Method and system used for high arsenic phosphorus ore pre-dearsenization

A high-arsenic phosphate rock, pre-removal technology, applied in chemical instruments and methods, arsenic oxide/arsenic hydroxide/oxyacid arsenic, arsenic compounds, etc., can solve a large amount of electrolytic waste liquid, high economic cost, production waste liquid and other problems, to achieve the effect of simple and easy process flow, broad application prospects and effective utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

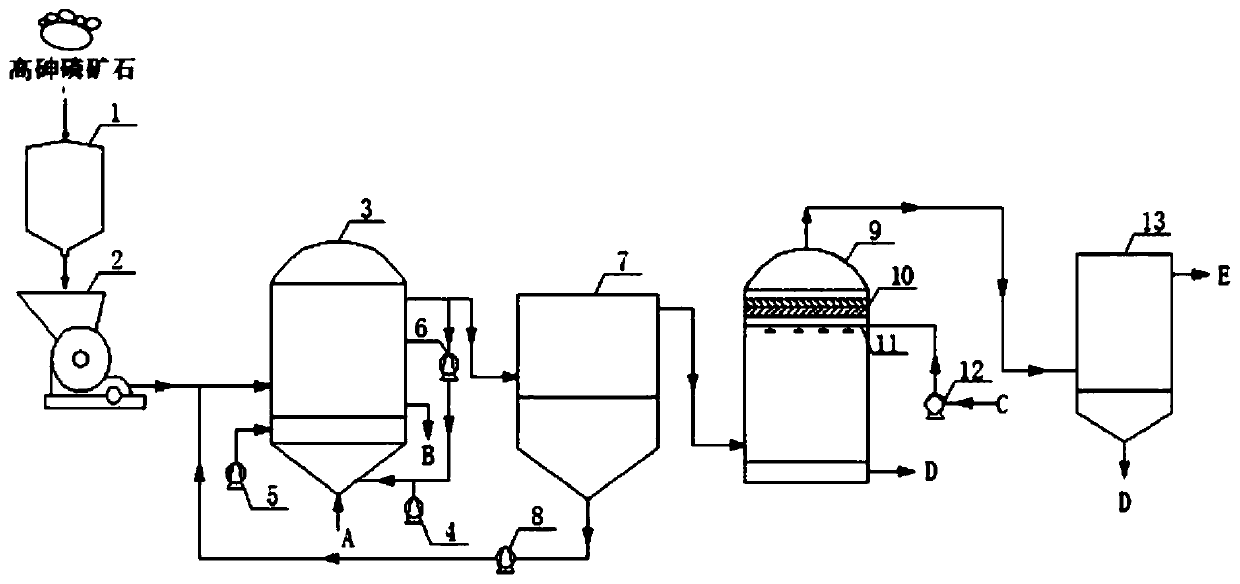

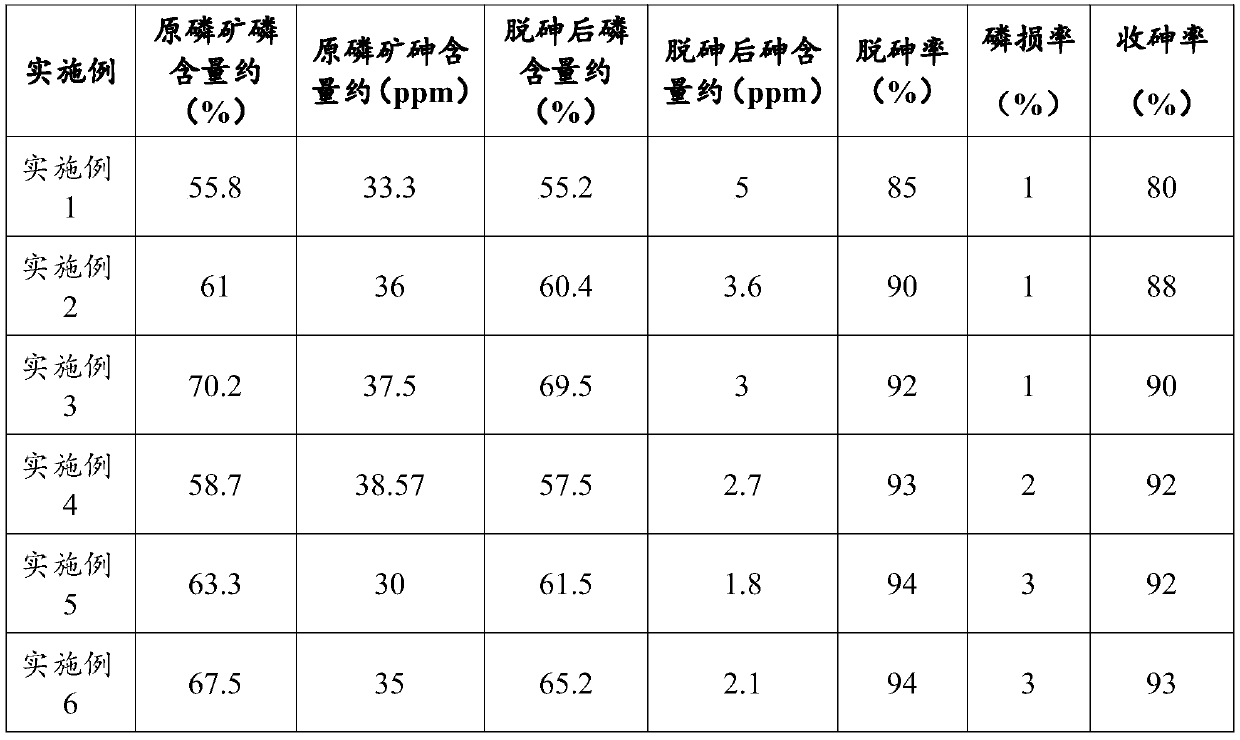

[0059] The high-arsenic phosphate rock is crushed into high-arsenic phosphate rock powder in a crusher, and then transported to the fluidized furnace, where yellow phosphorus tail gas is introduced, and burned at the bottom of the fluidized furnace to generate a large amount of heat to heat the high-arsenic phosphate rock powder. During the combustion process of yellow phosphorus tail gas, air is introduced by the blower to support combustion, and the phosphate rock powder is disturbed to be fully heated to 480°C, and arsenic is oxidized to gaseous arsenic trioxide to form arsenic dust. After 0.5h of heating time, the low-arsenic phosphate rock powder and the arsenic dust flue gas containing a small amount of phosphate rock powder produced after the reaction are exported to the fluidized fluidized furnace. Pass the flue gas of arsenic dust containing phosphate rock powder through a ceramic filter and dust collector. At this time, the filtration temperature is 400°C. tower. Th...

Embodiment 2

