Graphene sheet intercalation compound preparation method and in situ microRaman representation system

A graphene sheet and Raman characterization technology, which is applied in the field of material preparation and spectral analysis, can solve problems such as difficult Raman characterization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

[0041] The preparation method of this graphene sheet intercalation compound provided by the present invention is to place the graphene sheet in a cuvette connected and communicated with the glass tube; place ferric chloride in the glass tube; Vacuum the tube and cuvette; heat and seal the glass tube with an alcohol lamp; heat the glass tube and cuvette to 340 degrees Celsius and keep it for 6 to 24 hours; then cool down to room temperature.

[0042] Among them, if the ferric chloride is wet, use a molecular pump to evacuate the glass tube and cuvette, heat it to 100 degrees Celsius with a heating platform and keep it for 1 hour. After cooling, heat and seal the glass tube with an alcohol lamp.

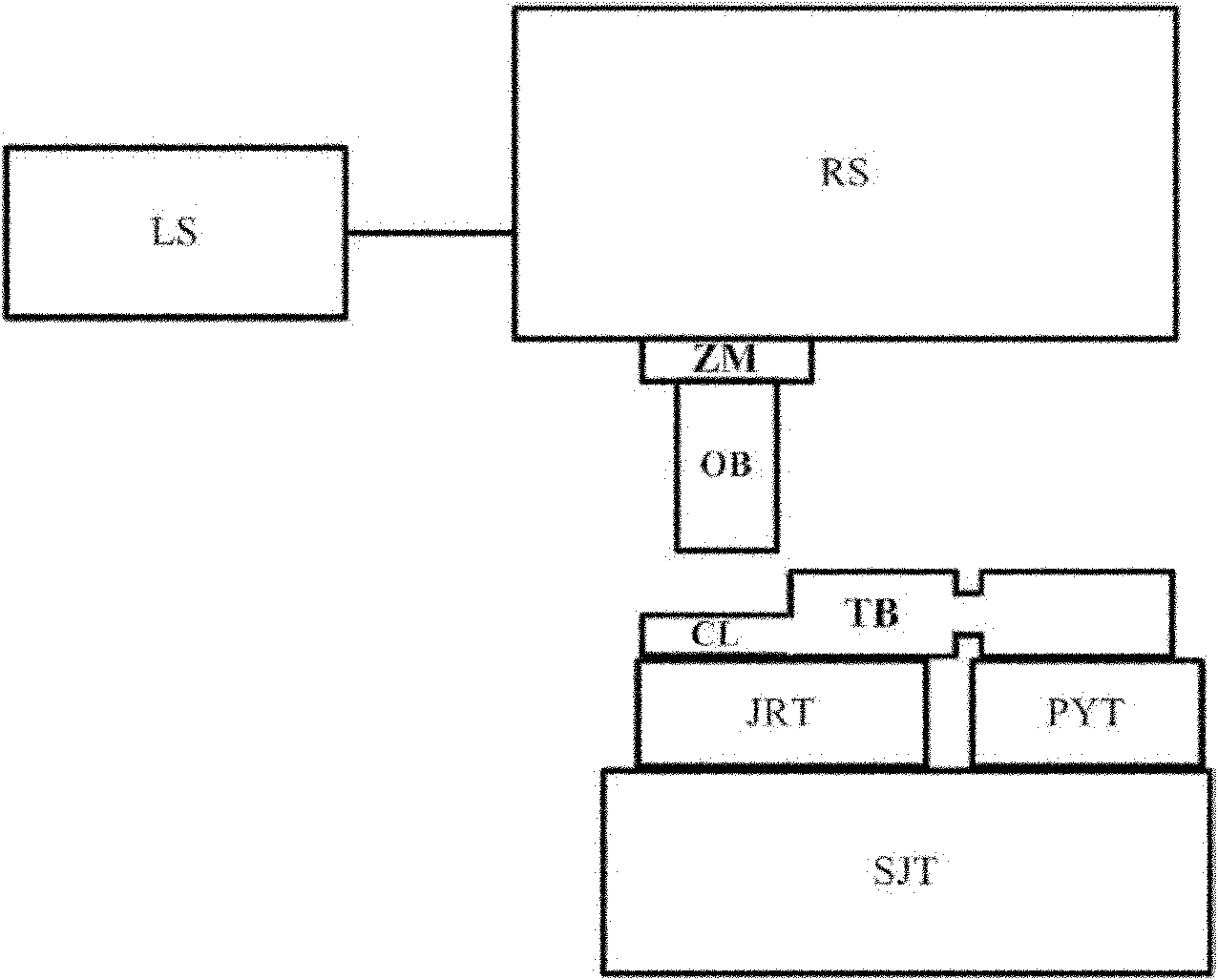

[0043] see figure 1 as sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com