Flocculant and preparation method thereof

A flocculant and catalyst technology, applied in the field of coal preparation wastewater treatment, can solve the problems of high operating costs, high investment in environmental protection facilities, large consumption of chemicals, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

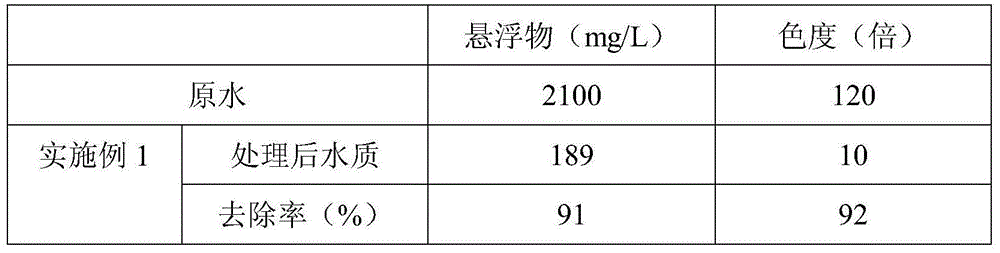

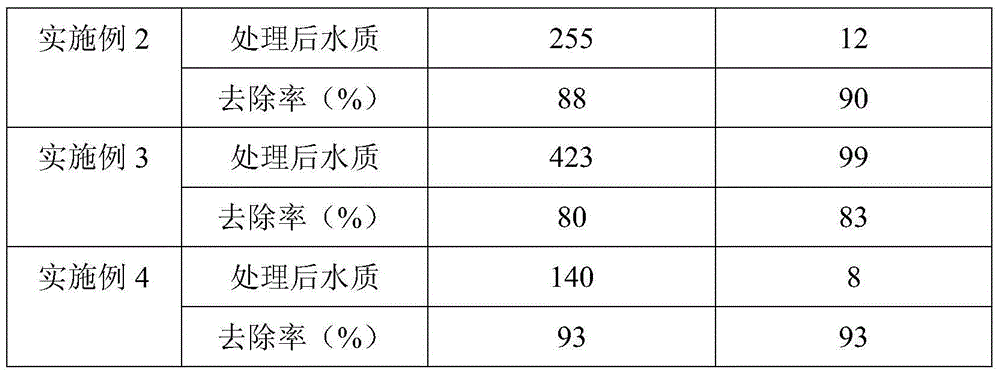

Embodiment 1

[0041] 1) Preparation of attapulgite powder

[0042] Place the attapulgite in an industrial calciner, calcinate at 400°C for 2 hours, then pulverize, pass through a 200-mesh sieve to obtain attapulgite powder with a particle size of ≤200 mesh, and set aside;

[0043] 2) Modification treatment

[0044] 2A) Ferric trichloride is added to the hydrochloric acid solution that the mass percent concentration is 4%, mixes evenly, is mixed with ferric chloride-hydrochloric acid solution, for subsequent use, and wherein the ferric chloride and the mass percent concentration are 4% hydrochloric acid solution The weight ratio is 2:100, that is, the mass percentage concentration of the prepared ferric chloride-hydrochloric acid solution is 2%;

[0045] In the embodiment of the present invention, except that the hydrochloric acid solution with a mass percentage concentration of 4% is used to prepare the ferric chloride-hydrochloric acid solution, other hydrochloric acid solutions with a ma...

Embodiment 2

[0057] 1) Preparation of attapulgite powder

[0058] Place attapulgite in an industrial calciner, calcinate at 380°C for 2 hours, then pulverize, pass through a 300-mesh sieve, and obtain attapulgite powder with a particle size of ≤300 mesh, and set aside;

[0059] 2) Modification treatment

[0060] 2A) Ferric trichloride is added to the hydrochloric acid solution that the mass percent concentration is 4%, mixes evenly, is mixed with ferric chloride-hydrochloric acid solution, for subsequent use, and wherein the ferric chloride and the mass percent concentration are 4% hydrochloric acid solution The weight ratio is 3:100, that is, the mass percentage concentration of the prepared ferric chloride-hydrochloric acid solution is 3%;

[0061] 2B) Accurately weighed attapulgite powder (1000g) is placed in a flask with a stirring and condensing device, then adding a mass percent concentration of 3% ferric chloride-hydrochloric acid solution (1200g) in the bottle, while stirring Rai...

Embodiment 3

[0067] 1) Preparation of attapulgite powder

[0068] Place attapulgite in an industrial calciner, calcinate at 400°C for 1.8 hours, then pulverize, pass through a 200-mesh sieve to obtain attapulgite powder with a particle size of ≤200 mesh, and set aside;

[0069] 2) Modification treatment

[0070] 2A) Ferric trichloride is added to the hydrochloric acid solution that the mass percent concentration is 4%, mixes evenly, is mixed with ferric chloride-hydrochloric acid solution, for subsequent use, and wherein the ferric chloride and the mass percent concentration are 4% hydrochloric acid solution The weight ratio is 1:100, that is, the mass percent concentration of the prepared ferric chloride-hydrochloric acid solution is 1%;

[0071] 2B) Accurately weighed attapulgite powder (2000g) is placed in a flask with a stirring and condensing device, and then adding a mass percentage concentration of 1% ferric chloride-hydrochloric acid solution (2000g) in the bottle, while stirring ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| decolorization rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com