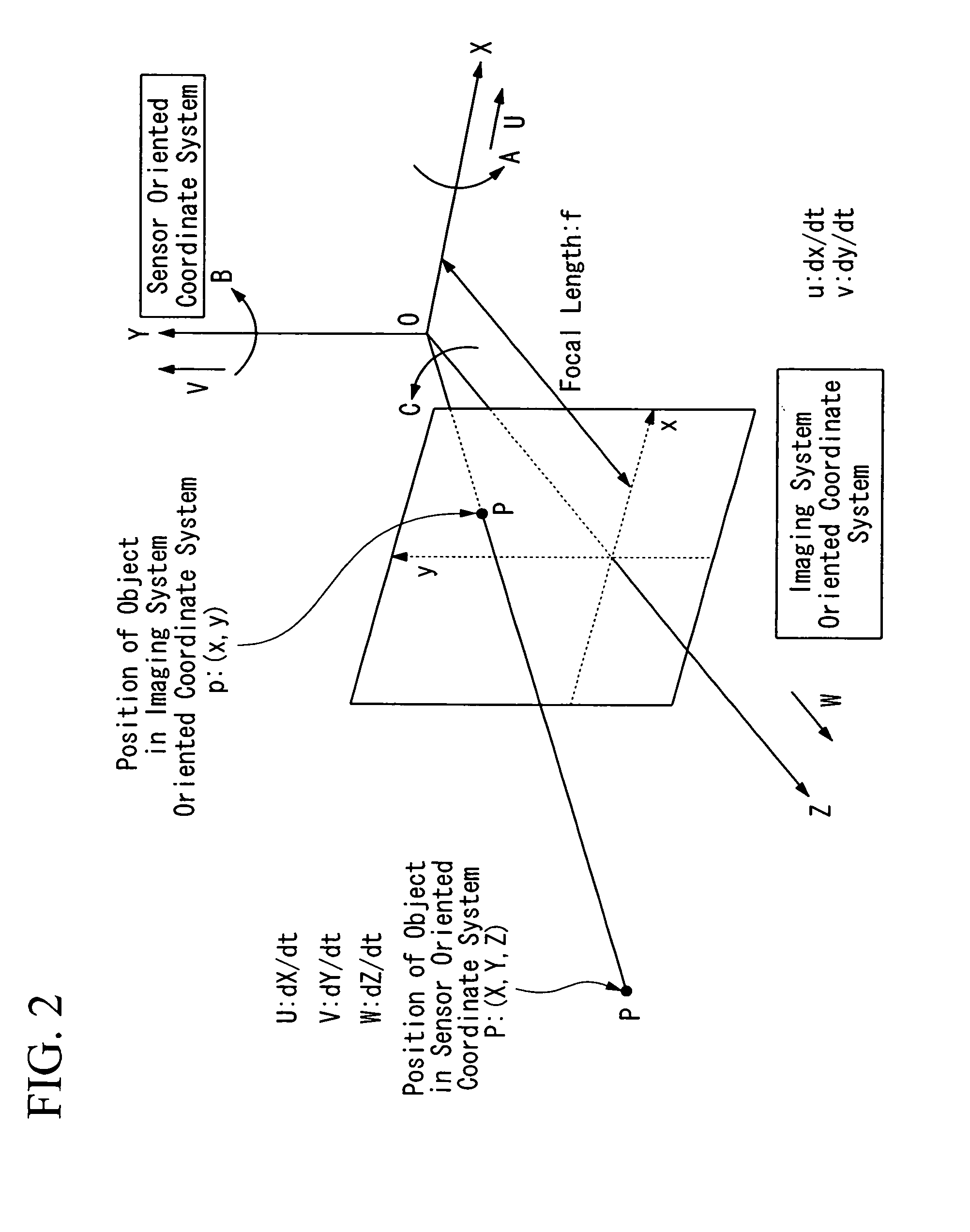

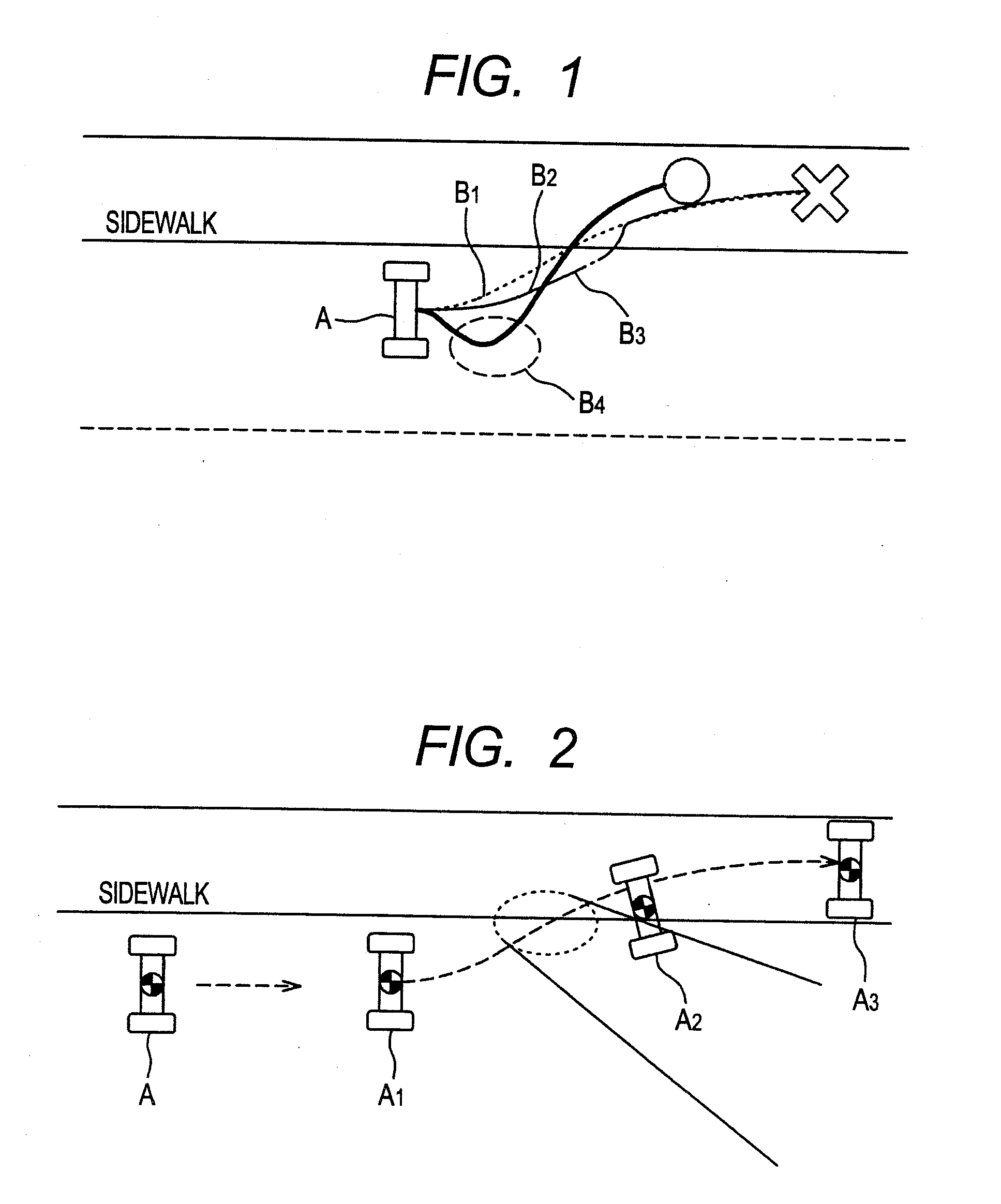

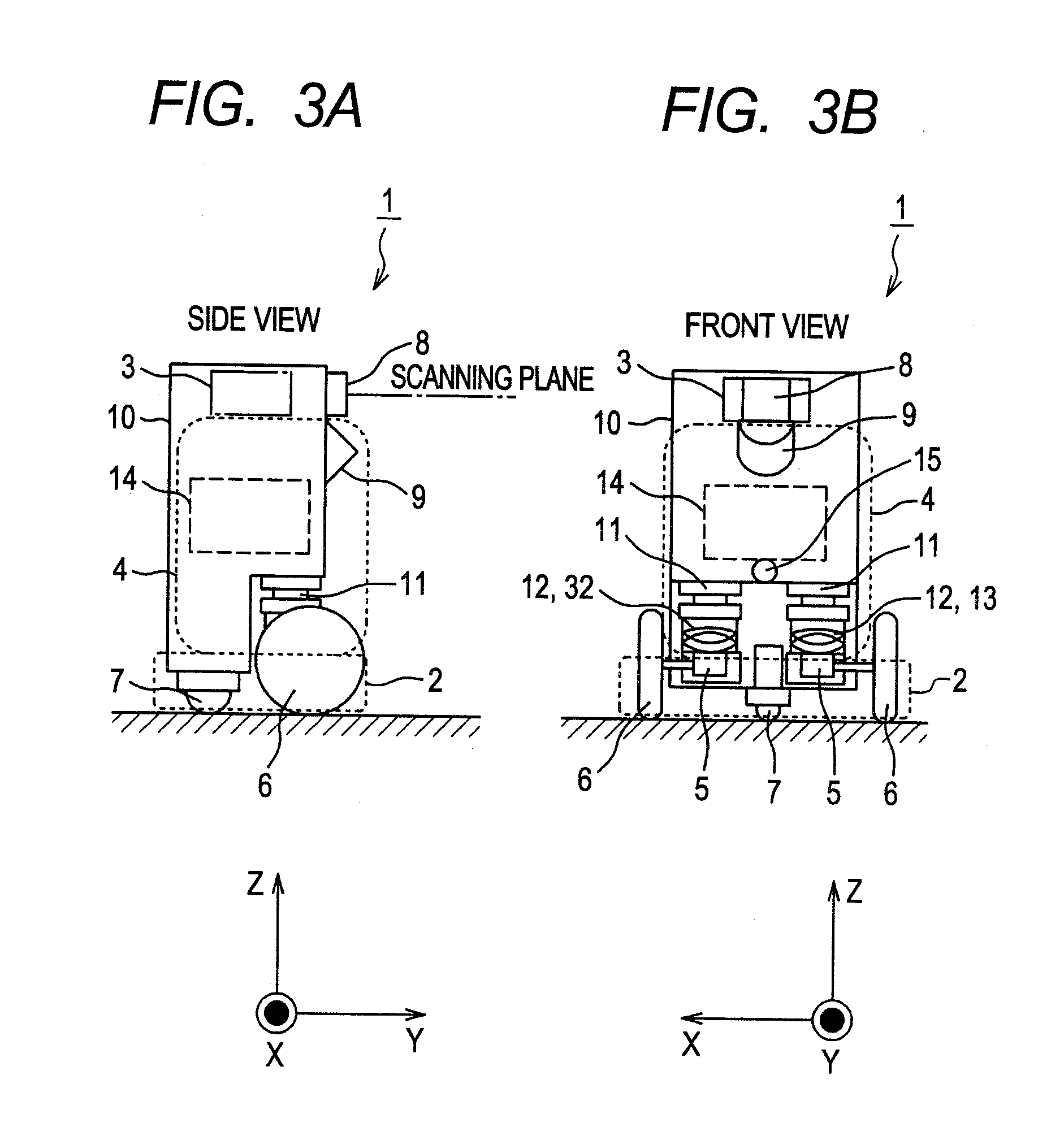

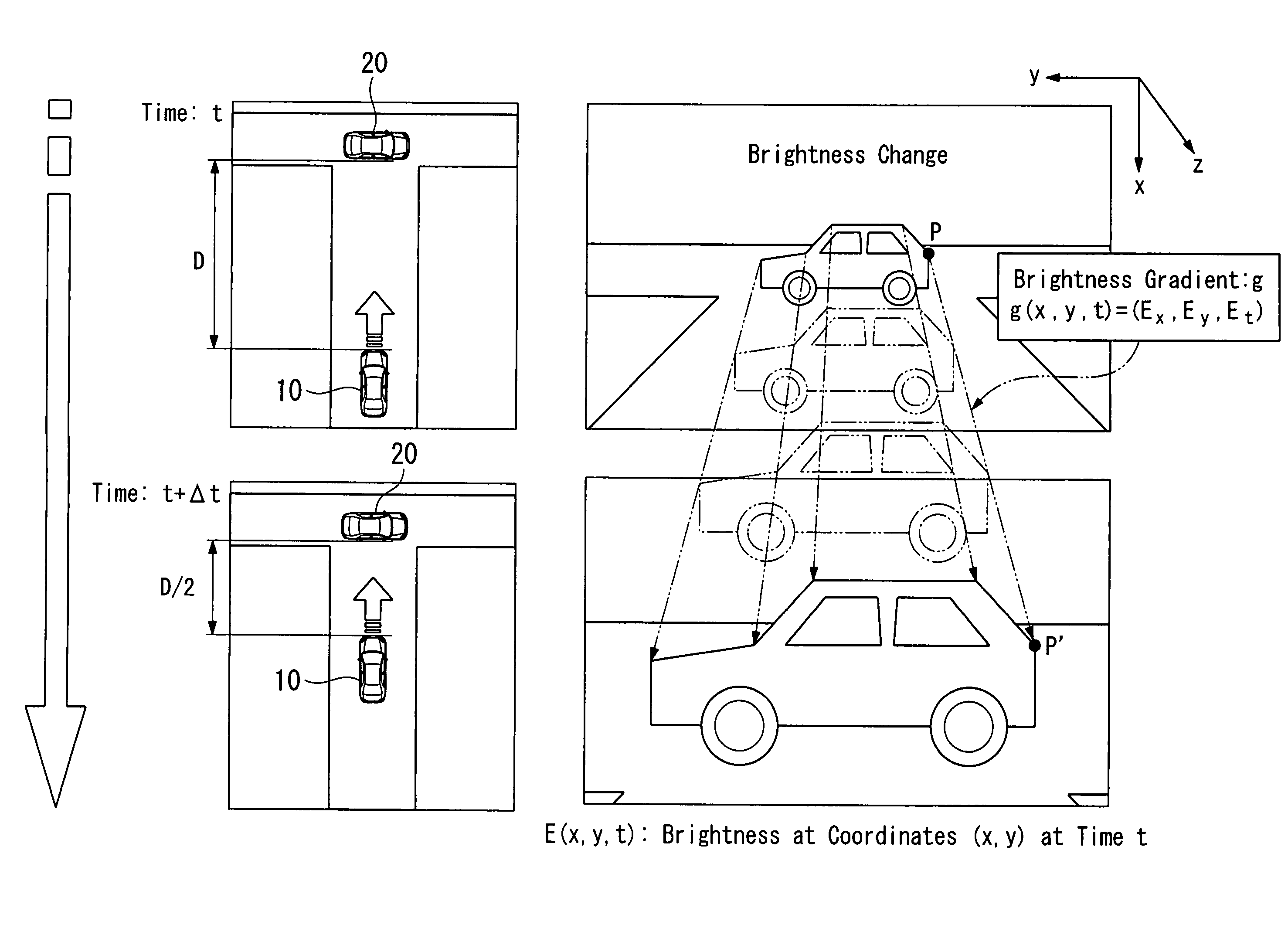

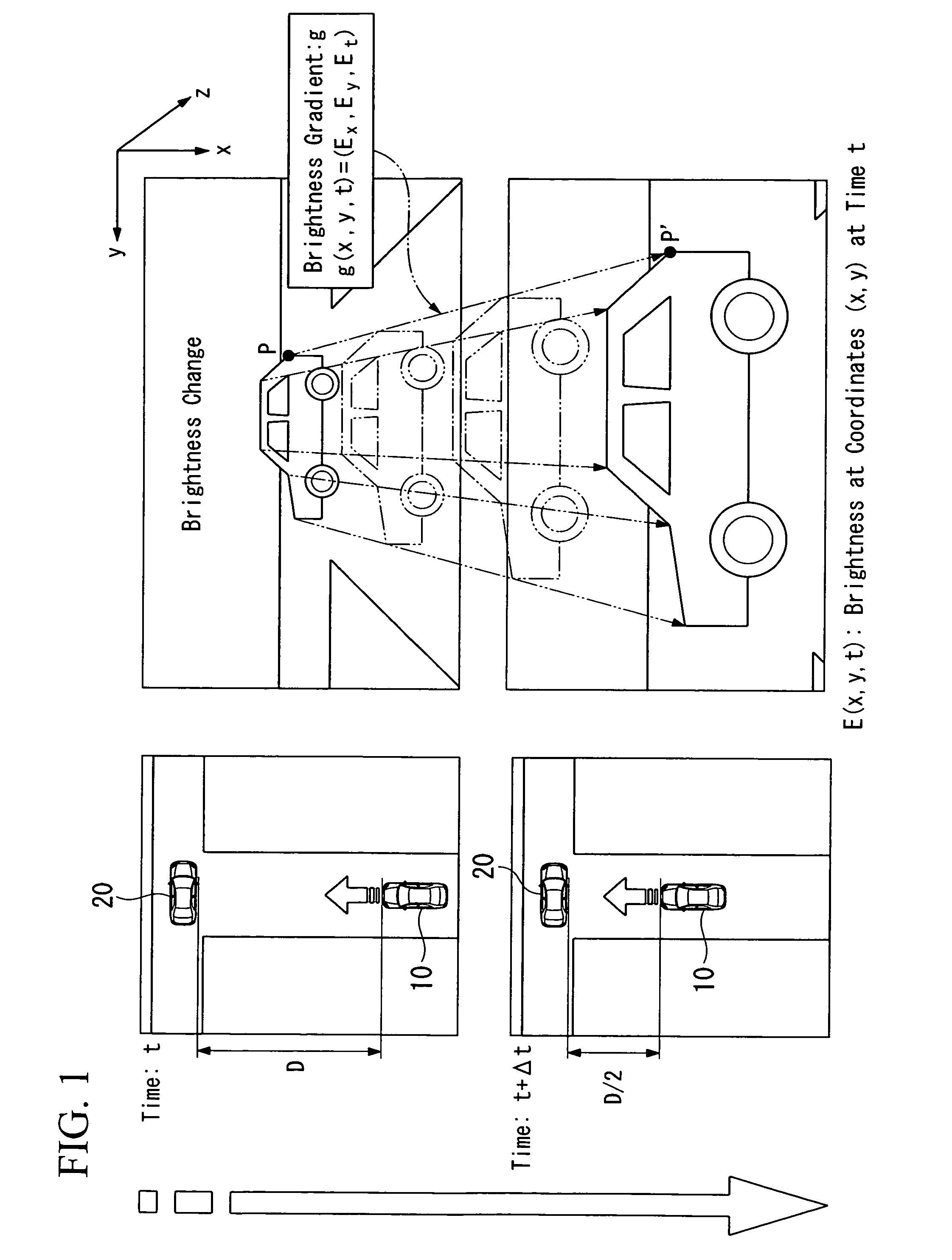

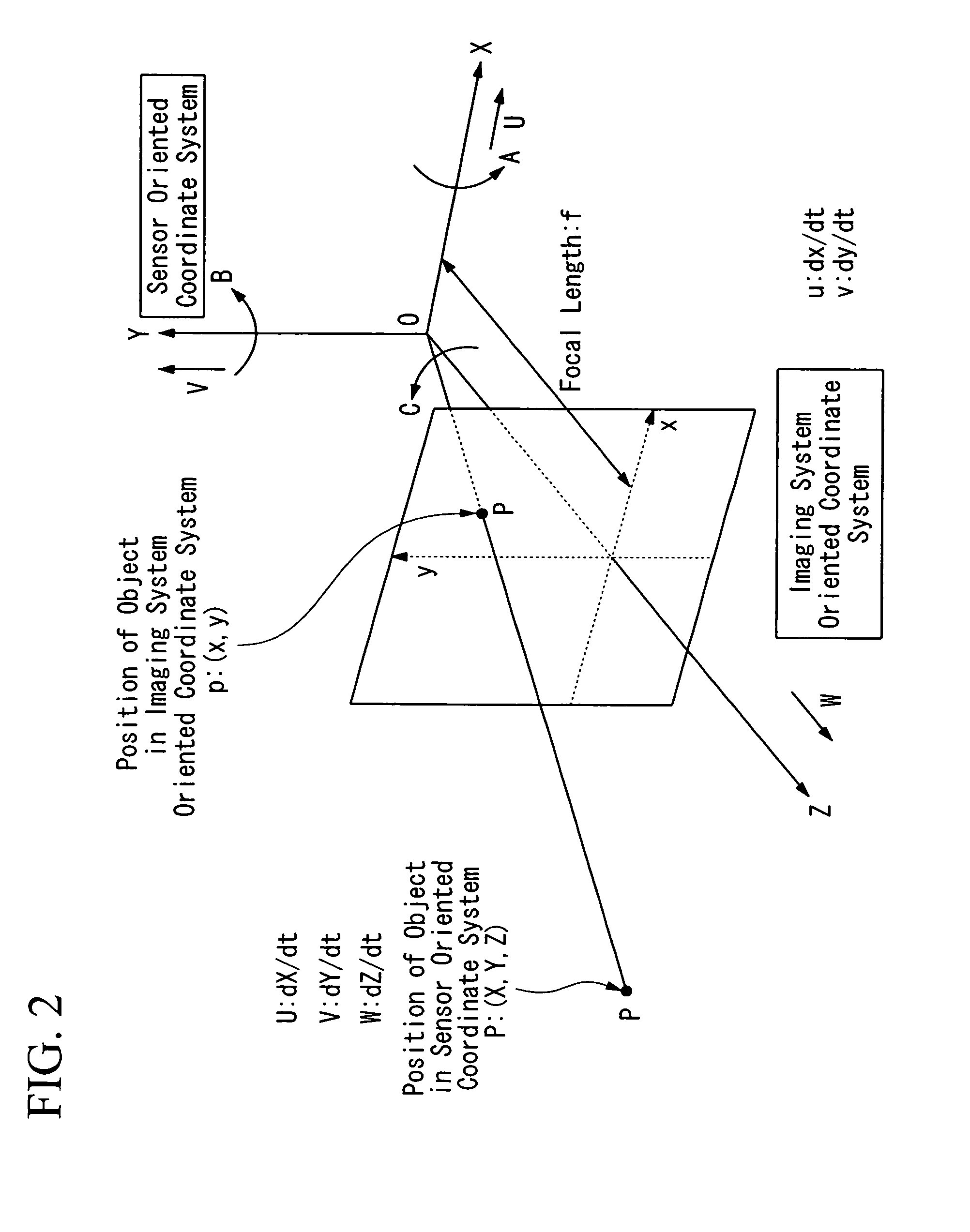

Time-to-contact estimation device and method for estimating time to contact

ActiveUS20080046181A1Lower latencyComputationally efficientImage enhancementImage analysisObject basedBrightness gradient

A time-to-contact estimation device for estimating a time to contact of a moving body to an object in surroundings of the moving body, includes: an image sensor provided on the moving body, and continuously capturing time-varying images of the surroundings of the moving body; a brightness change calculation unit calculating brightness changes in pixels between the time-varying images captured one after another; and a time-to-contact calculation unit calculating optimized brightness gradients based on the brightness changes calculated by the brightness change calculation unit, and calculating the time to contact of the moving body to the object based on the optimized brightness gradients.

