Hydrogenation reduction device for high-purity arsenic production and high-purity arsenic preparing method

A high-purity arsenic and hydrogen technology, applied in the field of high-purity arsenic, can solve the problems that the high-purity arsenic industry has not achieved a large scale and the market demand is not large, and achieve the effect of improving purity and yield and prolonging contact time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0054] The invention provides a method for preparing high-purity arsenic, comprising the following steps:

[0055] Pass arsenic trichloride and hydrogen gas into the feed pipe of the hydrogenation reduction tube of the device described in the above technical scheme, the arsenic trichloride and hydrogen gas are heated and reacted in the reaction section of the hydrogenation reduction tube, and a solid high temperature is obtained in the deposition section. pure arsenic.

[0056] In the present invention, arsenic trichloride and hydrogen are first passed into the feed pipe of the hydrogenation reduction device. The hydrogenation-reduction device includes: a hydrogenation-reduction tube, the feed end of the hydrogenation-reduction tube is provided with a feed tube; the interior of the hydrogenation-reduction tube is followed by a reaction section and a deposition section along the direction of its gas flow; the reaction section The outlet end of the gas outlet is provided with a...

Embodiment 1

[0066] Hydrogen reduction unit

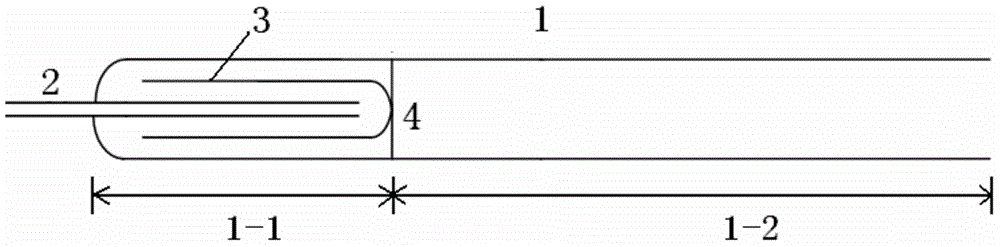

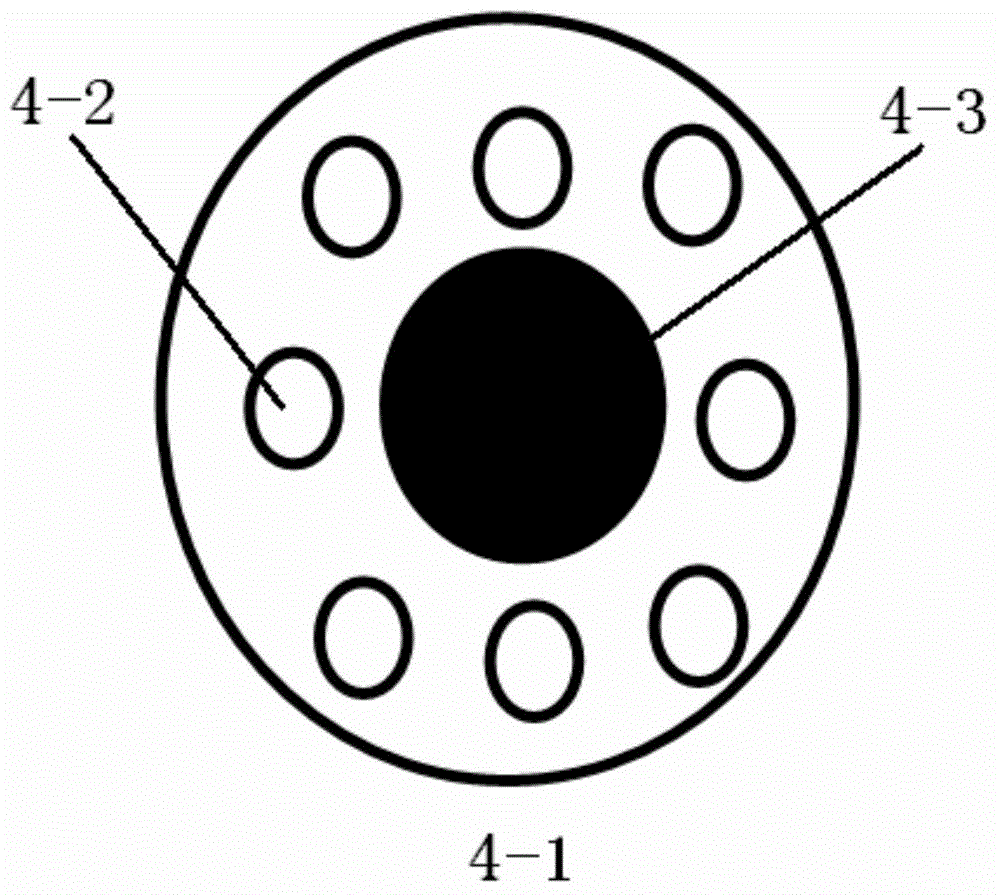

[0067] a kind of like figure 1 The hydrogenation reduction unit shown, figure 1 It is a structural schematic diagram of the hydrogenation reduction device provided by the embodiment of the present invention. figure 1 Among them, 1 is a hydrogenation reduction tube, 2 is a feed tube, 3 is a return tube, 4 is a partition with holes, 1-1 is a reaction section, and 1-2 is a deposition section.

