Patents

Literature

35results about How to "Remove harmful ingredients" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

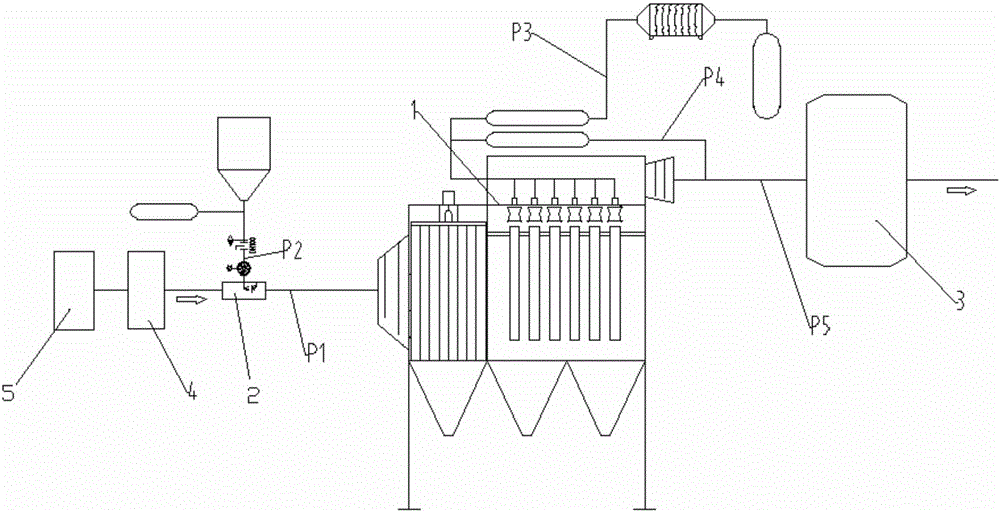

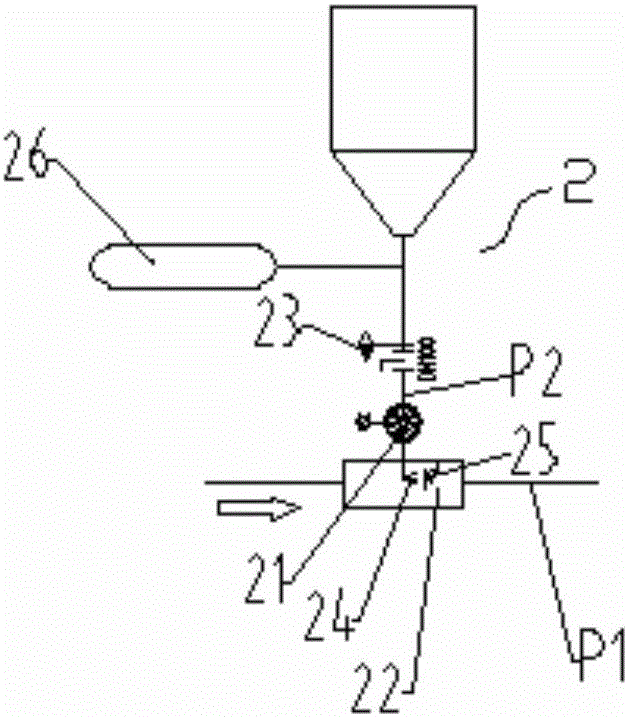

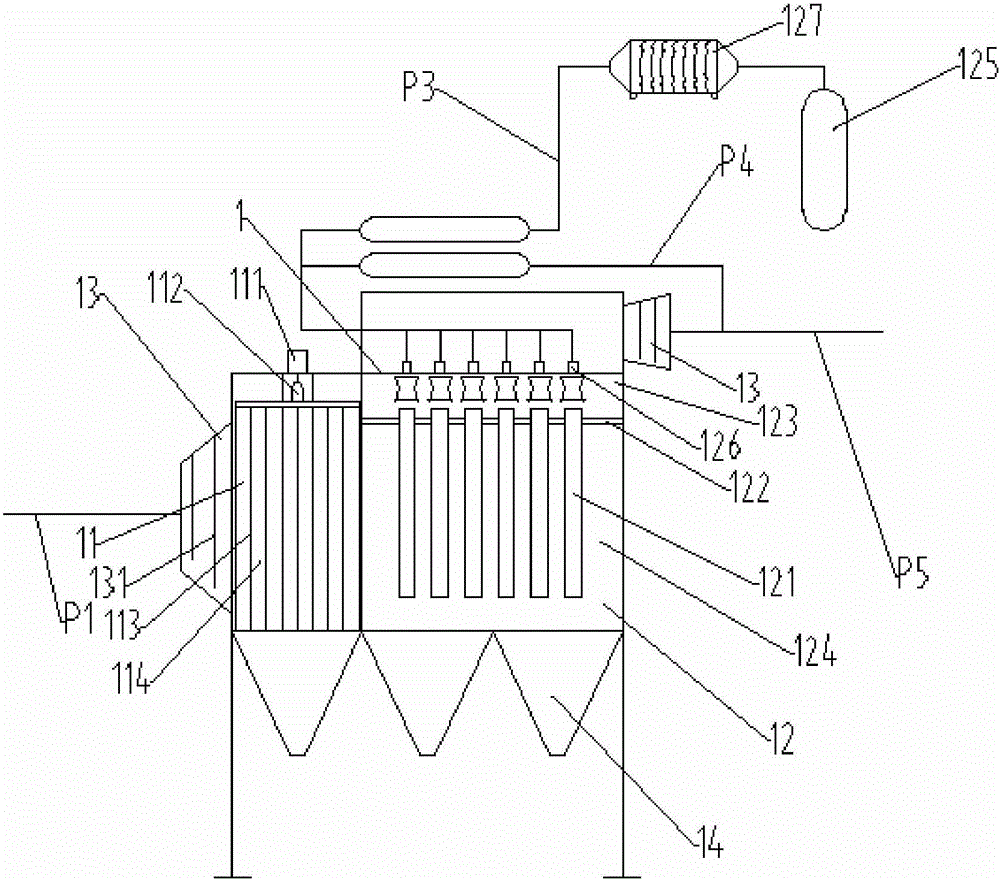

High-temperature smoke dust removal method and system

ActiveCN105749679AHigh filtration precisionReduce viscosityCombination devicesGas treatmentViscosityHot Temperature

The invention discloses a high-temperature smoke dust removal method and system. Before high-temperature smoke is sent into a dust remover, a hardening and tempering agent is added to the smoke to absorb SO3 in the smoke, the dust viscosity is reduced, and meanwhile, agglomeration and coagulation performance of fine particles in the smoke is improved. The adopted system comprises a waste heat boiler, smoke hardening and tempering equipment and an electric bag composite dust remover, wherein the waste heat boiler is connected with a smoke exhaust port of a glass kiln and used for heat exchange and cooling of the high-temperature smoke; a smoke inlet of the electric bag composite dust remover is communicated with the waste heat boiler through a first pipeline; the smoke hardening and tempering equipment is arranged on the first pipeline and used for adding the hardening and tempering agent to the high-temperature smoke in the pipeline; a smoke outlet of the electric bag composite dust remover is connected to a denitration reactor through a fifth pipeline. The hardening and tempering agent is sufficiently mixed with the smoke, dust removal treatment is performed in combination of the electric bag composite dust remover, the dust removal effect is remarkable, and damage of the high-temperature smoke to the dust removal equipment is reduced.

Owner:AEROSPACE KAITIAN ENVIRONMENTAL TECH CO LTD

Method for volatilizing and removing fluoride from aluminum electrolytic cell waste carbon material

ActiveCN105112938ALow roasting defluorination rateMeets the requirements for electrolytic anode carbon blocksHazardous substanceAdhesive

The invention relates to a method for volatilizing and removing fluoride from an aluminum electrolytic cell waste carbon material and belongs to the technical field of proposal and utilization of hazardous substances produced in the aluminum electrolytic process. The aluminum electrolytic cell waste carbon material containing fluorinated salt is crushed to 0.3-5mm, and an asphalt adhesive occupying one percent by mass of a powder material is added into the powder material which is smaller than 0.3mm so as to prepare 0.5-1mm pellets. The obtained material is introduced into wet air containing water, and is volatilized at 750-1100 DEG C for 1-2h so as to obtain volatile smoke containing fluorinated salt. The volatile smoke containing the fluorinated salt is blown into the air and burnt at 700-1050 DEG C, CO and HCN are thoroughly burnt, the burnt volatile smoke containing the fluorinated salt is cooled to a room temperature and then connected with a purifying device so as to obtain fluorinated alumina, the fluorinated alumina is used for aluminum electrolysis production, and the purified gas meets national GB28661-2012 emission requirements. The method for volatilizing and removing the fluorinated salt through utilizing the wet air containing water as carrying gas, provided by the invention, realizes the purpose of removing the fluorinated salt from a spent potliner carbon block containing the fluorinated salt.

Owner:KUNMING UNIV OF SCI & TECH

Method of harmlessly treating electrolytic manganese residue percolate

InactiveCN106186455AWide variety of sourcesSimple technologyWater contaminantsTreatment involving filtrationElectrolysisManganese

The invention discloses a method of harmlessly treating electrolytic manganese residue percolate, characterized by comprising the steps of 1), percolating electrolytic manganese residue percolate collected in a residue storage to obtain clarified filtrate; 2), adding saturated clarified limewater in a container of the clarified filtrate, and adjusting pH of a solution to 7.0-8.0 to obtain mixture A; 3), adding sodium silicate powder into the mixture A, and stirring for 1-2 hours to obtain mixture B, wherein a weight-volume ratio (g:mL) of the sodium silicate to the clarified filtrate of step 1) ranges from 1:150 to 1:200; 4), adding sodium chloride crystal into mixture B, and stirring to obtain mixture C, wherein sodium chloride concentration in the mixture C ranges from 200 mg / L to 250 mg / L; 5), adding a positive plate and a negative plate into a container of the mixture C, loading an electric field, and stirring for 3-4 hours to obtain the electrolytic manganese residue percolate that is harmlessly treated, wherein voltage of the electric field is 10-20 V.