Owner:VEONEER SWEDEN AB +1

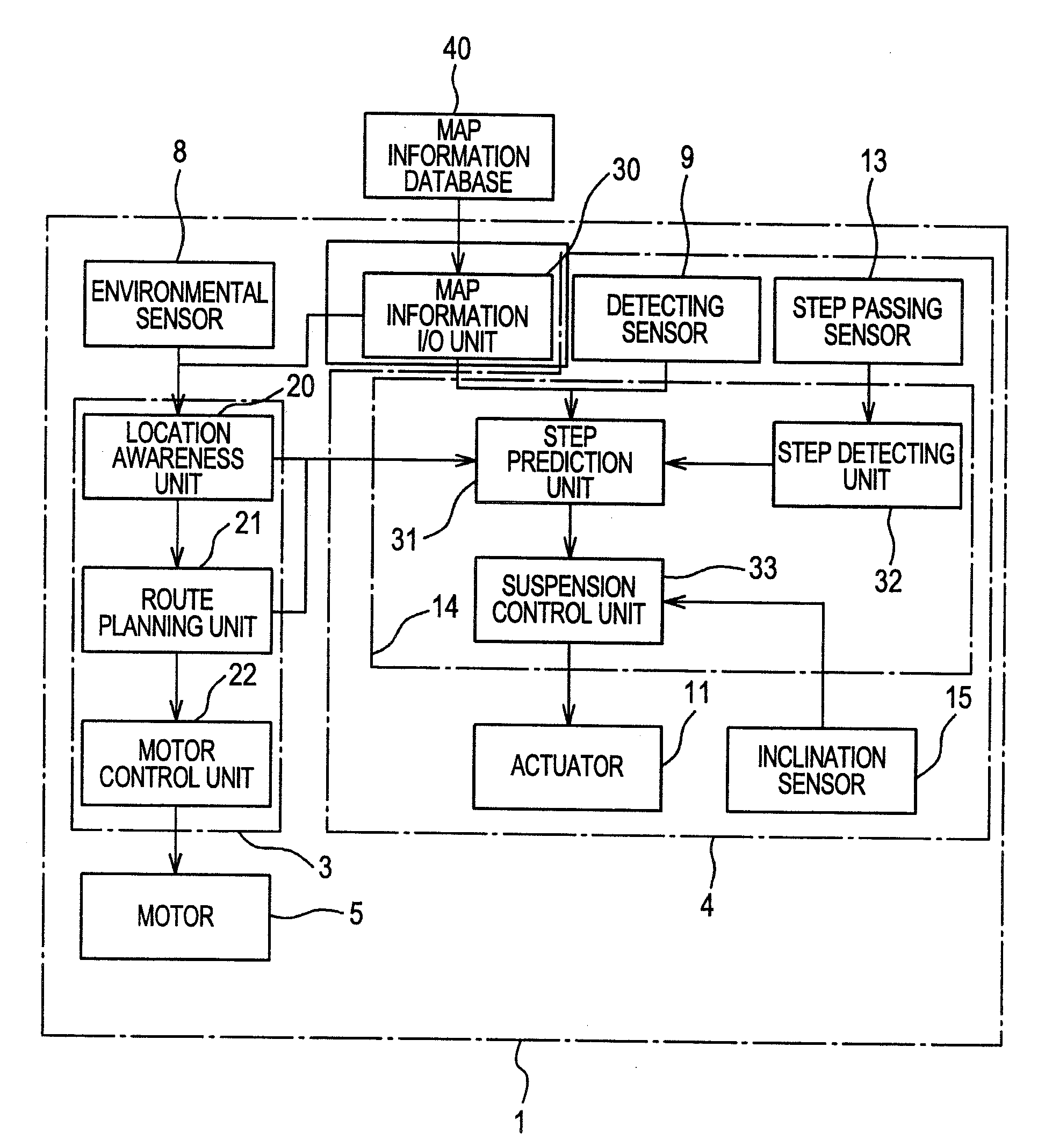

Mobile robot and travelling method for the same

Owner:HITACHI LTD

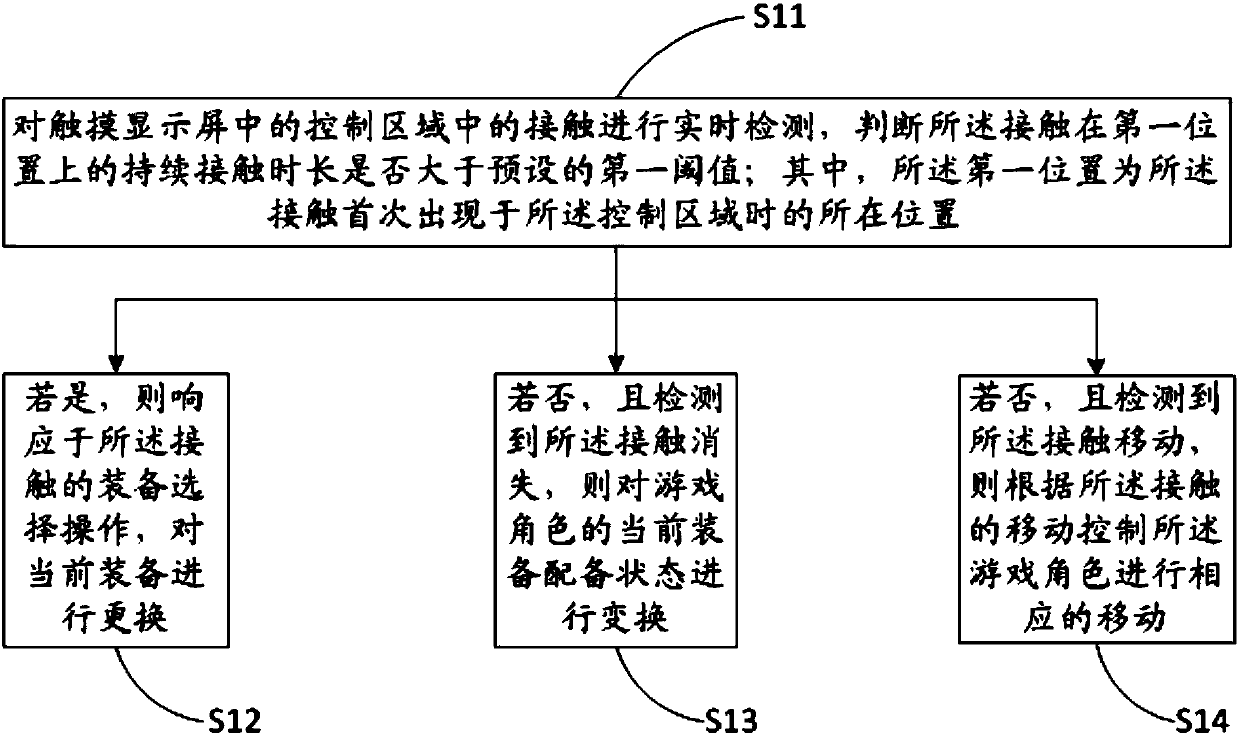

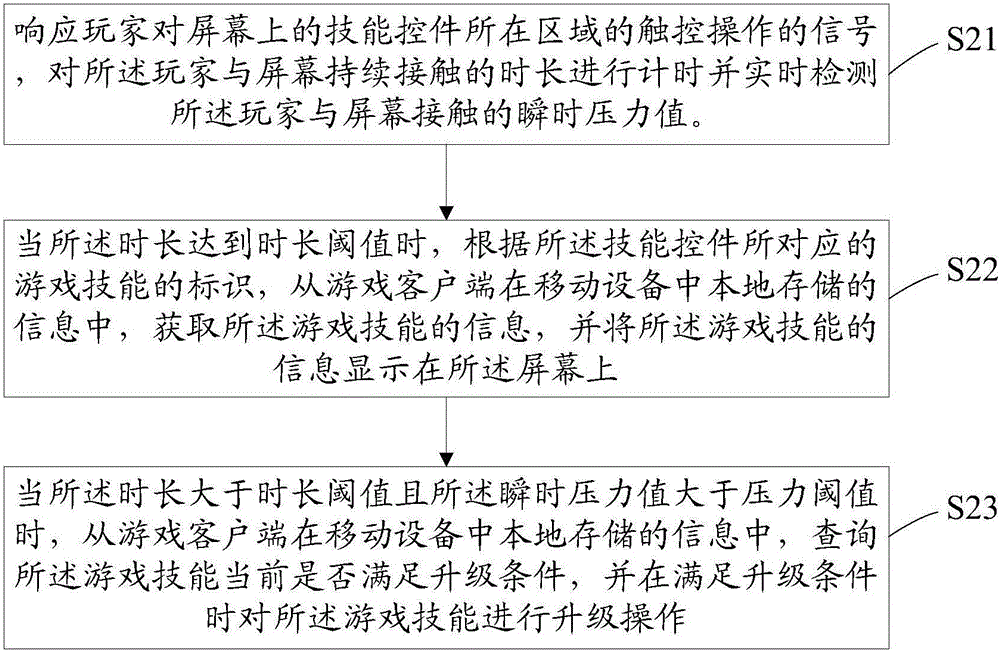

Game role and equipment control method and device, touch device and storage medium

InactiveCN107694085AEasy to controlImprove experienceInput/output for user-computer interactionVideo gamesHuman–computer interactionContact duration

The invention discloses a game role and equipment control method and device, a touch device and a storage medium. The game role and equipment control method comprises the steps that real-time detection is performed on touch in a control region in a touch display screen, whether or not the continuous contact duration of touch at the first position is larger than a first preset threshold value, wherein the first position is the position where the touch appears in the control region for the first time; if yes, the equipment selection operation of the touch is responded to, and the current equipment is replaced; if not, it is detected that the touch disappears, the current equipment state of a game role is changed; if not, it is detected that the touch is moved, and according to the motion ofthe touch, the game role is controlled to move correspondingly. By adopting the game role and equipment control method and device, the game role and equipment can be easily and rapidly controlled, andthe user experience can be improved.

Owner:NETEASE (HANGZHOU) NETWORK CO LTD

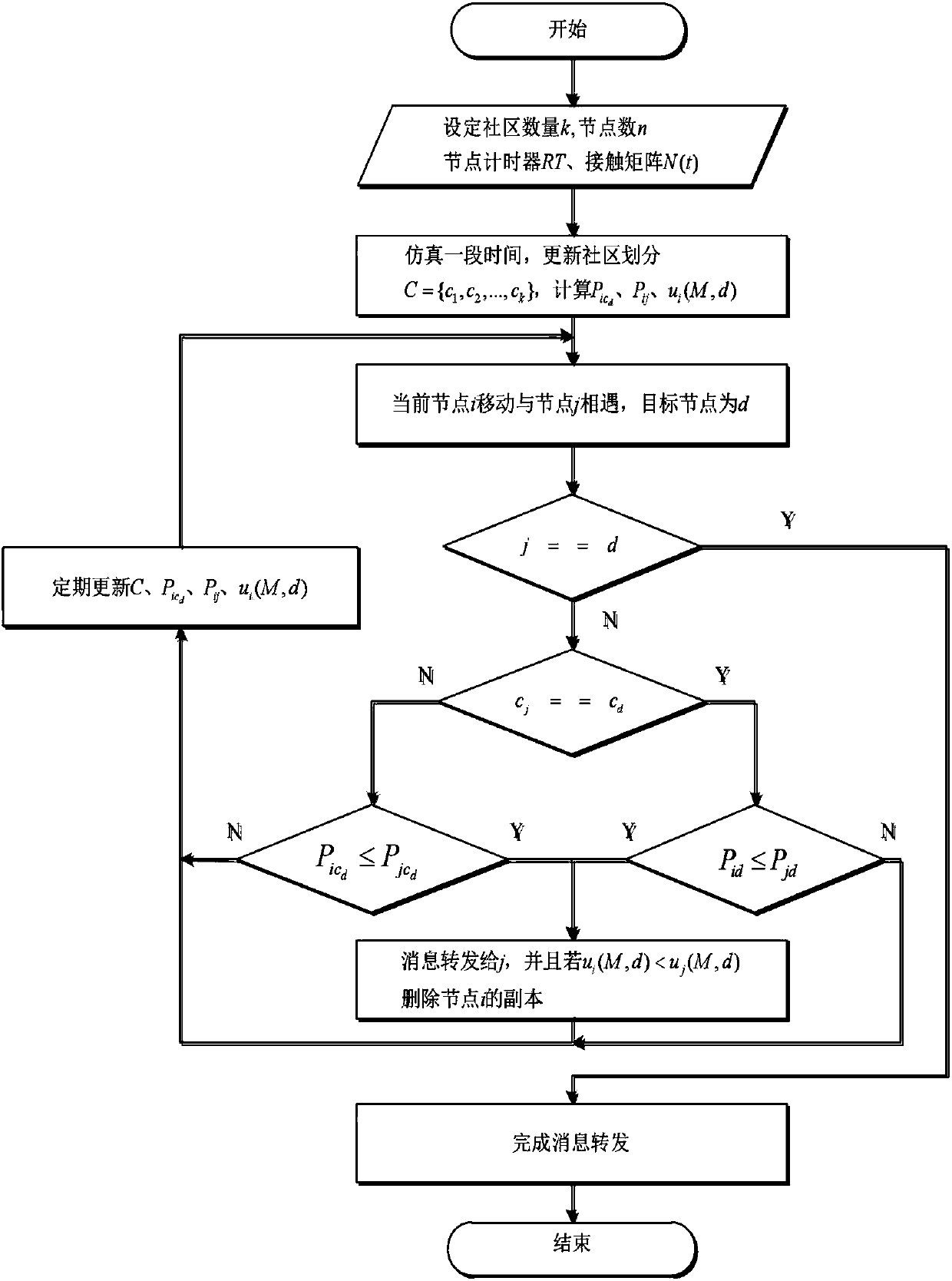

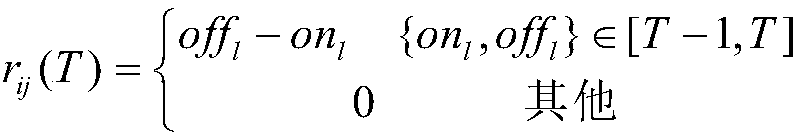

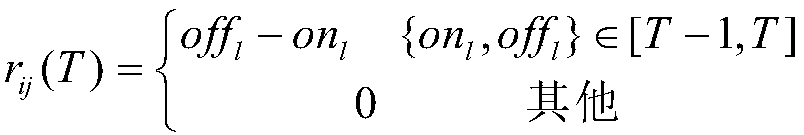

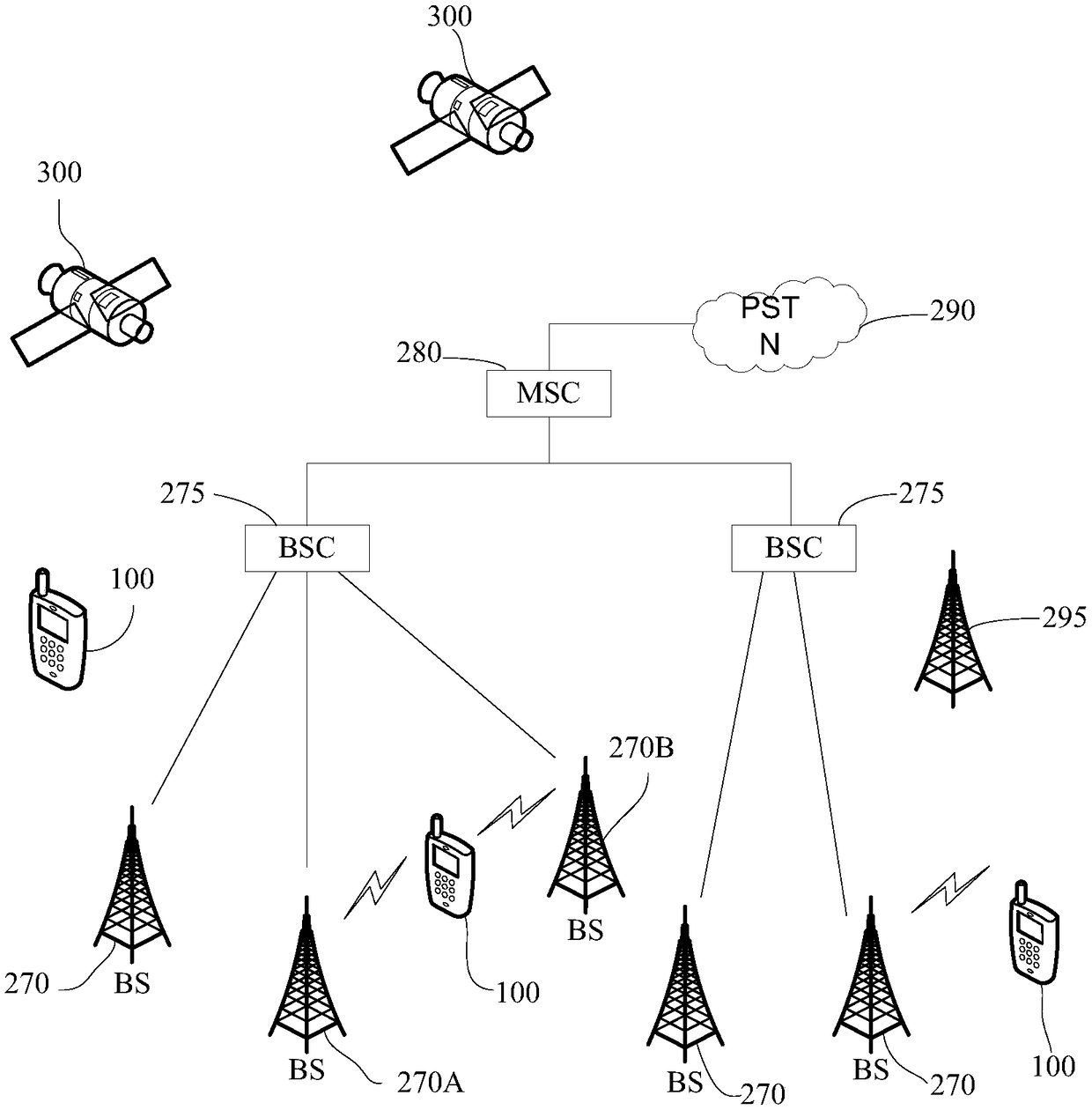

Opportunistic network routing method based on spectral clustering community division

InactiveCN107071844AReduce loadImprove transmission success rateData switching networksWireless communicationSpectral clustering algorithmCopy control

The invention discloses an opportunistic network routing method based on spectral clustering community division. The method comprises the following steps of setting the number of network node communities, division classes and the number of nodes and starting carrying out random movement by all nodes; after simulation is carried out for certain period of time, carrying out community division on the nodes in the network through utilization of a spectral clustering algorithm according to contact times and contact duration among the nodes; calculating community reachable probability centrality of a target node, intra-community node reachable probability centrality and a message copy control utility value according to community division results; carrying out movement and encounter by the nodes, and determining whether messages are forwarded or deleted according to the reachable probability centrality and the copy control utility; and periodically updating the community reachable probability centrality, the intra-community node reachable probability centrality and the message copy control utility value. According to the method, through adoption of the spectral clustering algorithm, the community division effect is good, the message transmission is clearly improved, and the network cost is reduced.

Owner:XIANGTAN UNIV

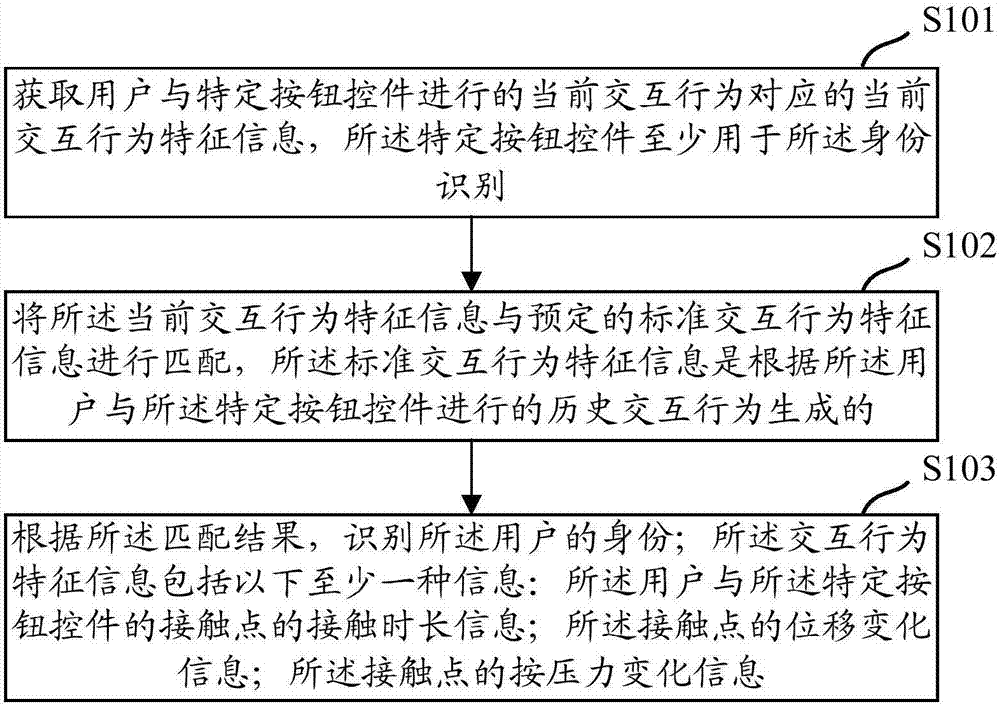

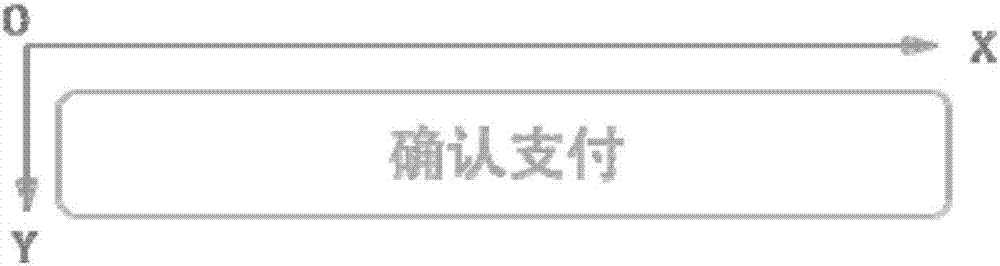

Identity recognition method and device

ActiveCN107194213AEasy to operateImprove convenienceDigital data authenticationIdentity recognitionHuman–computer interaction

The application discloses an identity recognition method and device. The method and device are used to solve the problem that an identity recognition mode in the prior art is complex in operation and poorer in convenience, or is higher in cost. The method comprises: acquiring current interaction behavior characteristic information corresponding to a current interaction behavior performed by a user with a specific button control, wherein the specific button control is at least used for identity recognition; matching the current interaction behavior characteristic information with predetermined standard interaction behavior characteristic information, wherein the standard interaction behavior characteristic information is generated according to historical interaction behaviors performed by the user with the specific button control; and recognizing the identity of the user according to a matching result. The interaction behavior characteristic information includes at least one type of the following information: contact duration information of the user with a contact point of the specific button control; displacement change information of the contact point; and press force change information of the contact point.

Owner:ADVANCED NEW TECH CO LTD

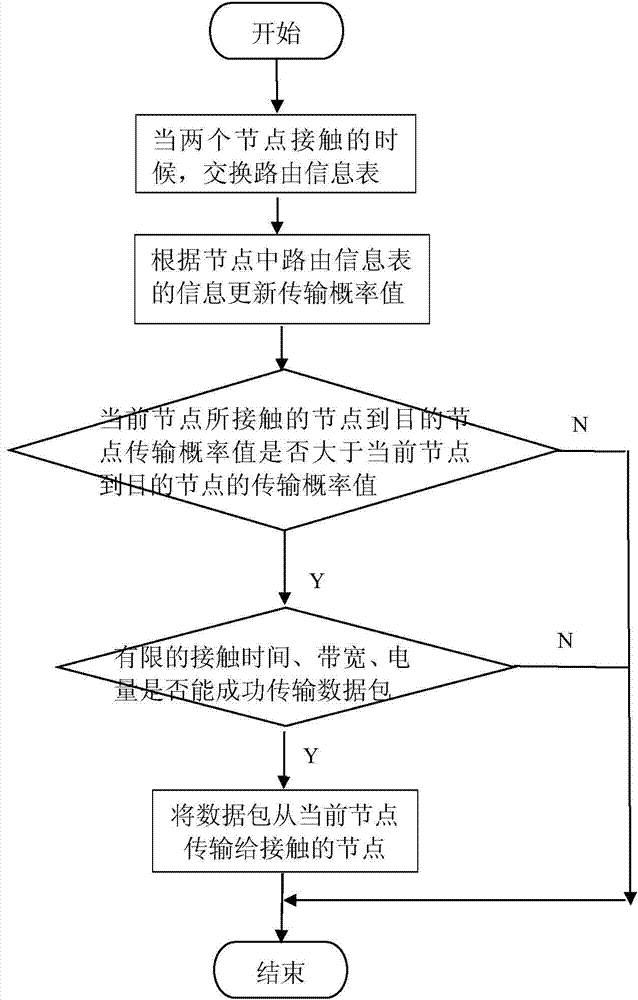

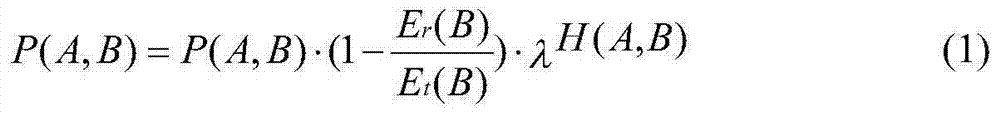

Method for transmitting data of delay tolerant network on basis of improved transmission probability estimation

ActiveCN103546377AImprove transmission success rateSave resourcesData switching networksProbability estimationNetwork packet

The invention discloses a method for transmitting data of a delay tolerant network on the basis of improved transmission probability estimation. The method is characterized in that contact durations among nodes and electric quantities of the nodes are considered when the transmission probability is computed, and whether an information data packet can be successfully transmitted by the nodes under the conditions of limited bandwidths, limited contact durations and limited electric quantities or not is judged. The method includes performing corresponding judgment according to values of the transmission probability; canceling transmission if the value of the probability of transmission from a current node to a target node is larger than a value of the probability of transmission from a certain node to the target node; judging whether the information data packet can be successfully transmitted by the node under the conditions of the limited contact durations and the limited electric quantities or not if the value of the probability of transmission from the current node to the target node is not larger than the value of the probability of transmission from the certain node to the target node; transmitting information from the current node to the certain contact node if the information data packet can be successfully transmitted by the node; canceling transmission if the information data packet cannot be successfully transmitted by the node. The certain node is in contact with the current node. The method has the advantages that the contact durations of the nodes and the electric quantities of the nodes are introduced into a routing algorithm when the routing algorithm is performed, so that a next hop can be selected correctly, and the transmission success rate can be increased; the size of the information data packet is compared to the quantity of data which can be transmitted under the conditions of the limited contact durations and the limited electric quantities, so that whether the information data packet is transmitted or not can be determined, and the purpose of saving network resources can be achieved.

Owner:NANJING UNIV OF POSTS & TELECOMM

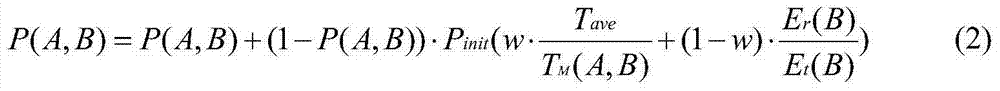

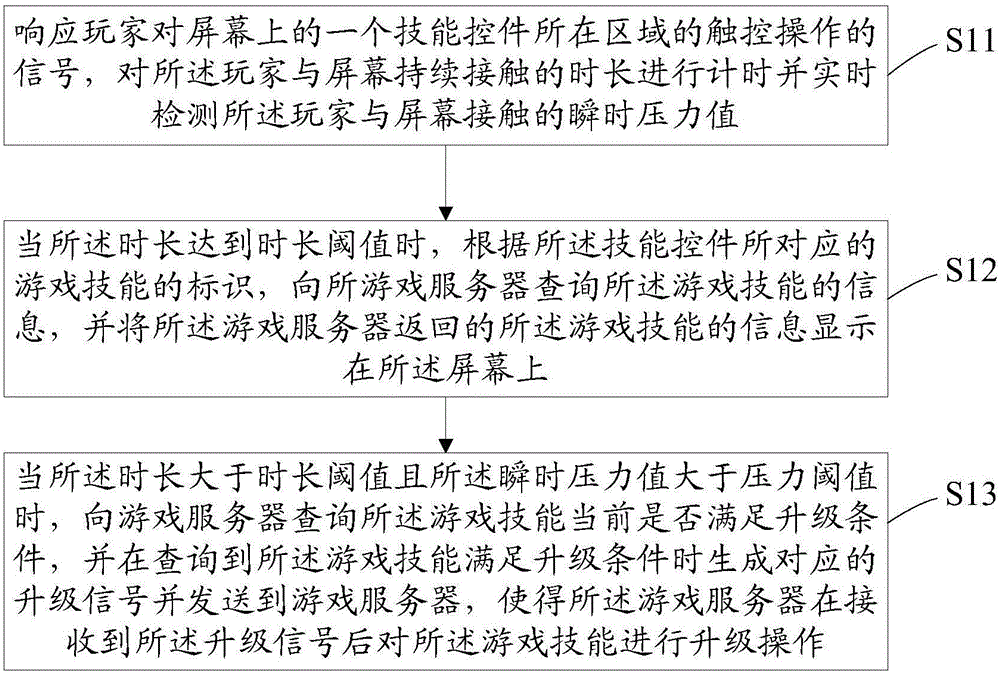

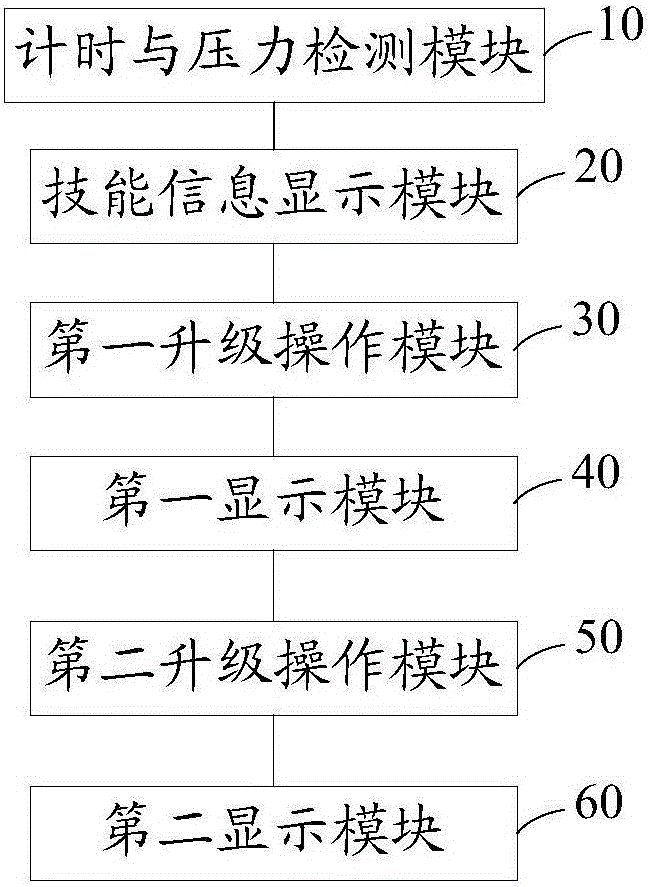

Control method and device for game skill upgrading

ActiveCN106055256ATouch operation is fastVideo gamesInput/output processes for data processingSkill setsHuman–computer interaction

The invention discloses a control method for game skill upgrading. The control method comprises the following steps: timing the continuous contact duration of a player and a screen and detecting the contact instant pressure value of the player and the screen in real time in response to a touch operation signal of a user to a skill control located region on the screen; when the duration achieves a duration threshold, acquiring the game skill information according to the identification of the game skill corresponding to the skill control, and displaying the information of the game skill on the screen; when the duration is greater than the duration threshold and the instant pressure value is more than a pressure threshold, detecting whether the game skill can meet the upgrading condition at present, and performing the upgrading operation of the game skill when the game skill meets the upgrading condition. Correspondingly, the invention further discloses a control device for the game skill upgrading. Through the adoption of the method disclosed by the embodiment of the invention, the player can fast perform the upgrading operation after previewing the skill information in the nervous game rhythm.

