Method for extracting arsenic trioxide from roasting dust of arsenic-containing gold concentrate powder

A technology of arsenic trioxide and gold concentrate, applied in chemical instruments and methods, arsenic compounds, inorganic chemistry, etc., can solve the problems of environmental pollution, high loss rate of gold components, waste of natural resources, etc., and achieve controllable process and low loss The effect of less, high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

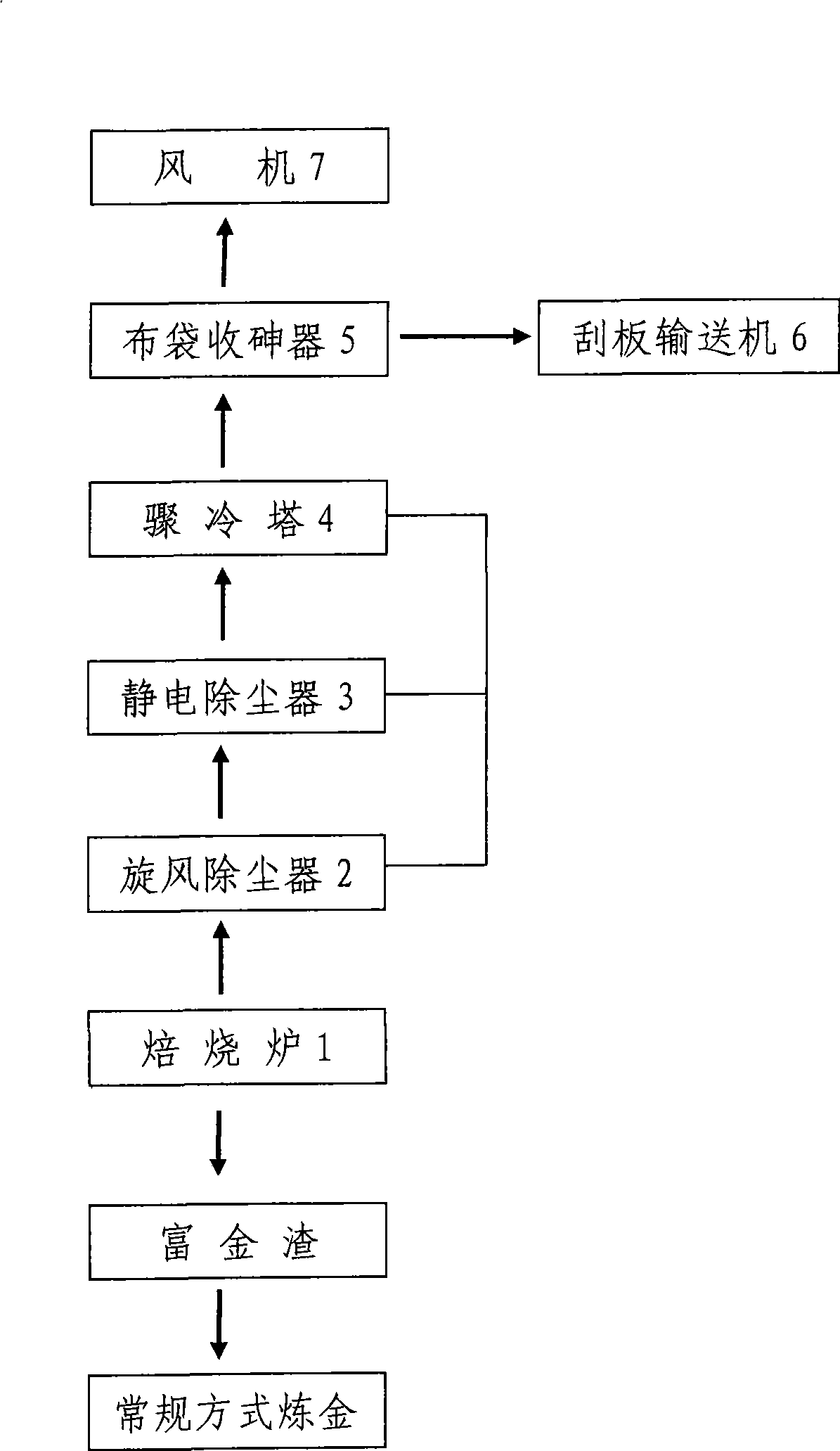

[0018] The present invention will be further described below in conjunction with the block diagram of the technological process shown in the accompanying drawings, and in conjunction with the embodiments.

[0019] The method for extracting arsenic trioxide from arsenic-containing gold concentrate powder roasting fumes comprises the following steps:

[0020] (1) Fill the arsenic-containing gold concentrate powder according to the capacity of the roasting furnace, raise the temperature in the furnace to 150-200°C and keep it warm for 60-90 minutes, the moisture in the arsenic-containing gold concentrate powder in the furnace becomes water vapor and passes through the fan 7 discharge, the ore dust formed in the furnace enters the cyclone dust collector 2 and the electrostatic precipitator 3 for purification;

[0021] (2) Following the previous procedure, the roasting furnace 1 is heated to 350-400°C and held for 60-90 minutes. Under this temperature condition, the sulfur in the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com