Owner:CHONGQING UNIV

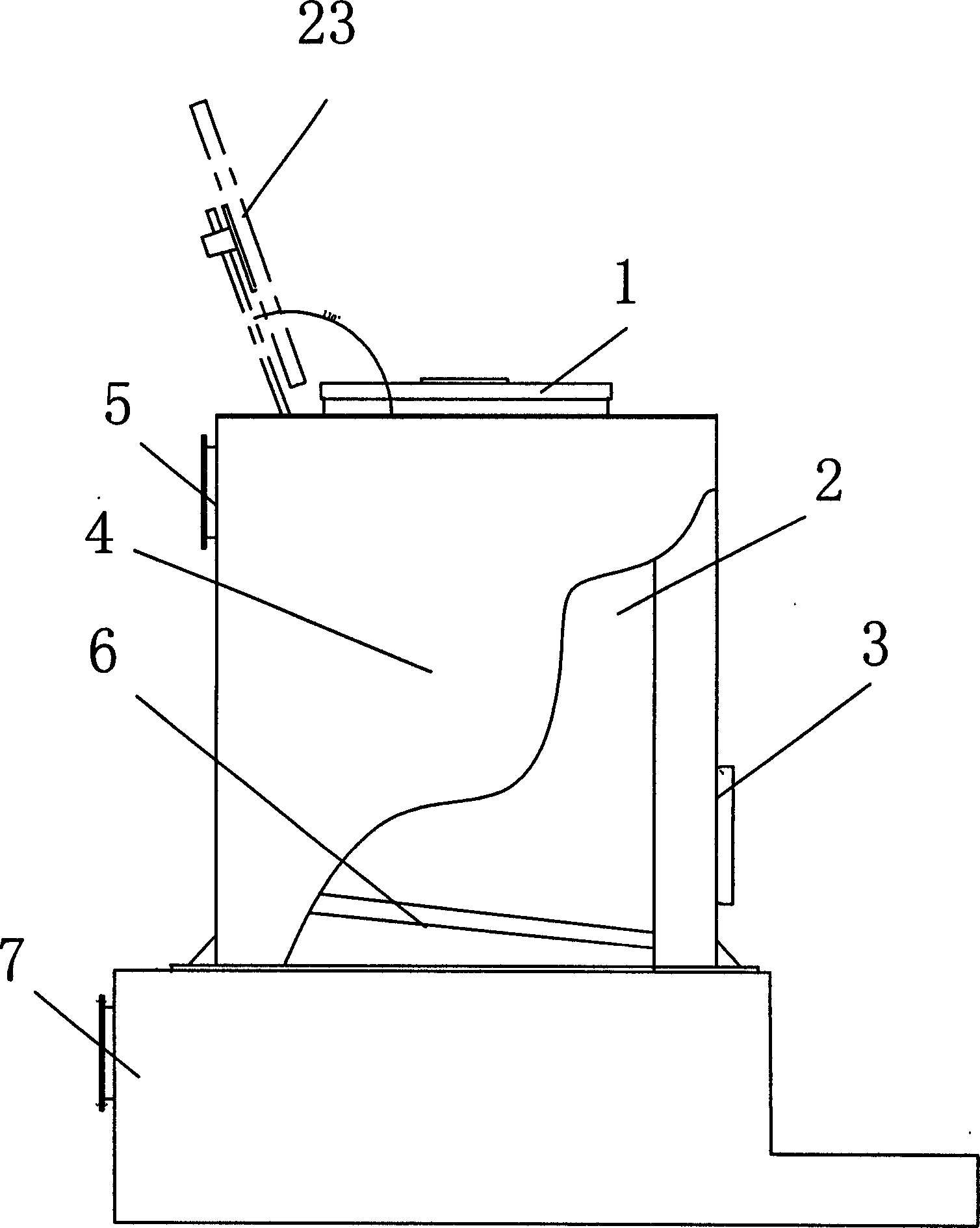

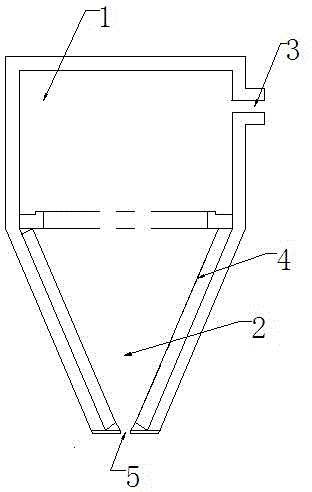

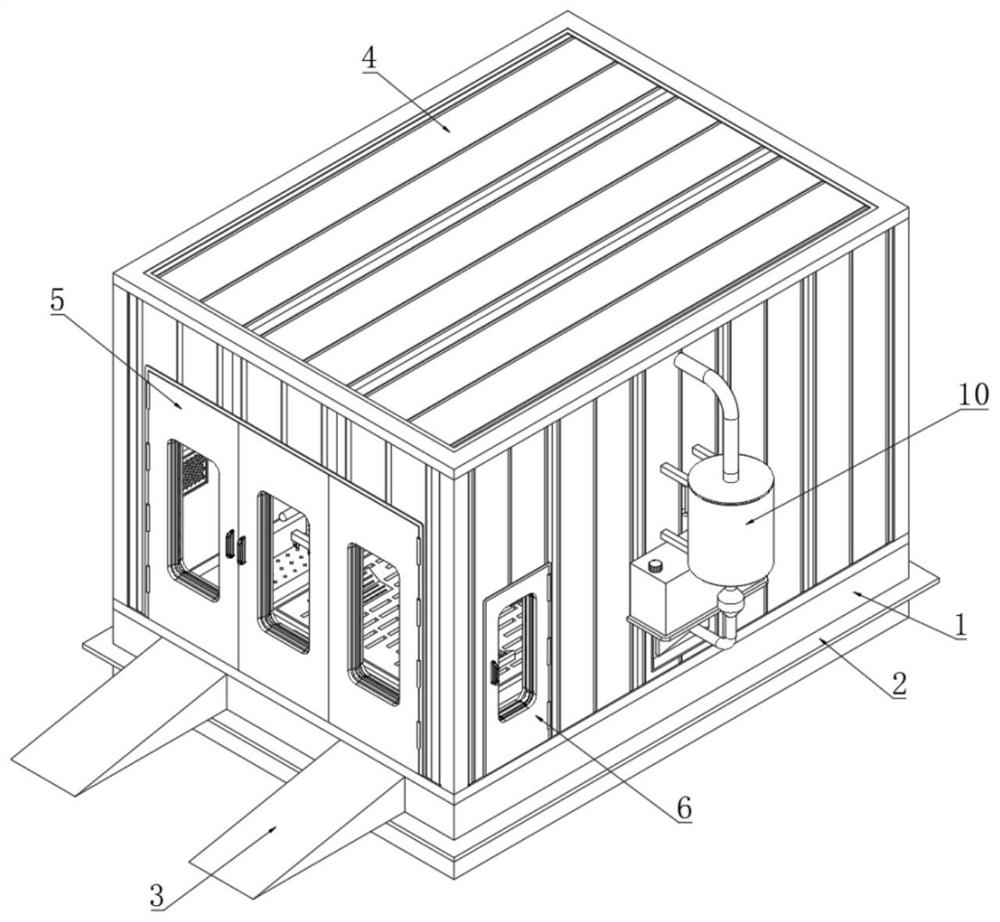

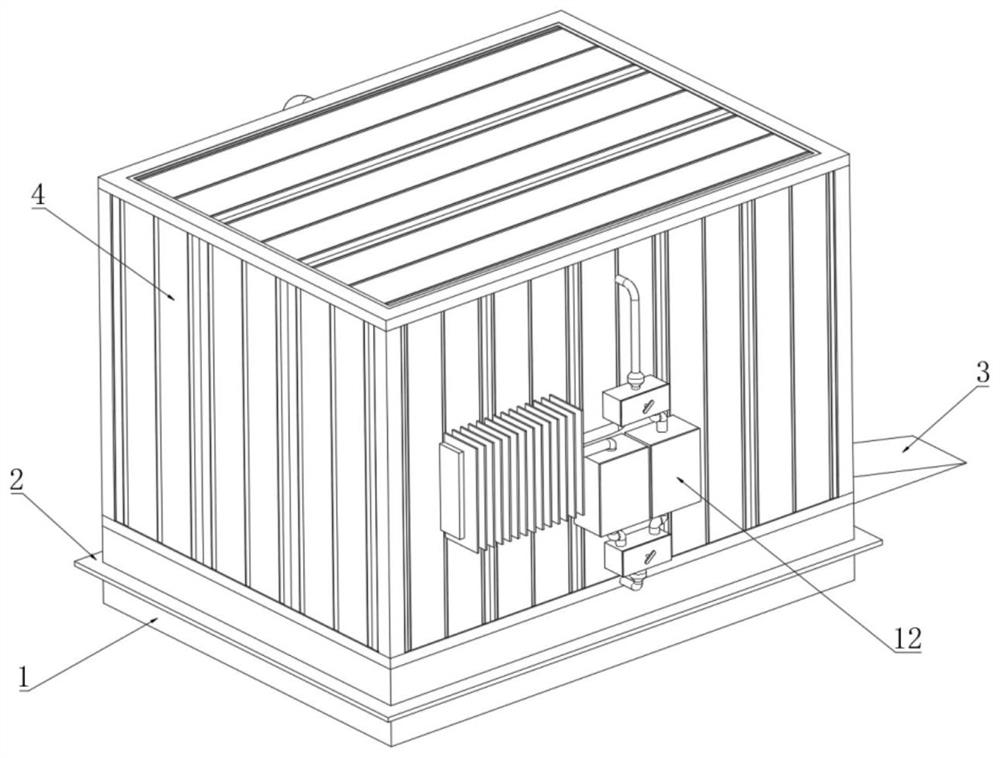

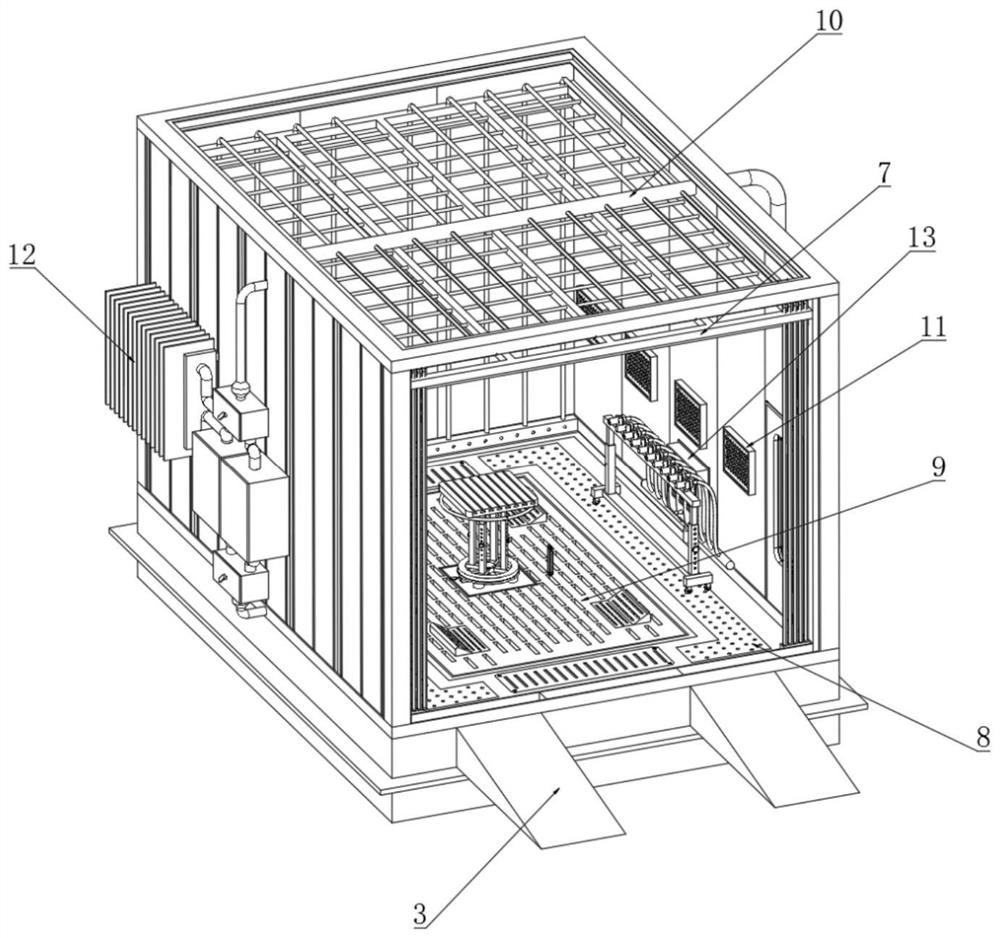

Garbage incinerator device using backfire method

InactiveCN1793731ARealize harmless treatmentRemove harmful ingredientsIncinerator apparatusCombustorCombustion chamber

The invention relates to a back-burning rubbish incinerator, comprising a furnace body provided with feed inlet and fume outlet, where the feed inlet is made in the upper part of the furnace body, the fume outlet is made in the bottom of the furnace and connected with a secondary combustion chamber through secondary fume inlet, the second combustion chamber is connected with a secondary combustor, and the fume outlet of the second combustion chamber is connected with a chimney; and the secondary combustion chamber mainly comprises secondary combustion hearth, secondary air feed pipe, combustion supporter interface and mixed fume flow stabilizing chamber, where the secondary combustor is connected with the secondary combustion hearth through the combustion supporter and the secondary combustion hearth is connected with the fume outlet of the secondary combustion chamber through the mixed fume flow stabilizing chamber. Its beneficial effects: 1. low operating expenses, needing no long time combustion supporting, and as long as starting ignition, automatic combusting; 2. applied to high-water content rubbishes and realizing fast drying; 3. converting rubbishes into gas for secondary combustion, saving secondary combustion expenses and able to eliminate harmful components from the fume, and realizing harmless processing of rubbishes.

Owner:徐顺宽

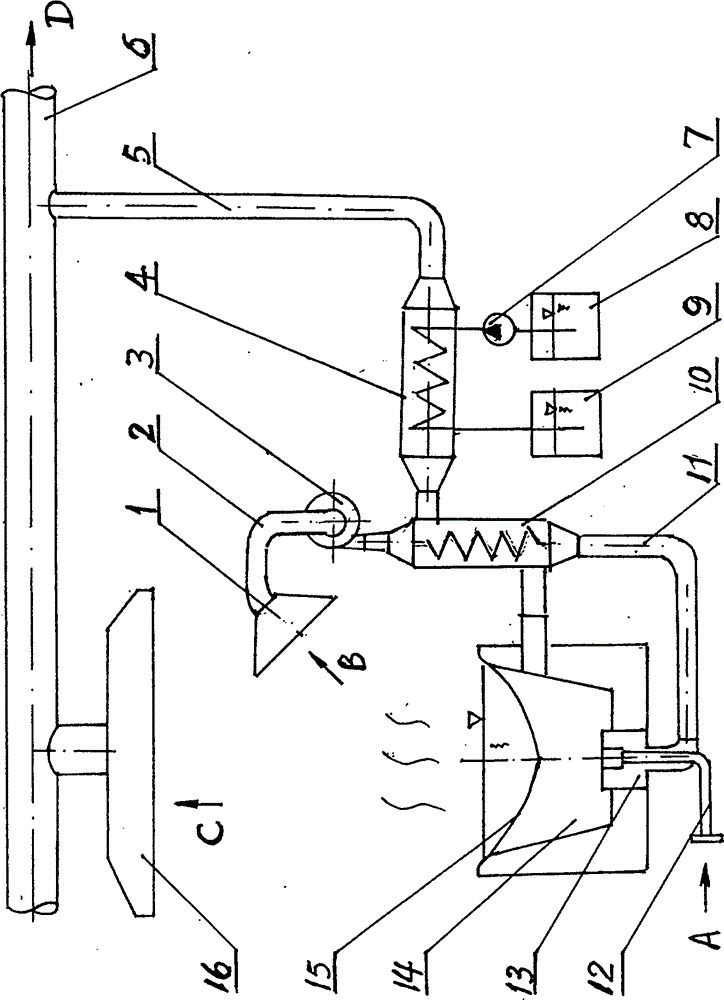

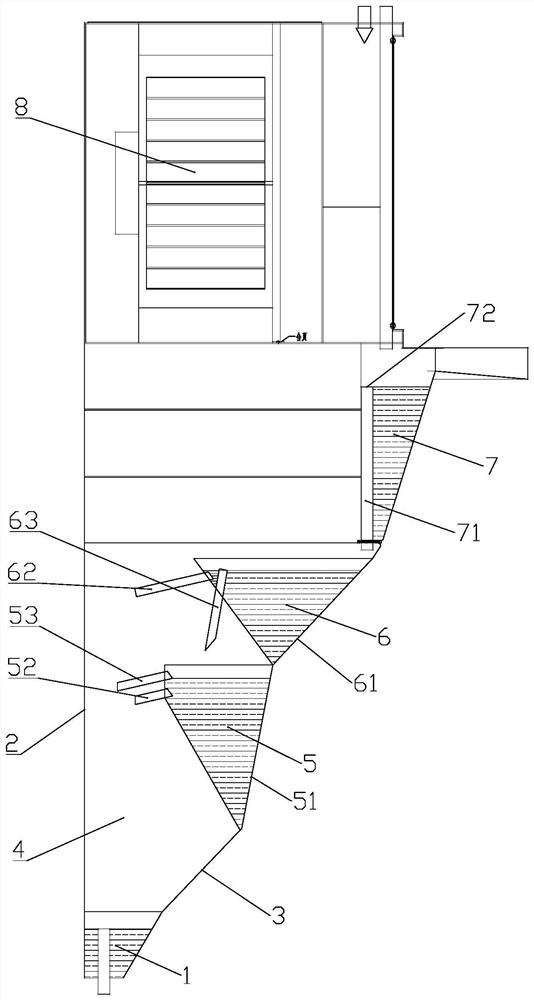

Coal powder injection mineral roasting device and technology

The invention discloses a coal powder injection mineral roasting device which comprises a furnace body, wherein the furnace body is divided into a preheating section, a roasting section and an air cooling section from the top down sequentially; a combustion chamber is arranged at the roasting section, and connected with a coal powder injection device; a smoke discharge port is formed in the preheating section; a circulation smoke inlet and a material outlet are formed in the air cooling section; a circulation air duct is formed between the smoke discharge port and the circulation smoke inlet; a directional pressure device is arranged on the circulation air duct; a feeding section is arranged at the top of the furnace body, and provided with an automatic sealing device; and a finished mineral collection section is arranged at the bottom of the furnace body. With the adoption of the mode of heating minerals through combustion of injected coal powder, the roasting and processing cost of the minerals is reduced effectively; in addition, smoke generated due to the combustion of the coal powder is treated circularly, so that the problem of pollutant emission is effectively solved; and energy conservation and environmental protection are facilitated.

Owner:QINGDAO ZHIBANG FURNACE DESIGN RES

Method for biologically fermenting kiwi fruit nutrient health-care wine

InactiveCN101633878AAdd flavorMaintain Nutrient EssenceAlcoholic beverage preparationFruit wineYeast

The invention relates to a method for biologically fermenting kiwi fruit nutrient health-care wine, comprising the following steps: preprocessing kiwi fruits by ethylene till ripening degree reaches 8-9; adopting a juice extraction method, i.e. combining a grinder and a centrifugal machine; carrying out clarification processing, i.e. adding edible gelatine and sodium bentonite to be combined; restraining the growth of germs by SO2; adding compound fruit wine yeast for fermentation; controlling the fermentation temperature from 16 DEG C to 22 DEG C, regulating the pH value to be about 3.4-4; and carrying out closed fermentation.