Owner:NETEASE (HANGZHOU) NETWORK CO LTD

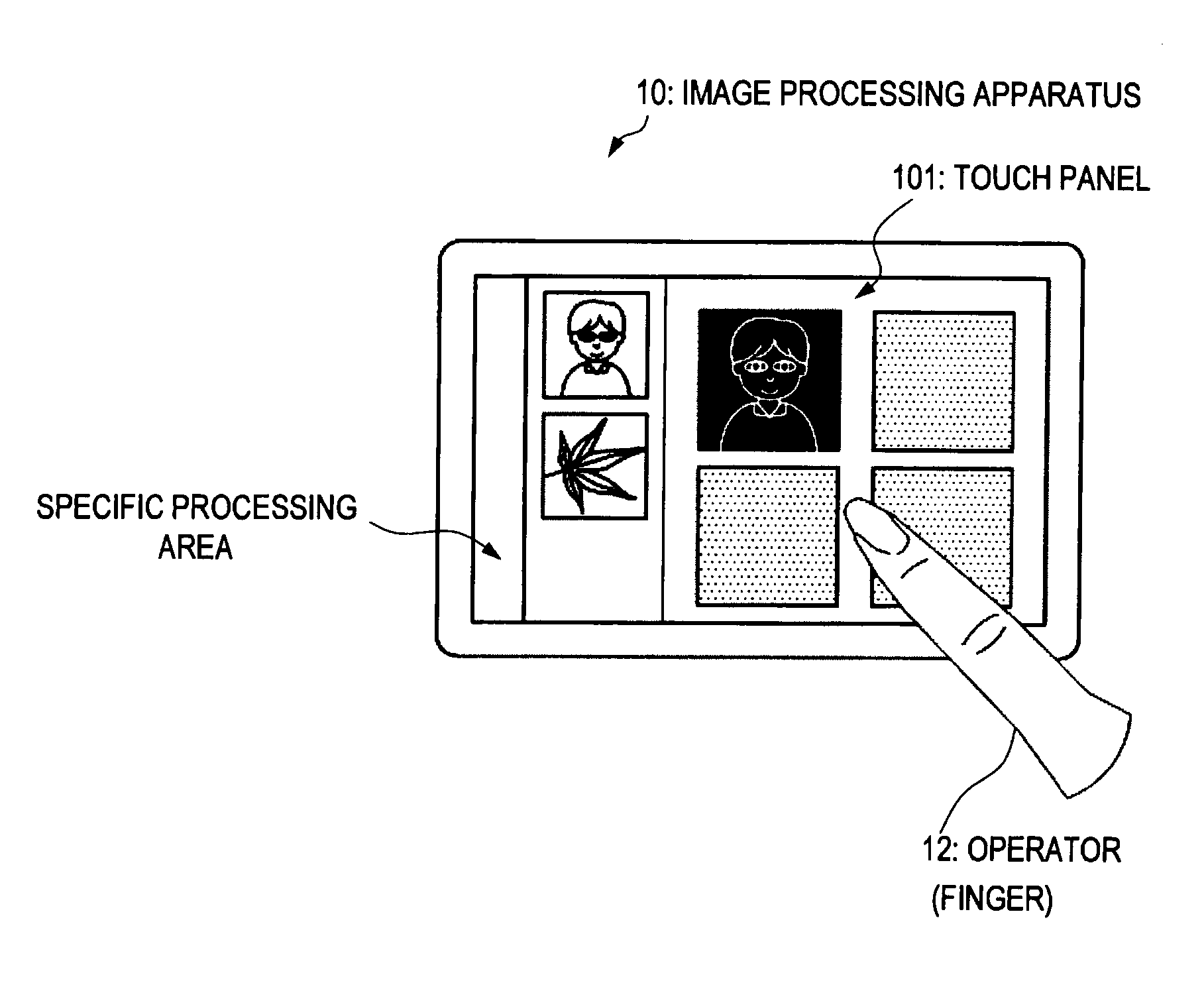

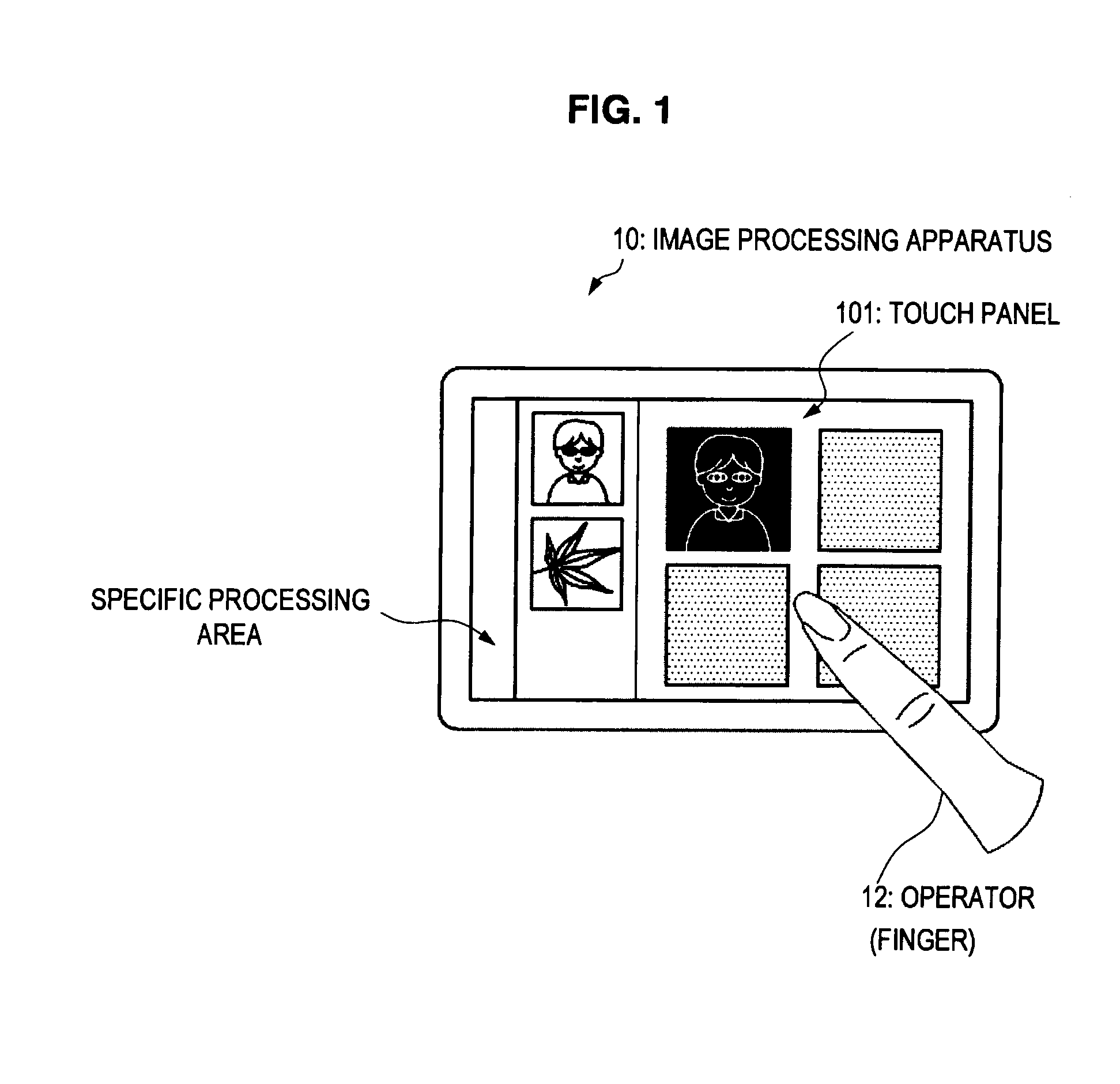

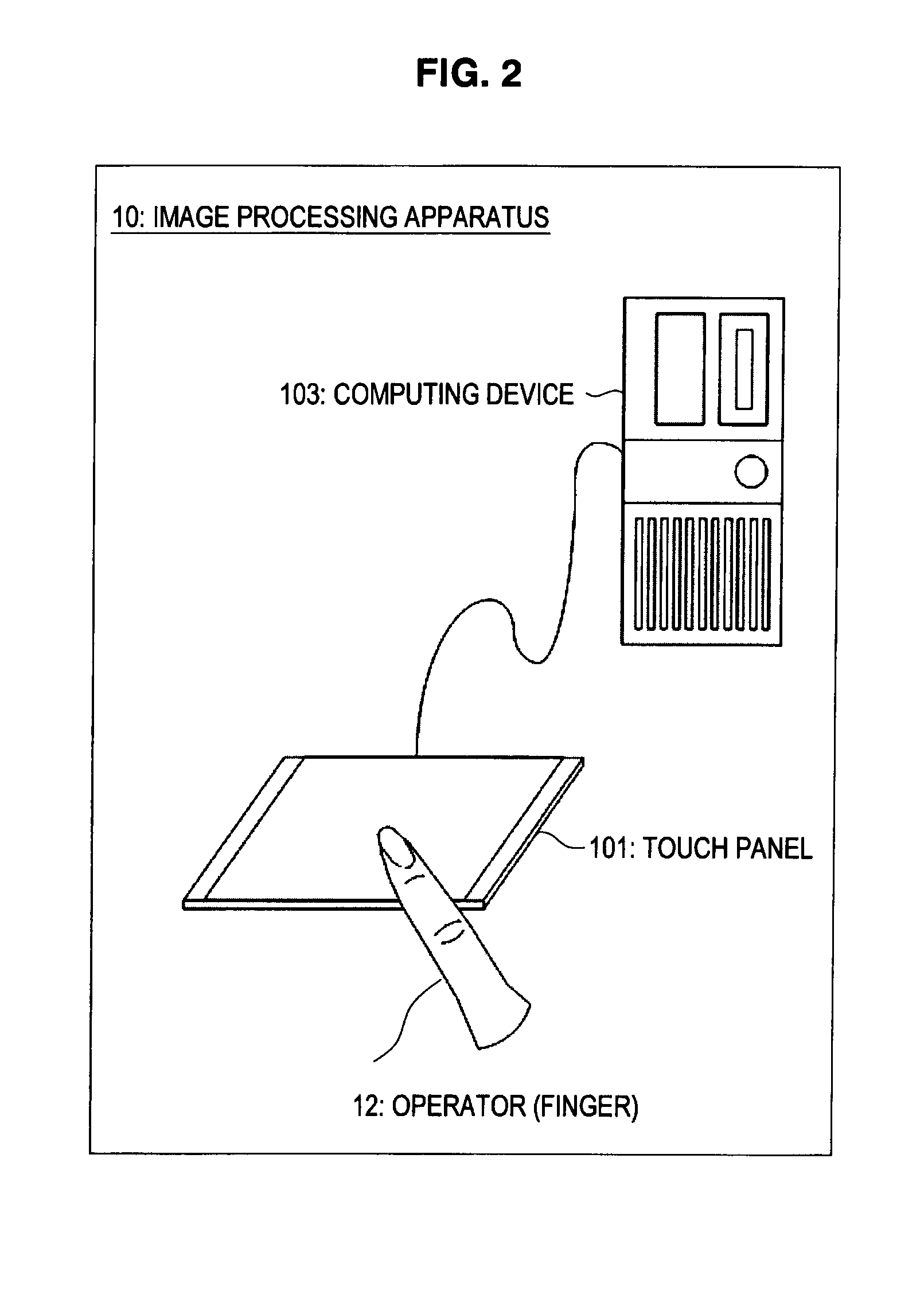

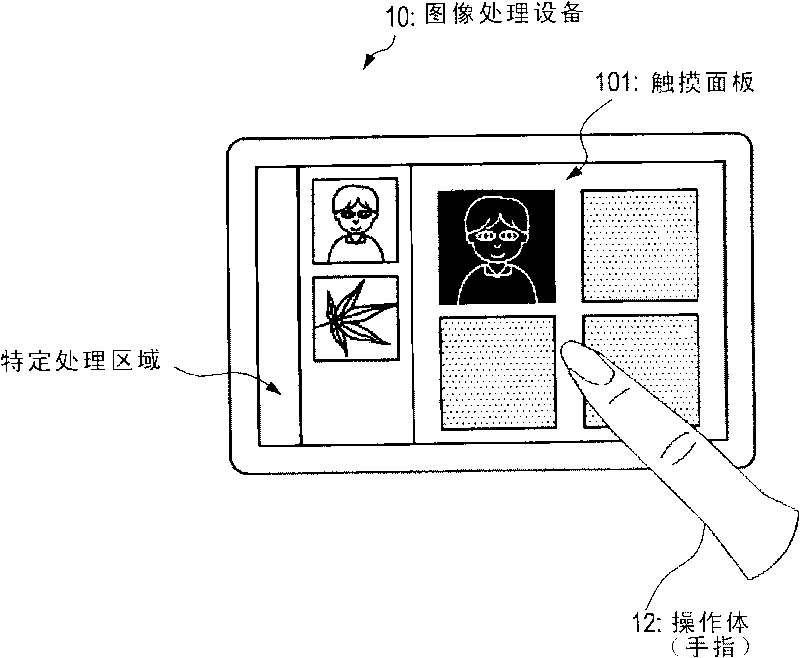

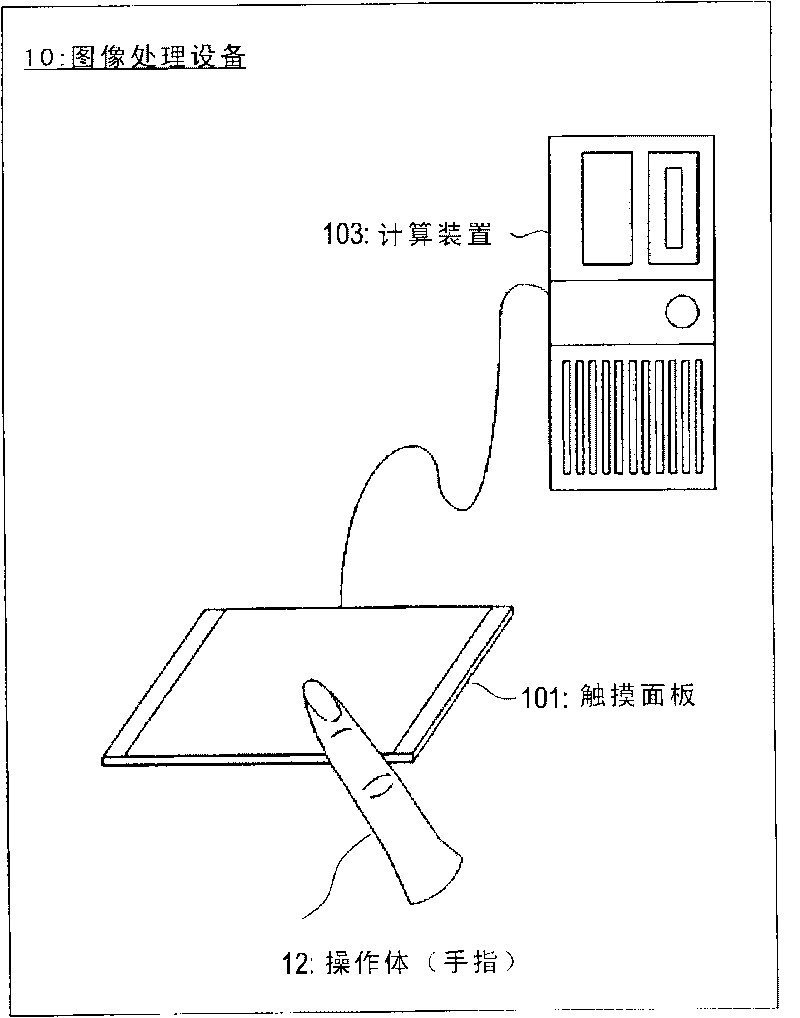

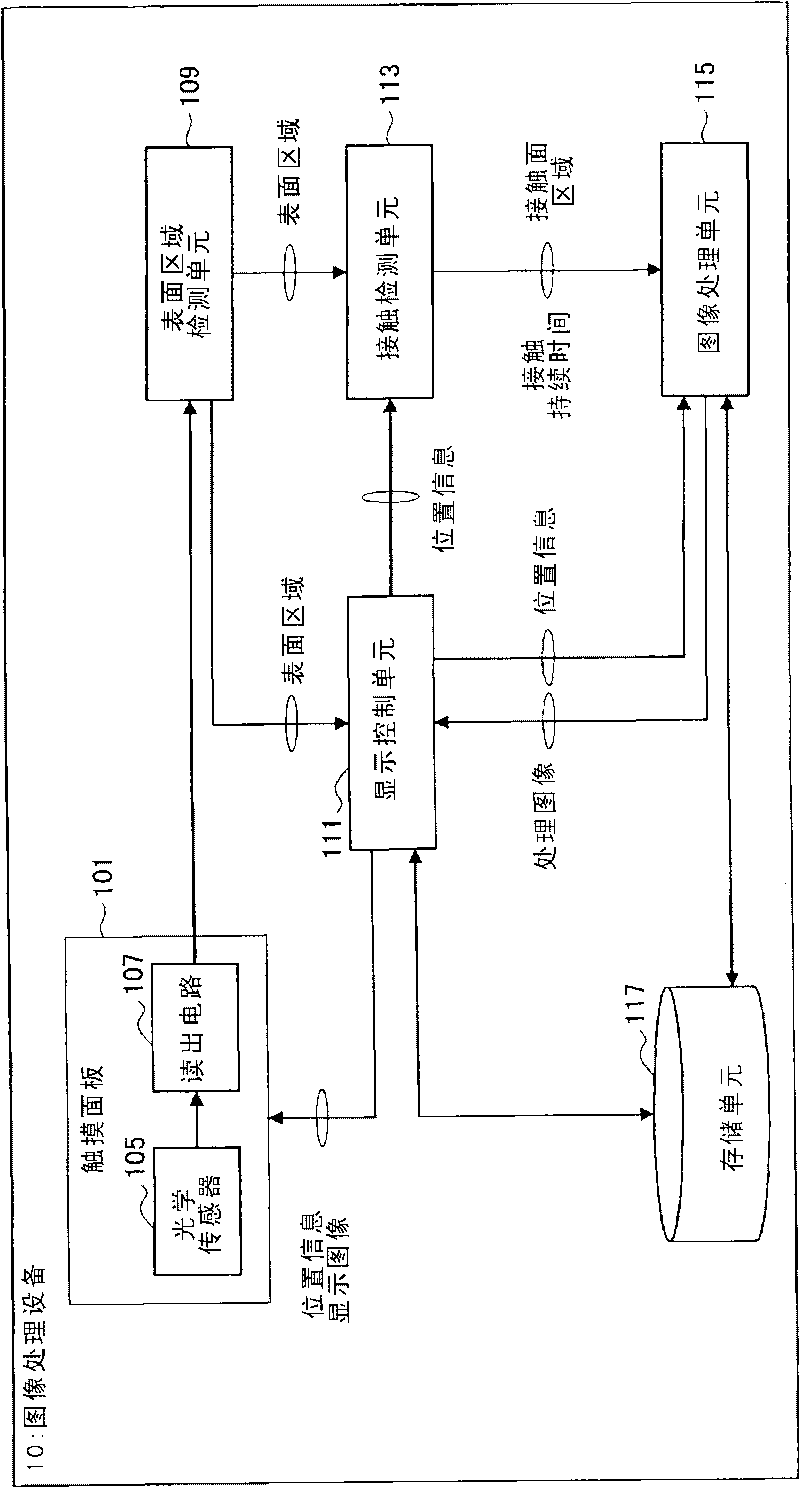

Image processing apparatus, image processing method, and program

InactiveUS20100097339A1Difficult to set upEasy to set upInput/output processes for data processingImaging processingComputer graphics (images)

The image processing apparatus according to the present invention is provided with an image processing unit for performing the image processing function by changing its execution parameter for the image processing function, which is associated with a processing result display area for displaying an image processing result acquired from applying a predetermined image processing function to specified image data, based on at least one of a surface area size of an operator contacting the processing result display area or contact duration in which the operator contacts the processing result display area.

Owner:SONY CORP

Time-to-contact estimation device and method for estimating time to contact

ActiveUS7711147B2Computationally efficientLower latencyImage enhancementImage analysisObject basedPixel brightness

Owner:VEONEER SWEDEN AB +1

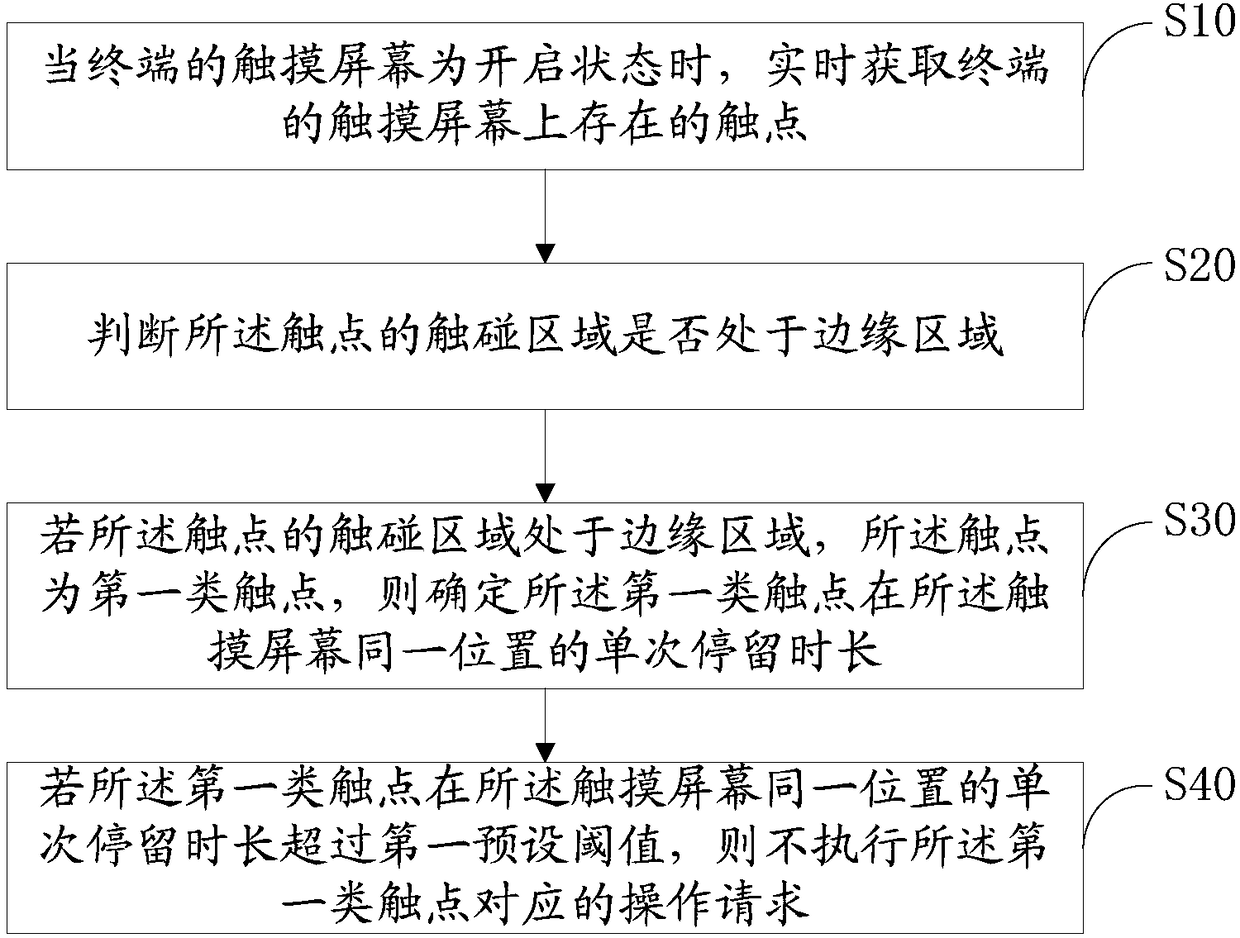

Terminal control method, terminal and computer-readable storage medium

InactiveCN108595106AImprove experienceAvoid misuseSubstation equipmentInput/output processes for data processingSimulationComputer terminal

The invention discloses a terminal control method, a terminal and a computer-readable storage medium. According to the terminal control method, a contact point existing on a touch screen of the terminal is acquired in real time when the touch screen of the terminal is in a starting state; whether a touch area of the contact point is in an edge area is judged; if the touch area of the contact pointis in the edge area and the contact point is a first-type contact point, single-stay duration of the first-type contact point at the same position of the touch screen is determined; and an operationrequest corresponding to the first-type contact point is not executed if the single-stay duration of the first-type contact point at the same position of the touch screen exceeds a first preset threshold. Whether the contact point is a misoperation is judged through combining two conditions of the contact duration of the contact point and the area where the contact point is located, a case where amisoperation is judged as a non-misoperation or a non-misoperation is judged as a misoperation due to that whether a contact point is the misoperation is judged by a single judgment condition is avoided, the determination conditions of judging misoperations by the terminal are optimized, and determination accuracy of the misoperations and user experience are improved.