[0068] The hydrogenation reduction device provided in this embodiment includes a hydrogenation reduction tube 1 , the axial length of the hydrogenation reduction tube is 2200 mm, the outer diameter is 120 mm, and the wall thickness is 3 mm. The feed end of the hydrogenation reduction tube 1 is provided with a feed tube 2 with an outer diameter of 10 mm and a wall thickness of 2 mm. Inside the hydrogenation-reduction tube 1 along the forward direction of its gas flow are the reaction section 1-1 and the deposition section 1-2. The axial length of the reac...

Embodiment 2

[0071] Hydrogen reduction unit

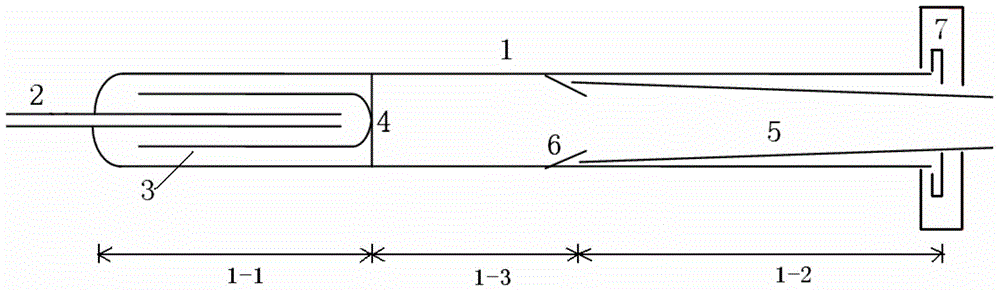

[0072] a kind of like Figure 5 The hydrogenation reduction unit shown, Figure 5 It is a structural schematic diagram of the hydrogenation reduction device provided by Example 2 of the present invention. Figure 5 Among them, 1 is the hydrogenation reduction pipe, 2 is the feed pipe, 3 is the return pipe, 4 is the partition with holes, 5 is the deposition pipe, 7 is the flange, 1-1 is the reaction section, 1-2 is the deposition section .

[0073] The hydrogenation reduction device provided in this embodiment includes a hydrogenation reduction tube 1 , the axial length of the hydrogenation reduction tube is 2200 mm, the outer diameter is 120 mm, and the wall thickness is 3 mm. The feed end of the hydrogenation reduction tube 1 is provided with a feed tube 2 with an outer diameter of 10 mm and a wall thickness of 2 mm. Inside the hydrogenation-reduction tube 1 along the forward direction of its gas flow are the reaction section 1-1 and the d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com