Owner:王怀能 +2

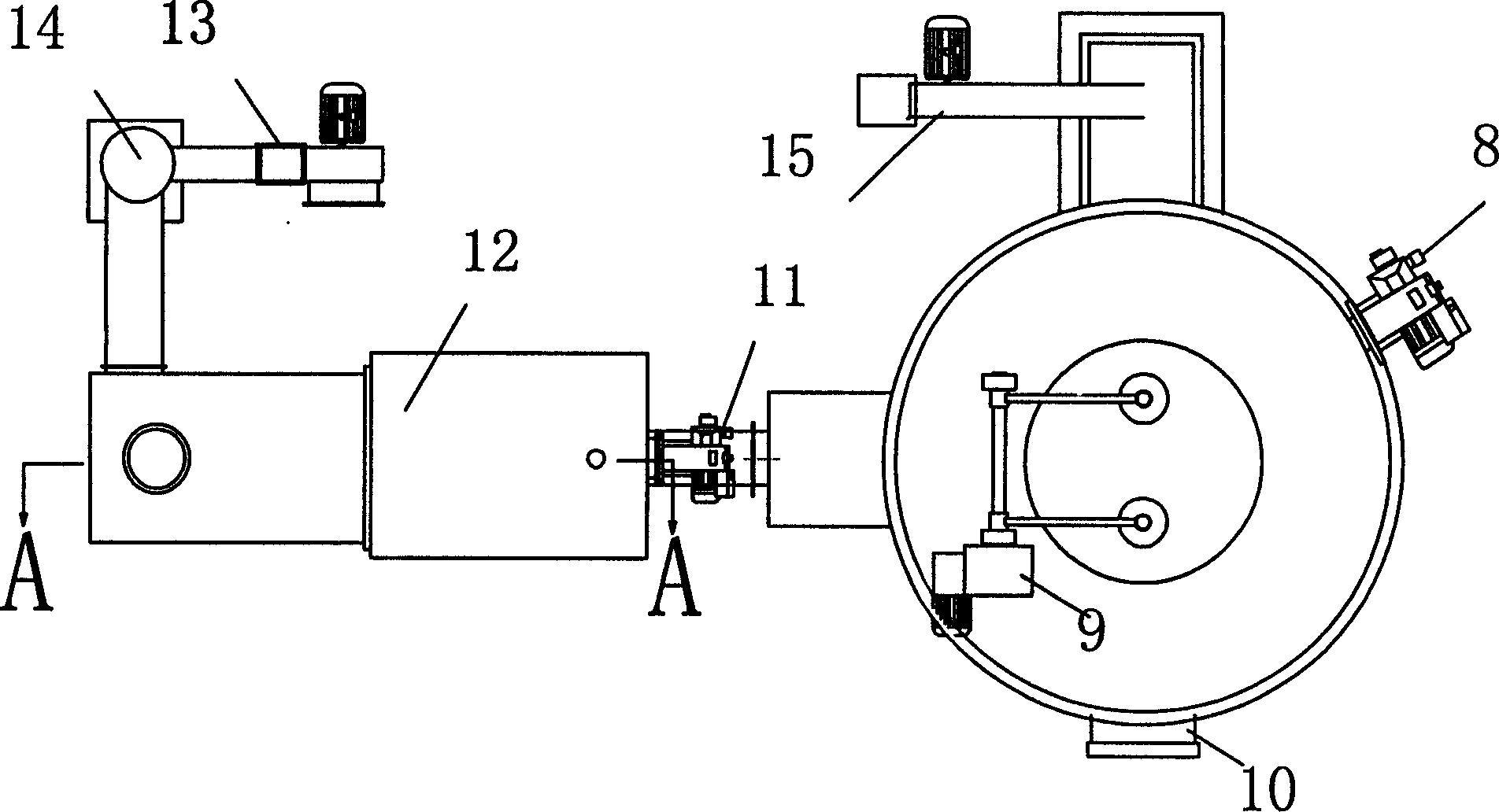

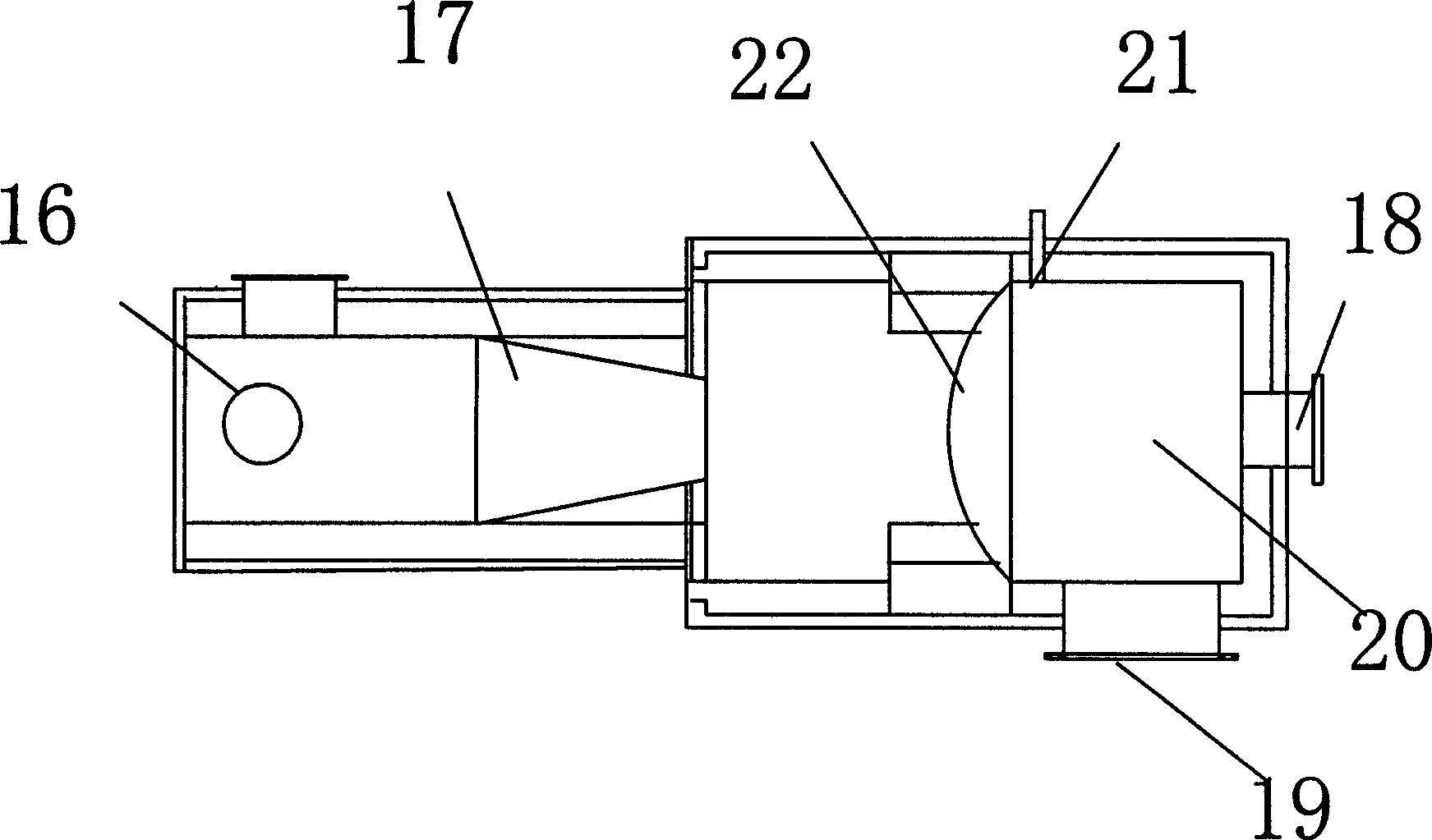

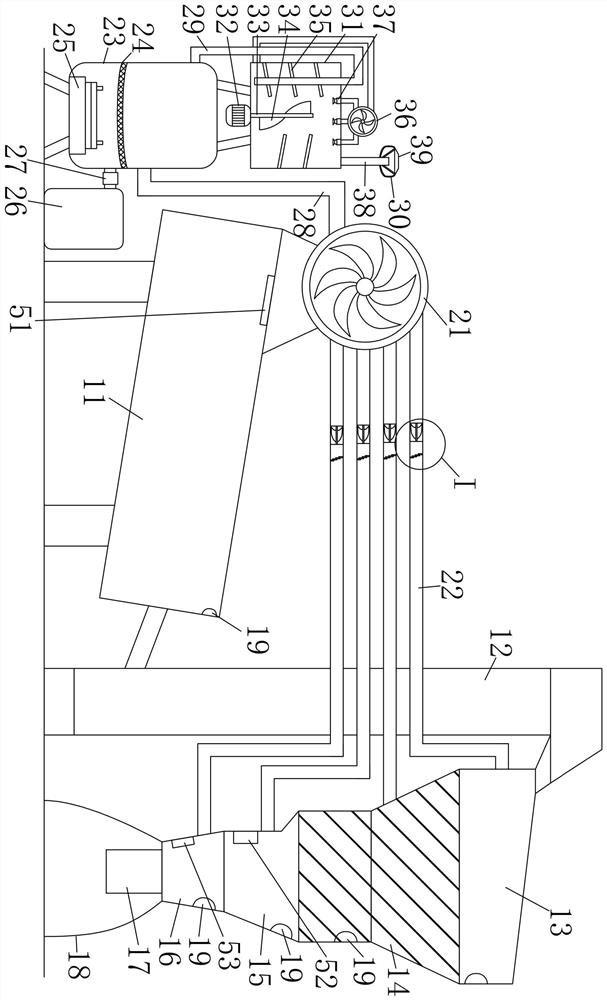

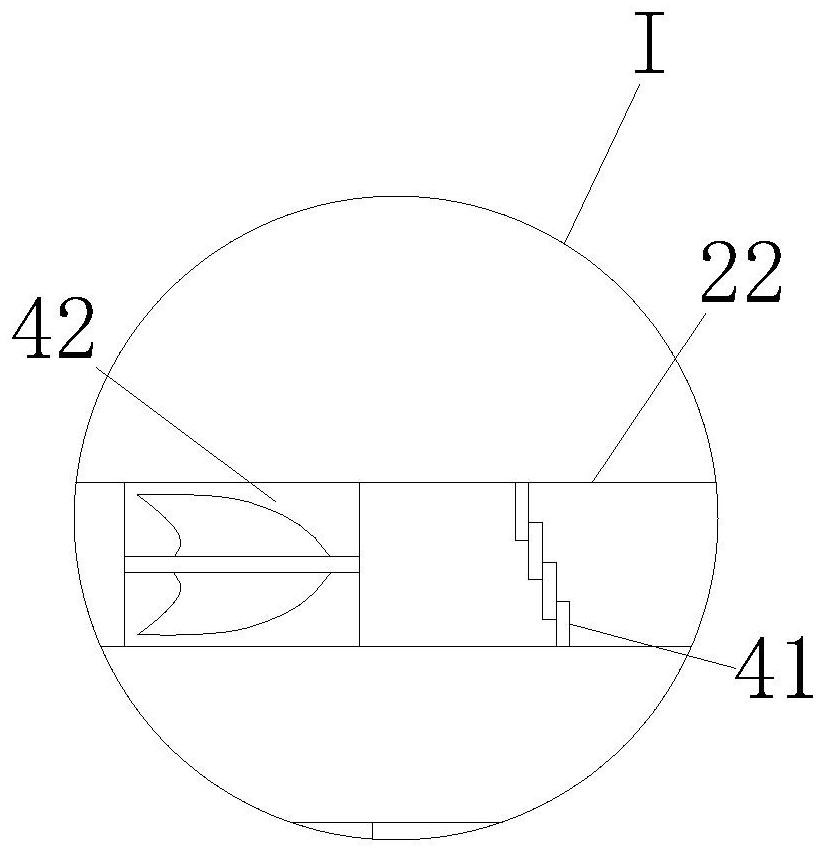

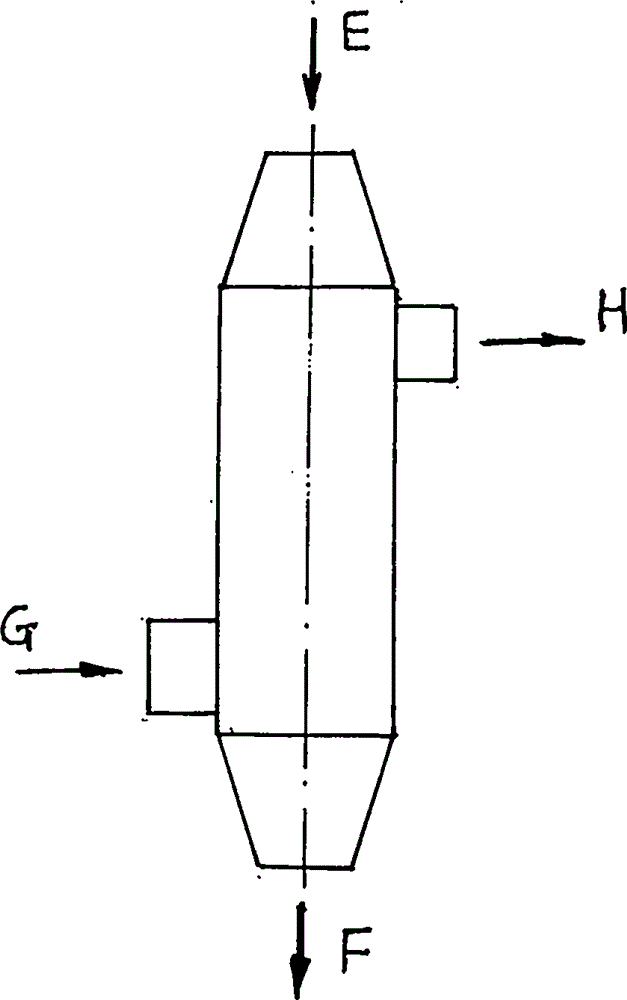

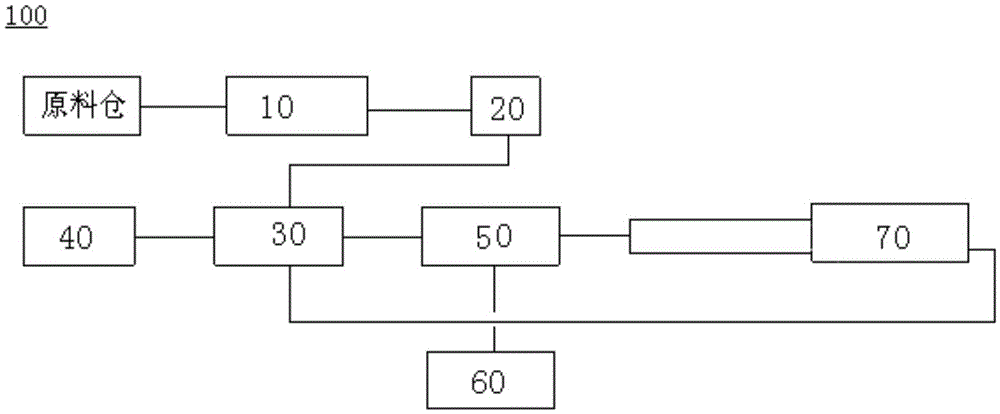

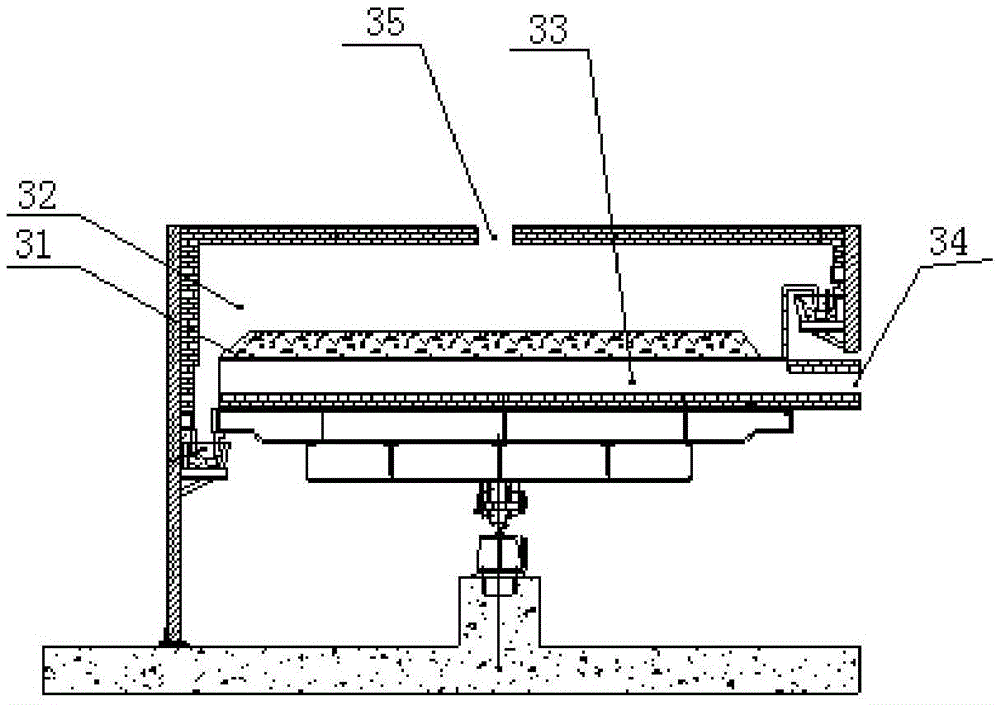

Waste tire pyrolysis system and pyrolysis method

ActiveCN104560100AImprove heating uniformityImprove pyrolysis efficiencyProductsReagentsProcess engineeringWaste tires

The invention provides a waste tire pyrolysis system and a pyrolysis method. The waste tire pyrolysis system comprises a spinning device, a crushing device, a rotating bed pyrolysis furnace, a pyrolysis solid processing device, a cooling and purification device, an oil storage tank and a regenerative rotary heat exchanger; the rotating bed pyrolysis furnace is suitable for performing pyrolysis treatment on pyrolysis raw materials; a rotatable feeding plate for containing the pyrolysis raw materials is arranged in the rotating bed pyrolysis furnace, and divides the rotating bed pyrolysis furnace into a pyrolysis chamber located above the feeding plate and a heating chamber located under the same, wherein the feeding plate is provided with multiple through holes for communicating the pyrolysis chamber with the heating chamber; the regenerative rotary heat exchanger is respectively connected with the cooling and purification device and a hot gas inlet of the rotating bed pyrolysis furnace, and is used for heating non-condensable gas and then performing pyrolysis treatment. Therefore, the waste tire pyrolysis system provided by embodiments of the invention can be used for performing pyrolysis on waste tires effectively.

Owner:SHENWU TECH GRP CO LTD

Jun porcelain wine bottle capable of improving mellowness of Baijiu and preparation method of Jun porcelain wine bottle

The invention relates to a Jun porcelain wine bottle capable of improving the mellowness of Baijiu and a preparation method of the Jun porcelain wine bottle. The Jun porcelain wine bottle is preparedfrom the following raw materials in parts by weight: blank materials: 20 parts of potassium feldspar, 10 parts of red feldspar, 10 parts of calcite, 10 parts of quartz, 3 parts of frit, 3 parts of copper oxide, 2 parts of tin oxide, 5 