Treatment method and application of arsenic removal material

A treatment method, a technology for removing arsenic, which is applied in the fields of chemistry and food, and can solve the problems of excessive arsenic content and utilization restrictions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

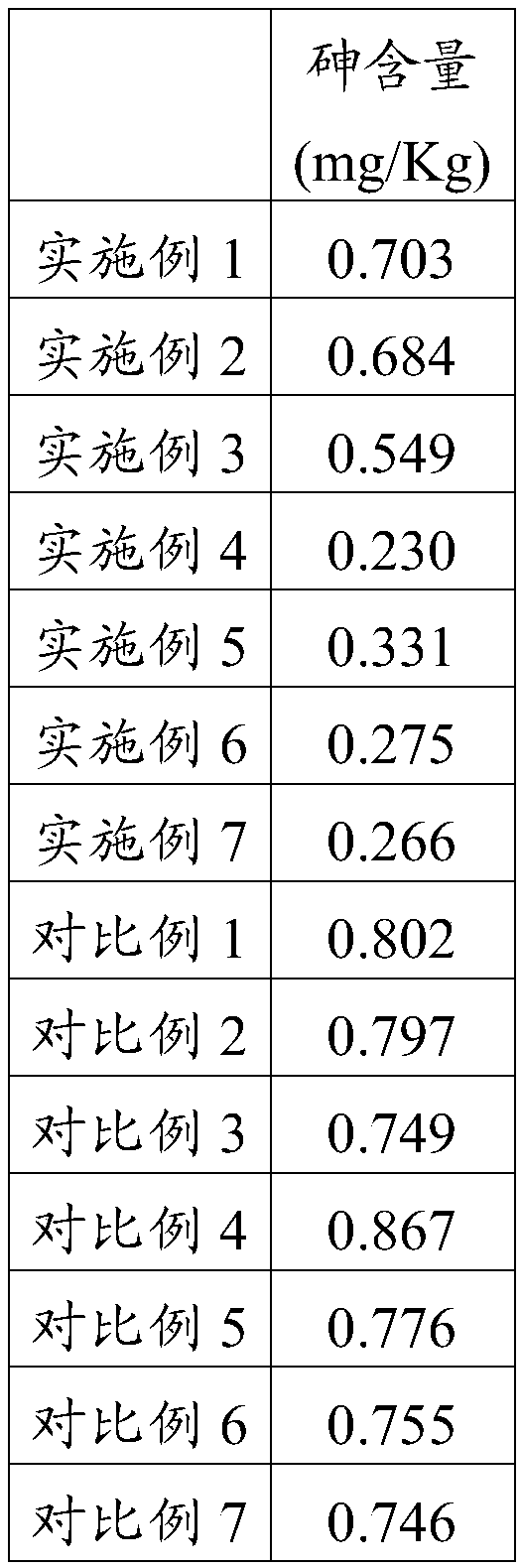

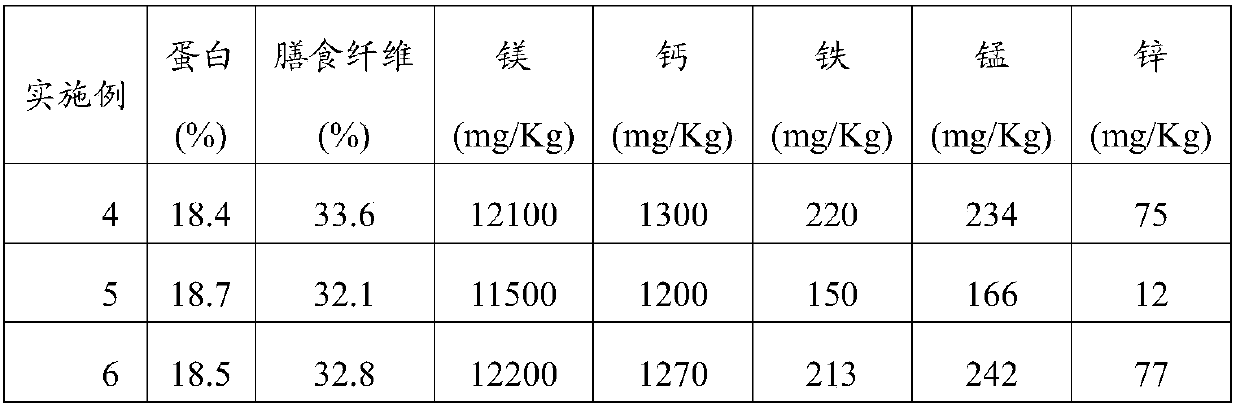

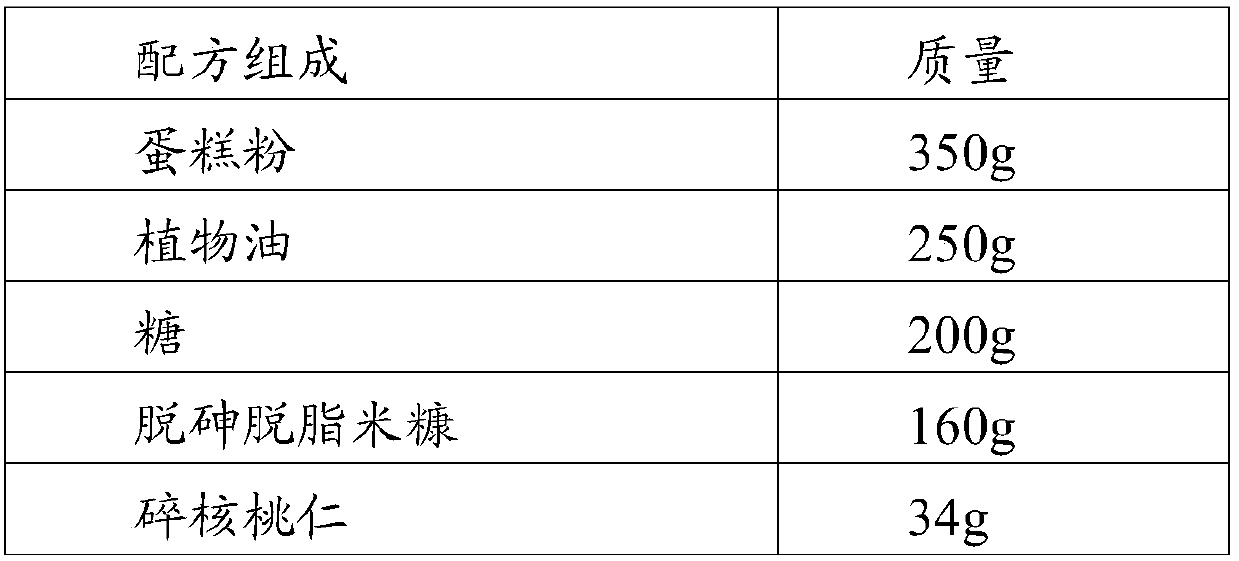

Examples

Embodiment

[0133] The following examples are for the purpose of illustration only and not limiting the scope of the application.

[0134] The specific information of raw materials and equipment used in the following examples are as follows:

[0135] The raw material of defatted rice bran is commercially available feed grade, the raw material of rice selenium powder is food grade, ultrasonic cleaning machine (JH-1018, Suzhou Juhong Ultrasonic Equipment Co., Ltd.), 200L reaction tank (GS2016-340, Shanghai Guoshun Chemical Equipment Co., Ltd. ), centrifuge (SS600, Jiangsu Saideli Pharmaceutical Machinery Manufacturing Co., Ltd.), SXG-3 spin flash dryer (Jiangsu Yutong Drying Engineering Co., Ltd.).

preparation example 1

[0136] Preparation example 1-reducing agent treatment

[0137] The chicken felt lining was treated in 2% dithiothreitol aqueous solution for 2 hours to obtain the arsenic-removing material 1 .

preparation example 2

[0138] Preparation example 2-ultrasonic treatment + reducing agent treatment

[0139] The wool felt lining was treated in 35KHz ultrasonic waves for 60 minutes, and then treated in 2% dithiothreitol aqueous solution for 2 hours to obtain arsenic-removing material 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com