[0061] The high-arsenic phosphate rock is crushed into high-arsenic phosphate rock powder in a crusher, and then transported to the fluidized furnace, where yellow phosphorus tail gas is introduced, and burned at the bottom of the fluidized furnace to generate a large amount of heat to heat the high-arsenic phosphate rock powder. During the combustion process of yellow phosphorus tail gas, air is introduced through the blower to support combustion, and at the same time, the phosphate rock powder is disturbed to be fully heated to 480°C, and arsenic is oxidized to gaseous arsenic trioxide to form arsenic dust. After 1.5 hours of heating time, the low-arsenic phosphate rock powder and the arsenic dust flue gas containing a small amount of phosphate rock powder produced after the reaction are exported to the fluidized fluidized furnace. Pass the flue gas of arsenic dust containing phosphate rock powder through a ceramic filter and dust collector. At this time, the filtration tempe...

Embodiment 3

[0063] The high-arsenic phosphate rock is crushed into high-arsenic phosphate rock powder in a crusher, and then transported to the fluidized furnace, where yellow phosphorus tail gas is introduced, and burned at the bottom of the fluidized furnace to generate a large amount of heat to heat the high-arsenic phosphate rock powder. During the combustion process of yellow phosphorus tail gas, air is introduced by the blower to support combustion, and at the same time, the phosphate rock powder is disturbed to be fully heated to 530°C, and arsenic is oxidized to gaseous arsenic trioxide to form arsenic dust. After 0.5h of heating time, the low-arsenic phosphate rock powder and the arsenic dust flue gas containing a small amount of phosphate rock powder produced after the reaction are exported to the fluidized fluidized furnace. Pass the flue gas of arsenic dust containing phosphate rock powder through a ceramic filter and dust collector. At this time, the filtration temperature is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com