Method for separating and purifying high-antimony crude tin

A crude tin, control and grading technology, applied in the direction of improving process efficiency, can solve the problems of antimony open circuit rate of only 50%, complex anode slime composition, and difficult comprehensive treatment, etc., to achieve friendly working environment, high metal recovery efficiency, The effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

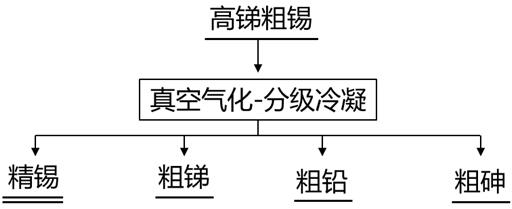

[0020] Such as figure 1 Shown, the method for the separation and purification of this high antimony thick tin, it comprises the following steps:

[0021] Step 1. Carry out vacuum gasification treatment to 1 kg of high-antimony crude tin (its composition is as shown in Table 1), so that the volatile impurity elements in the crude tin are gasified to the maximum extent, and the mixed metal vapor formed by gasification and volatilization; The temperature in the vacuum gasification treatment is 1400°C, the system pressure is 100Pa, and the gasification time is 200min;

[0022] Table 1

[0023] element sn Pb Sb As Content (wt%) 71.65 8.46 16.72 3.17

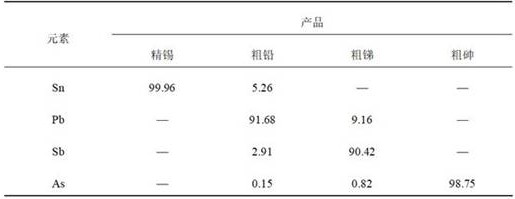

[0024] Step 2. The mixed metal vapor obtained in step 1 is introduced into the graded condenser connected with the vacuum gasification furnace, and the temperature of the condensation area of the graded condenser is controlled to be 550~700°C, 300~450°C and 100~250°C, respectively, to obtain Crude l...

Embodiment 2

[0029] Such as figure 1 Shown, the method for the separation and purification of this high antimony thick tin, it comprises the following steps:

[0030] Step 1. Carry out vacuum gasification treatment to 1 kg of high-antimony crude tin (its composition is as shown in Table 3), so that the volatile impurity elements in the crude tin are gasified to the maximum extent, and the mixed metal vapor formed by gasification volatilization; The temperature in the vacuum gasification treatment is 900°C, the system pressure is 1Pa, and the gasification time is 30min;

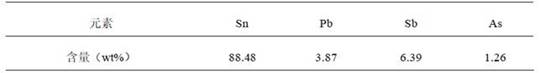

[0031] table 3

[0032]

[0033] Step 2. The mixed metal vapor obtained in step 1 is introduced into the graded condenser connected with the vacuum gasification furnace, and the temperature of the condensation area of the graded condenser is controlled to be 550~700°C, 300~450°C and 100~250°C, respectively, to obtain Crude lead, crude antimony and crude arsenic products, and refined tin products left by gasification...

Embodiment 3

[0038] Such as figure 1 Shown, the method for the separation and purification of this high antimony thick tin, it comprises the following steps:

[0039] Step 1. Carry out vacuum gasification treatment to 1kg of high-antimony crude tin (its composition is as shown in Table 5), so that the volatile impurity elements in the crude tin are gasified to the maximum extent, and the mixed metal vapor formed by gasification volatilization; The temperature in the vacuum gasification treatment is 1200°C, the system pressure is 10Pa, and the gasification time is 30min;

[0040] table 5

[0041] element sn Pb Sb As Content (wt%) 94.29 1.27 3.49 0.95

[0042] Step 2. The mixed metal vapor obtained in step 1 is introduced into the graded condenser connected with the vacuum gasification furnace, and the temperature of the condensation area of the graded condenser is controlled to be 550~700°C, 300~450°C and 100~250°C, respectively, to obtain Crude lead, cru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com