Owner:NUBIA TECHNOLOGY CO LTD

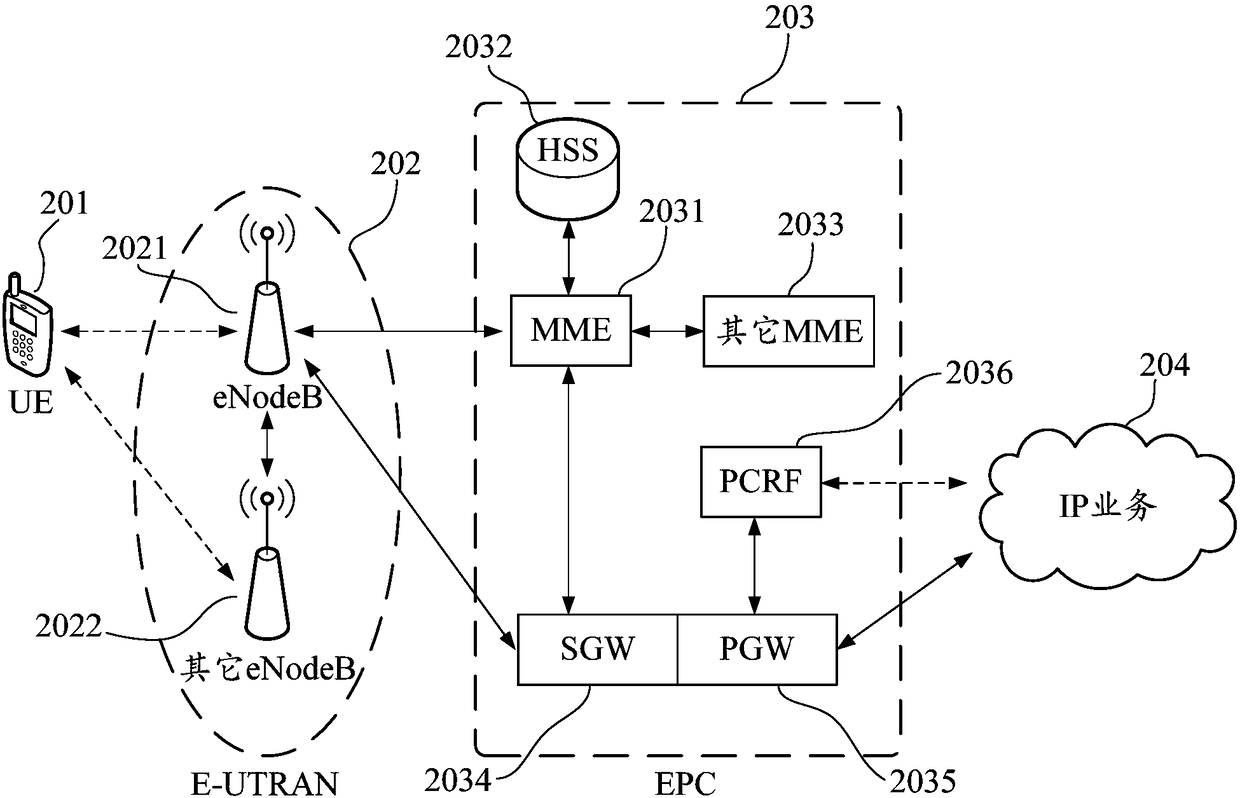

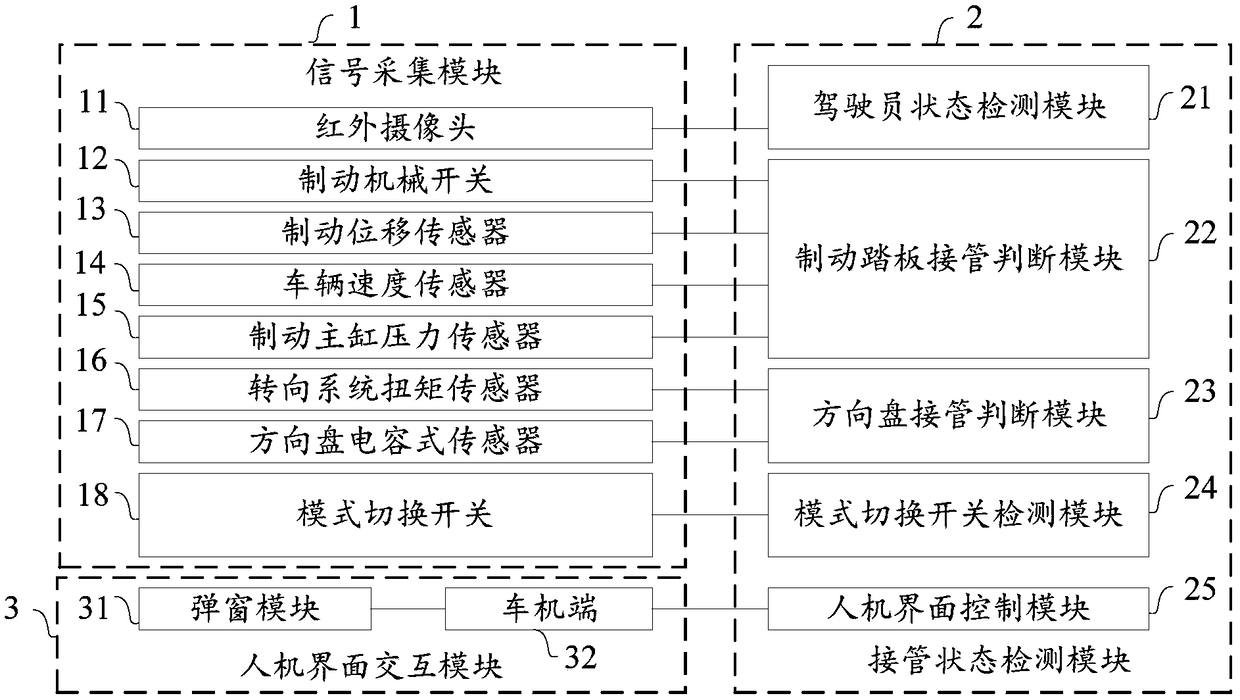

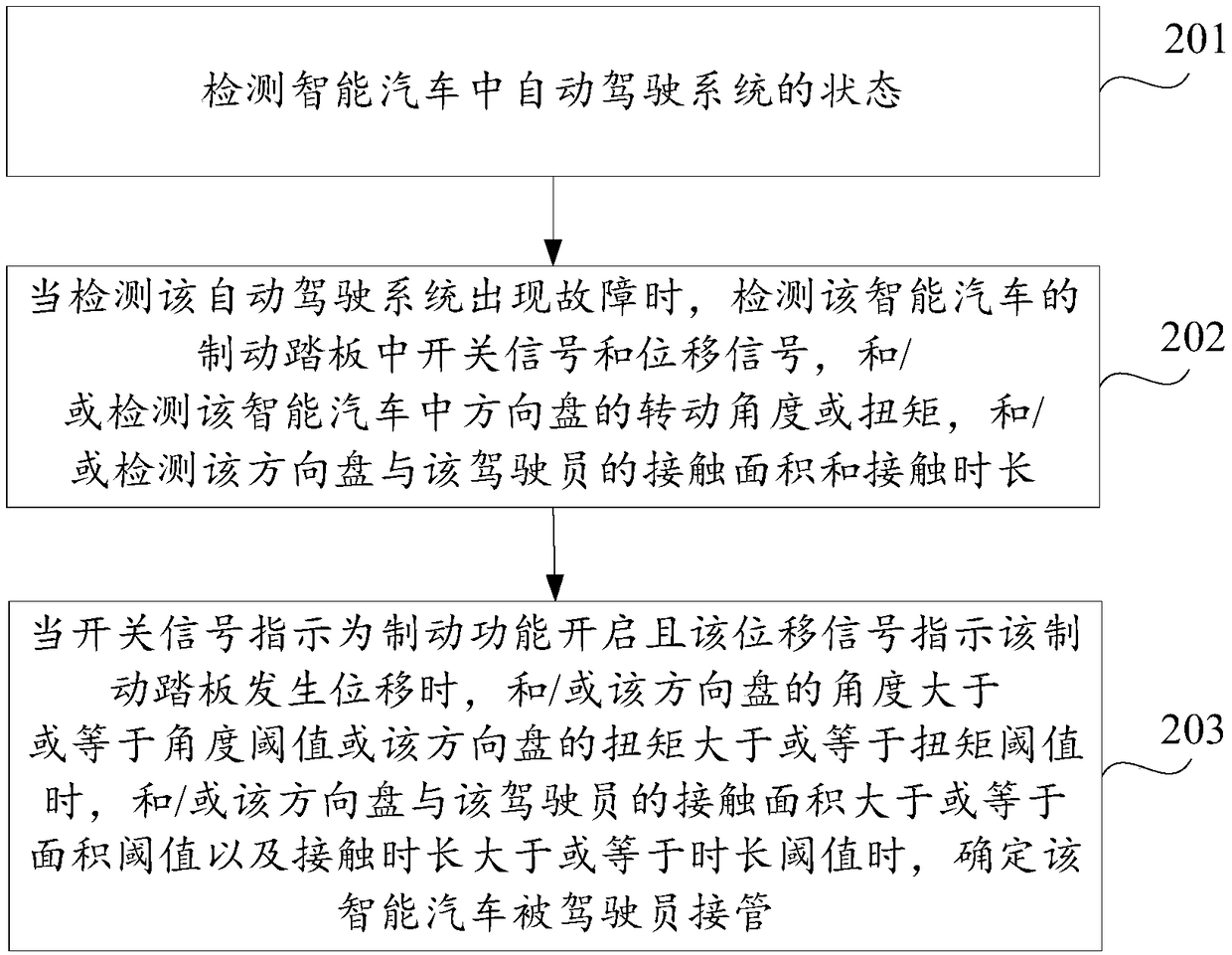

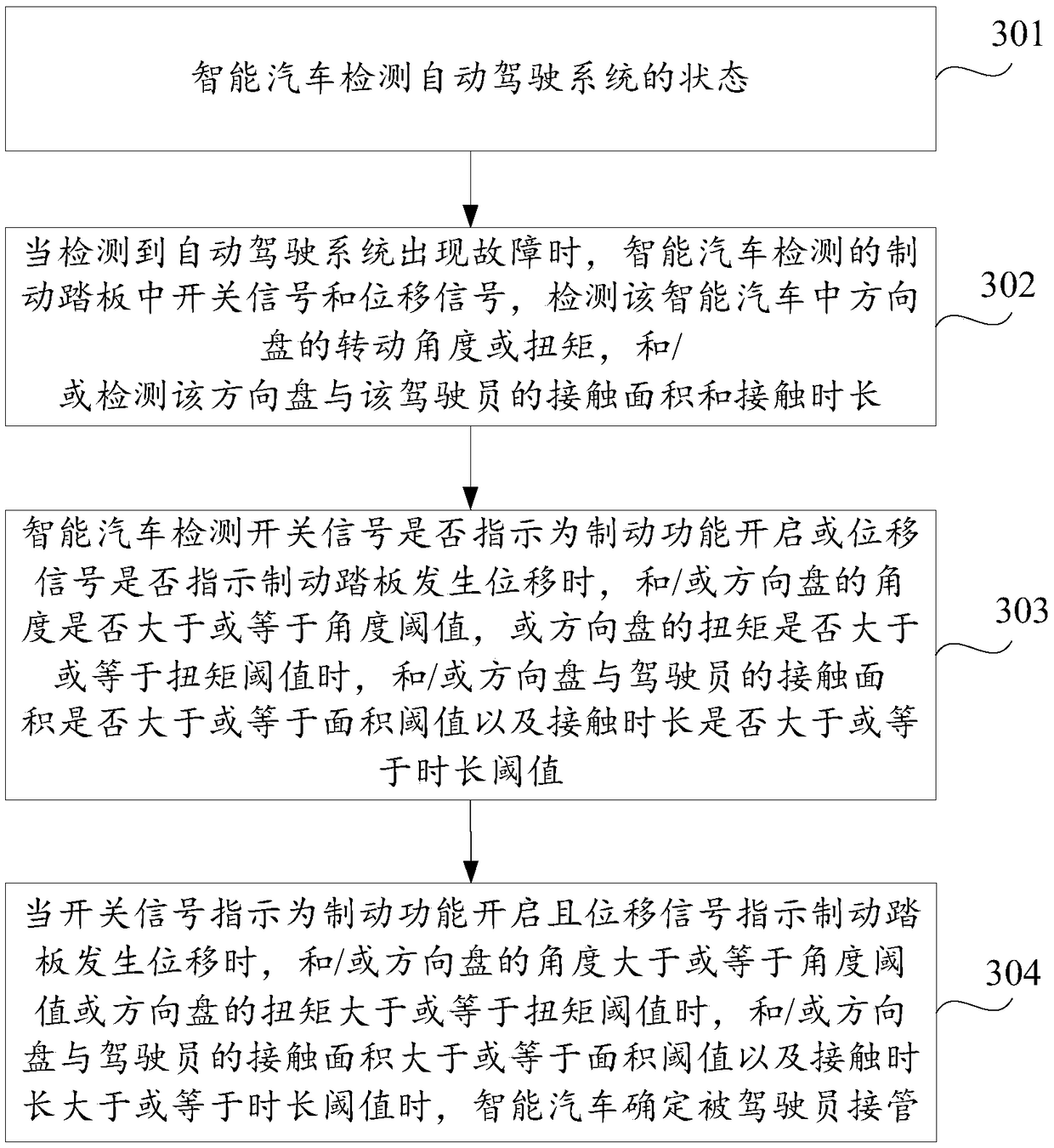

Takeover detection method and device of intelligent automobile and storage medium

ActiveCN109318906AImprove driving safetyAvoid short-term loss of controlAutomatic initiationsDriver input parametersSteering wheelSwitching signal

The invention discloses a takeover detection method and device of an intelligent automobile and a storage medium, and belongs to the technical field of intelligent automobiles. The takeover detectionmethod of the intelligent automobile comprises the steps that the state of an automatic driving system in the intelligent automobile is detected; when the failure of the automatic driving system is detected, a switch signal and a displacement signal in a brake pedal of the intelligent automobile are detected, and / or a rotation angle or torque of a steering wheel in the intelligent automobile is detected, and and / or a contact area and contact duration between the steering wheel and a driver are detected; and when the switch signal indicates that a brake function is on and the displacement signal indicates that the brake pedal is displaced, and / or the angle of the steering wheel is greater than or equal to a angle threshold value or the torque of the steering wheel is greater than or equal to a torque threshold value, and / or the contact area between the steering wheel and the driver is greater than or equal to a area threshold value and the contact duration between the steering wheel andthe driver is greater than or equal to a duration threshold value, and then the intelligent automobile is determined to be taken over by the driver.

Owner:WUHU LION AUTOMOTIVE TECH CO LTD

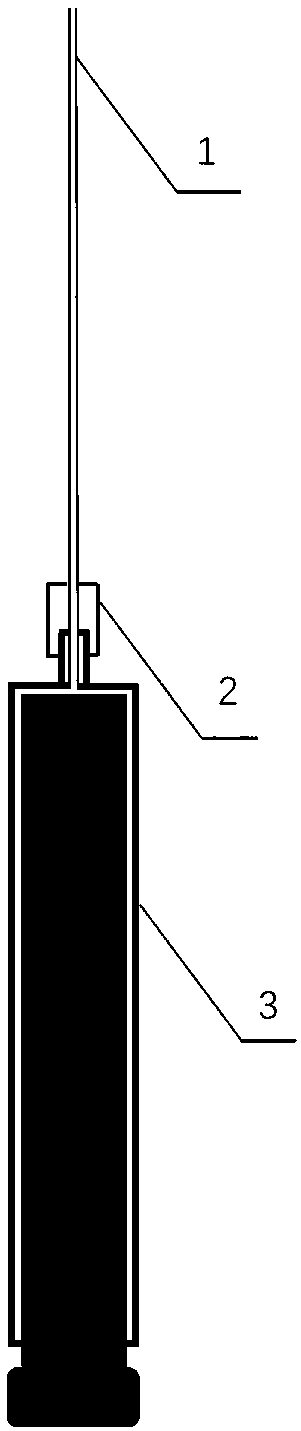

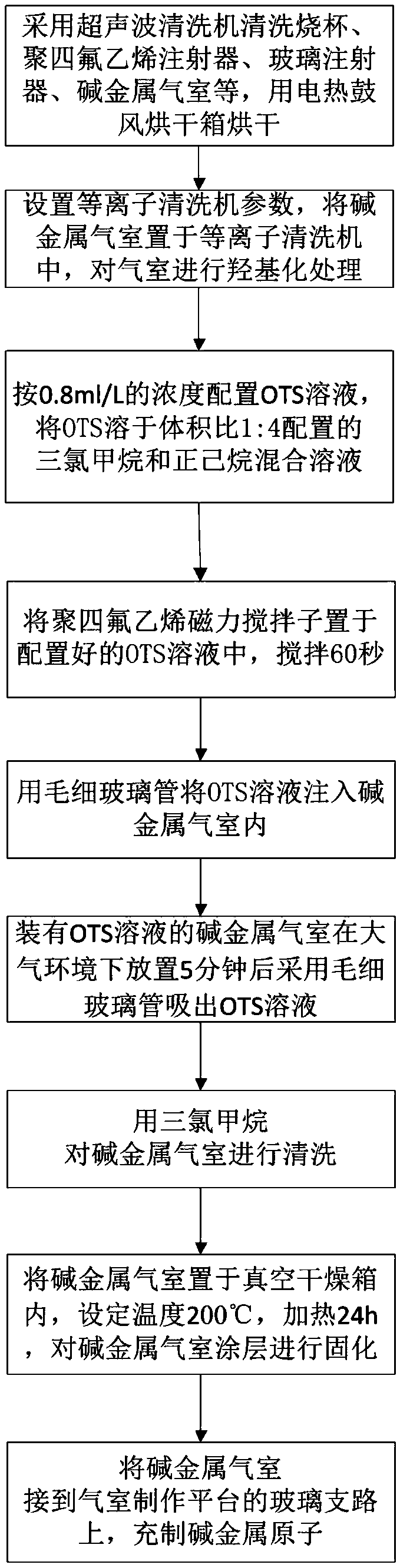

Alkali metal air chamber manufacturing method for improving relaxation resistance of coating based on Plasma hydroxylation

ActiveCN109518177AReduce pollutionImproved anti-relaxation propertiesMetallic material coating processesProblem of timeEngineering

The invention relates to an alkali metal air chamber manufacturing method for improving the relaxation resistance of a coating based on Plasma hydroxylation. According to the method, a plasma cleaningmachine is adopted for hydroxylating the inner surface of an air chamber; since a tail pipe of the alkali metal air chamber is thin, the operation that a thick cleaning solution needs to be extractedby adopting a capillary glass tube after cleaning through a traditional hydroxylation method is omitted, so that the air chamber is prevented from being pricked during a cleaning solution extractionprocess, and the problems of time waste, effort waste, nonideal consistency and nonideal relaxation resistance during the current air chamber manufacturing process are solved; and meanwhile, more hydroxide radicals can be formed on the glass surface, and no cleaning solution removal and follow-up drying is needed, so that the contact time of the hydroxide radicals and the outside environment is shortened, the hydroxide radical pollution is reduced, more hydroxide radical number can be maintained, a smooth and uniform covering surface is realized during the organochlorosilane reaction process,the surface covering rate on paramagnetic impurities is increased, and the relaxation resistance of the coating is improved. In addition, multiple air chambers can be processed at the same time, so that the consistency and the repeatability in manufacturing the coating are improved.

Owner:杭州诺驰生命科学有限公司

Image processing apparatus, image processing method, and program

InactiveCN101727283AWithout compromising convenienceEasy to set upInput/output processes for data processingImaging processingComputer graphics (images)

Owner:SONY CORP

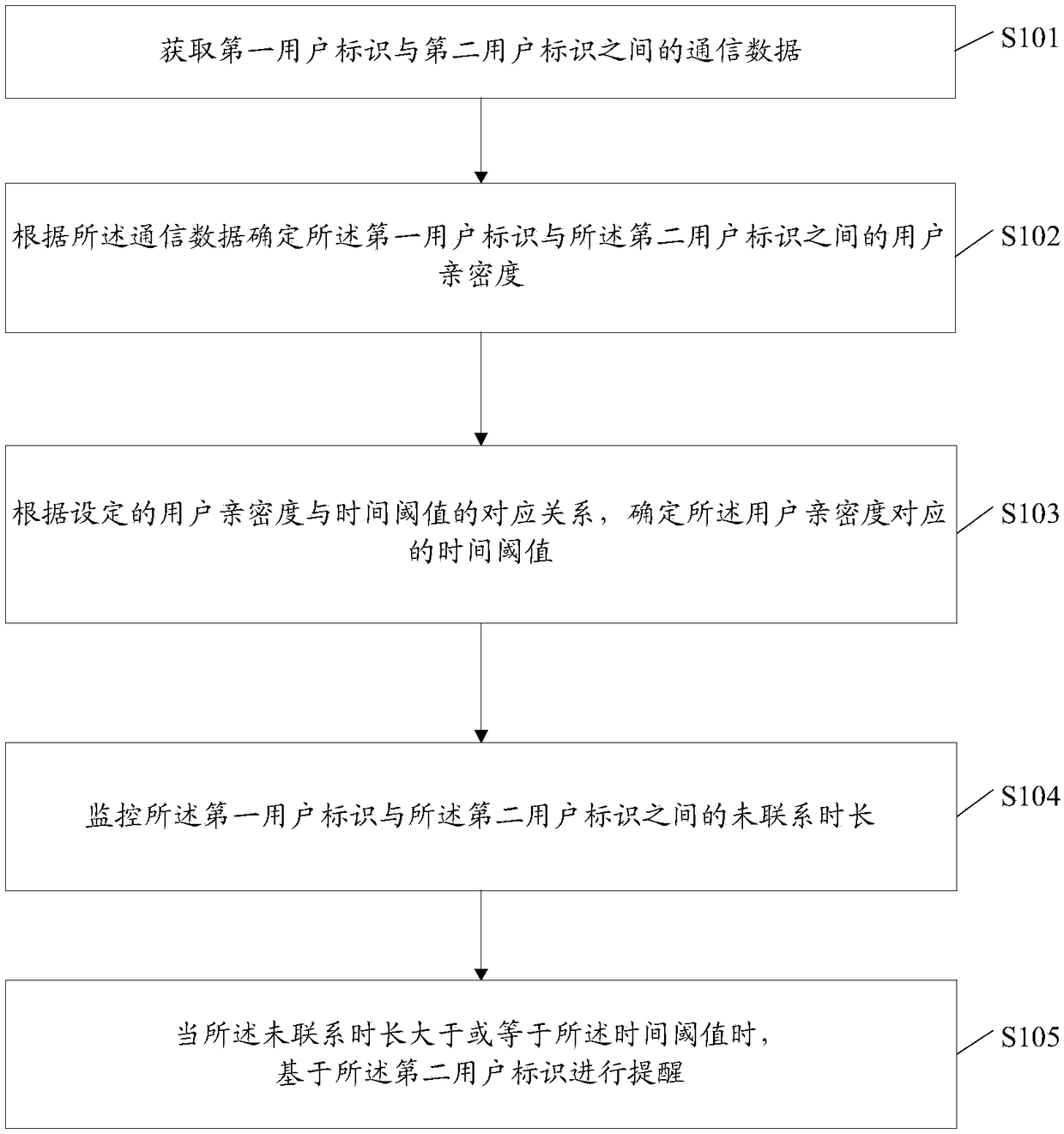

Information prompting method and device based on user intimacy and storage medium

The present invention discloses an information prompting method and device based on user intimacy and a storage medium. The method comprises the steps of: obtaining communication data between a firstuser identifier and a second user identifier; determining user intimacy between the first user identifier and the second user identifier according to the communication data; determining a time threshold value corresponding to the user intimacy according to a set corresponding relation between the user intimacy and the time threshold value; monitoring non-contact duration between the first user identifier and the second user identifier; and when the non-contact duration is longer than or equal to the time threshold value, performing prompting based on the second user identifier. The embodimentof the invention further provides a device implementing the method mentioned above and a computer readable storage medium. The information prompting method and device based on user intimacy and the storage medium can perform automatic prompting based on the user intimacy and can improve the user experience.

Owner:NUBIA TECHNOLOGY CO LTD

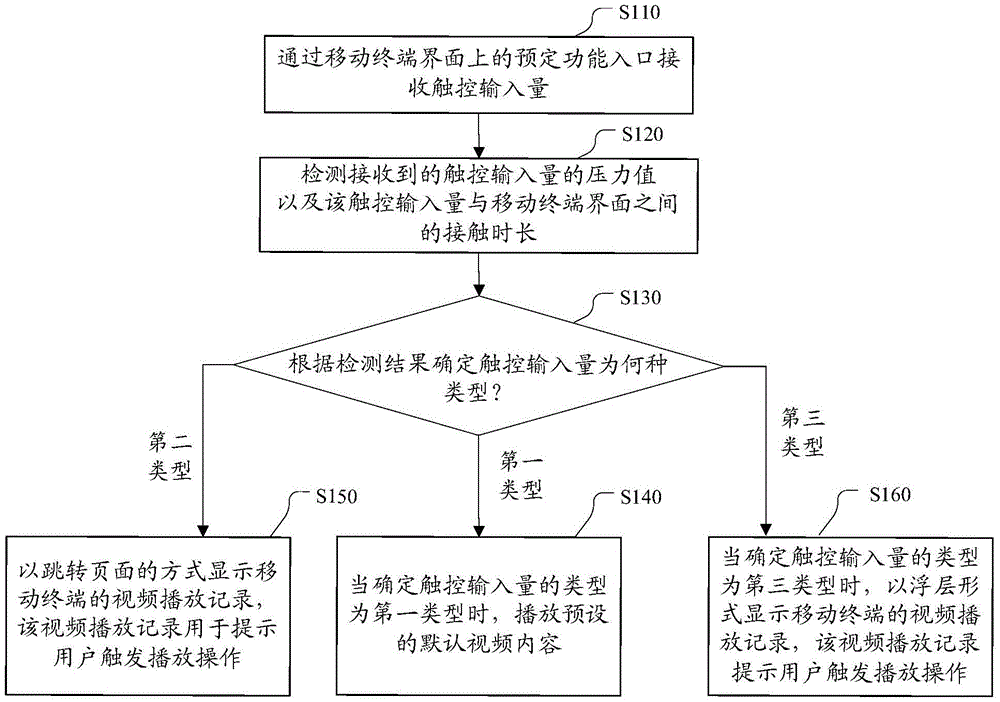

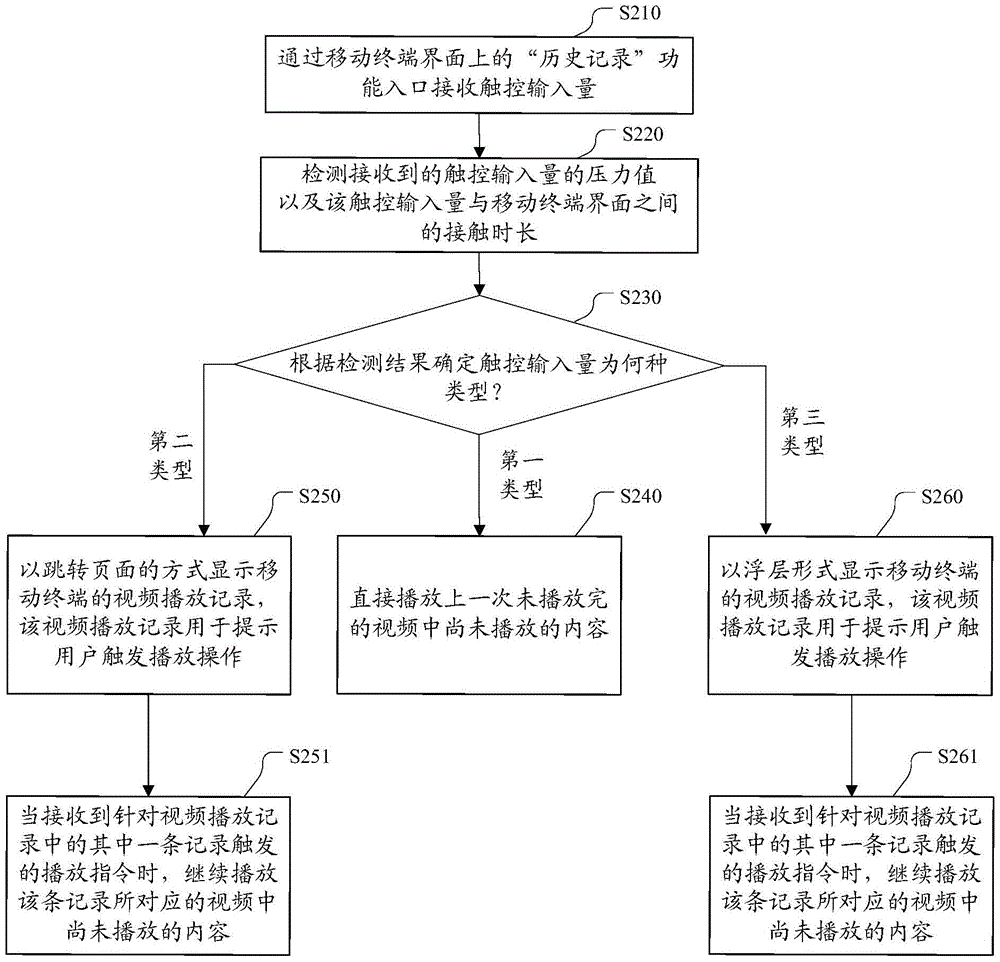

Video playing method and device based on mobile terminal

InactiveCN105872644AMeet diverse needsSubstation equipmentSelective content distributionComputer terminalHuman–computer interaction

The invention discloses a video playing method and device based on a mobile terminal. According to the method and the device, at least the problem that the traditional video playing mode only can provide a single triggering mode for a user and cannot satisfy the diversified demands of the user is solved. The method comprises following steps of receiving touch input quantity at a preset function entry on a mobile terminal interface; detecting the pressure value of the touch input quantity and the contact duration between the touch input quantity and the mobile terminal interface; determining the type of the touch input quantity according to a detection result; playing preset default video contents when the determined type of the touch input quantity is a first type; displaying the video playing records of the mobile terminal in a page skipping mode when the determined type of the touch input quantity is a second type; and displaying the video playing records of the mobile terminal in a floating layer form when the determined type of the touch input quantity is a third type.

