Alkali metal air chamber manufacturing method for improving relaxation resistance of coating based on Plasma hydroxylation

An alkali metal gas chamber and hydroxylation technology, applied in the direction of metal material coating process, etc., can solve the problems of complex cleaning steps, poor anti-relaxation effect, uneven coating coverage, etc., so as to improve the anti-relaxation performance and solve the Poor consistency, the effect of simplifying the operation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

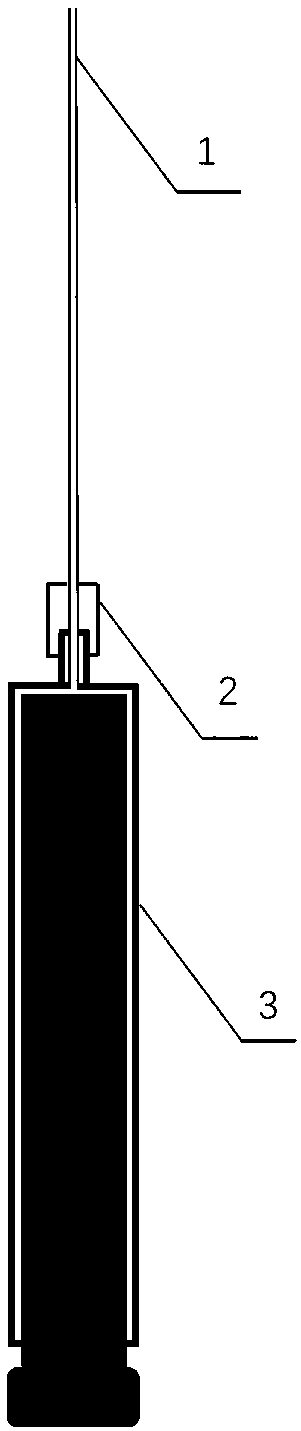

[0021] Such as figure 1 As shown, the glass syringe connected with capillary glass tube includes capillary glass tube 1, syringe 2, and polytetrafluoroethylene tube 3; it has the function of a general syringe, and because it is all made of glass, it can effectively reduce the coating process. , The introduction of impurities.

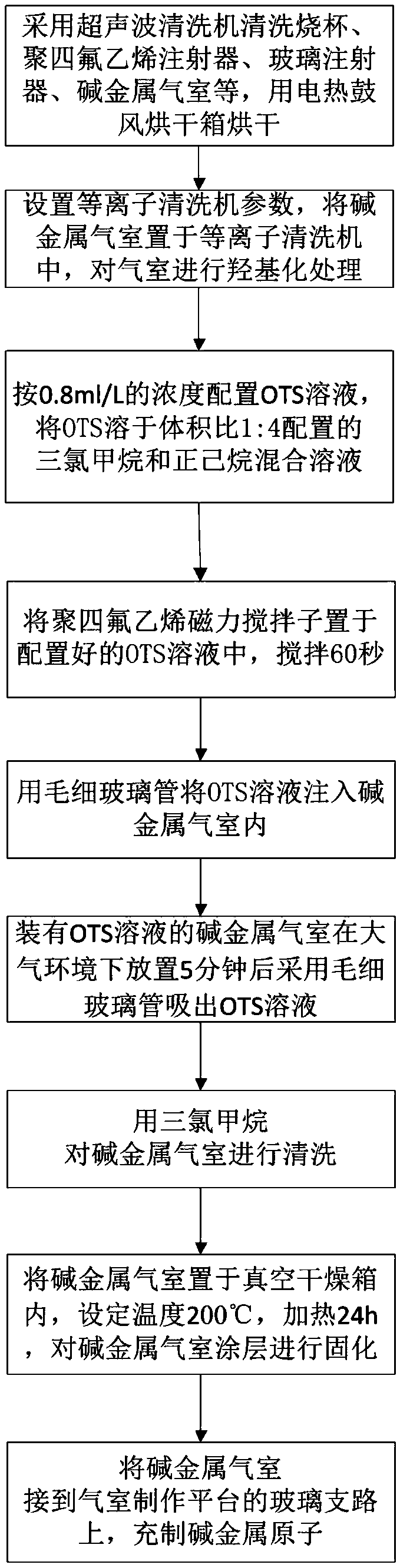

[0022] Such as figure 2 As shown, a kind of alkali metal air cell manufacturing method based on Plasma hydroxylation of the present invention to improve the anti-relaxation performance of the coating is realized as follows:

[0023] (1) Select a 0.9-1.1mm capillary glass tube and connect it to a glass syringe through polytetrafluoroethylene.

[0024] (2) Put the alkali metal gas chamber made of high borosilicate, glass syringe with capillary glass tube, beaker, and polytetrafluoroethylene magnetic stirrer in an ultra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com