parts of Benshiyue and 3 parts of Nanpo hard soil (mainly containing silicon dioxide); outer wall glaze materials of a bottle body: 10 parts of melilite, 5 parts ofquartz, 2 parts of talcum powder, 5 parts of beef bone meal, 5 parts of fluorite, 0.5 part of copper ore, 6 parts of alkaline stone and 3 parts of Hunan Leiyang soil; inner wall glaze materials of thebottle body: 35 parts of Yushan red feldspar, 8 parts of calcite, 3 parts of meteorite powder, 10 parts of volcanic rock, 10 parts of medical stone, 1 part of zinc oxide and 2 parts of tin dioxide; the Jun porcelain wine bottle can release various beneficial mineral substances and microelements beneficial to human bodies and has very good social and economic benefits.

Owner:禹州市华盛钧窑有限公司

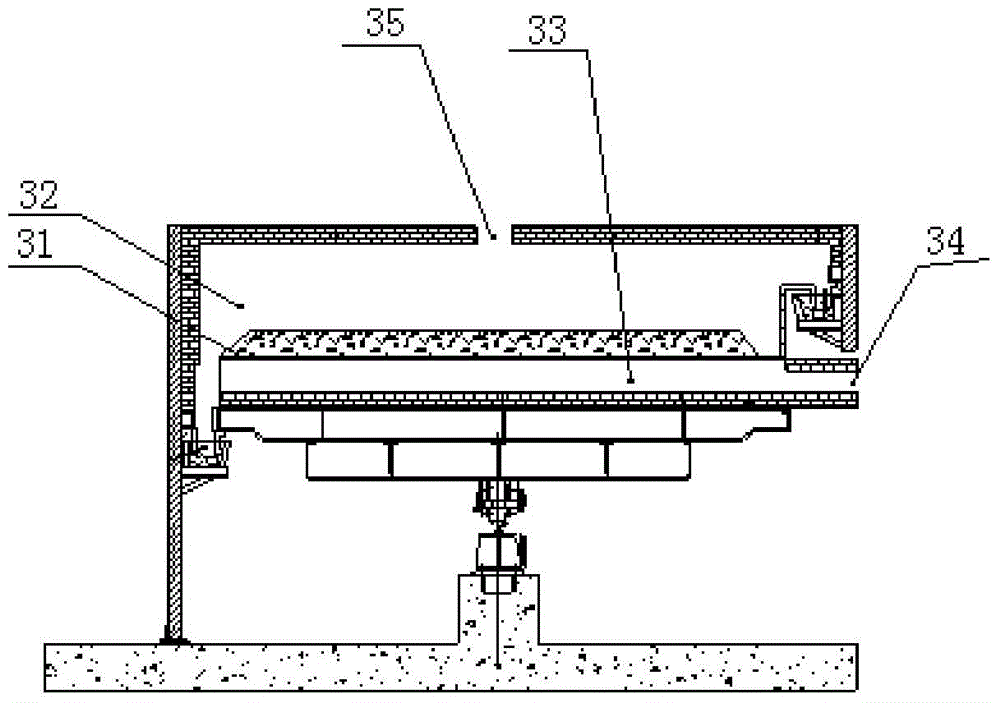

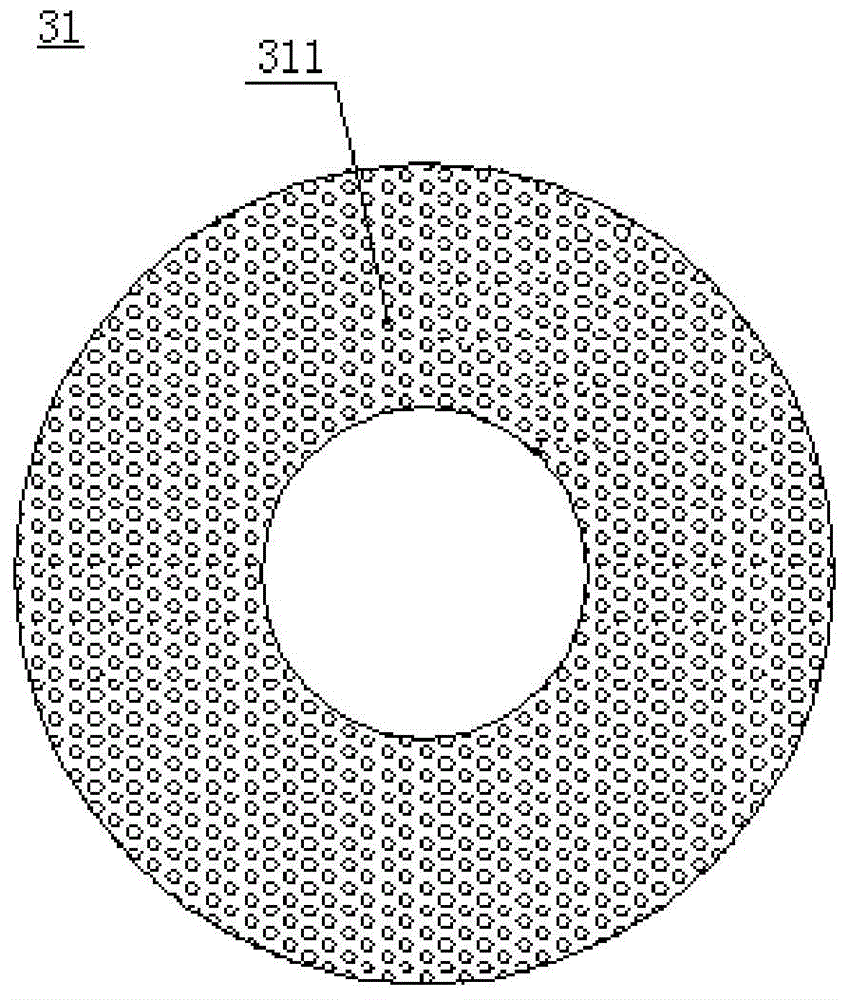

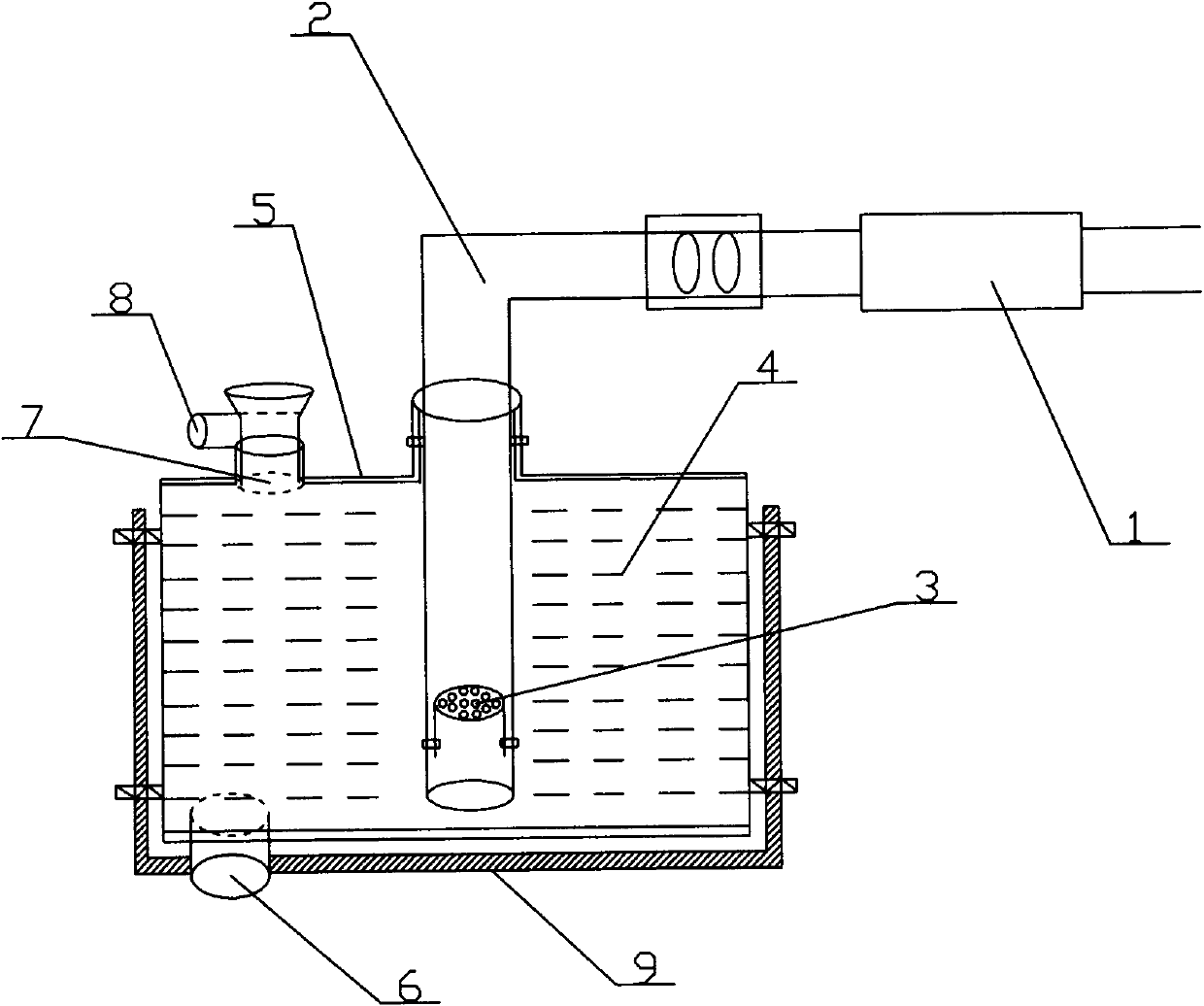

Environment-friendly facility for asphalt mixing plant

InactiveCN113235361APrevent water vapor ingressQuality is not affectedUsing liquid separation agentRoads maintainenceExhaust fumesFlue gas

The invention discloses an environment-friendly facility for an asphalt mixing plant, which belongs to the field of supporting facilities of asphalt mixing equipment and is characterized in that raised dust and waste gas in a screening bin, a metering bin, a mixing cylinder and a drying roller in the mixing plant are guided into a combustion cylinder for combustion treatment through a fan. After asphalt flue gas is combusted, harmful ingredients in gas can be eliminated, meanwhile, solid ash generated after combustible parts in dust are combusted settles on a dust isolation net of a combustion cylinder, waste gas generated after combustion enters a spraying cylinder, the spraying cylinder is filled with water, solid particles and water-soluble ingredients in the waste gas can be left in the water, the waste gas is subjected to secondary purification by water mist sprayed by the spraying head after floating out of the water, so that the waste gas and dust are fully removed. In addition, combustion cylinders are arranged among the spraying tank, the drying roller and the mixing plant, so that the influence on the quality of finished products caused by backward flowing of water vapor is effectively prevented.