Owner:LETV INFORMATION TECH BEIJING

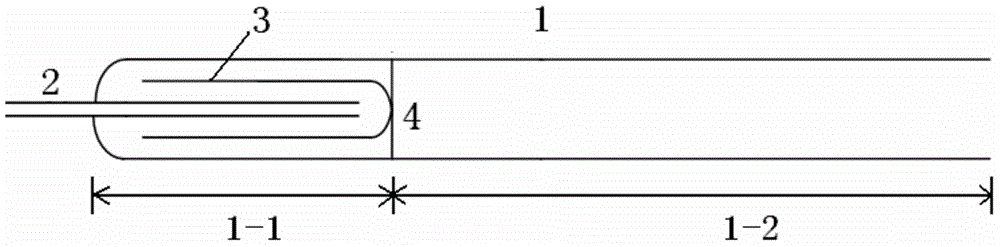

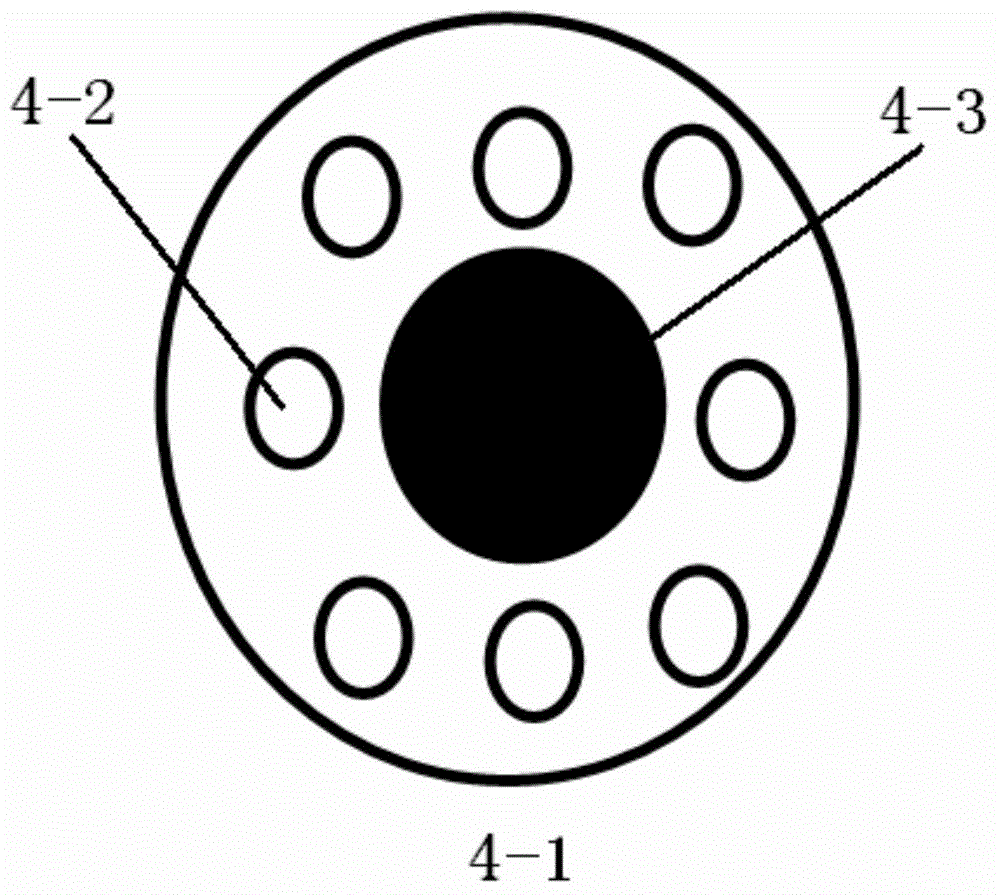

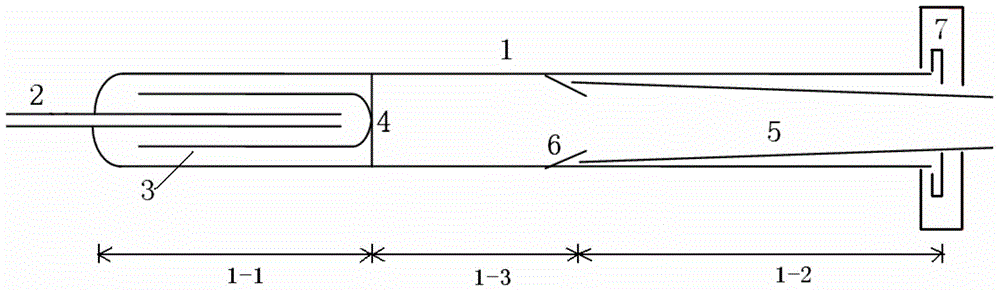

Hydrogenation reduction device for high-purity arsenic production and high-purity arsenic preparing method

The invention belongs to the field of high-purity arsenic and particularly relates to a hydrogenation reduction device for high-purity arsenic production and a high-purity arsenic preparing method. The hydrogenation reduction device for high-purity arsenic production comprises a hydrogenation reduction pipe. A feed pipe is arranged at the feed end of the hydrogenation reduction pipe. A reaction section and a deposition section are arranged inside the hydrogenation reduction pipe in sequence in the airflow advancing direction. A partition board with a hole is arranged at the air outlet end of the reaction section. A return pipe with an opening facing the feed end of the hydrogenation reduction pipe is arranged on the reaction section. The return pipe is fixed to the partition board. The discharge end of the feed pipe stretches into the return pipe. The air outlet end of the deposition section is located at the air outlet end of the hydrogenation reduction pipe. According to the hydrogenation reduction device for high-purity arsenic production, the return pipe is arranged on the reaction section of the hydrogenation reduction pipe, in this way, the contact duration of arsenic trichloride and hydrogen is prolonged, the purity of products is improved, and the yield of the products is increased.

Owner:威科赛乐微电子股份有限公司

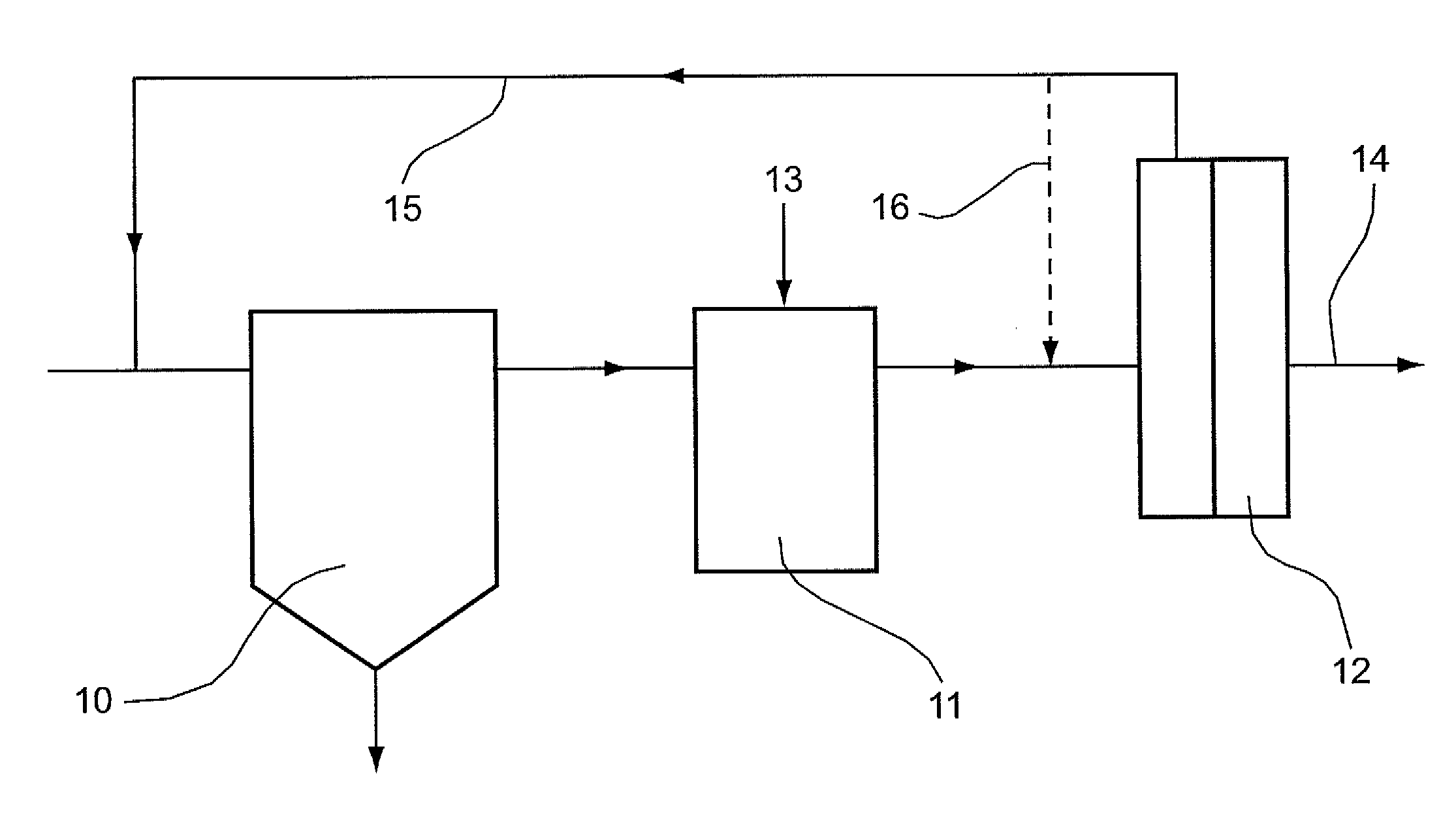

Water Treatment Method Including Powdered Activated Carbon Recycling

InactiveUS20110192795A1Improve recovery rateIncrease PAC concentrationMembranesUltrafiltrationActivated carbonFiltration

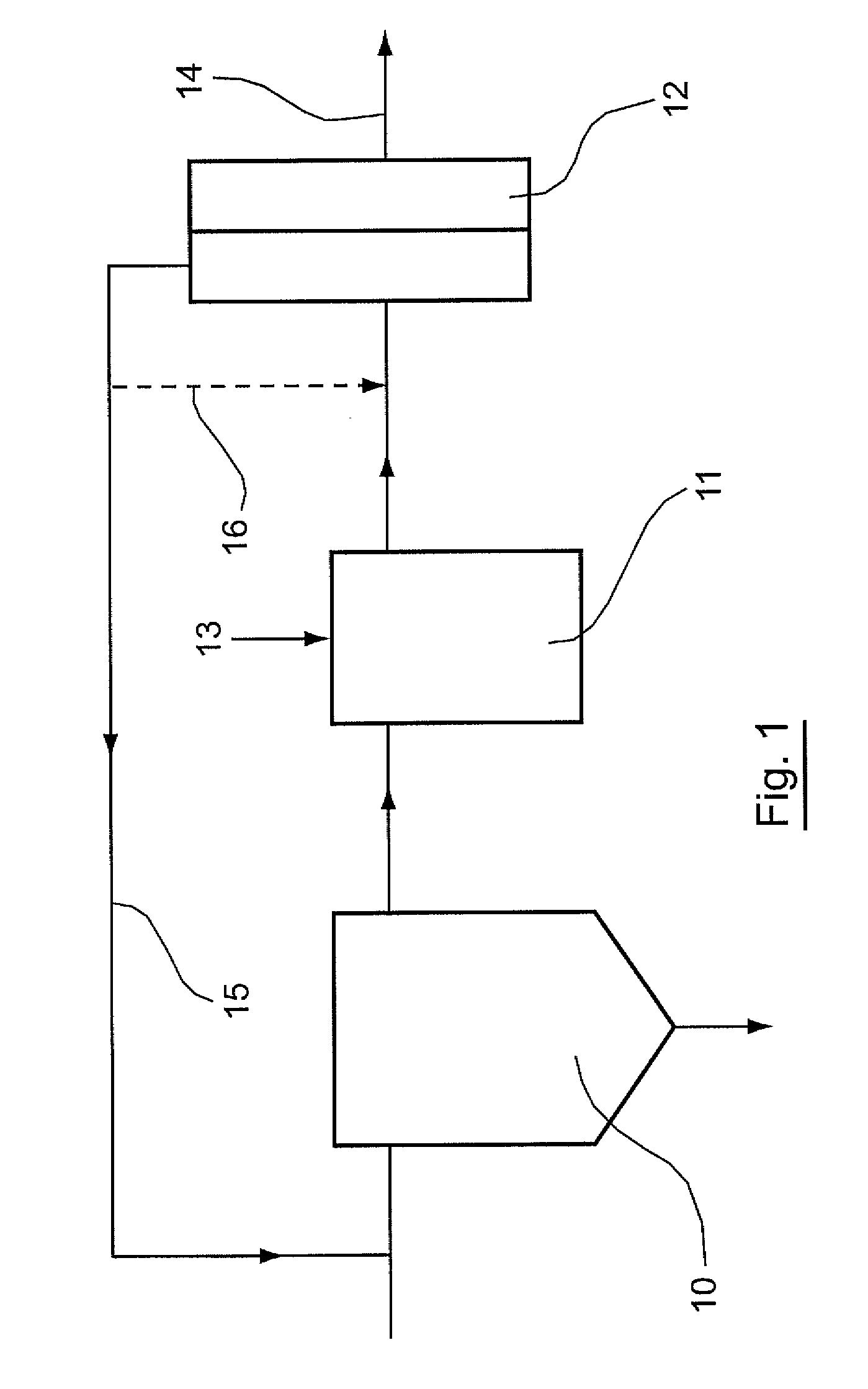

The invention relates to a water treatment method with a view to purifying the same or making it drinkable, characterised in that the method includes the following steps: a step of injecting powdered activated carbon (PAC) into said water in order to obtain a water to be treated / PAC mixture; a step of feeding said water to be treated / PAC mixture into a contacting agitated area in order to obtain an agitated water to be treated / PAC mixture; a step of filtering said water to be treated / PAC mixture within a membrane filtration unit in order to produce treated water and a PAC-rich concentrate; a step of recirculating said PAC-rich concentrate upstream from and / or within said agitated area, the PAC concentration of said mixture ranging from 1 to 10 g / l; wherein said water to be treated / PAC mixture is maintained in said agitated area for a contact duration of between 2 and 20 minutes; and the method further comprises an ozonation step of the water to be treated that comprises injecting ozone in the water to be treated before injecting PAC in order to obtain a water to be treated / ozone mixture having an ozone concentration of between 0.5 and 3 mg / l.

Owner:VEOLIA WATER SOLUTIONS & TECH SUPPORT

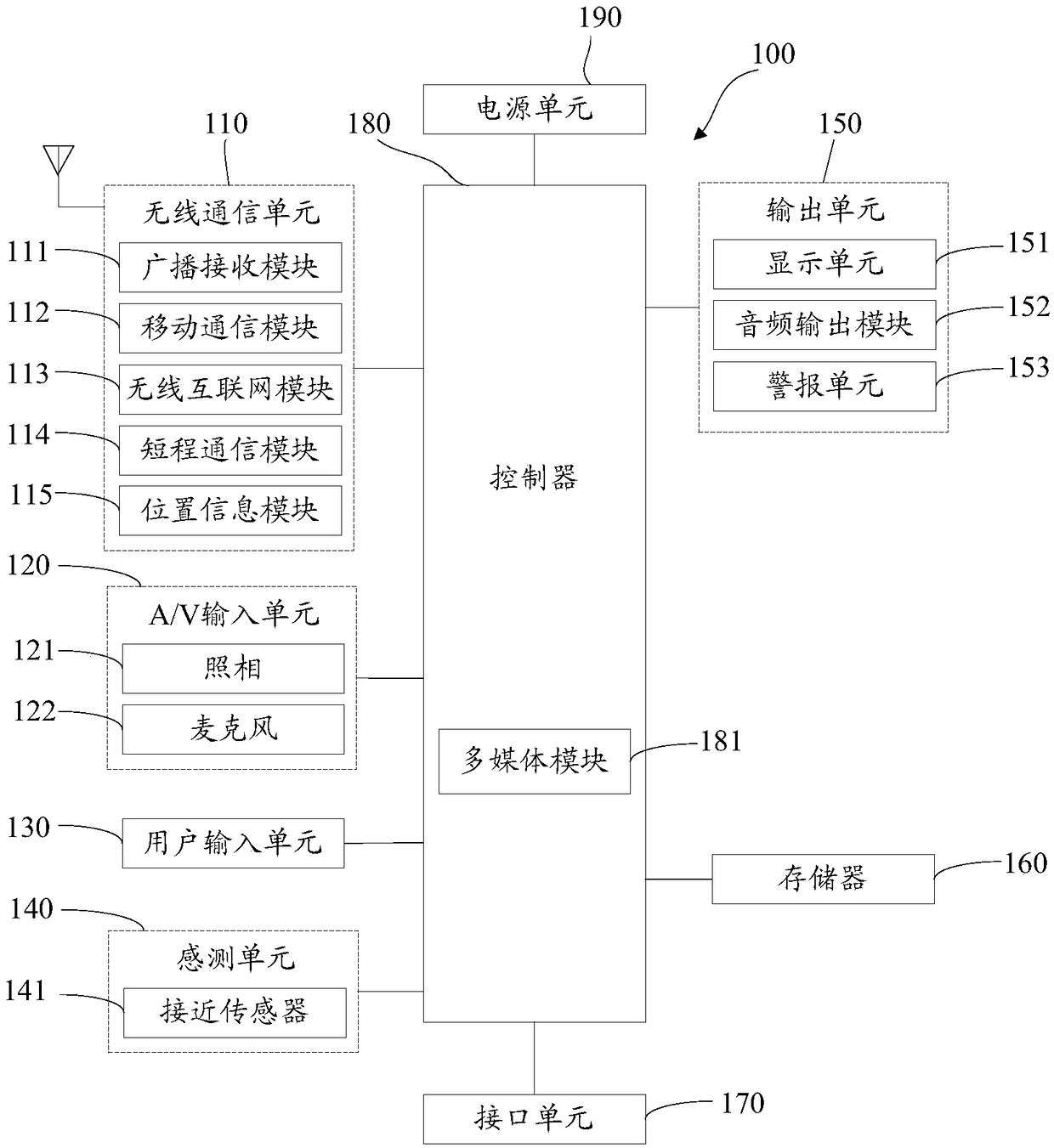

Function execution program, terminal device, function execution method, recording medium and information processing system

ActiveUS9671952B2Simple methodInput/output for user-computer interactionGraph readingInformation processingTerminal equipment

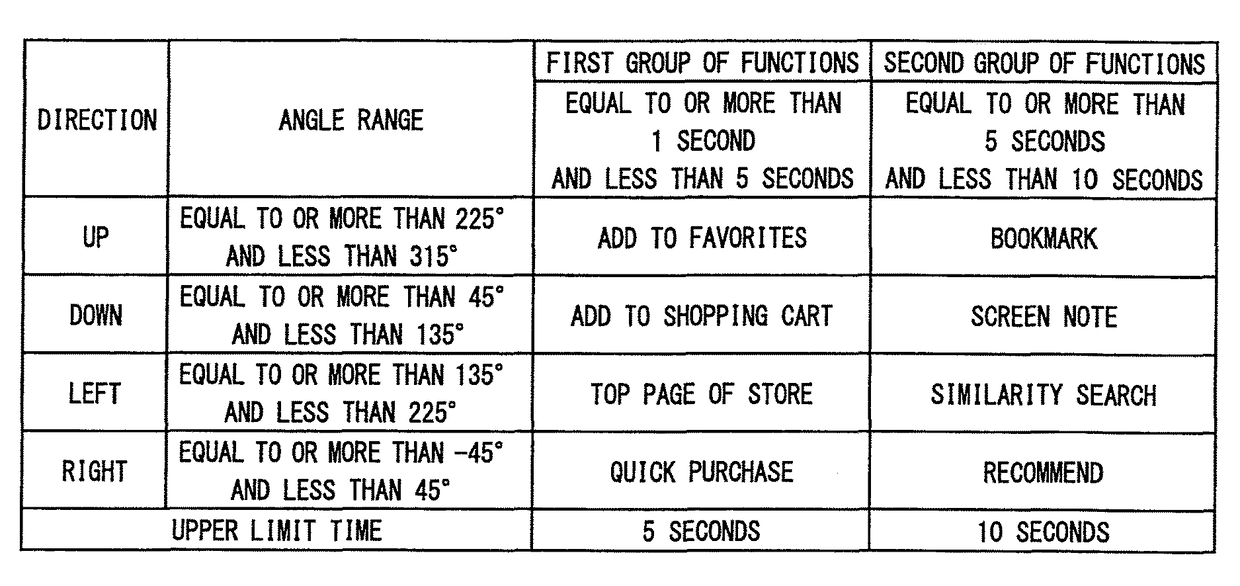

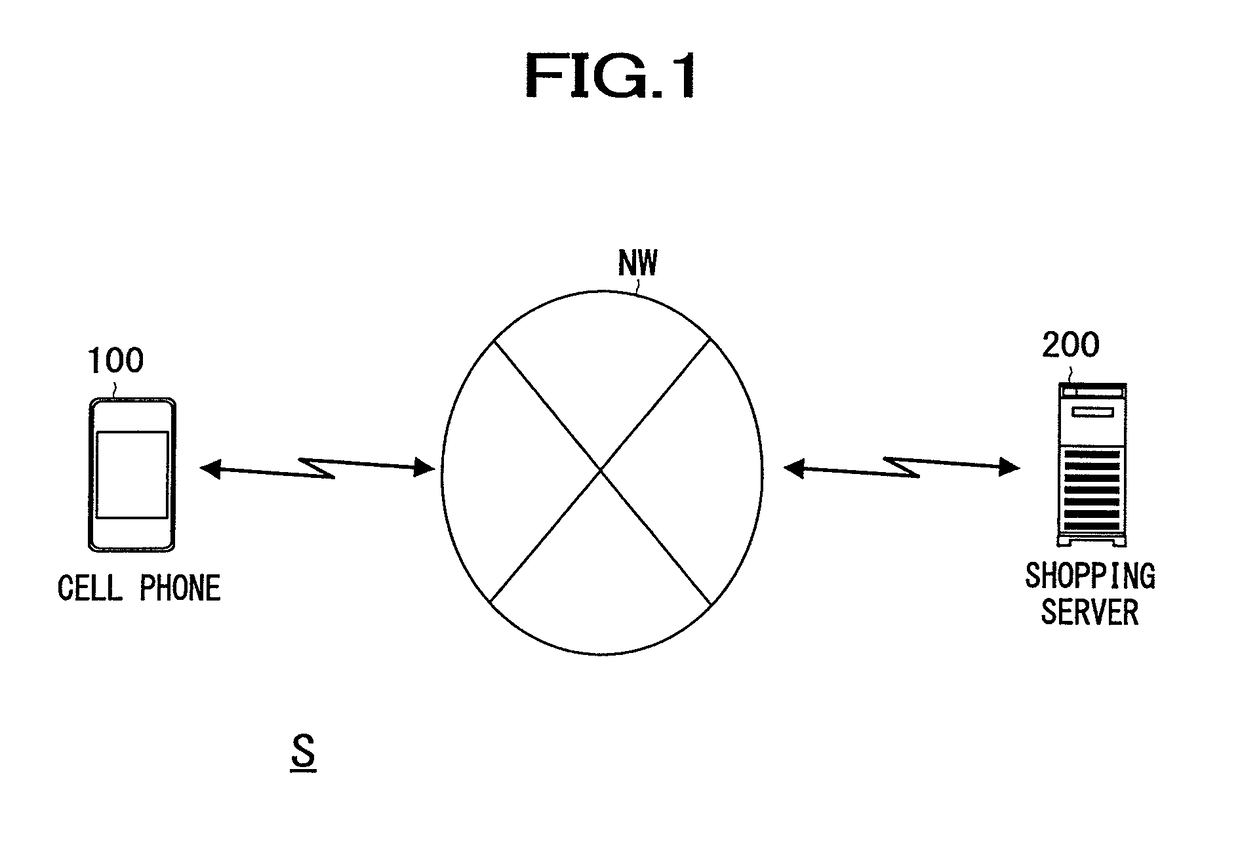

There are provided a function execution program, a terminal device, a function execution method, a recording medium and an information processing system capable of providing a more convenient touch panel operation method to a user. A computer is caused to function as a time measure means that detects a contact on an input means integral with a display means and measures contact duration at the contact point, a distance measure means that detects a continuous movement of the contact point and measures a moving distance, and an execution means that when the contact duration is a predetermined time or more and the moving distance is a predetermined distance or more, executes a preset function.

