Method for precipitating and separating arsenic from waste acid wastewater

A technology of sewage acid wastewater and precipitation separation, which is applied in the field of precipitation and separation of arsenic, can solve the problems of effluent that cannot meet the reuse requirements, many types of heavy metals, and high treatment costs, so as to improve the quality of separated products, produce less hazardous solid waste, and treat low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

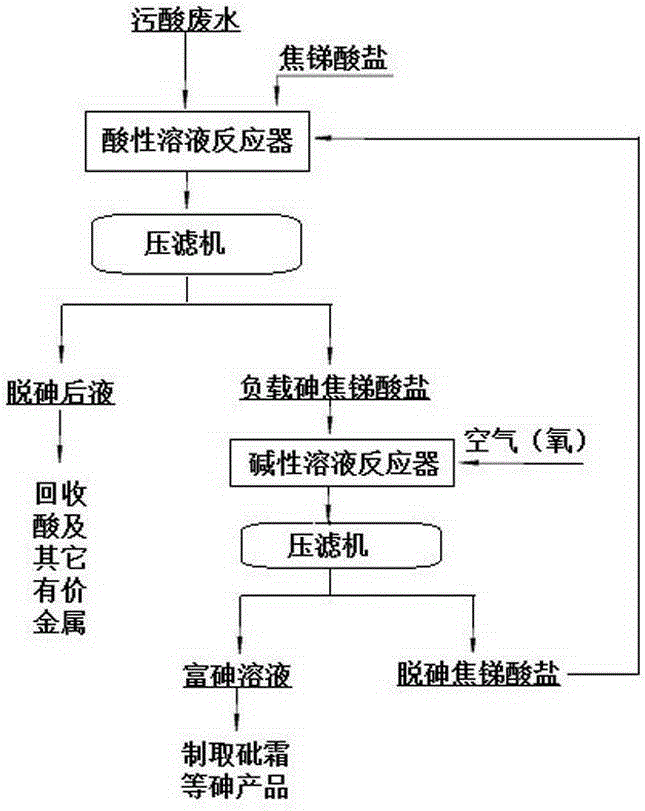

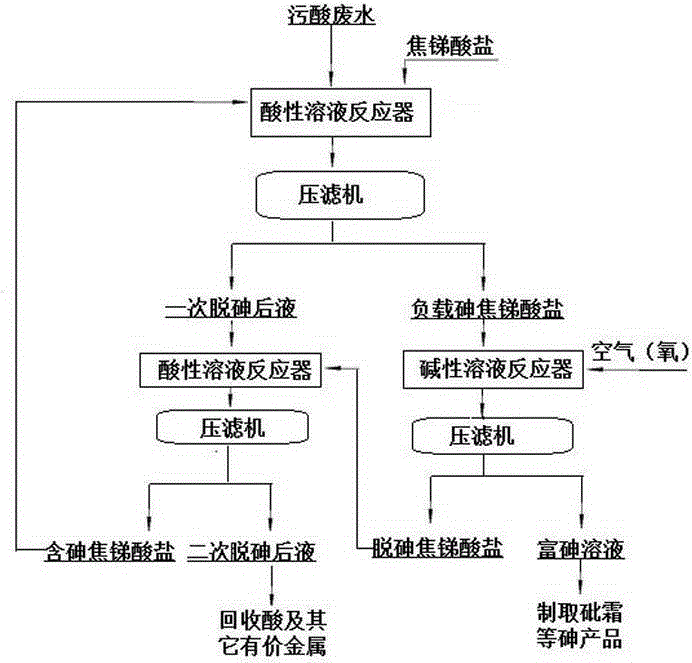

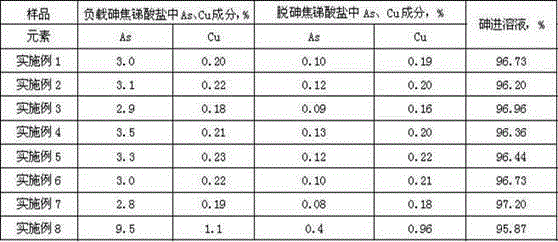

[0023] like figure 1As shown, the treatment of a kind of dirty acid produced by copper smelting flue gas purification. Extract the dirty acid wastewater from the dirty acid wastewater collection pool and put it into the acid solution reactor (reactor). According to the amount of input, add sodium pyroantimonate at a liquid-solid ratio of 6mL:1g, heat to 50°C, and stir with a stirrer for 15 minutes. Finally, pyroantimonate selectively reacts with arsenite and arsenate and precipitates, the arsenic is separated by precipitation, the reaction solution is pumped to the filter press for pressure filtration, and the arsenic-removed filtrate flows to the acid and valuable metal recovery process. Most of the arsenic is removed in one step, copper, zinc, lead, tin and other valuable metals are extracted more easily by vulcanization method, the quality is improved, and the wastewater after heavy metal separation is reused or discharged after neutralization. The arsenic-loaded pyroantim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com