Clean production technological method and device for extracting arsenic

A clean production and equipment technology, applied in the field of environmental protection, can solve the problems that affect the sustainable and healthy development of the non-ferrous smelting industry, and the poor quality makes it difficult to continue to comprehensively utilize arsenic-containing hazardous waste, so as to achieve the effect of improving comprehensive economic and environmental benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

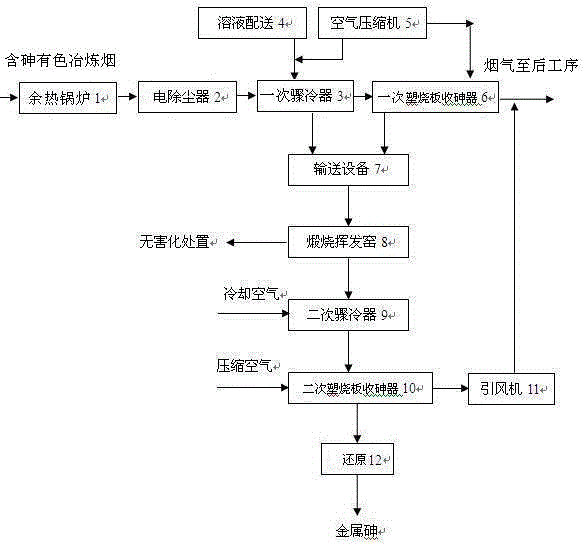

[0022] The invention proposes a process method and a device for recovering arsenic from arsenic-containing nonferrous metal material or arsenic-containing nonferrous metal smelting flue gas through a continuous secondary arsenic extraction process.

[0023] Arsenic-containing non-ferrous metal materials are smelted or roasted in various forms of smelting furnaces or kilns, and arsenic sulfides or compounds are oxidized to As 2 o 3 Into the flue gas, while the flue gas also contains dust, SO 2 , SO 3 , CO, CO 2 , NO X and other gas components. After the high-temperature flue gas passes through the waste heat boiler to recover heat, and the electrostatic precipitator removes most of the dust, it is sprayed with an alkaline atomized solution through a quencher, and the flue gas is quenched to 110-170°C, and the As in the gas 2 o 3 solidifies as a solid, SO in gas 3 It is neutralized by alkaline substances into sulfate solids, part of the gas-solid mixture is collected from...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com