Owner:广州市市政实业有限公司 +1

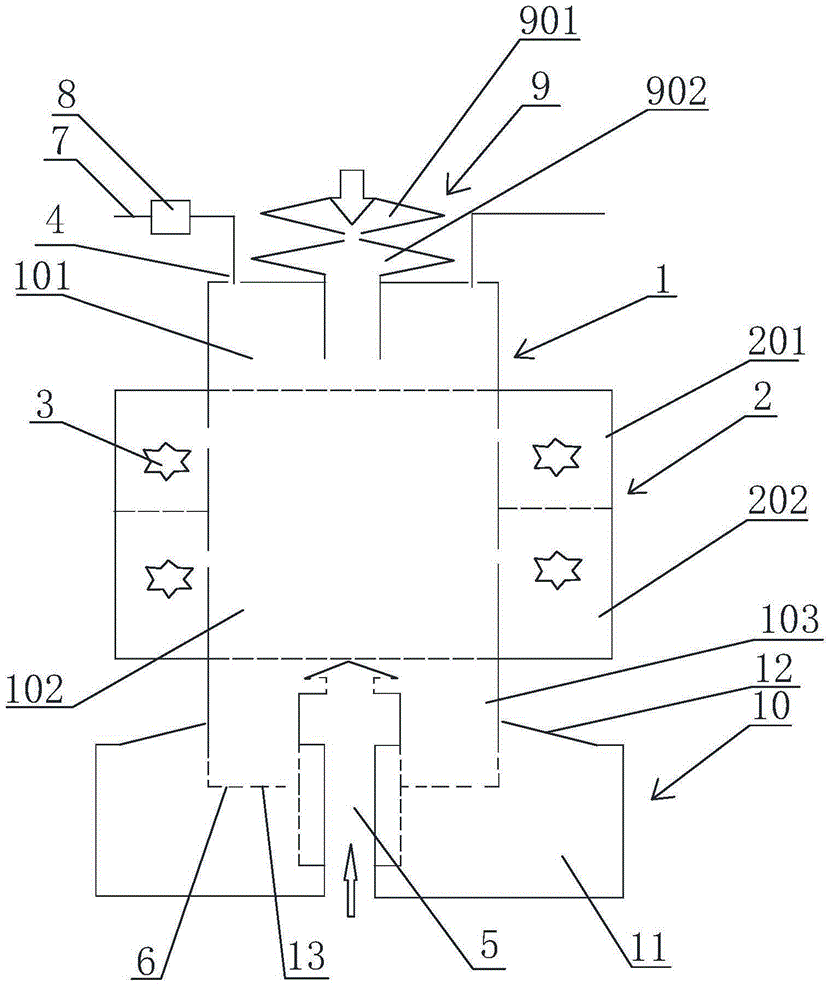

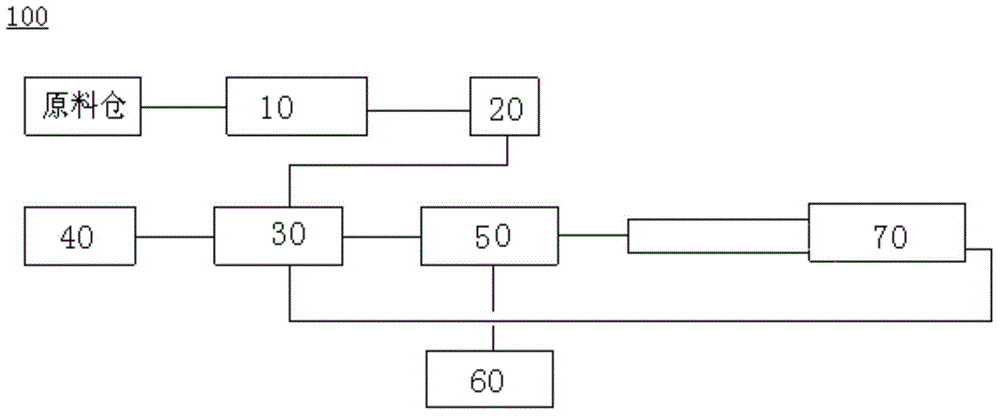

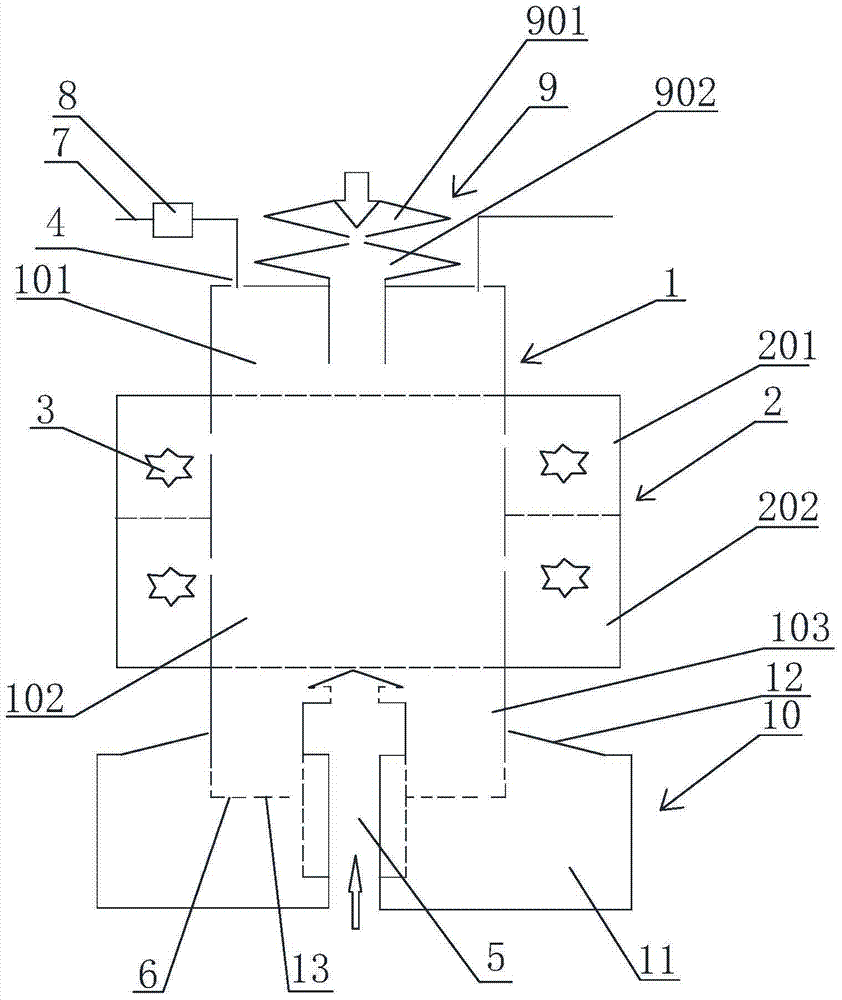

Innocent treatment process of domestic garbage

ActiveCN102716899AEffective handlingEffective resourcesSolid waste disposalGas turbine plantsEnvironmental engineeringOxygen

The invention discloses an innocent treatment process of domestic garbage. The process includes the following steps objectifying the domestic garbage, micro-nanometer oxygen bubble degrading, pyrolysis gasifying and recycling fuel gas to achieve zero emission of the domestic garbage. The innocent treatment process can effectively conduct innocent treatment and recycling on the domestic garbage, recycles energy in the garbage to the largest extent, achieves innocent treatment of the garbage, removes secondary pollution in the garbage treating process and achieves zero emission of the garbage treatment.

Owner:CHENGDU BRANCH TIBET GUOCE ENVIRONMENTAL PROTECTION TECH

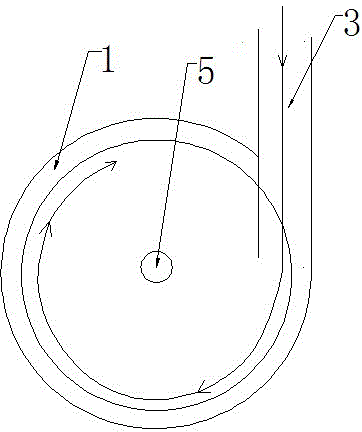

Energy-saving gas cooking stove

InactiveCN105605622AIncrease temperatureReduce consumptionDomestic stoves or rangesLighting and heating apparatusAir preheaterAtmospheric air

The invention provides an energy-saving gas cooking stove. The cooking stove comprises a large gas-collecting hood, a small gas-collecting hood, a centrifugal blower, a high-temperature air preheater, a low-temperature hot water heater, a cooking stove burner, a furnace, a water pump, a cold water tank, a hot water tank, a pan, a chimney, etc. The small gas-collecting hood collects an oil smoke gas mixture generated in a cooking process, the centrifugal blower absorbs the gas mixture, the gas mixture is sent to the high-temperature air preheater, high temperature flue gas discharged from the furnace heats the gas mixture, the gas mixture returns to the cooking stove burner, and the gas mixture and gas are mixed for combustion. Energy feedback technology is used for recycling waste heat of the cooking stove, so that energy saving effect is realized. The low-temperature hot water heater is arranged behind the high-temperature air preheater for continuously recycling unexhausted heat in the flue gas and generating hot water which is used for kitchen. A small chimney is connected to the low-temperature hot water heater, so that flue gas is sent to a main chimney by the small chimney and discharged to atmosphere. The cooking stove employs the oil smoke gas mixture as a gas combustion improver instead of air, and high temperature combustion ensures elimination of components which are harmful for human body in the oil smoke gas mixture, so that kitchen environment conditions are improved.

Owner:SHANGHAI ZIKANG ELECTROMECHANICAL NEW TECH RES INST

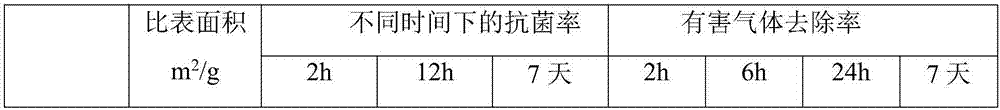

Activated carbon-based air conditioner filter cartridge and preparation process thereof

InactiveCN107569911ALarge specific surface areaWide variety of sourcesDispersed particle filtrationFiltration separationActivated carbonWater vapor

The invention relates to the technical field of automotive air conditioner components, and particularly relates to an activated carbon-based air conditioner filter cartridge and a preparation processthereof. A preparation method of the activated carbon-based air conditioner filter cartridge comprises the following steps: (1) placing leaves of liliaceous plant in a muffle furnace, feeding an inertia gas, drying at 100-160 DEG C for 2-24 h, heating up to 300-700 DEG C, calcining for 1-8 h to obtain activated carbon; (2) grinding Chinese herbal medicines into powder, screening by using a 200-mesh sieve, then mixing with the activated carbon in the step (1) uniformly, placing in water vapor at 100-150 DEG C for 30-120 min to obtain a mixture 1; (3) mixing a high polymer with the mixture 1 toobtain a mixed material; (4) curing and molding the mixed material to prepare the activated carbon-based air conditioner filter cartridge. According to the invention, the activated carbon is preparedby plant carbonization to realize wide source of raw materials and low preparation cost; the obtained activated carbon has a large specific surface area.

Owner:SHENZHEN WOHAISEN TECH CO LTD

Soap powder prepared from kitchen waste grease and preparation method thereof

InactiveCN111073779AReduce pollutionTake advantage ofFatty acids production/refiningFatty-oils/fats refiningActive agentOil phase

The invention discloses soap powder prepared from kitchen waste grease and a preparation method thereof. The soap powder is prepared from the following formula raw materials in parts by weight: 30-90parts of fatty acid, 10-40 parts of alkali and 1-20 parts of a surfactant. The fatty acid preparation method comprises the following steps: firstly, performing acid treatment on activated carbon, filtering, washing, drying, adding 0.5-12g of activated carbon into 100g of kitchen waste grease and uniformly mixing; heating to 85 to 95 DEG C, and stirring for 15 to 25 minutes; filtering after stirring is completed, and carrying out centrifugal separation on the obtained kitchen waste grease; adding water into the centrifuged kitchen waste grease, stirring and heating to 80-90 DEG C, and mixing; dropwise adding concentrated nitric acid until the pH value is 2-3, stirring for 35-45 minutes, and standing for layering to obtain an oil layer after the reaction is finished; washing the oil layer, and standing for layering to obtain an oil layer; and adding lipase, carrying out a reaction on a shaking table at a speed of 100-130 r / min and a temperature of 50-65 DEG C for 4-8 h, carrying out enzyme deactivation in boiling water for 10-20 min after the reaction is finished, and carrying out centrifugation to obtain an upper oil phase, and drying the upper oil phase to obtain the fatty acid extracted from the kitchen waste grease. The soap powder has the advantages of soap powder environmental protection, high low-temperature volume fraction, good fatty acid decolorization effect and high purity.

Owner:江西省金泰茶脂开发有限公司

Waste gas treatment device for printing

InactiveCN109569204AConvenient and effective collectionAvoid pollutionGas treatmentDispersed particle filtrationTreatment pondEnvironmental engineering

The invention discloses a waste gas treatment device for printing. The waste gas treatment device comprises a waste gas collection pipeline, a filter device, a treatment pond device and a gas purification device, wherein the waste gas collection pipeline is used for collecting waste gas generated in a printing process; the filter device comprises a filter box and a first filter screen plate; the treatment pond device comprises a treatment pond body, an upper top cover, a second filter screen plate, a water suction pump and a water spraying device; and the gas purification device comprises a base, a gas drying device, a third filter screen, a purification gas inlet pipe and a purification outlet. The waste gas treatment device is used for collecting the waste gas generated in the printing process; through arranging the filter device, the treatment pond device and the gas purification device, the waste gas is treated and then becomes clean gas which can be emitted; the waste gas is prevented from being directly emitted to cause pollution to surrounding environment and air; a harmful component in the waste gas is removed; and the waste gas treatment device is applicable to the waste gas treatment in the printing process.

