A comprehensive recovery method for complex arsenic-containing and valuable metal slag dust materials

A technology of valuable metals and recycling methods, applied in the direction of process efficiency improvement, cement production, etc., can solve the lack of systematic process research and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with embodiment.

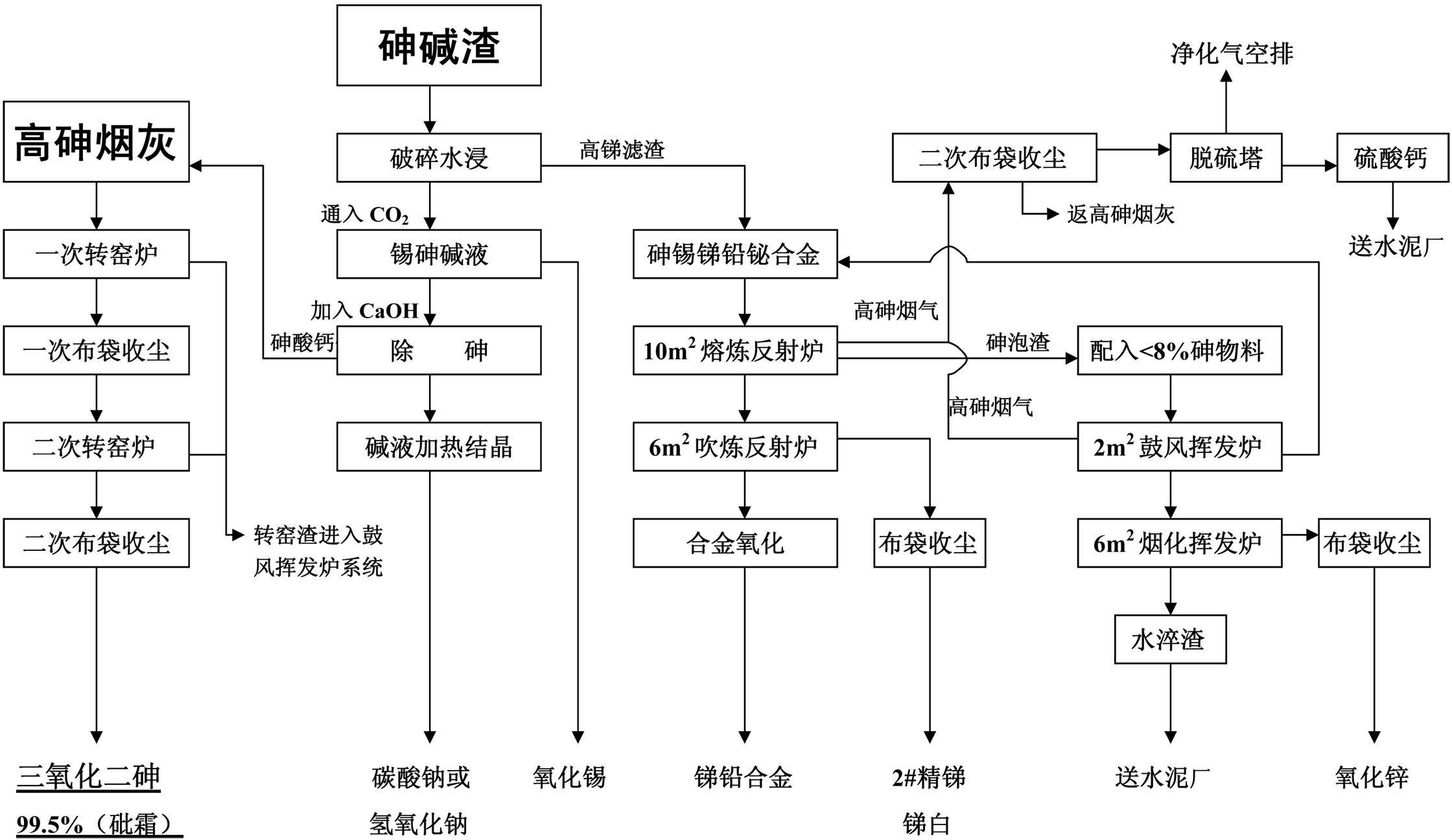

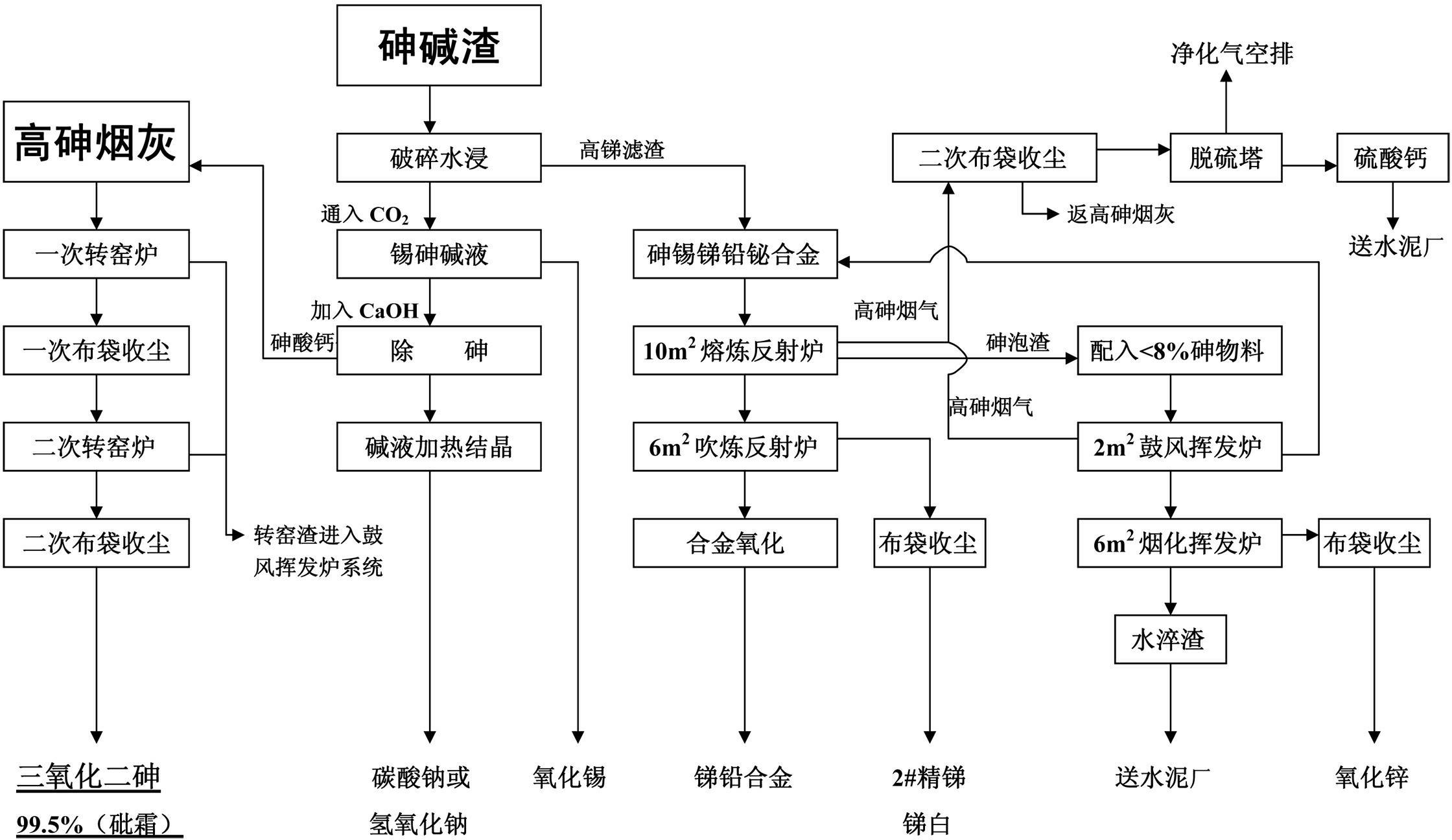

[0022] Such as figure 1 As shown, the comprehensive recovery method of complex arsenic-containing and valuable metal slag dust materials of the present invention comprises the following steps:

[0023] (1), one-time rotary kiln volatilization and enrichment of arsenic: 80 parts containing As 2 o 3 40%, Pb25%, Sb5%, Bi3% high arsenic dust, 15 parts containing As 2 o 3 30%, Pb20%, Sb8%, Bi2% blast volatilization furnace dust, and 5 parts of anthracite coal powder with a fixed carbon content of 80% are fed into the primary rotary kiln. 2 o 3 36.5%, the block degree is controlled below φ20mm, the effective size of the furnace of the primary rotary kiln is φ1.6m×28m, the slope control is 1:25, the speed control is 4 rpm; the temperature of the furnace head is 750°C±50°C , the furnace tail temperature is 600°C±50°C, and the output of primary rotary kiln smoke contains As 2 o 3 70%,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com