Owner:RAKUTEN GRP INC

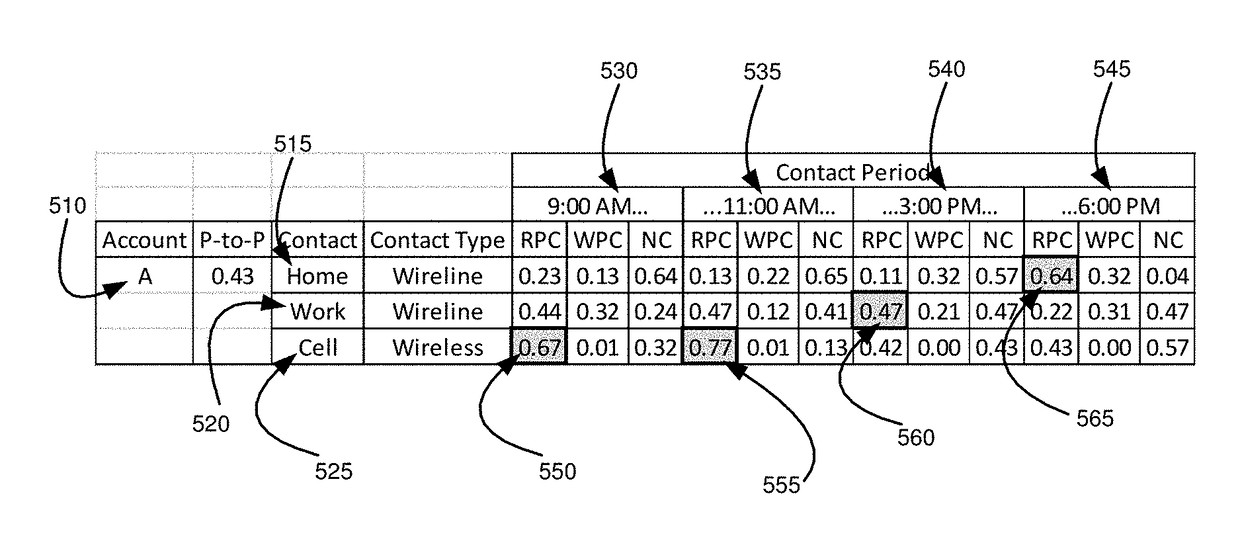

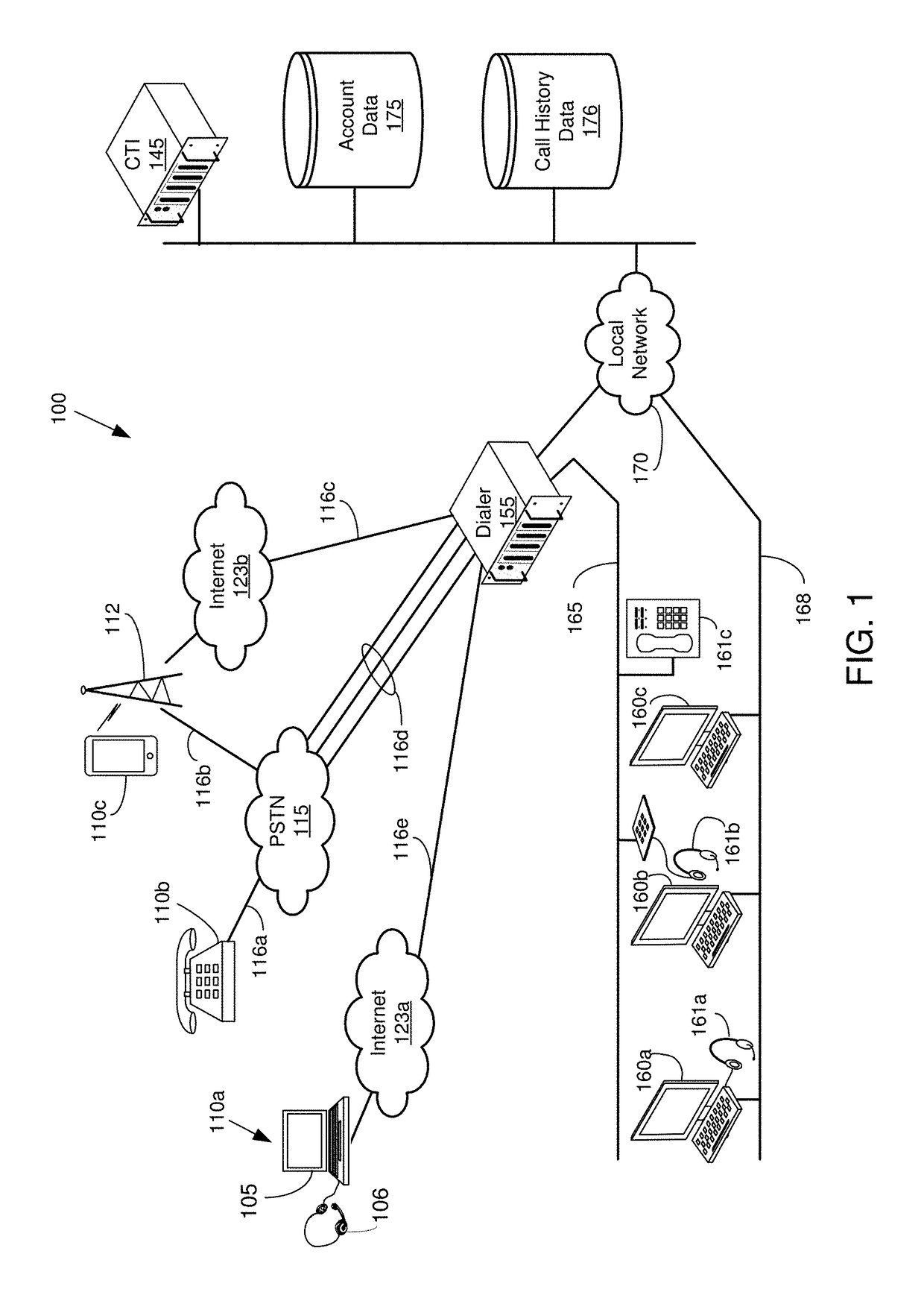

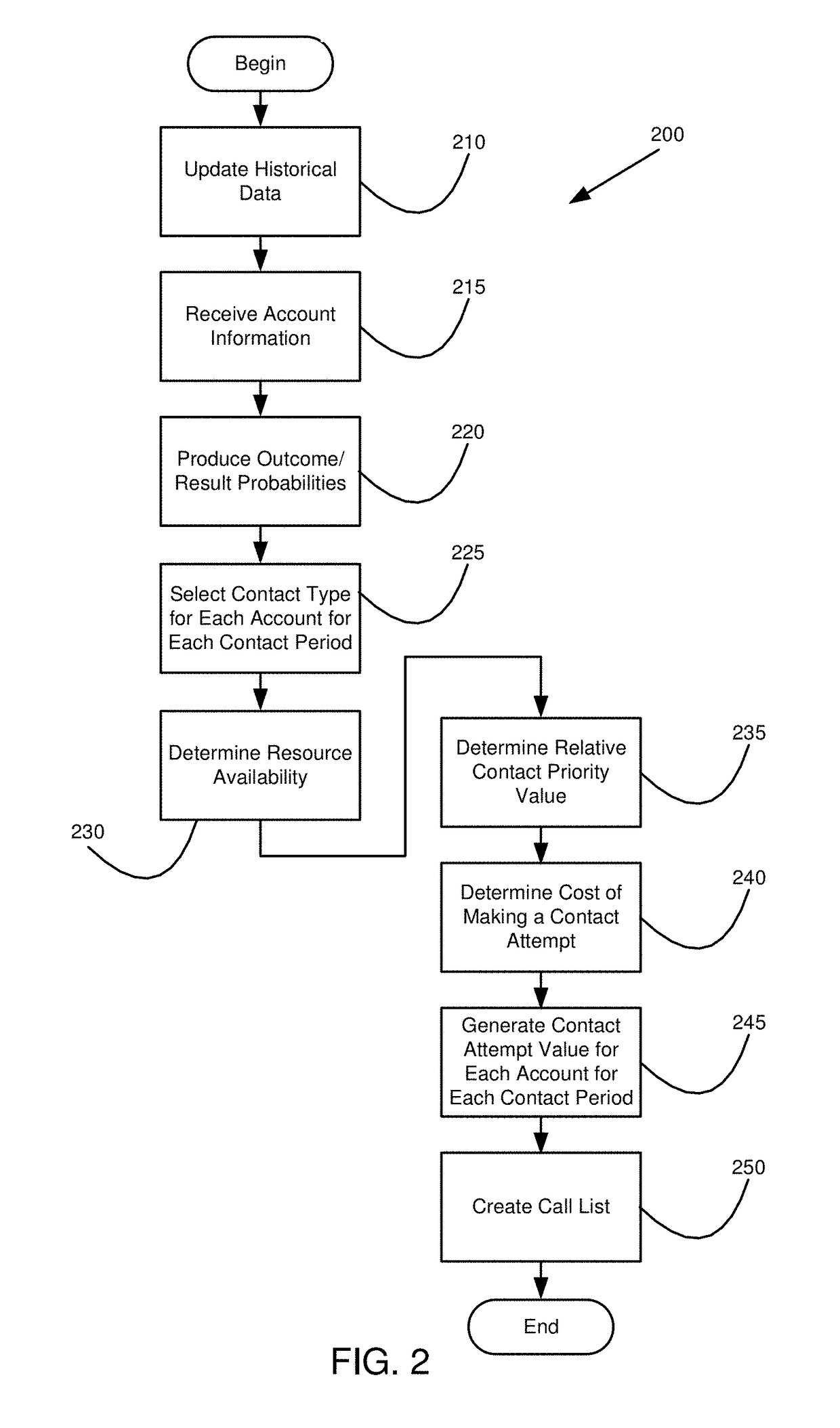

Best time to communicate with parties having multiple contacts

Technologies are disclosed for determining a best time to contact a party over a plurality of contact periods of time to achieve at least one of a desired outcome and a desired result. In various embodiments, the party has multiple contact types that can be utilized to contact the party. Accordingly, an optimal contact type for the party for each contact period is selected that identifies the contact type with a probability having the highest likelihood of achieving at least one of the desired outcome and the desired result by utilizing the contact type to contact the party during the contact period. A best time to contact the party is then identified as one of the contact periods based on the optimal contact types selected for the party for each contact period and associated probabilities.

Owner:ALVARIA CAYMAN (CX)

Low temperature metal oxide synthesis

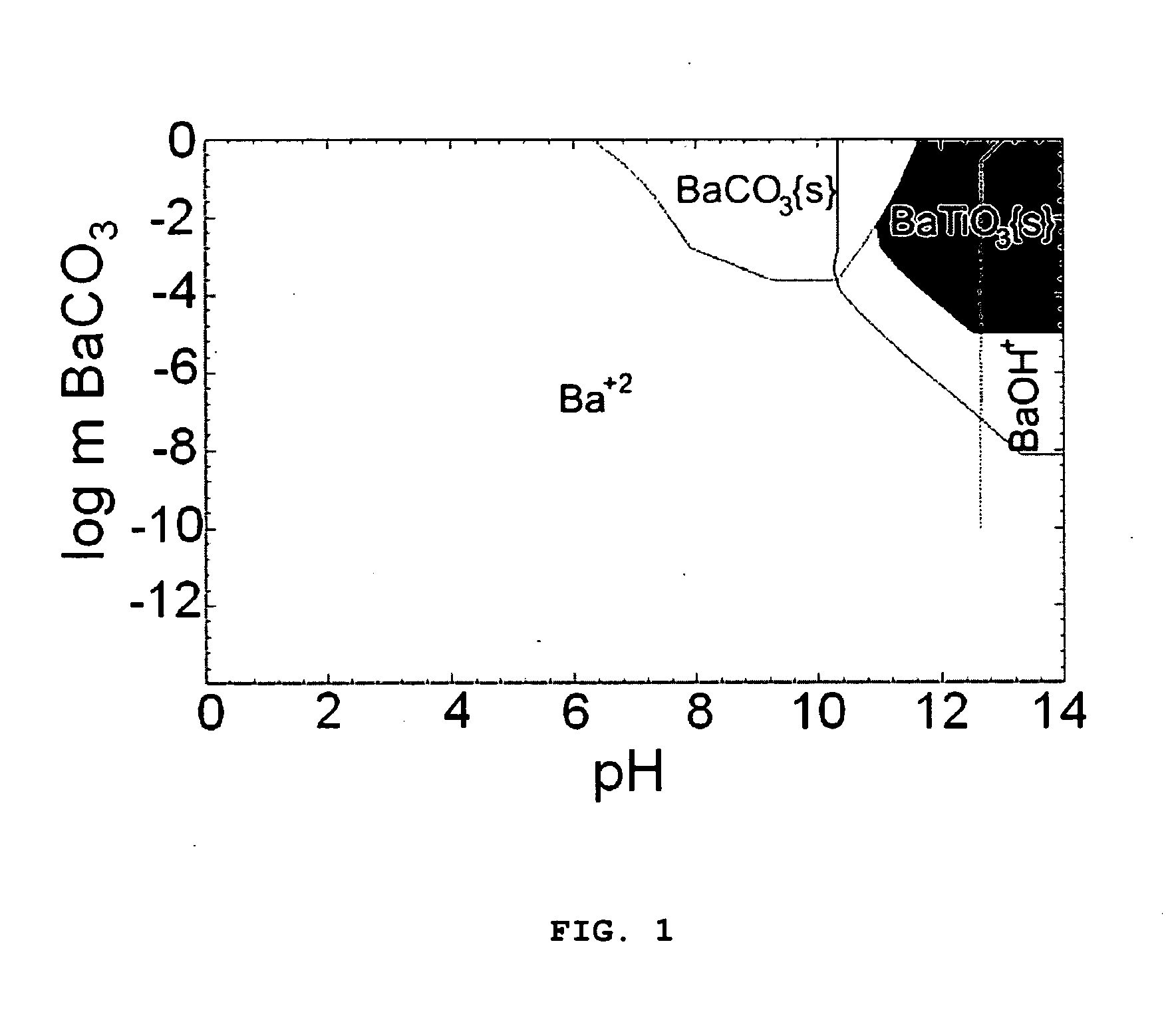

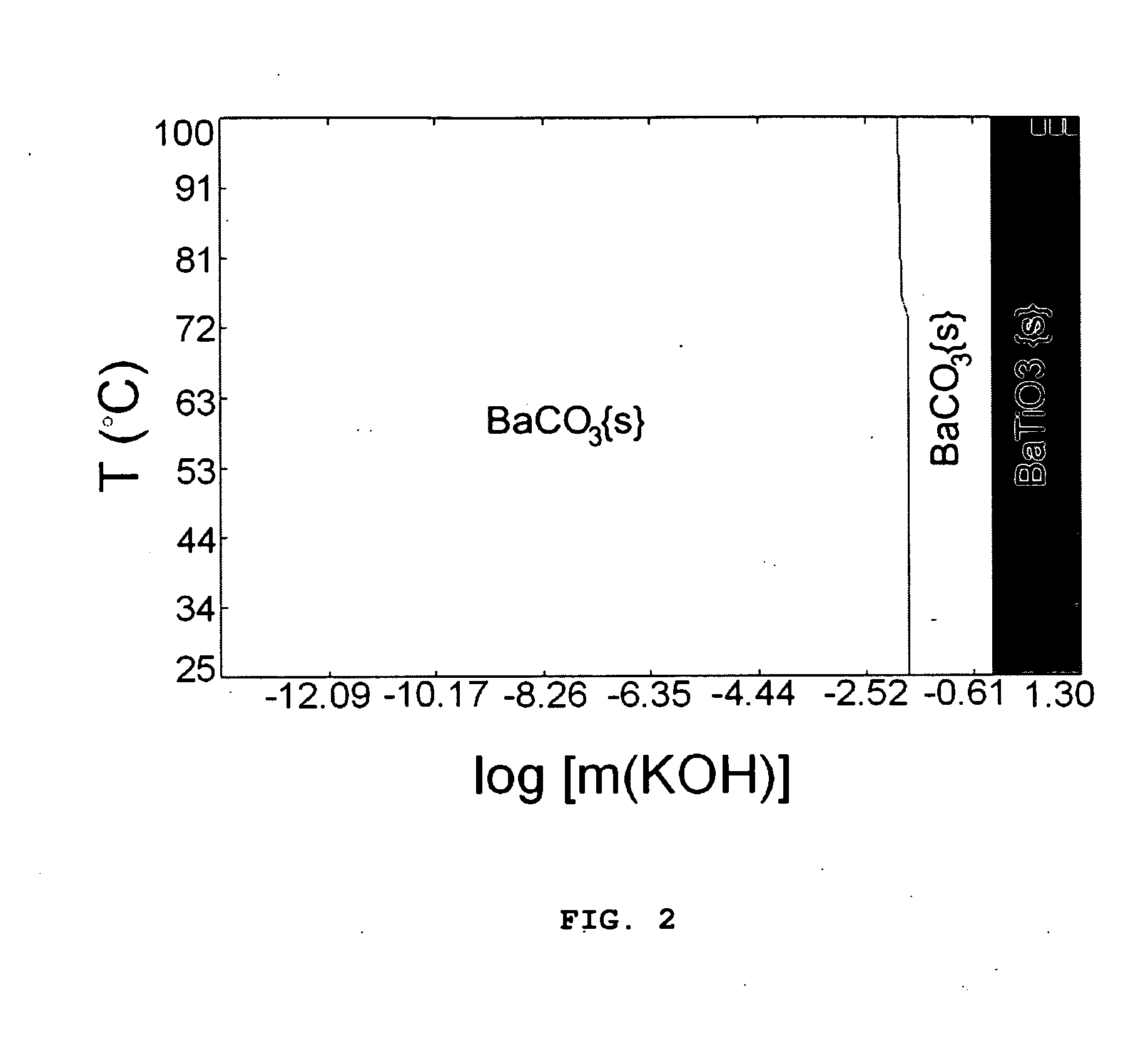

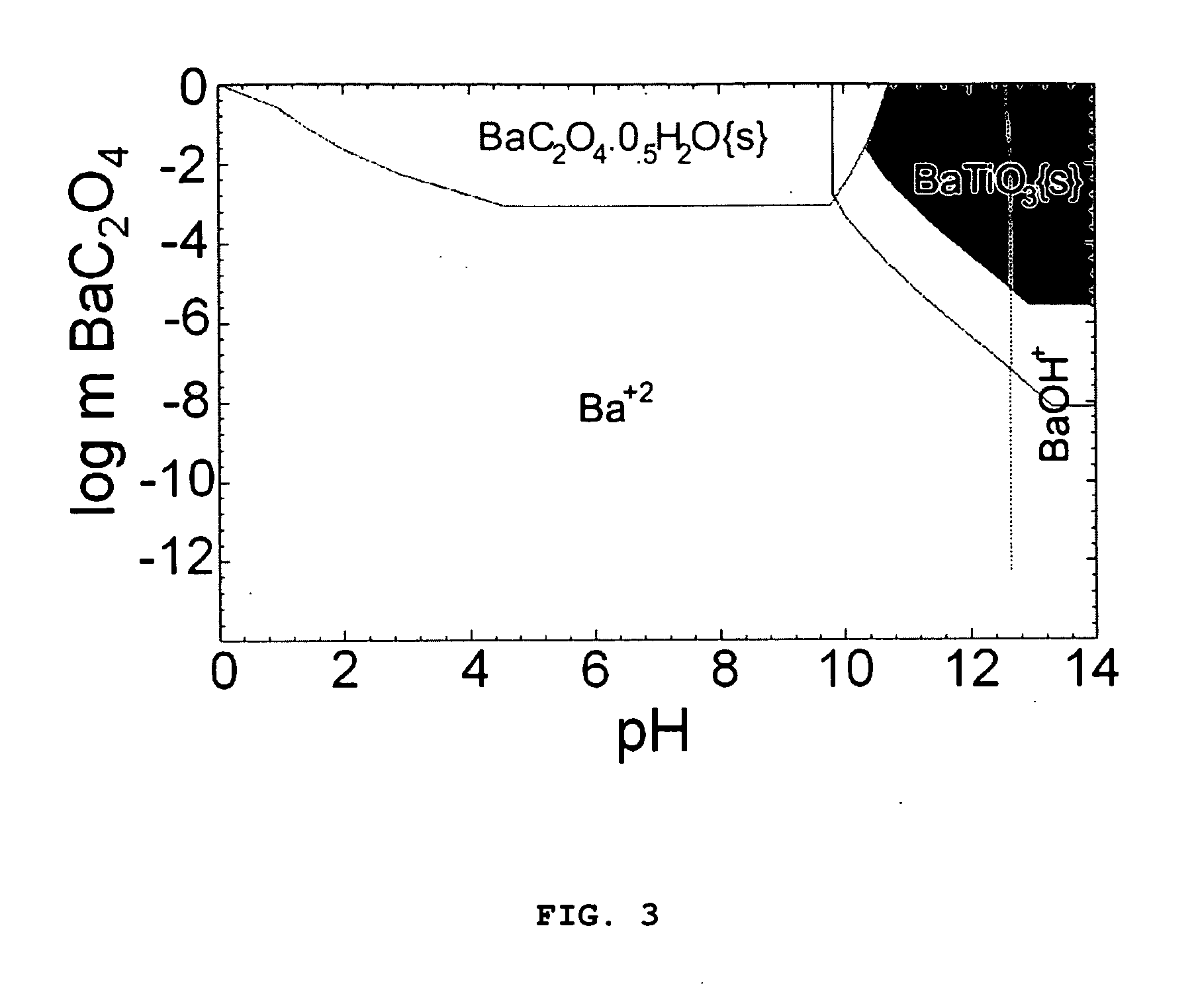

InactiveUS20110044876A1Low costHigh purityAlkaline earth titanatesIron oxides/hydroxidesDecompositionCarboxylic salt

A method for the decomposition of one or more metal oxide precursor compounds, at least one of which is a metal carboxylate salt, to a metal oxide or mixed metal oxide by contacting the metal oxide precursor compound or compounds with an aqueous reaction mixture at a pH, pressure and temperature effective to decompose all metal oxide precursor compounds, wherein the temperature is between about room temperature and about 350° C. and the contact duration is effective to decompose all metal oxide precursor compounds to form an essentially pure metal oxide or mixed metal oxide.

Owner:RUTGERS THE STATE UNIV

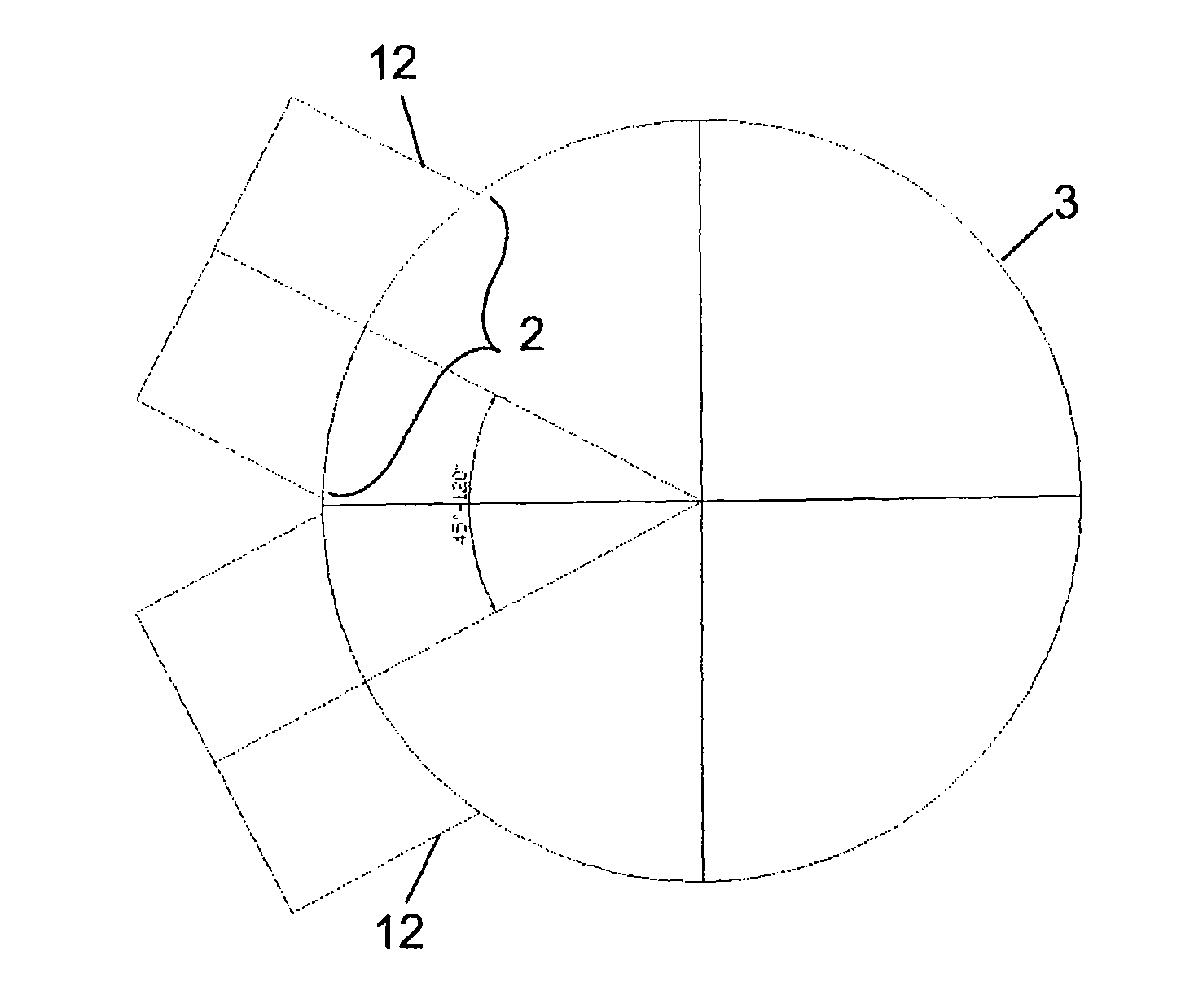

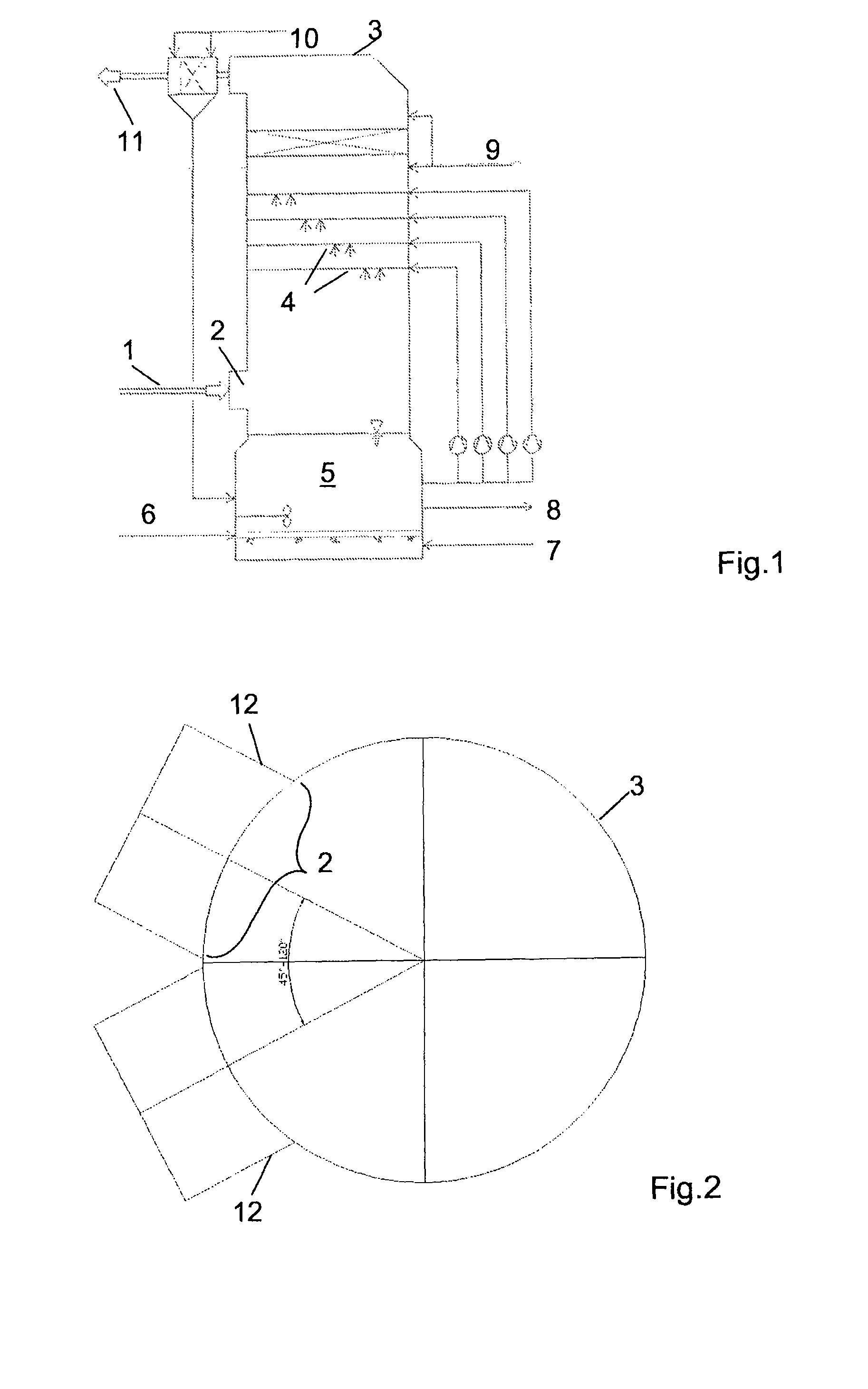

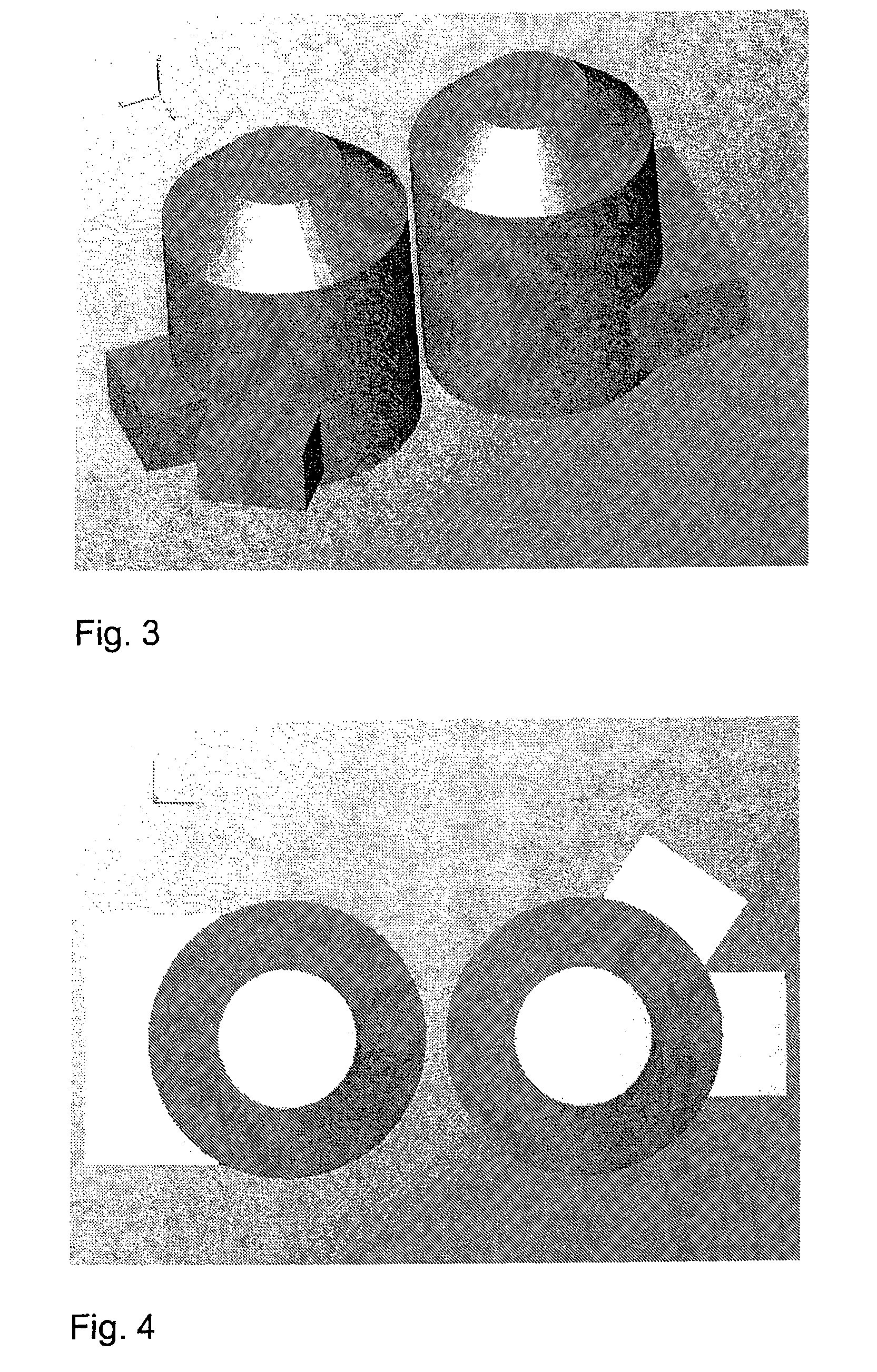

Method and spray tower for contacting gases and liquid droplets for mass and/or heat transfer

