Method and equipment for recovering arsenic from titanium-arsenic slag

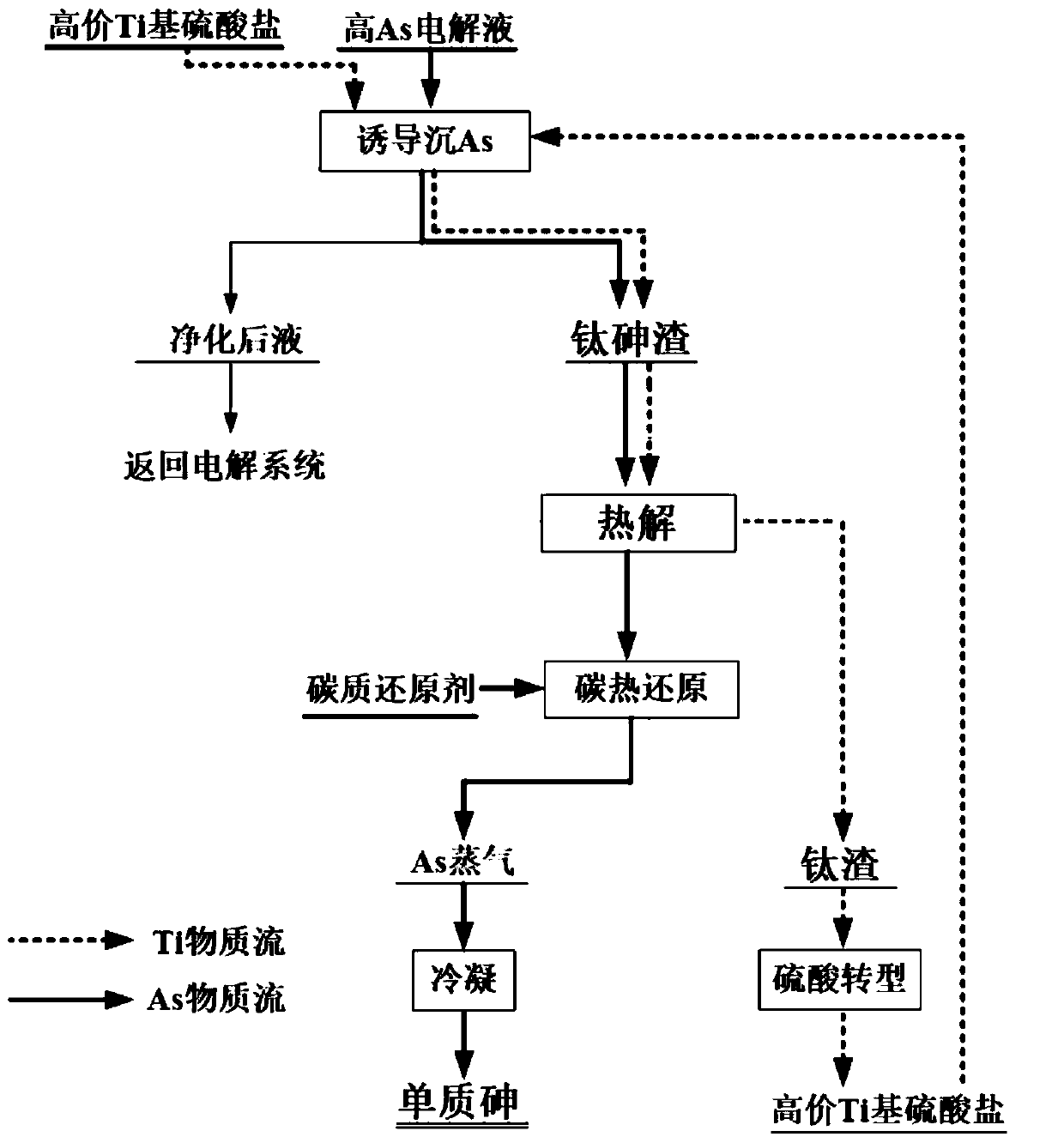

A technology for recovering arsenic and arsenic slag, which is applied in the direction of improving process efficiency, etc., can solve problems such as the need for a large number of processing equipment, failure to achieve harmless and resource utilization of arsenic, complex process flow, etc., to achieve no environmental pollution, Solve the problem of harmlessness and resource recycling, and the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

