Comprehensive recovery method for complicated materials containing arsenic and valuable metal slag dust

A technology for valuable metals and recovery methods, which can be used in the improvement of process efficiency, cement production, etc., and can solve problems such as lack of systematic process research.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with embodiment.

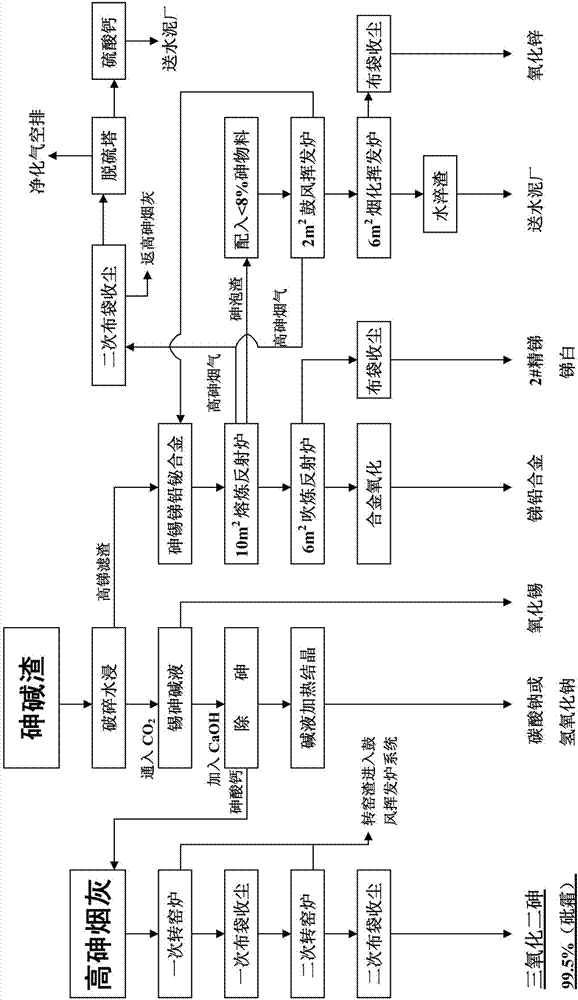

[0022] Such as figure 1 As shown, the comprehensive recovery method of complex arsenic-containing and valuable metal slag dust materials of the present invention comprises the following steps:

[0023] (1), one-time rotary kiln volatilization and enrichment of arsenic: 80 parts containing As 2 o 3 40%, Pb25%, Sb5%, Bi3% high arsenic soot, 15 parts containing As 2 o 3 30%, Pb20%, Sb8%, Bi2% blast volatilization furnace dust, and 5 parts of anthracite coal powder with a fixed carbon content of 80% are sent to the primary rotary kiln. 2 o 3 36.5%, the block degree is controlled below φ20mm, the effective size of the furnace of the primary rotary kiln is φ1.6m×28m, the slope control is 1:25, the speed control is 4 rpm; the temperature of the furnace head is 750°C±50°C , the furnace tail temperature is 600°C±50°C, and the output of primary rotary kiln smoke contains As 2 o 3 70%, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com