ActiveUS8109489B2Reducing horizontal gas speedIncrease the angleLiquid-gas reaction as foam/aerosol/bubblesLighting and heating apparatusGas passingSpray tower

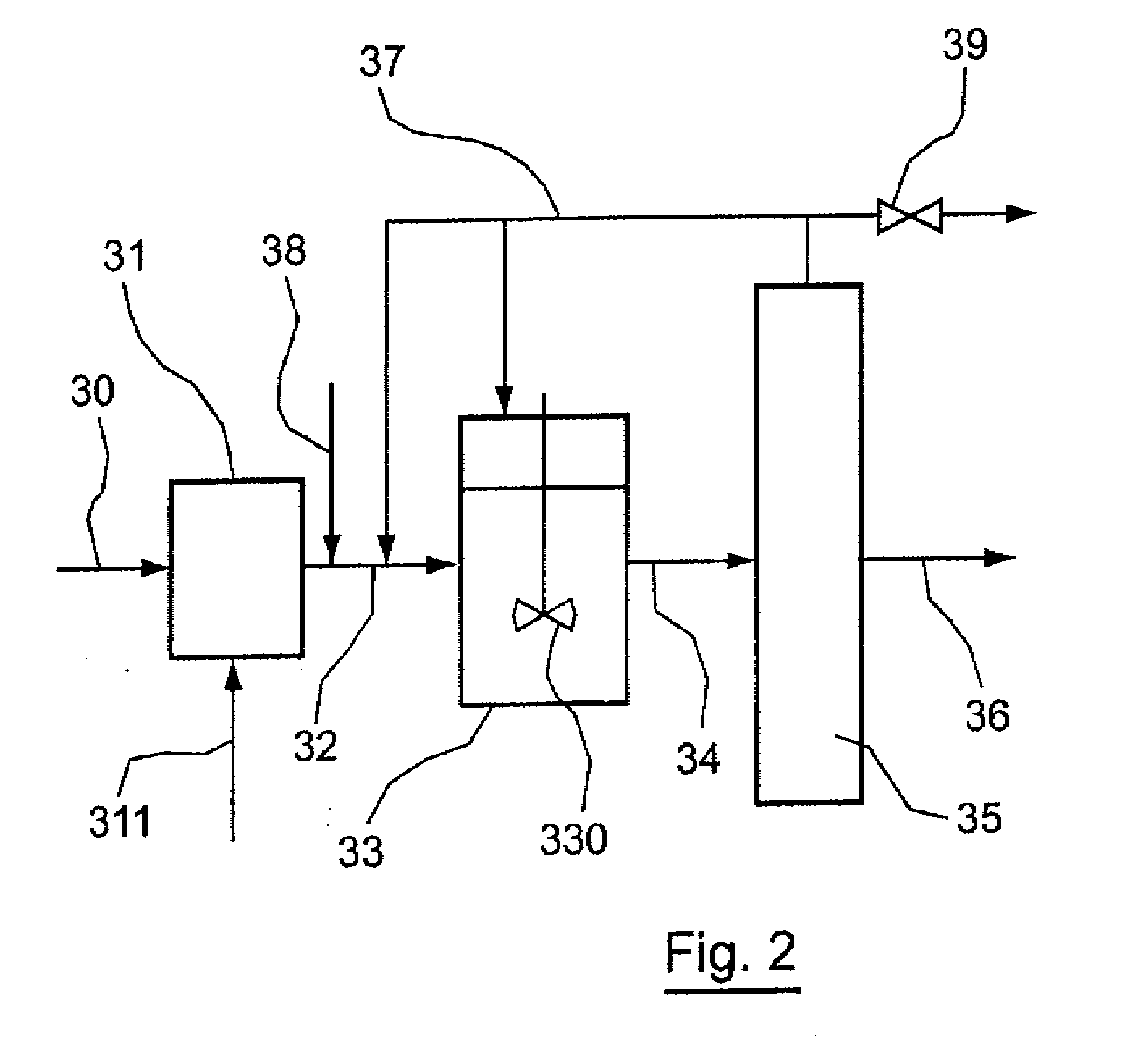

A method for contacting gases and liquid droplets for mass and / or heat transfer and a spray tower are disclosed, in which liquid is injected at a number of levels in counterflow to the gas, the gas being fed through at least two inlet openings in the shell of the spray tower. In this case, in order to reduce the differences in the contact duration, the flow direction of the gas at the inlet openings points into the internal region of the spray tower, which has a diameter of greater than or equal to 12 m, in particular greater than 20 m, such that the flow directions of the at least two gas streams intersect on their extension inside the spray tower, in particular at the center of the spray tower at up to half the spray tower radius downstream of the center of the spray tower.

Owner:ANDRITZ ENERGY & ENVIRONMENT

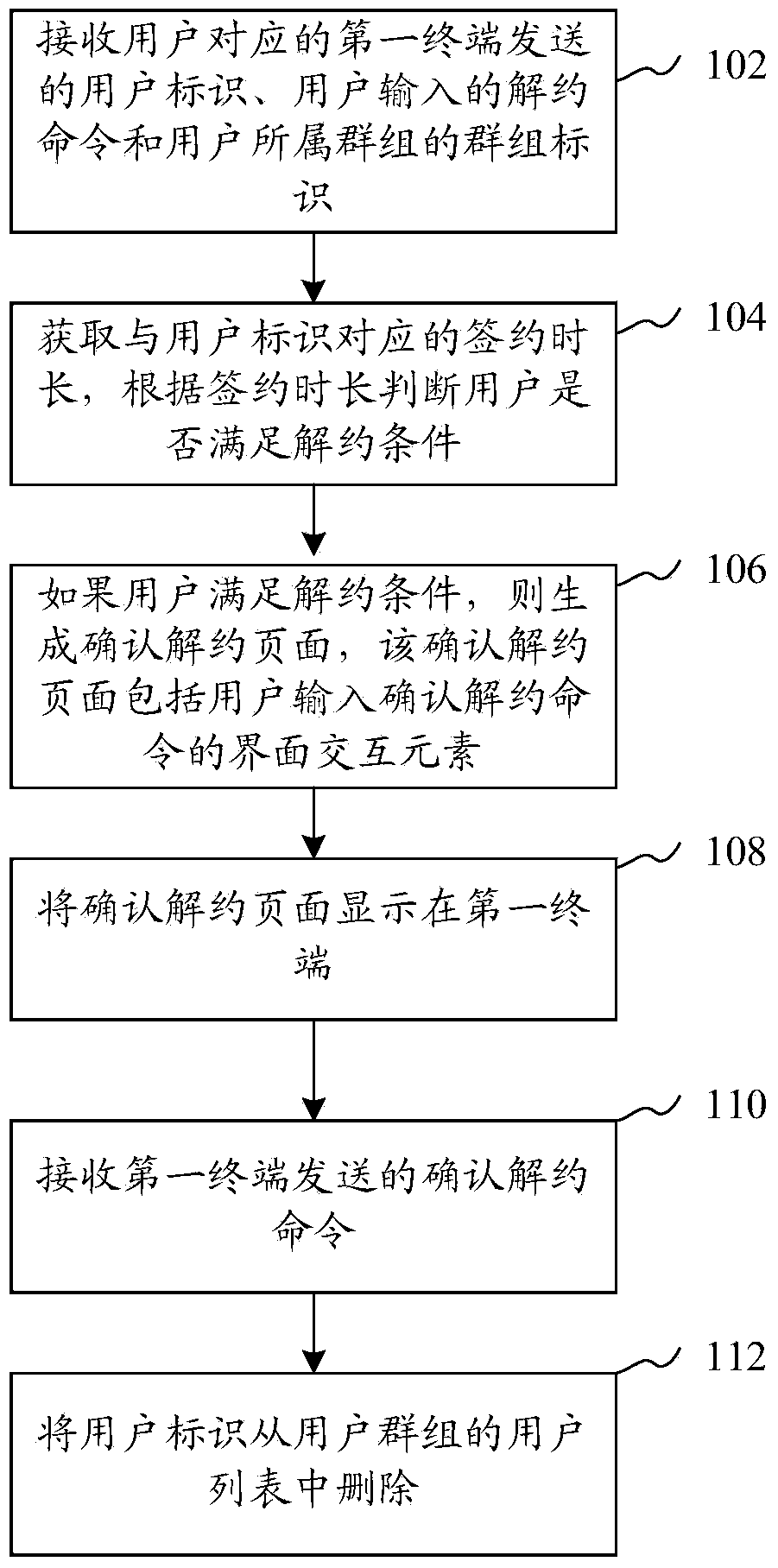

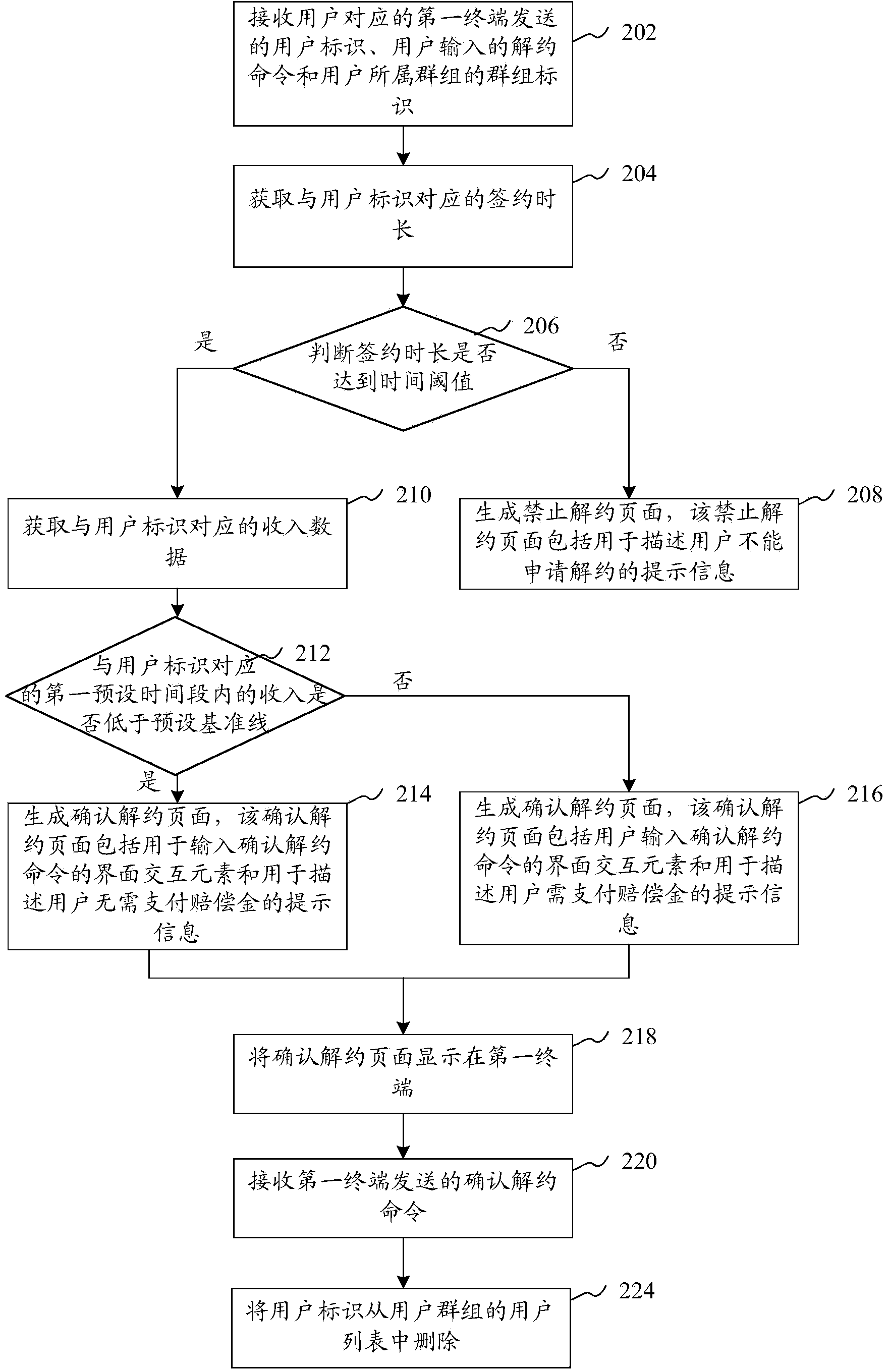

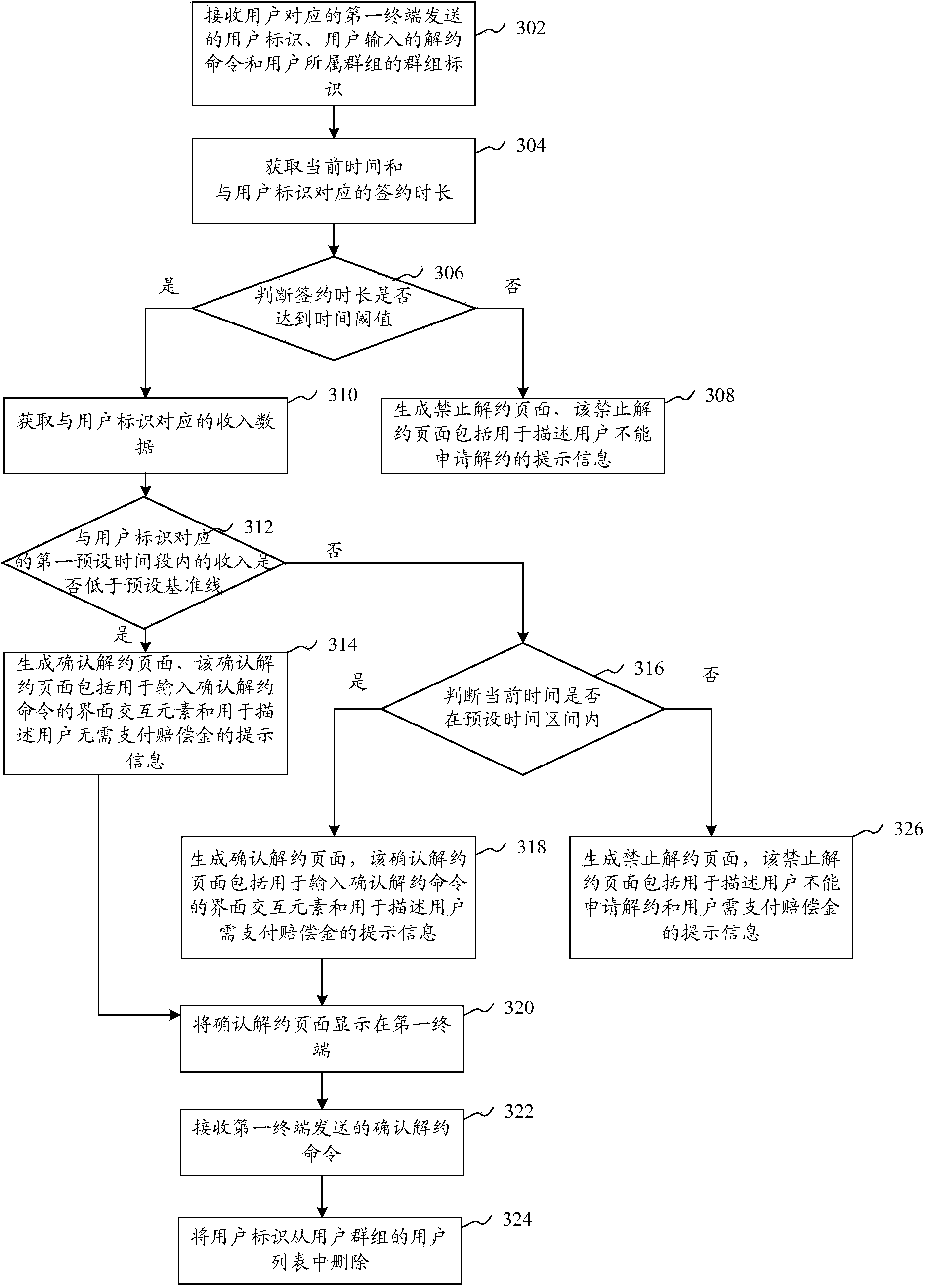

Method and device for quitting user group

InactiveCN103679366AReduce churnReduce idlingBuying/selling/leasing transactionsResourcesVoice communicationUser input

The invention provides a method for quitting a user group. The method comprises the steps that a user identity sent by a first terminal corresponding to a user, a termination command input by the user and the group identity of the user group are received, and the user belongs to the user group; contact duration corresponding to the user identity is acquired, and whether the user meets a termination condition or not is judged according to the contact duration; if the user meets the termination condition, a termination validation page is generated, and the termination validation page comprises interface interaction elements used for inputting a termination validation command; the termination validation page is displayed on the first terminal; the termination validation command sent by the first terminal is received; the user identity is deleted from the user list of the user group. Through the method, the user outflow rate of a voice communication platform can be lowered, the waste of server resources can be reduced, and therefore resources in the voice communication platform can be effectively managed. In addition, the invention further provides a device for quitting the user group.

Owner:TENCENT TECH (SHENZHEN) CO LTD

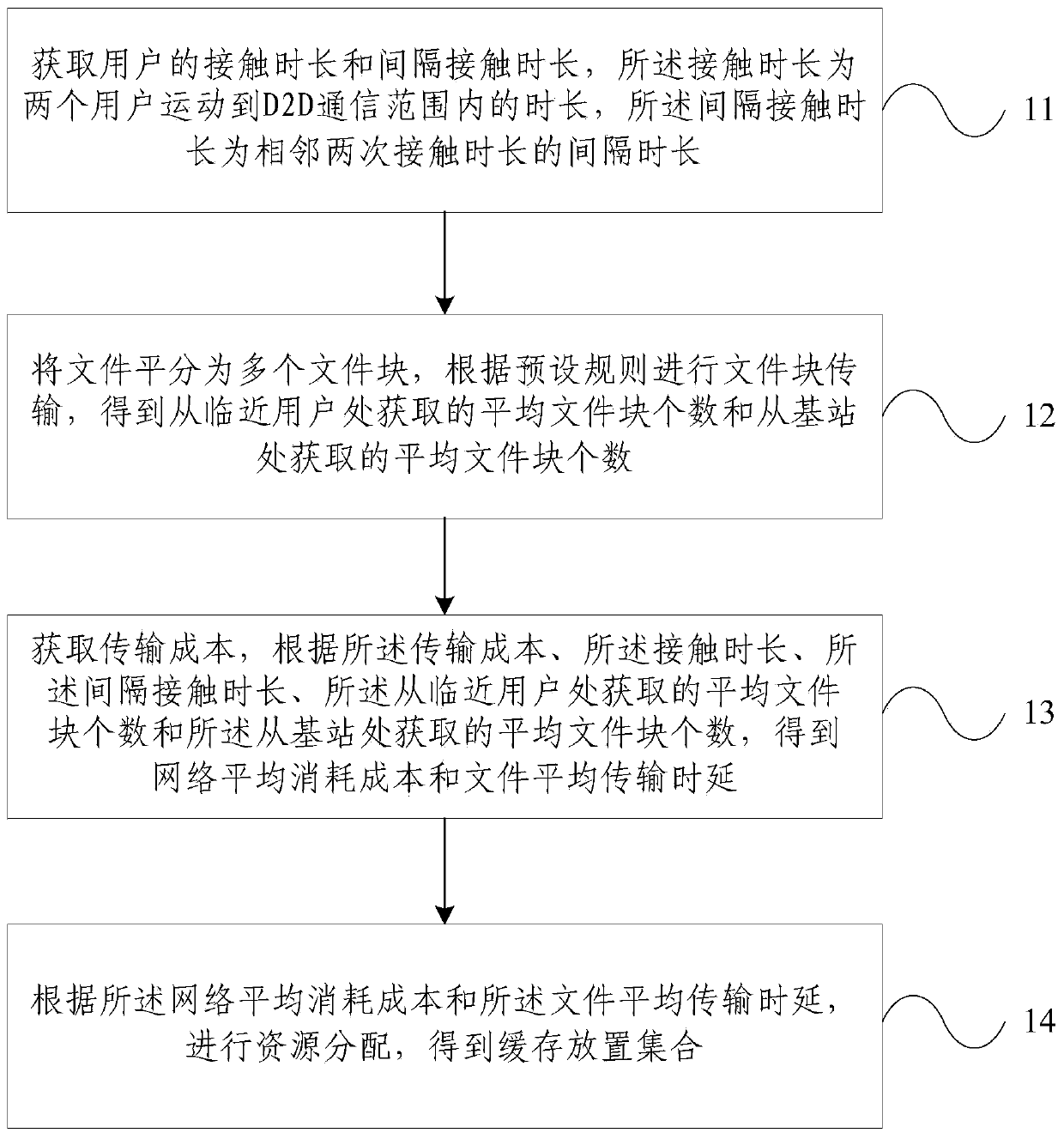

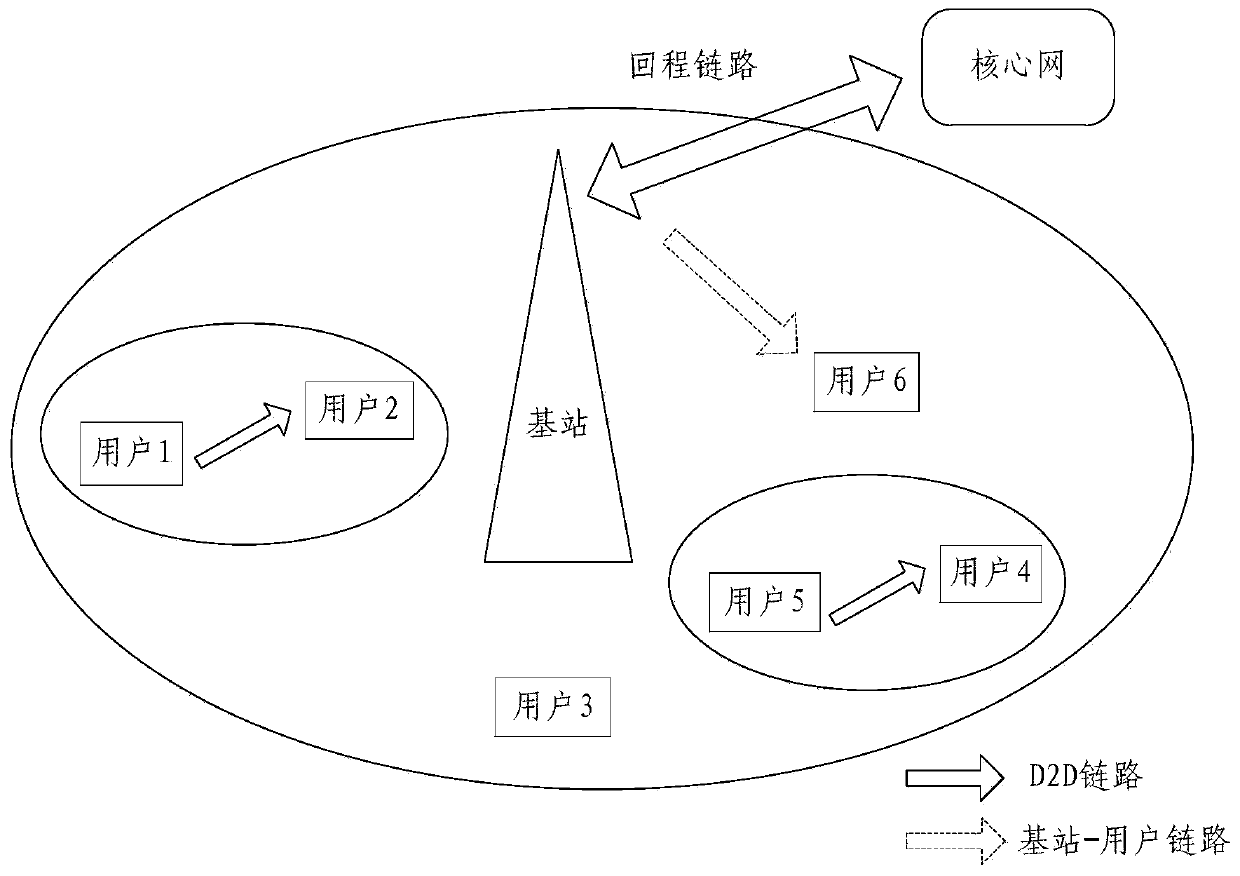

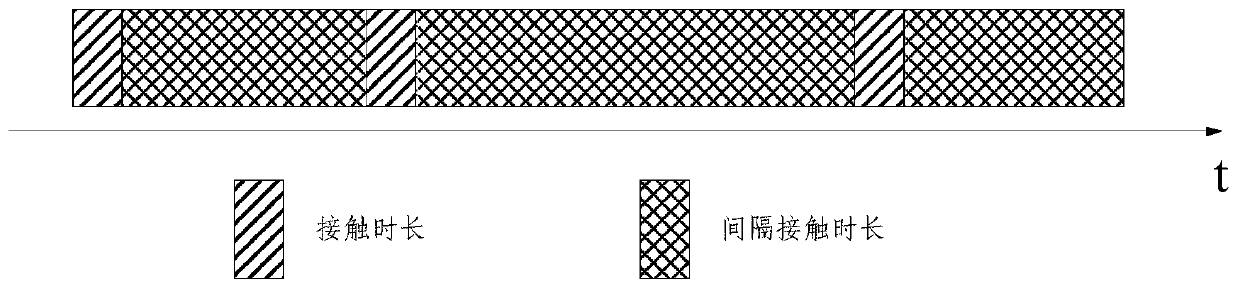

Cache placement method and device in D2D network

ActiveCN110022547AEfficient use ofSolve the surge problemNetwork traffic/resource managementTransmissionFile transmissionPlacement method

The embodiment of the invention provides a cache placement method and device in a D2D network. The method comprises the following steps: acquiring contact duration and interval contact duration of a user, equally dividing a file into a plurality of file blocks, and transmitting the file blocks according to a preset rule to obtain the average number of the file blocks acquired from an adjacent userand the average number of the file blocks acquired from a base station; obtaining the transmission cost, and obtaining the average network consumption cost and the average file transmission delay according to the transmission cost, the contact time length, the interval contact time length, the average file block number obtained from the adjacent user and the average file block number obtained from the position of the base station; and performing resource allocation according to the network average consumption cost and the file average transmission delay to obtain a cache placement set. According to the cache placement method and device in the D2D network provided by the embodiment of the invention, a file cache placement scheme based on minimum average consumption cost is designed, and the problem of sharp increase of a mobile internet video service in a mobile scene of a user terminal is solved.

