Practical stirring device

A stirring device and practical technology, which are applied to mixers with rotary stirring devices, accessories of mixers, transportation and packaging, etc., can solve the problems of low probability of mutual contact, complicated temperature control methods, and inability to understand the degree in real time, and achieve heating Convenience, simple structure, and the effect of improving the stirring effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be described in further detail below in conjunction with the accompanying drawings.

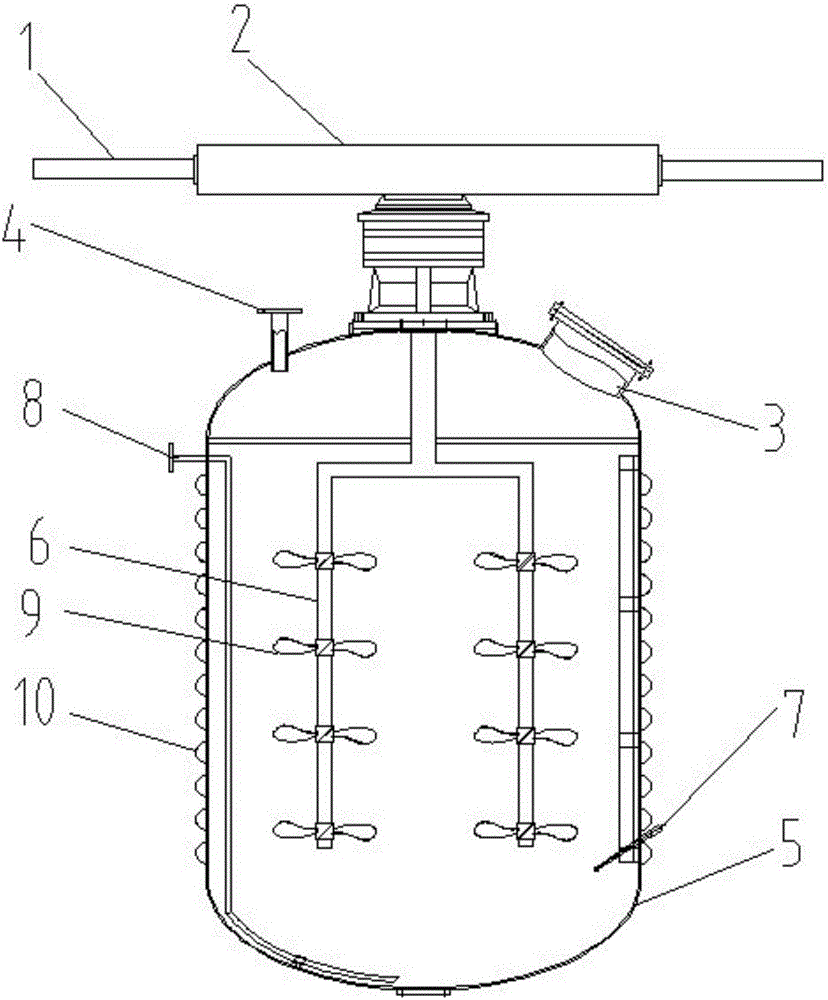

[0011] Such as figure 1 A practical stirring device shown includes a tank body 5 and a stirring shaft body. The stirring shaft body penetrates into the tank body 5 vertically from the top of the tank body 5. The stirring shaft body is driven to rotate by a driving device, and is evenly and densely covered on the tank body 5. An electric heating ring 10 is installed, and a plurality of detection probes 7 are installed from the side of the tank body 5, and the detection probes 7 penetrate into the tank body 5; the lower end of the stirring shaft body is divided into two symmetrical stirring shafts 6, and 4 A stirring impeller 9, the driving device includes a rack case 2, and one end of the stirring shaft body upper end extending out of the tank body 5 is connected with the rack in the rack case 2 through a gear, and the two ends of the rack are respectively con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com