Owner:安徽本色印刷有限公司

Automotive vehicle tail gas filtration purification and noise elimination system

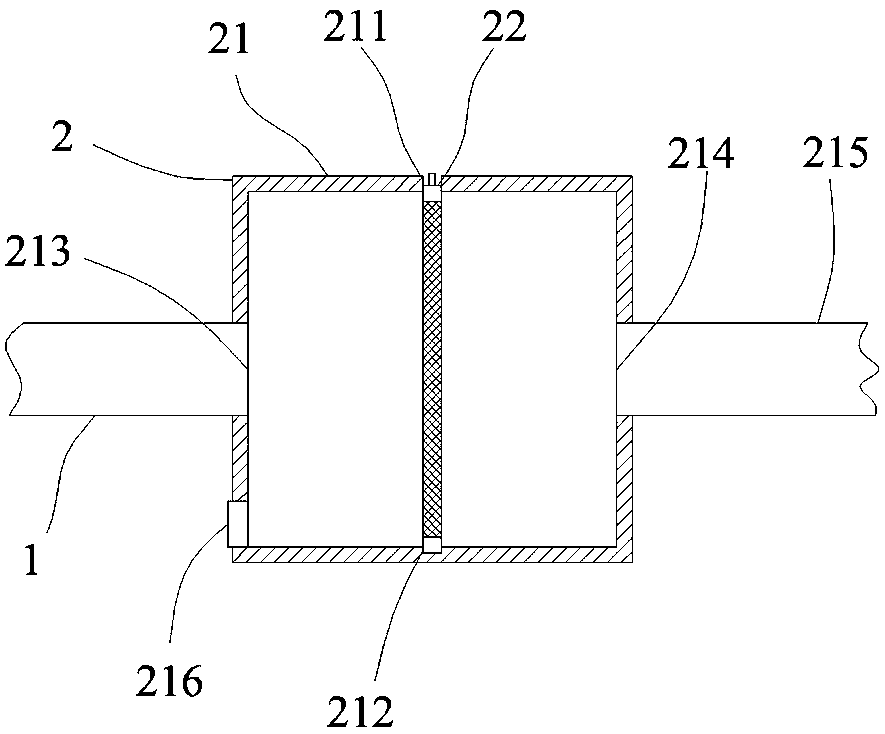

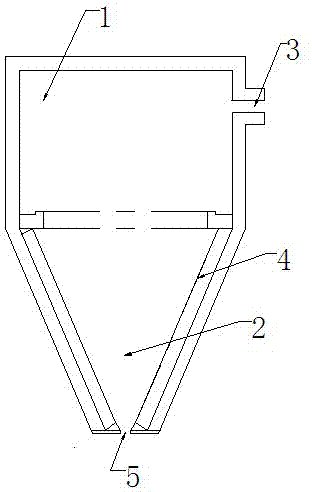

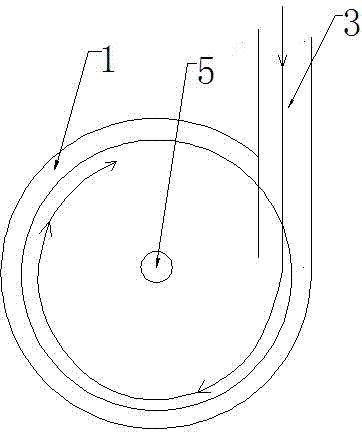

InactiveCN104420944AReduce pollutionRemove harmful ingredientsExhaust apparatusSilencing apparatusEcological environmentFiltration

The invention discloses an automotive vehicle tail gas filtration purification and noise elimination system which comprises a noise elimination device, a venting device and a purification device, wherein the noise elimination device is provided with a silencer; the venting device is provided with a vent pipe; the silencer is fixedly connected with one end of the vent pipe, and the other end of the vent pipe is fixedly connected with a stainless steel pressure-relief porous hole which is fixedly connected with the interior of a port of the vent pipe; the purification device is provided with a water trough; the water trough is provided with a water trough cover matched with the water trough, and the water trough cover is provided with a pipe communicating hole; an exhaust device comprises an exhaust port; the exhaust port is fixedly connected with the water trough cover and is internally provided with an exhaust pipeline matched with the exhaust port. According to the automotive vehicle tail gas filtration purification and noise elimination system, noise elimination is performed on automobile tail gas by use of the silencer, the automobile tail gas is introduced into the water trough and is filtered by use of water so as to eliminate harmful ingredients in the tail gas, so that the purposes of reducing noise pollution, alleviating automobile tail gas pollution, facilitating people and protecting the ecological environment are achieved.

Owner:戎瑞芝

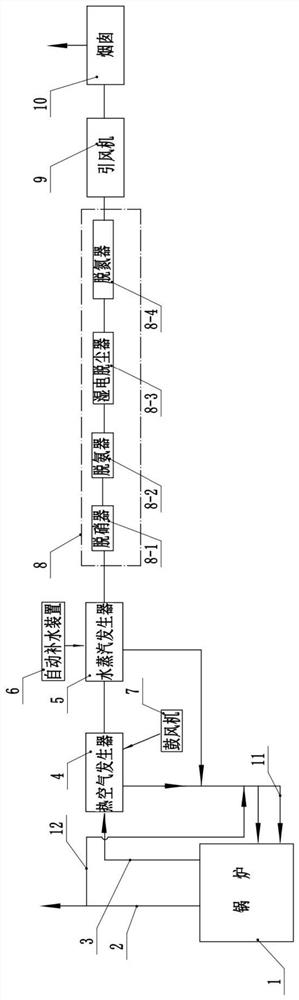

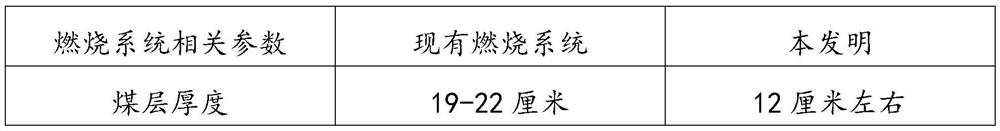

Coal fired boiler novel combustion system

InactiveCN111780151AIncrease contentIncrease oxygen contentEmission preventionDispersed particle separationAir blowerHeat consumption

The invention relates to a coal fired boiler novel combustion system. The coal fired boiler novel combustion system comprises a boiler and further comprises a steam outlet pipe and a flue which are connected with the boiler. The flue is connected with a chimney, and a pipeline between the flue and the chimney is provided with a hot air generator, a water steam generator, an air blower, a smoke treatment device and an induced draft fan. The hot air generator is connected with the air blower and an air inlet pipe of the boiler. The water steam generator is connected with the air inlet pipe of the boiler. The pipeline between the flue and the chimney is provided with the water steam generator, waste heat of smoke is utilized for converting water into the steam state from the liquid state, thewater steam is connected with the air inlet pipe of the boiler, and accordingly, the content of water steam in the boiler is increased. The water steam is used for adsorbing oxygen molecules in air,the oxygen content in the boiler is increased, sufficient combustion of fuel is guaranteed, accordingly, the oxygen content in smoke is reduced, and energy is saved; and waste heat of the smoke is utilized for heating air entering the boiler, and heat consumption of the boiler is reduced.

Owner:王苗苗

Polybasic and multifunctional liquid cement grinding aid and production technology thereof

The invention discloses a polybasic and multifunctional liquid cement grinding aid and production technology of the polybasic and multifunctional liquid cement grinding aid. The polybasic and multifunctional liquid cement grinding aid and the production technology of the polybasic and multifunctional liquid cement grinding aid are characterized by comprising the following raw materials of tri ethanol amine, polymerization polybasic alcohol and water. The raw materials comprise, by weight percentage, 60 percent of the tri ethanol amine, 20 percent of the polymerization polybasic alcohol and 20 percent of the water. The production technology comprises the following steps. Firstly, weighing is performed based on proportion, and the raw materials are prepared. Secondly, the water is heated to 80 DEG C by a boiler and put in a reaction kettle, the polymerization polybasic alcohol is added, and meanwhile, the reaction kettle is started for stirring for 20 minutes. The tri ethanol amine is then added and stirred for 3 hours and cooling is performed. Thirdly, after the solution is cooled, the solution is transferred into an end product jar, and production is finished. The liquid cement grinding aid is high in comprehensive use performance, plasticity protection performance of cement mixed plastic soil is improved, and the liquid cement grinding aid has good compatibility with a concrete high-efficiency slushing agent. Comprehensive performance of cement is improved, in addition, the production technology is simple, short in production time, and high in production yield.

Owner:GUIZHOU CHUZHI BUILDING MATERIAL SCI & TECH

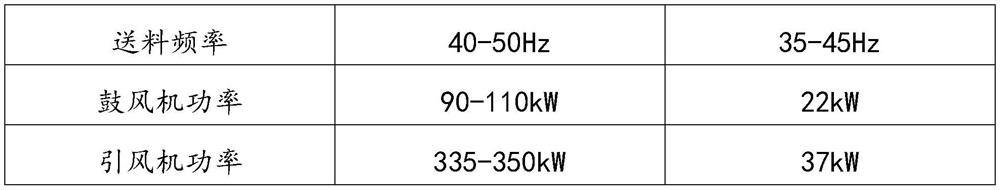

Regenerative flexible photosensitive resin plate

InactiveCN105467768ARemove harmful ingredientsPhotosensitive materials for photomechanical apparatusSolventSolubility

The invention relates to a regenerative flexible photosensitive resin plate. Currently, the flexible photosensitive resin plate is widely used for printing of carton boxes and flexible package printing material; generally, the flexible photosensitive resin plate is used for placing a negative image film with patterns or words on an unexposed flexible plate containing a photosensitive resin layer to be exposed with ultraviolet light; through ultraviolet irradiation, the solubility difference of solvents of a transparent part and an opaque part of the negative image film occurs, and a relief image containing the word patterns is obtained by cleaning and brushing; and the resin removed by cleaning and brushing is mixed in the solvent, the solvent is recycled through high temperature, and the resin and a part of solvent are abandoned as waste. Such waste resin is buried in the ground and cannot be rotten for hundreds of years, and a part of solvent also pollutes underground water and air; the waste resin reaches 30-50% of the purchase volume every year; and great harm is brought to the environment with the increasing use of the resin; and now the environmental protection department only charges environmental fees as a limitation way. The invention aims to protect the environment, waste resin pollution of the industry is prevented, the waste is utilized, and favorable economic benefit is achieved. The invention creates the flexible solid photosensitive resin plate using waste and old materials to produce and a preparation method of the flexible solid photosensitive resin plate.

Owner:王允慧

Self-degradable Jun porcelain wine bottle and preparation method thereof

InactiveCN107640960AEnhance activation andAvoid heating up too quicklyAlcoholic beverage preparationClaywaresIonCalcite

The invention relates to a self-degradable Jun porcelain wine bottle and a preparation method thereof. The self-degradable Jun porcelain wine bottle is prepared from the following raw materials in parts by weight: a blank material: 30 parts of a natural glaze stone, 20 parts of calcite, 15 parts of plant ash, 15 parts of copper ore, 6 parts of medical stone and 10 parts of agate; a glaze material:5 parts of beef bone ash, 5 parts of fluorite, 0.5 part of iron oxide red powder, 6 parts of alkaline ore and 3 parts of boundary stone soil. According to the self-degradable Jun porcelain wine bottle and the preparation method thereof, harmful components in traditional Jun porcelain can be removed, and the self-degradable Jun porcelain wine bottle is used for containing substances and can be used for activating wine molecules, decomposing harmful substances in wine, adsorbing the sharp taste in the wine and improving the activating effect of the wine; meanwhile, the self-degradable Jun porcelain wine bottle also can be used for adsorbing heavy metal ions in the wine, releasing various mineral substances and microelements beneficial to human bodies and degrading the harmful components inthe wine.

Owner:禹州市华盛钧窑有限公司

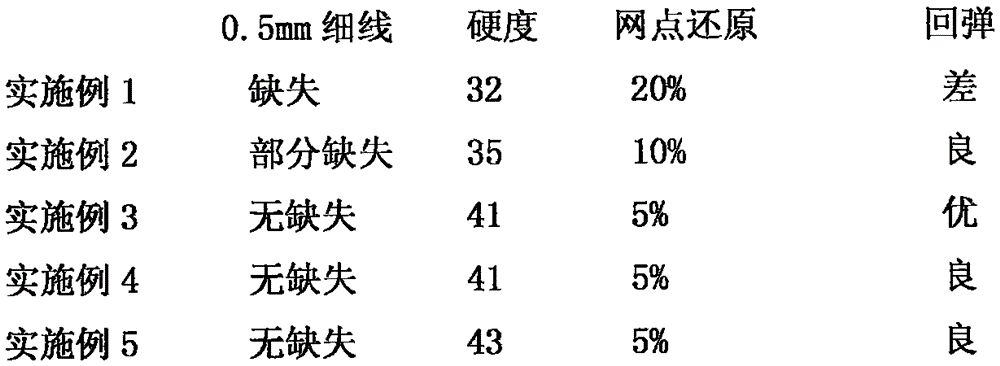

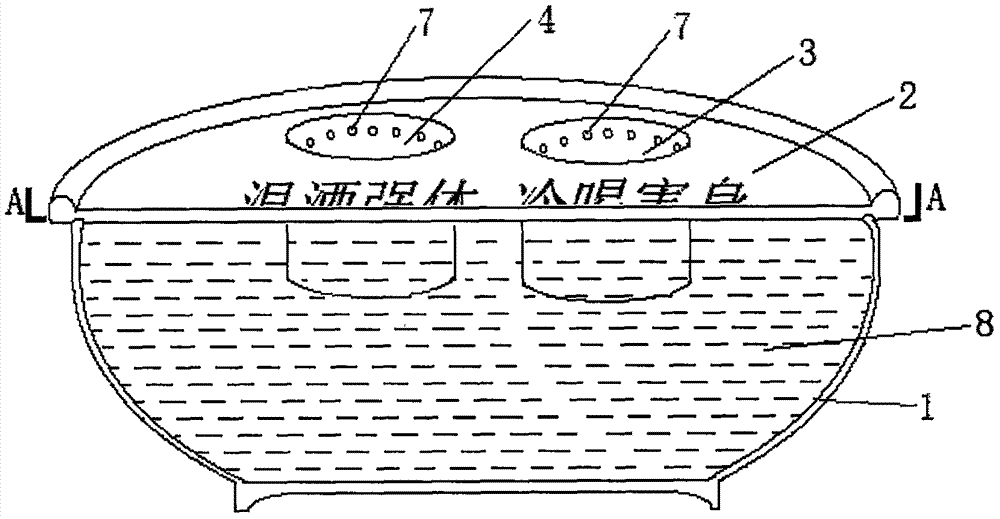

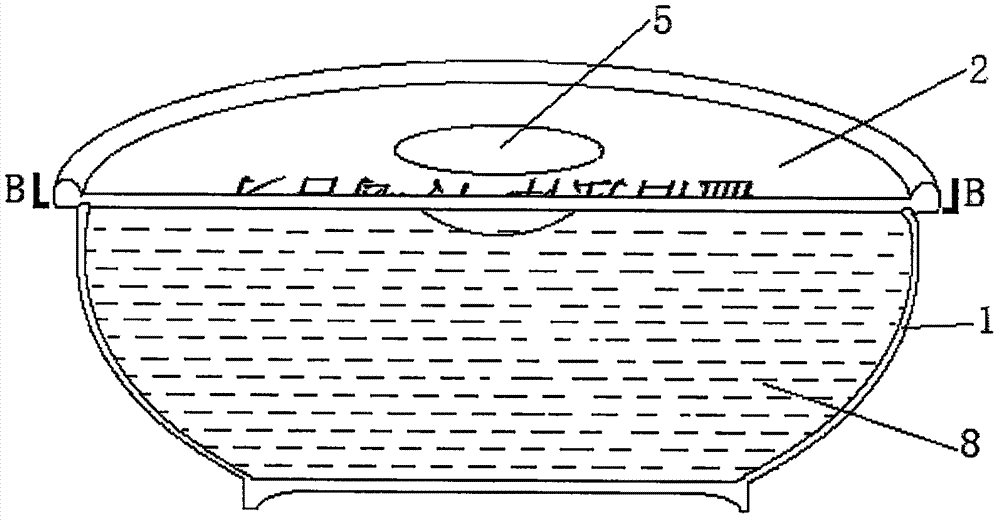

Wine plate

InactiveCN107960823AEliminate or reduce poisonReduce concentrationTable equipmentsEngineeringThermal water

