Method for curing arsenic-containing waste residues through industrial waste residues

A technology of industrial waste residue and waste residue, which is applied in the field of arsenic pollution control, can solve the problems of high processing cost, poor stability, and inability to separate arsenic, and achieve the effect of strengthening the effect of arsenic fixation and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

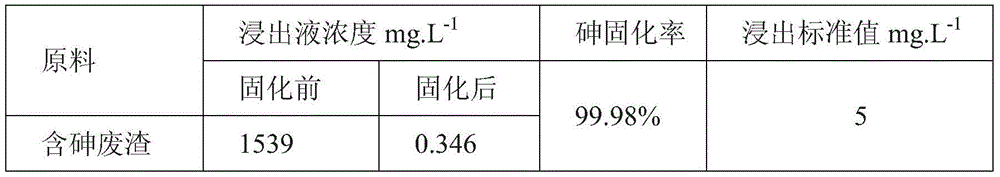

Embodiment 1

[0026] A method of the present invention for solidifying arsenic-containing waste slag by using industrial waste slag, the object of treatment is arsenic sulfide slag from a copper smelter, the main chemical components and leaching toxicity analysis of the arsenic sulfide slag are shown in Table 1, Table 2 and Table 3 respectively Shown, specifically include the following steps:

[0027] (1) Raw material preparation: the tailings after the copper smelting slag flotation copper of the copper smelter is obtained by magnetic separation to obtain the magnetic separation iron concentrate, for subsequent use; the Fe in the magnetic separation iron concentrate 3 o 4 The mass fraction is 80%, and the particle size is -400 mesh. The neutralized slag produced by adding lime milk to neutralize the smelter in the sewage acid treatment or wastewater treatment process is crushed to a particle size of less than 0.5cm, and dried at 200°C for 2 hours to an anhydrous state for later use.

[0...

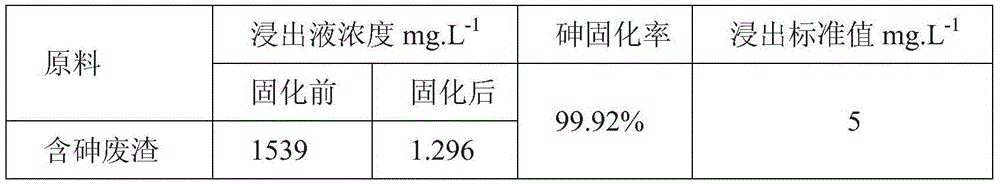

Embodiment 2

[0041] A method of using industrial slag to solidify arsenic-containing waste slag according to the present invention, the object of treatment is arsenic sulfide slag from a copper smelter, the main chemical components and leaching toxicity analysis of the arsenic sulfide slag are shown in Table 4, Table 5 and Table 6 respectively Shown, specifically include the following steps:

[0042] (1) Raw material preparation: ball mill the tailing sand after the copper smelting slag flotation copper in the copper smelter until the particle size is -800 mesh, and set aside. The neutralized slag was crushed to a particle size of less than 0.5 cm, dried at 200°C for 2 hours to anhydrous state, and set aside.

[0043](2) Pretreatment of arsenic-containing waste slag: put arsenic-containing waste slag into a stirring tank and add water to slurry to form a slurry. The concentration of slag in the slurry is 20%, and the pH value of the slurry is 2.

[0044] (3) fix arsenic: add the tailings ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com