Owner:BEIJING UNIV OF POSTS & TELECOMM

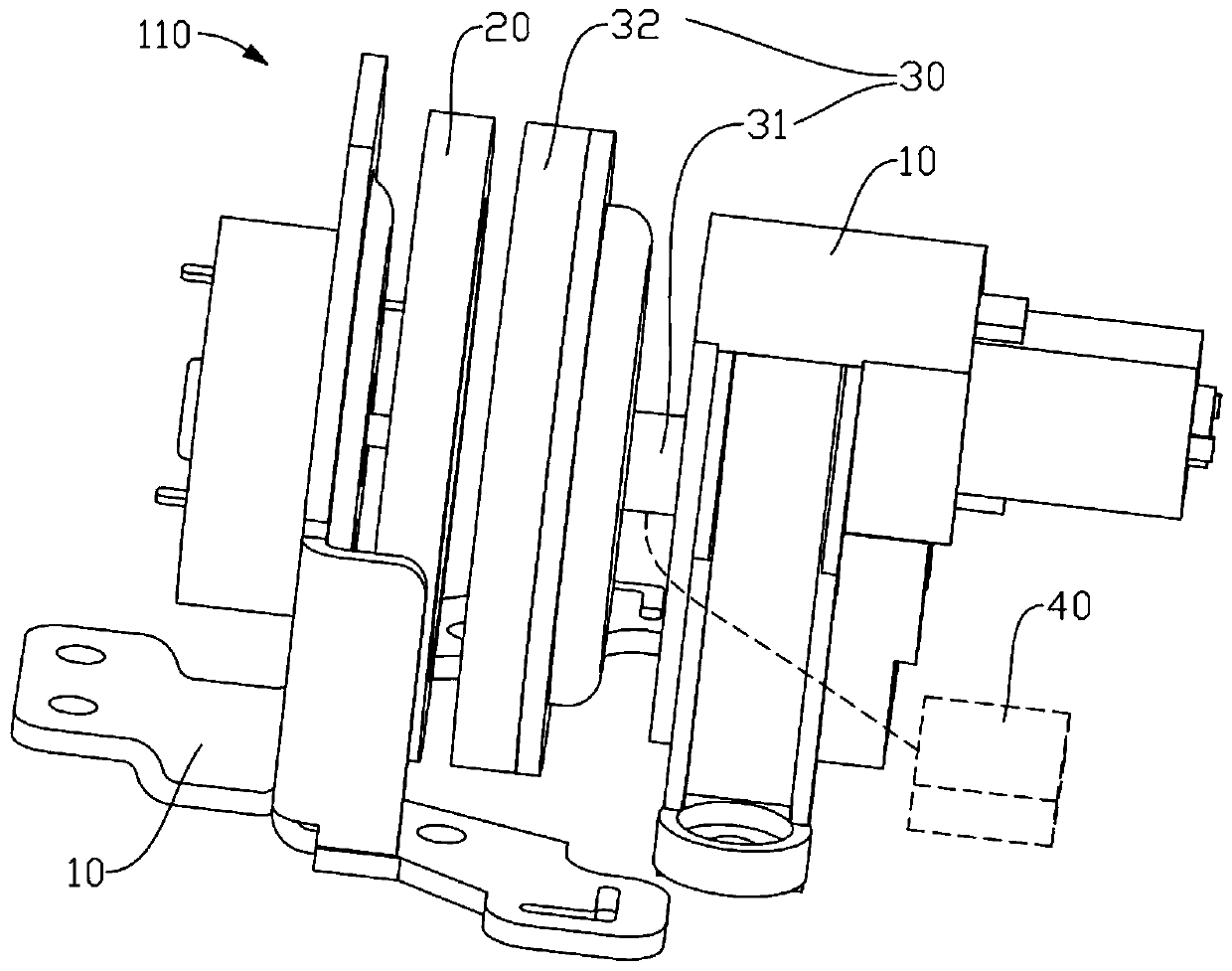

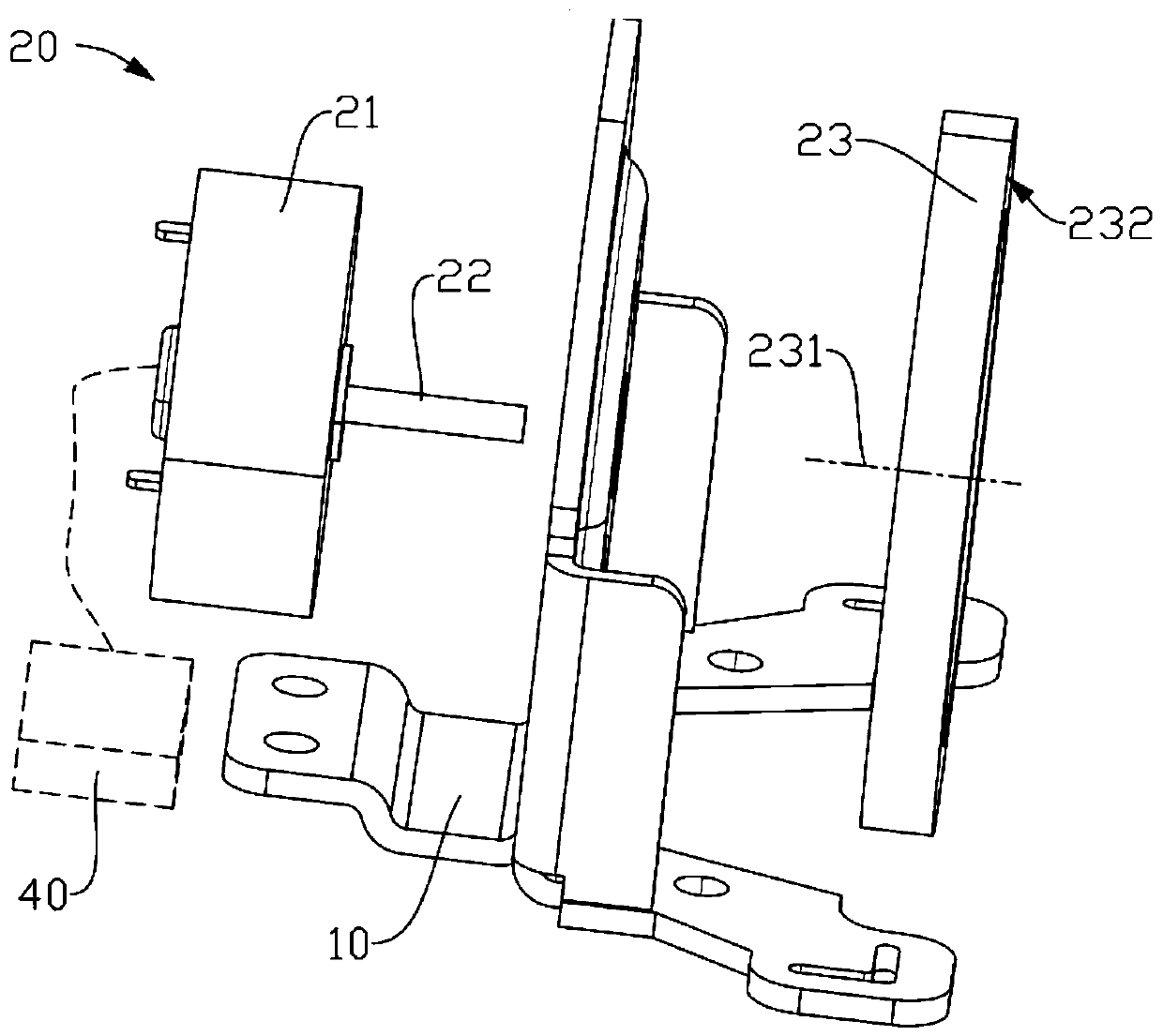

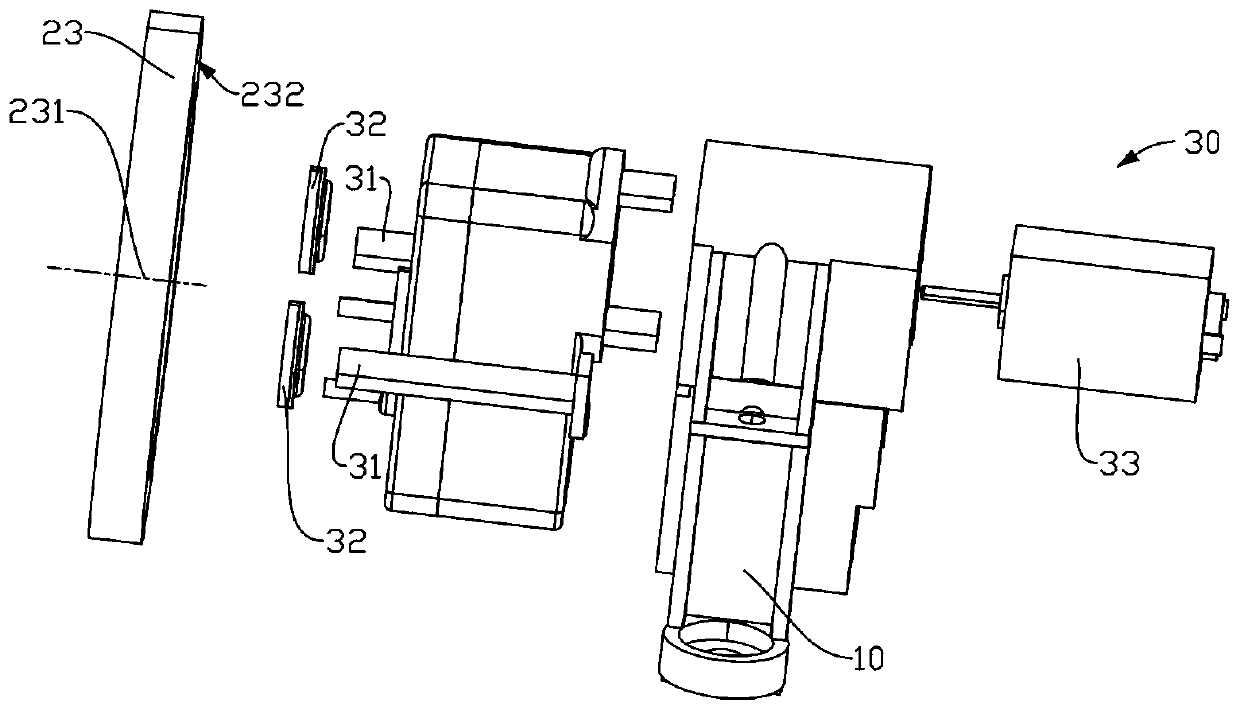

Turnover mechanism, toy car and control method thereof

The invention discloses a turnover mechanism (110), a toy car (200) comprising the turnover mechanism (110) and a control method thereof. The turnover mechanism (110) comprises a support (10), a rotating part (20), a braking part (30) and a controller (40), wherein the support (10) is fixedly connected to the toy car (200); the braking part (30) comprises a telescopic mechanism (31) facing the rotating part (20) and a brake part (32), and the braking part (30) is electrically connected with the controller (40); when the rotating part (20) rotates relative to the support (10), the controller (40) controls the telescopic mechanism (31) to drive the brake part (32) to move towards the rotating part (20) for the contact duration and interval, so that the toy car (200) is turned over; and the overturning mechanism (110) can control the overturning moment of the turnover mechanism (110) through the controller (40), so that the toy car (200) forms different overturning effects, and the interestingness of the toy car (200) is enhanced.

Owner:尤中乾

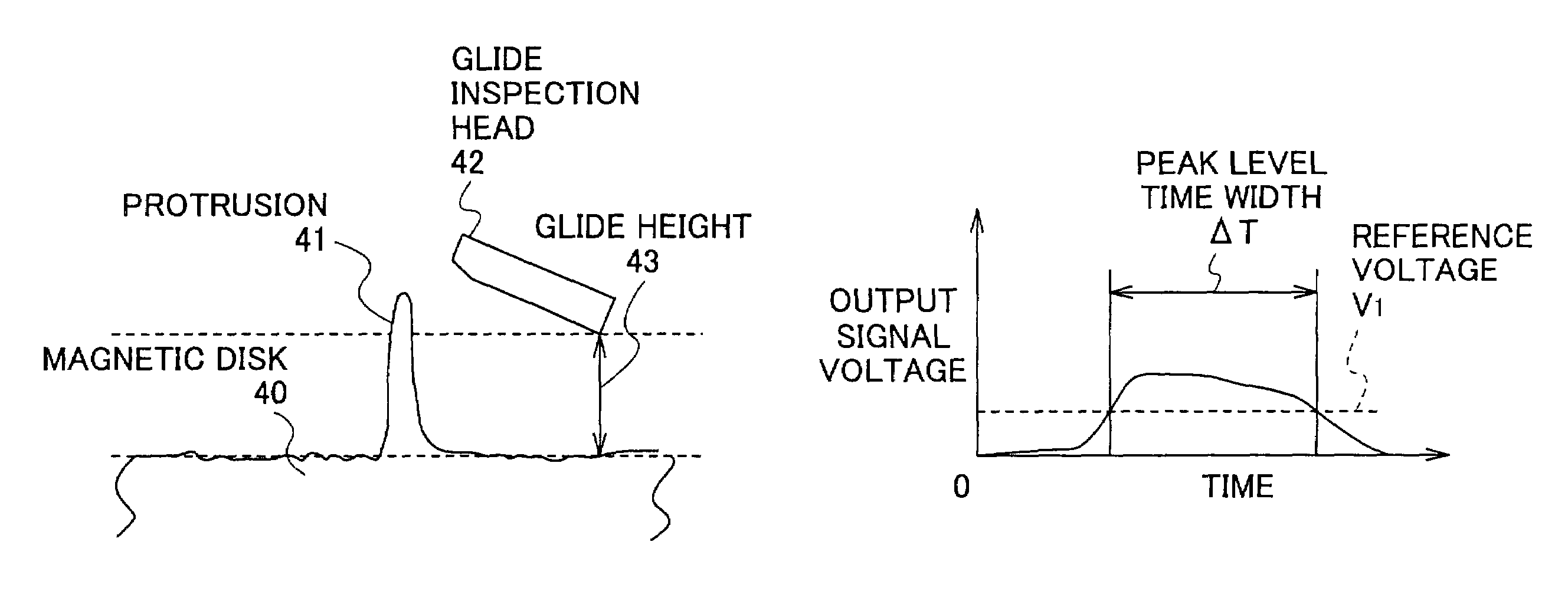

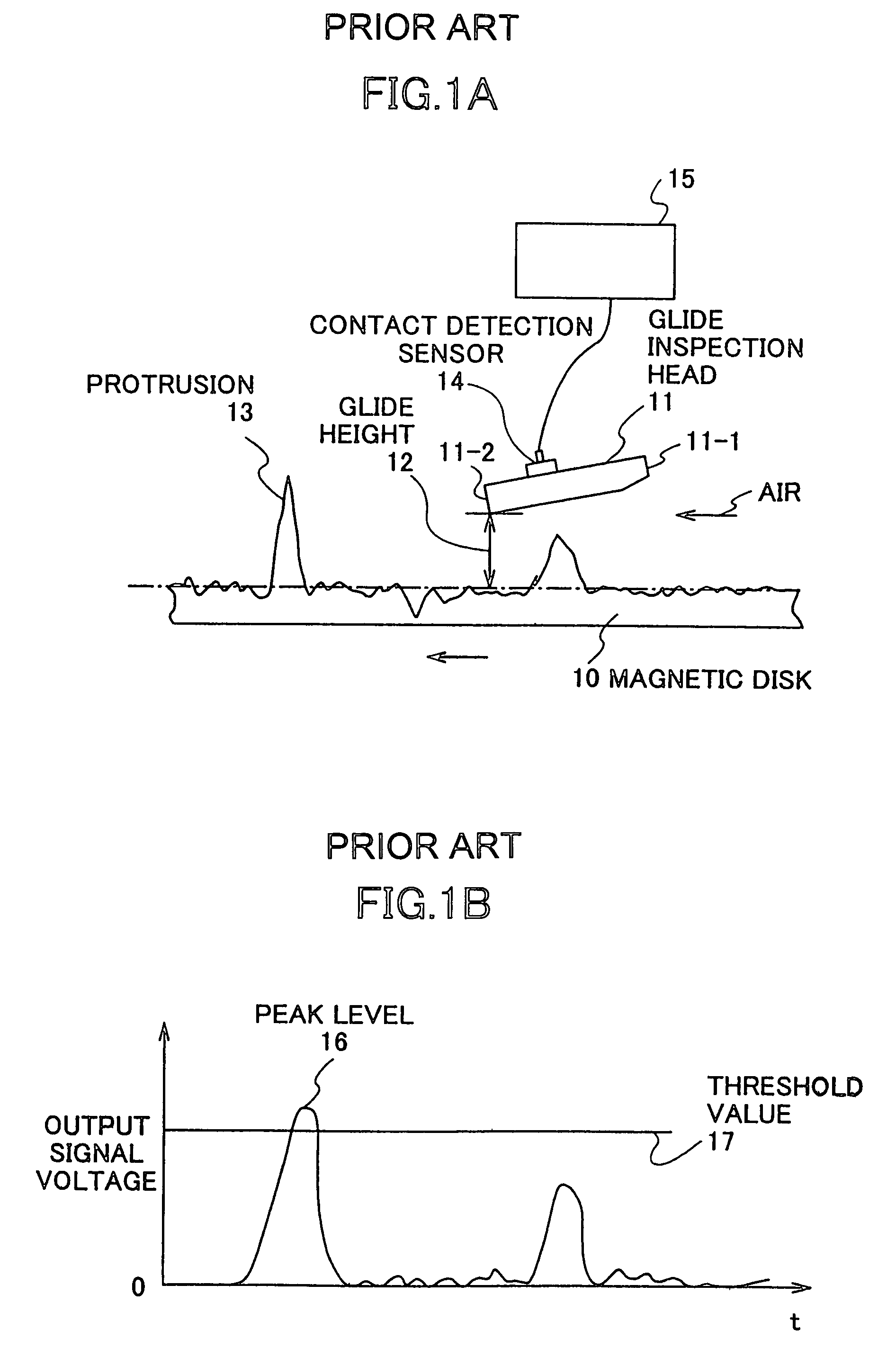

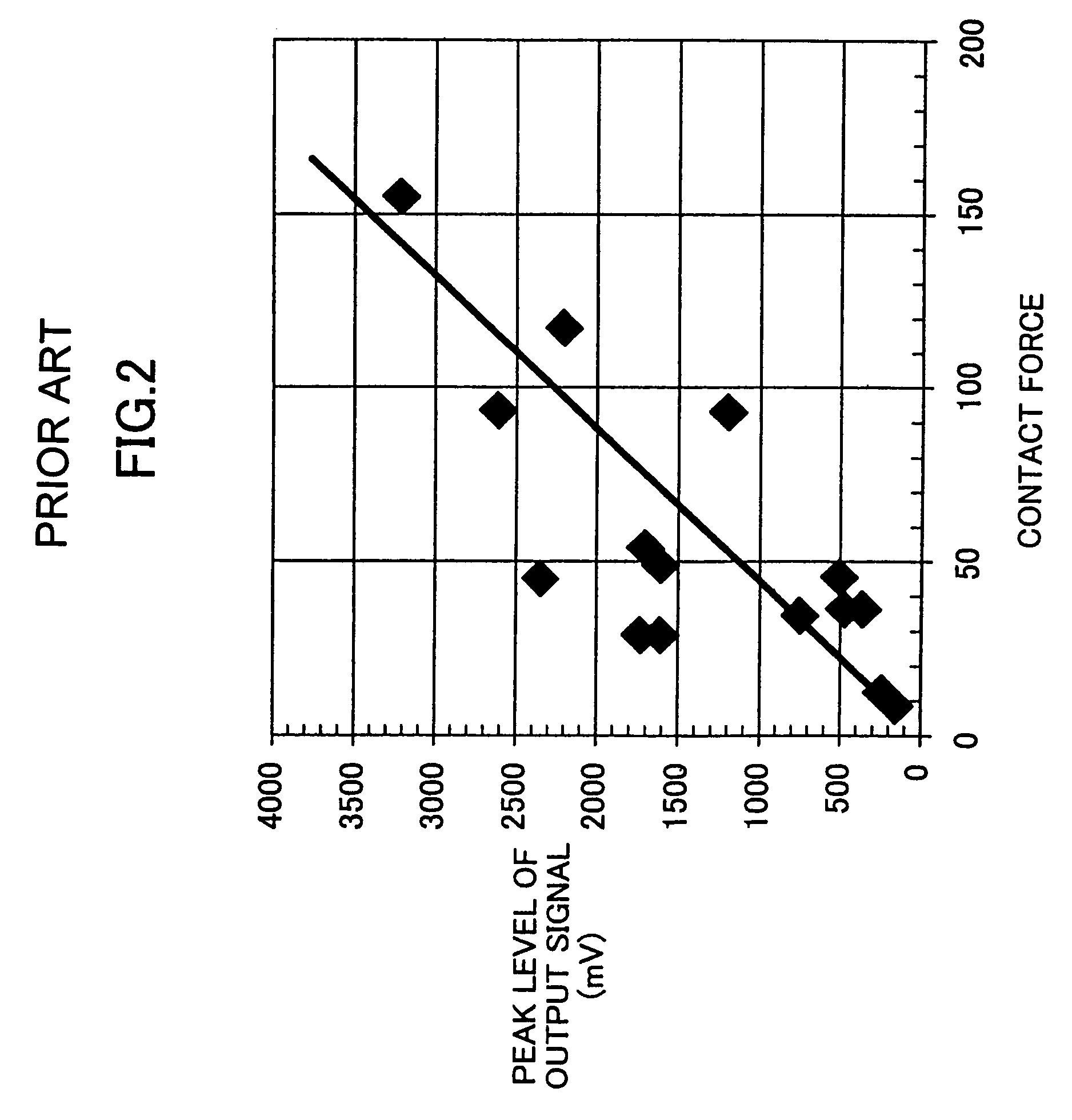

Method of inspecting magnetic recording medium based on contact duration time

InactiveUS7057385B2Accurate detectionImprove reliabilityFluid-dynamic spacing of headsMagnetic property measurementsEngineeringRecording media

A magnetic recording medium inspection method detects small protrusions that constitute defects on the surface of a magnetic recording medium. The method includes flying a glide inspection head at a predetermined height over the surface of the moving magnetic recording medium; detecting a contact duration time during which the glide head is in contact with a protrusion on the surface of the magnetic recording medium using a contact detection sensor attached to the glide inspection head; and determining the small protrusion based on the contact duration time.

Owner:SHOWA DENKO KK

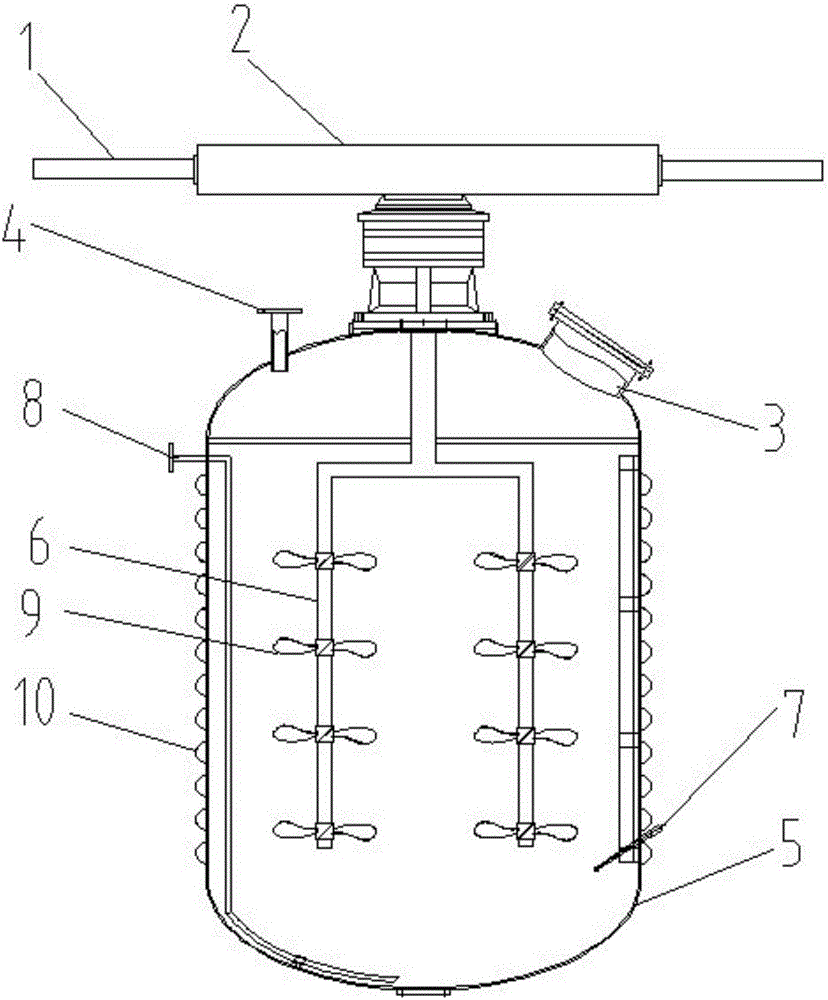

Practical stirring device

InactiveCN105664823AIncrease contact timeIncrease speedRotary stirring mixersTransportation and packagingBiochemical engineeringContact duration

The invention discloses a practical stirring device. Electric heating rings are uniformly and densely arranged on a tank body in a sleeving way; a plurality of detecting probes are arranged on the side face of the tank body and extend into the tank body; the lower end of a stirring shaft body is divided into two symmetric stirring shafts; four stirring impellers are uniformly arranged on each stirring shaft; a driving device comprises a rack box; one end, extending out of the tank body, of the upper end of the stirring shaft body, is connected with a rack in the rack box through a gear; each of two ends of the rack is connected with an oil cylinder. According to the practical stirring device disclosed by the invention, the structure is simple, relevant parameters of materials can be detected in real time, and the progress of reaction can be known in real time; by setting a reciprocated stirring mode and arranging the two stirring shafts, mutual contact time of different materials is shortened, the speed of a chemical reaction and the stirring effect can be improved, and the production efficiency is improved; the stirring shafts are driven by the oil cylinders and the gear box to rotate, and an electric motor is omitted, so that energy consumption is low; by arranging the electric heating rings, the heating is realized more conveniently.

Owner:XUZHOU BEIER ELECTRIC CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com