The invention discloses a wine plate, which comprises a hot water pot, a countertop and an electric heater; the wine plate is characterized in that the countertop is arranged on the hot water pot; theelectric heater is arranged in the hot water pot; a first preheating groove, a second preheating groove and a dice pool are arranged in the countertop; characters 'Wenjiuqiangti, Lenghehaishen' in Chinese (warm wine can strengthen body, and cold wine can harm body) are arranged in the countertop; and hot gas holes are kept in the first preheating groove and the second preheating groove. The wineplate provided by the invention has the beneficial effects that warm wine can be continuously offered to guests elegantly no matter the wine plate is applied to large restaurants for broad people or used at home to entertain the coming guests; especially, by arranging the dice pool in the countertop, the guests can play an entertainment item, which belong to drinking games, conveniently; and withthe design of the characters 'Wenjiuqiangti, Lenghehaishen' in Chinese, an elegant demeanour of continuously promoting healthy wine culture is added. The wine plate provided by the invention is simplein structure; and the wine plate is convenient and practical when applied to the large restaurants for broad people and homes.

Owner:田文

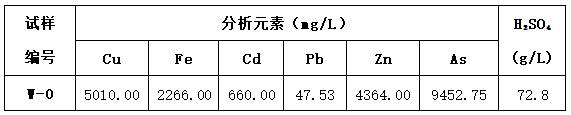

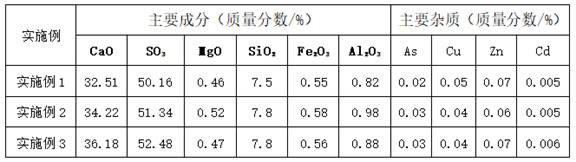

A kind of combined treatment method of arsenic-containing acid wastewater, red mud and carbide slag

ActiveCN109078962BRealize harmless useRemove harmful ingredientsSolid waste disposalCalcium/strontium/barium sulfatesSlagToxic industrial waste

The invention discloses a combined treatment method of arsenic-containing acidic wastewater, red mud and carbide slag, belonging to the technical field of industrial waste treatment and comprehensive utilization. The method comprises the following steps: firstly treating the red mud with arsenic-containing acidic wastewater to remove impurity and de-alkalization of the red mud to become a harmless environment-friendly building material or soil conditioner; The obtained gypsum slag does not contain arsenic and heavy metals, which is convenient for the comprehensive utilization of gypsum slag; finally, the wastewater is jointly treated with hydrogen peroxide, gypsum slag and red mud extract, so that the arsenic and heavy metals in the wastewater can be removed and discharged up to the standard. The invention is a simple and economical waste treatment method, which realizes the harmless comprehensive utilization of arsenic-containing acid waste water, red mud and calcium carbide slag.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

Innocent treatment process of domestic garbage

ActiveCN102716899BEffective resourcesRealize harmless treatmentSolid waste disposalGas turbine plantsEngineeringEnvironmental engineering

Owner:CHENGDU BRANCH TIBET GUOCE ENVIRONMENTAL PROTECTION TECH

A coal powder-injected mineral roasting device and process

Owner:QINGDAO ZHIBANG FURNACE DESIGN RES

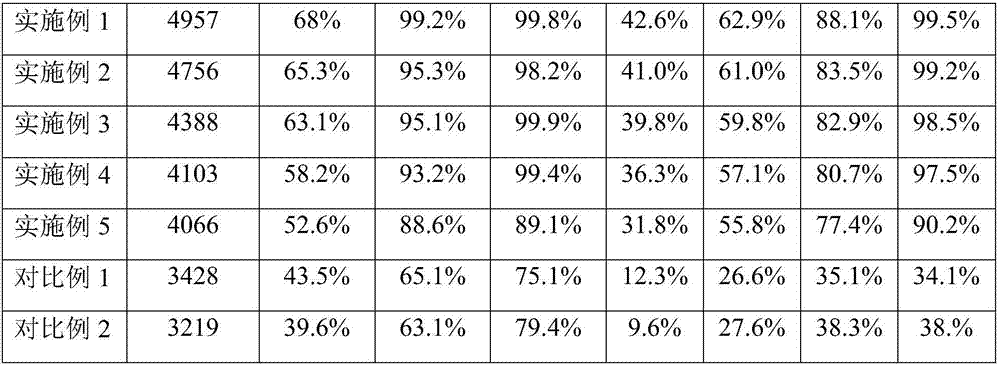

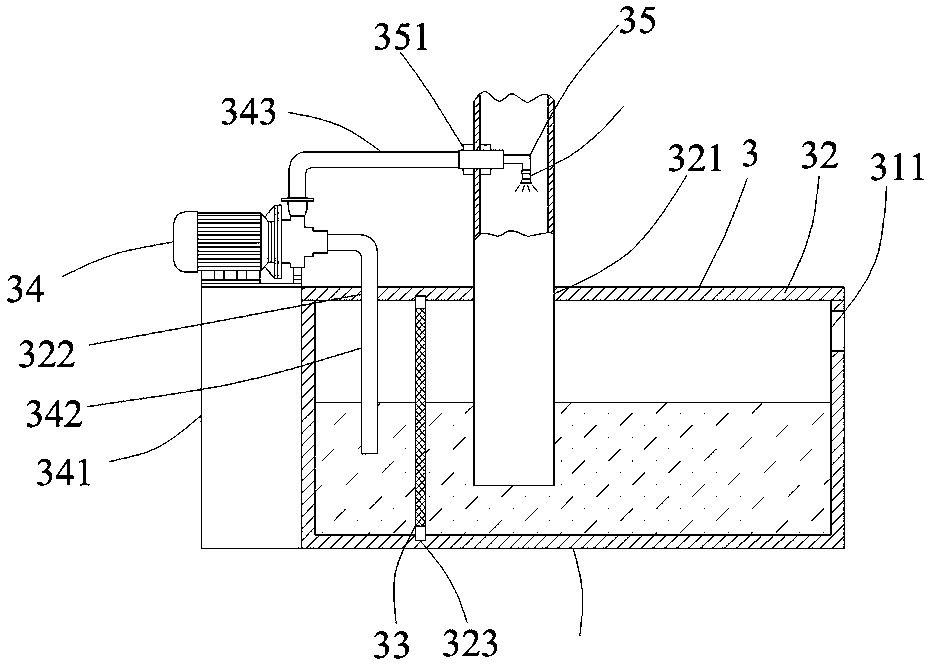

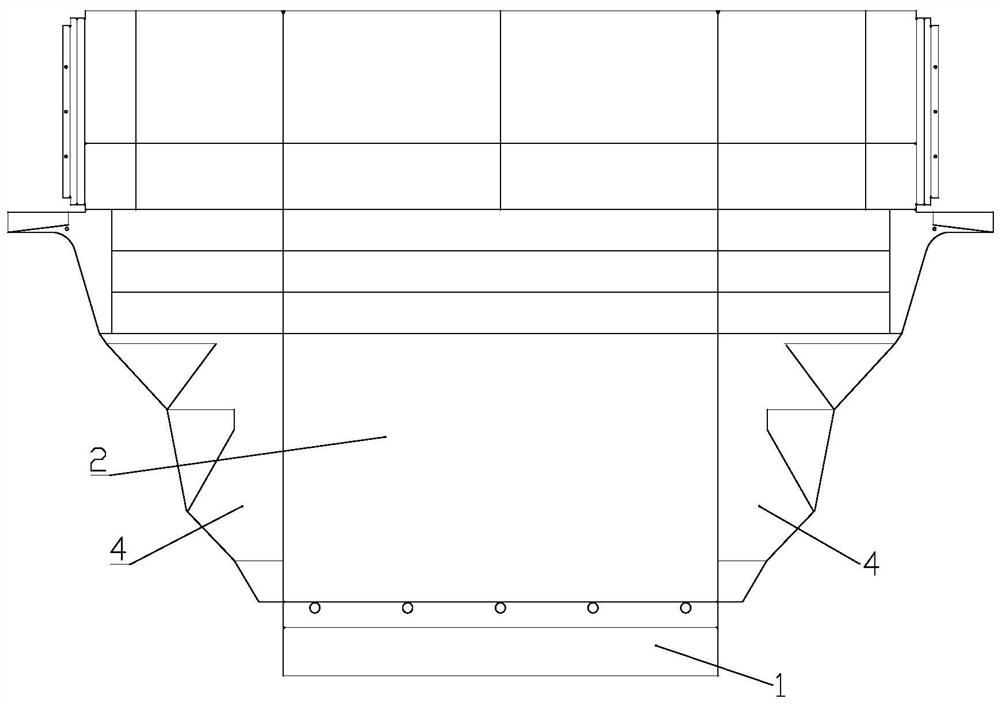

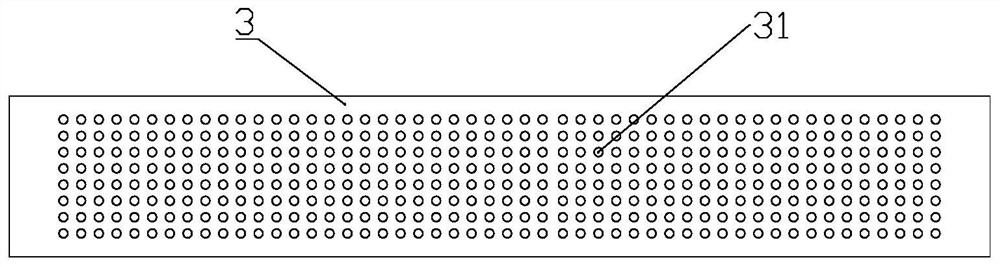

Power rotary purification device for smoke collecting demister and purification method

InactiveCN111974171AQuick and full accessPromotes fast and thorough mixingGas treatmentDispersed particle separationPurification methodsThermodynamics

The invention discloses a power rotary purification device for a smoke collecting demister. The power rotary purification device is characterized by comprising an oil collecting water tank, a rear plate, an air inlet pore plate and two side plates, wherein the two side plates are oppositely arranged and connected to the two sides of the rear plate and the air inlet pore plate, the oil collecting water tank is fixedly connected to the rear plate, and the air inlet pore plate and the lower sides of the two side plates form a bin body with the sealed lower portion; a fan is arranged in the bin body, the air inlet hole plate is obliquely arranged, and a plurality of air inlet holes are formed in the air inlet hole plate. The invention further provides a smoke collecting demister power rotary purification method suitable for the power rotary purification device of the smoke collecting demister, when the fan sucks gas and the gas passes through the air inlet hole plate connected with the upper side of the oil collecting water tank, negative pressure can be formed on the upper side of the oil collecting water tank, and water in the oil collecting water tank or water and other liquid for absorbing the purified liquid to upward flow in the air inlet hole plate so as to be rapidly and sufficiently mixed with the gas. A good absorption and purification effect can be achieved through rapidfusion of water and gas, and harmful ingredients and peculiar smells in the gas can be removed.

Owner:许廷杨

Environment-friendly full-degradable plastic and production method thereof

PendingCN111286210ARemove harmful ingredientsImprove structural strengthPolyvinyl alcoholPlasticizer

The invention relates to the technical field of plastic production, in particular to environment-friendly full-degradable plastic and a production method thereof. The environment-friendly full-degradable plastic is prepared from the following components in percentage by weight: 1-3% of konjak flour, 4-7% of flour, 0.2-0.4% of glycerol, 3-5% of quick lime, 0.8-1.2% of polyvinyl alcohol, and 0.3-0.6% of a plasticizer, with the balance being water. The invention further discloses the production method of the environment-friendly full-degradable plastic. The method comprises the following steps: crushing konjak by a crusher, proportionally weighing the konjak flour and the quick lime powder, adding water, putting the obtained mixture into a water bath kettle, heating, stirring, decocting intoa porridge form, putting the obtained mixture into a mixer, proportionally adding the flour, the glycerol, the polyvinyl alcohol and the plasticizer, uniformly stirring, and granulating in drying andgranulating equipment. The method is reasonable in process, can eliminate harmful components in the plastic, has the characteristics of easy degradation and environmental protection, and does not cause environmental pollution.

Owner:张红丽

Waste tire pyrolysis system and pyrolysis method

ActiveCN104560100BGuaranteed non-condensable gas calorific valueEvenly heatedProductsReagentsEngineeringProcess engineering

The invention provides a waste tire pyrolysis system and a pyrolysis method. The waste tire pyrolysis system comprises a spinning device, a crushing device, a rotating bed pyrolysis furnace, a pyrolysis solid processing device, a cooling and purification device, an oil storage tank and a regenerative rotary heat exchanger; the rotating bed pyrolysis furnace is suitable for performing pyrolysis treatment on pyrolysis raw materials; a rotatable feeding plate for containing the pyrolysis raw materials is arranged in the rotating bed pyrolysis furnace, and divides the rotating bed pyrolysis furnace into a pyrolysis chamber located above the feeding plate and a heating chamber located under the same, wherein the feeding plate is provided with multiple through holes for communicating the pyrolysis chamber with the heating chamber; the regenerative rotary heat exchanger is respectively connected with the cooling and purification device and a hot gas inlet of the rotating bed pyrolysis furnace, and is used for heating non-condensable gas and then performing pyrolysis treatment. Therefore, the waste tire pyrolysis system provided by embodiments of the invention can be used for performing pyrolysis on waste tires effectively.