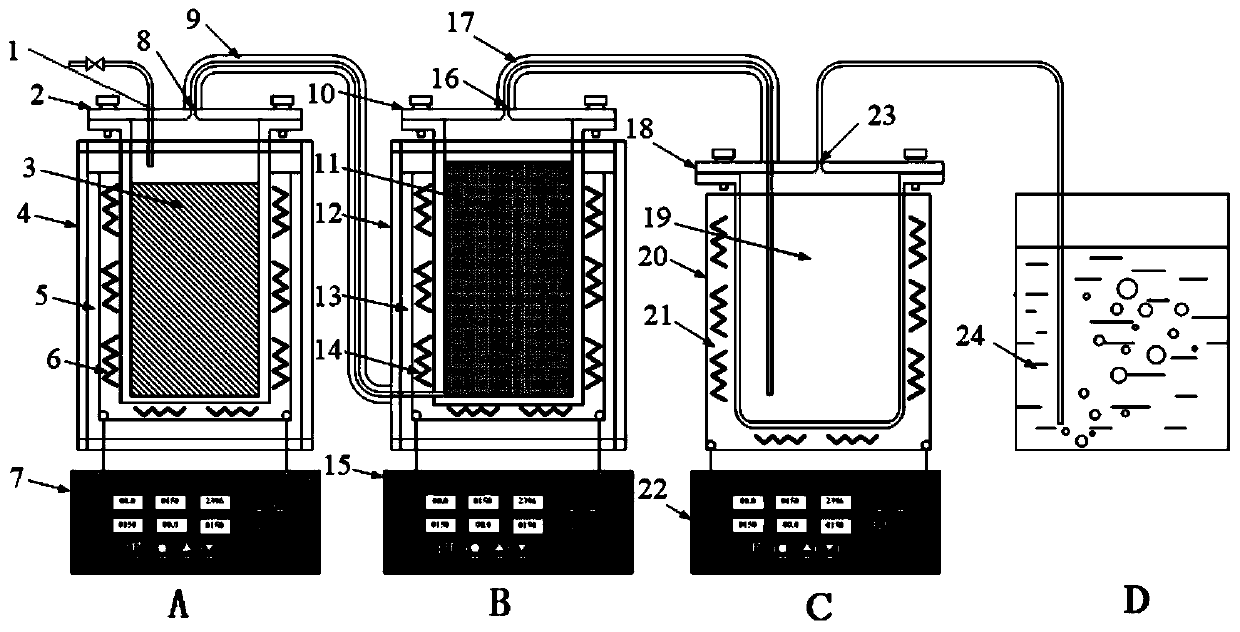

[0042] Such as figure 1 As shown, this embodiment provides a device for recovering elemental arsenic from titanium arsenic slag, which includes a pyrolysis device A, a reduction device B, and a condensation device C connected in sequence.

[0043] Pyrolysis device A comprises pyrolysis device furnace cover 2, pyrolysis furnace cavity 3, pyrolysis device shell 4, pyrolysis device insulation layer 5, pyrolysis device electric heating layer 6 and pyrolysis device heating control cabinet 7; A pyrolysis device electric heating layer 6 is arranged around and at the bottom of the outside of the pyrolysis furnace chamber 3 for heating the pyrolysis furnace chamber 3, and a pyrolysis device is arranged between the pyrolysis device electric heating layer 6 and the pyrolysis device shell 4 The device insulation layer 5 is used for the heat preservation of the pyrolysis furnace chamber 3, and an air inlet 1 is provided on the furnace cover 2 of the pyrolysis device so that a protective a...

Embodiment 2

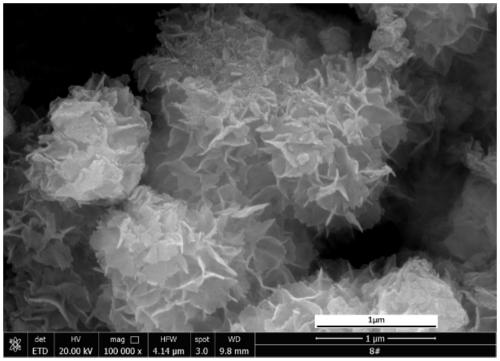

[0054] The chemical composition and electron microscope energy spectrum ( image 3 and Figure 4 ) analysis is shown in Table 1.

[0055] The chemical composition of the titanium arsenic slag in the embodiment 2 of table 1

[0056]

[0057] The method for reclaiming arsenic from titanium arsenic slag in this embodiment: adding titanium arsenic slag in the pyrolysis furnace cavity (the titanium arsenic slag material is not less than 2 / 3 of the pyrolysis furnace cavity volume and cannot exceed the pyrolysis furnace cavity 3 / 4 of the volume), and at the same time, carbon black is added to the reduction furnace chamber (the volume of carbon is not less than 2 / 3 of the volume of the reduction furnace chamber and cannot exceed 3 / 4 of the volume of the reduction furnace chamber), and then heat Put the cover of the pyrolysis device on the cover of the furnace cavity, and cover the cover of the reduction device, and seal it with bolts; adjust the reaction temperature of the heatin...

Embodiment 3

[0059] The chemical composition of the titanium arsenic slag involved in this example is shown in Table 2.

[0060] The chemical composition of the titanium arsenic slag in the embodiment 3 of table 2

[0061]

[0062] The method for reclaiming arsenic from titanium arsenic slag in this embodiment: adding titanium arsenic slag in the pyrolysis furnace cavity (the titanium arsenic slag material is not less than 2 / 3 of the pyrolysis furnace cavity volume and cannot exceed the pyrolysis furnace cavity 3 / 4 of the volume), and at the same time, carbon black is added to the reduction furnace chamber (the volume of carbon is not less than 2 / 3 of the volume of the reduction furnace chamber and cannot exceed 3 / 4 of the volume of the reduction furnace chamber), and then heat Put the cover of the pyrolysis device on the cover of the furnace chamber, and cover the cover of the reduction device, and seal it with bolts; adjust the reaction temperature of the heating control cabinet of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com