Owner:SHENWU TECH GRP CO LTD

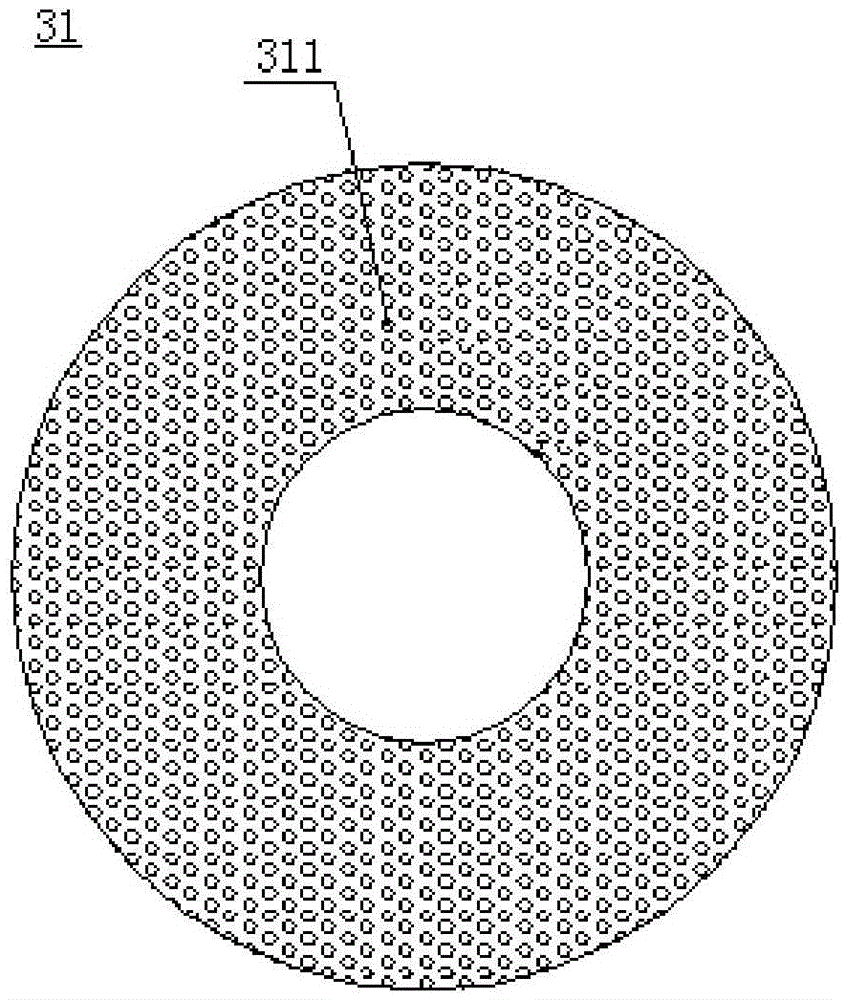

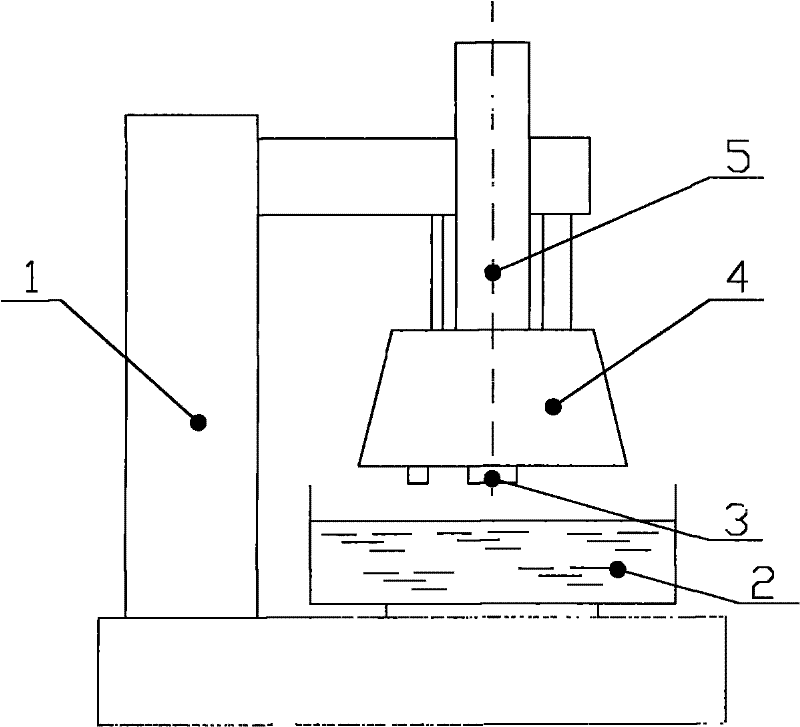

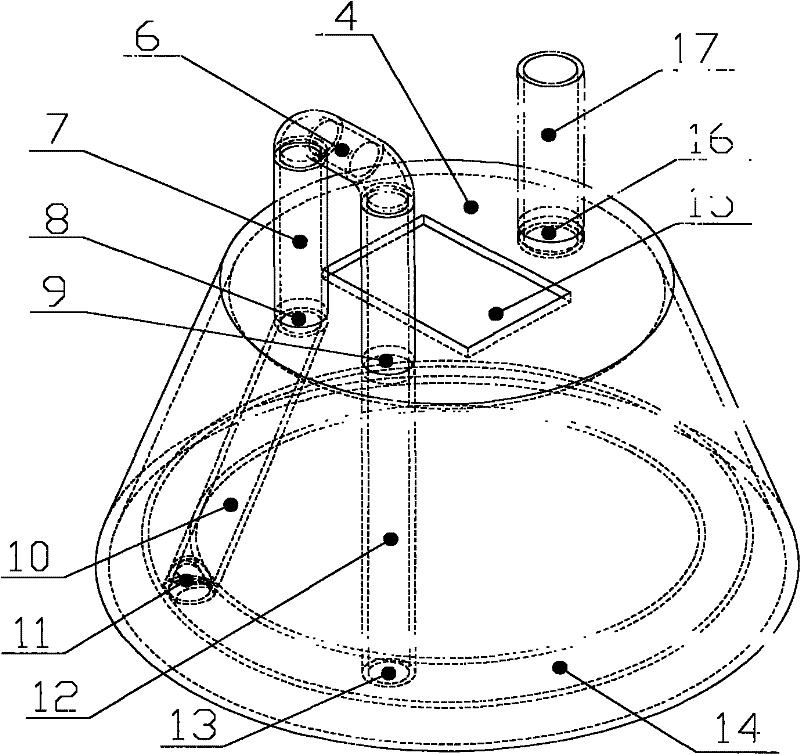

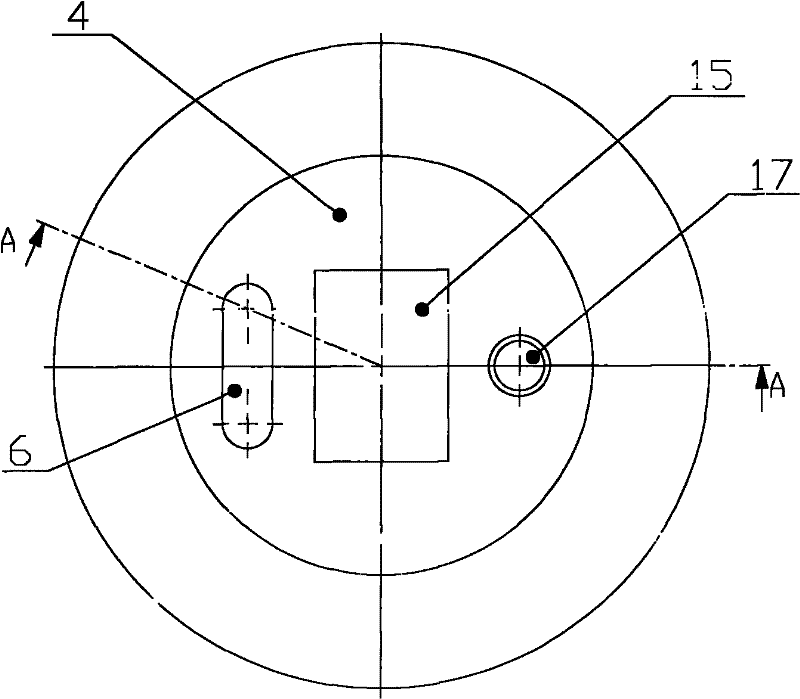

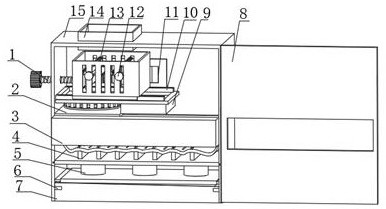

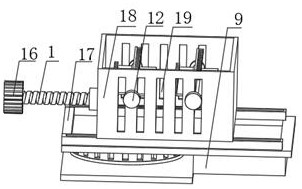

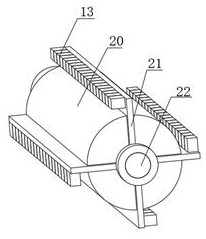

Main spindle hood of electric spark moulding machine

InactiveCN102009236BGuarantee processing qualityRemove harmful ingredientsAdditive ingredientEngineering

The invention discloses a main spindle hood of an electric spark moulding machine, comprising a main spindle hood body, a connecting pipeline, a medium purifying channel, a medium downlink channel upper port, a medium uplink channel upper port, a medium downlink channel, a medium downlink channel lower port, a medium uplink channel, a medium uplink channel lower port, an annular oil screen spraying channel, a main spindle connecting hole, a smoke purifying channel port and a smoke purifying channel. The main spindle hood of the electric spark moulding machine can circularly purify the electric spark processing media so as to guarantee the processing and moulding quality; and simultaneously an enclosed oil screen is formed in the moulding and processing region of the electric spark, and the harmful smoke generated by processing can be collected and purified through a smoke purifying port so as to eliminate the harmful ingredients in the discharged air, thus realizing green manufacturing.

Owner:ZHEJIANG UNIV +2

Orthopaedic removed waste gypsum refining treatment device

PendingCN112762457AEasy to crushSmooth and even deliveryIncinerator apparatusGrain treatmentsBandageOrthopaedic department

The invention belongs to the technical field of orthopedics department, and particularly relates to an orthopedic removed waste gypsum refining treatment device. As for the problem that an existing device cannot remove flammable impurities and harmful components, the invention puts forward the following scheme: the orthopedic removed waste gypsum refining treatment device comprises a working box, the front surface of the working box is rotatably connected with a sealing cover through a rotating shaft, and a material inlet is formed in the top of the working box; a heating plate is fixedly installed in the working box and located directly below the material inlet, a heating box is fixedly installed at the bottom of the heating plate, sliding rails are fixedly installed on the two sides of the top of the heating plate, a combustion box is slidably connected into the sliding rails, a suction opening is formed in the surface of the combustion box, and an adjusting rod is fixedly mounted on one side of the combustion box through a bearing. Flammable impurities such as bandages and residual drugs in orthopaedic waste gypsum can be burnt, harmful ingredients are removed, and the device can effectively recycle the waste gypsum conveniently.

Owner:刘永轩

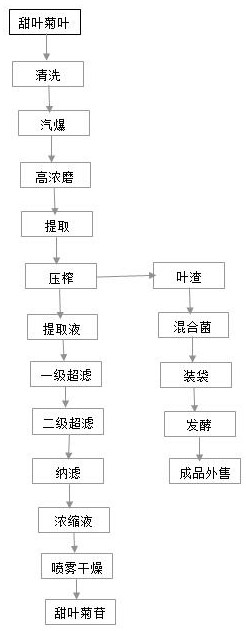

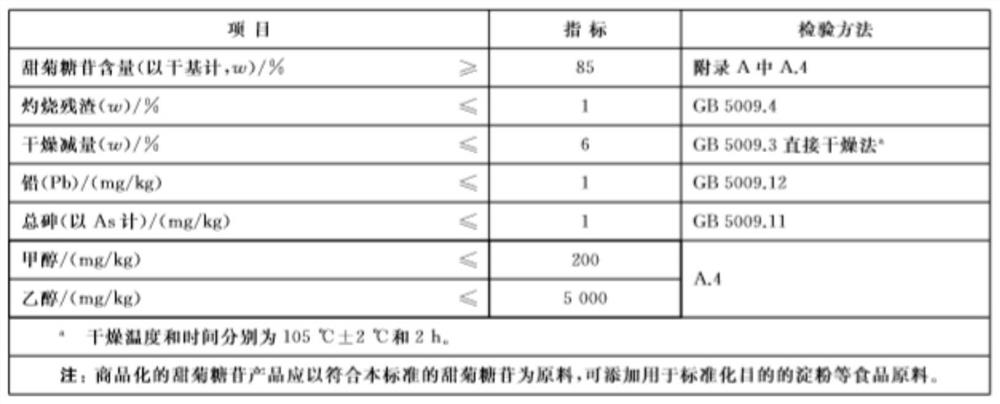

A preparation process for extracting stevioside and fermented feed through steam explosion treatment of stevia rebaudiana

ActiveCN110041385BReduce internal diffusion resistanceImprove dissolution efficiencySugar derivativesFood processingBiotechnologyHigh concentration

The invention belongs to the field of plant extraction, and specifically relates to a process for extracting stevioside by steam explosion treatment of stevia rebaudiana. The steps of the process are: 1) After cleaning the leaves of Stevia rebaudiana and filtering the surface moisture, put them into the steam explosion device for steam explosion. The steam explosion conditions are: temperature 130-180°C, pressure 1.4-2.0MPa; The steam-exploded stevia leaves are decomposed by replenishing water through a high-consistency mill; 3) The slurry decomposed in step 2) is put into a continuous countercurrent extractor to extract stevioside, and then the stevia leaf residue is squeezed dry with a squeezer When the water content is 50wt%, the extract and leaf residue are obtained; 4) The extract is treated with two-stage ultrafiltration membrane, then desalted and pigmented by ion exchange resin, and finally concentrated to 30wt% by nanofiltration membrane before spraying Dry to obtain the finished steviol glycoside. The method can fundamentally solve the influence of the dense structure of stevia leaf cell wall on the dissolution of active ingredients, and can improve the dissolution efficiency of stevioside extract.

Owner:SICHUAN GOLDEN ELEPHANT SINCERITY CHEM CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com