Main spindle hood of electric spark moulding machine

A molding machine and spindle machine technology, applied in the field of EDM spindle cover structure, can solve the problems of the human nervous system, cardiovascular system, respiratory system, eyesight and skin tissue damage, to ensure the quality of molding processing, eliminate The effect of harmful ingredients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below in conjunction with the drawings and specific embodiments:

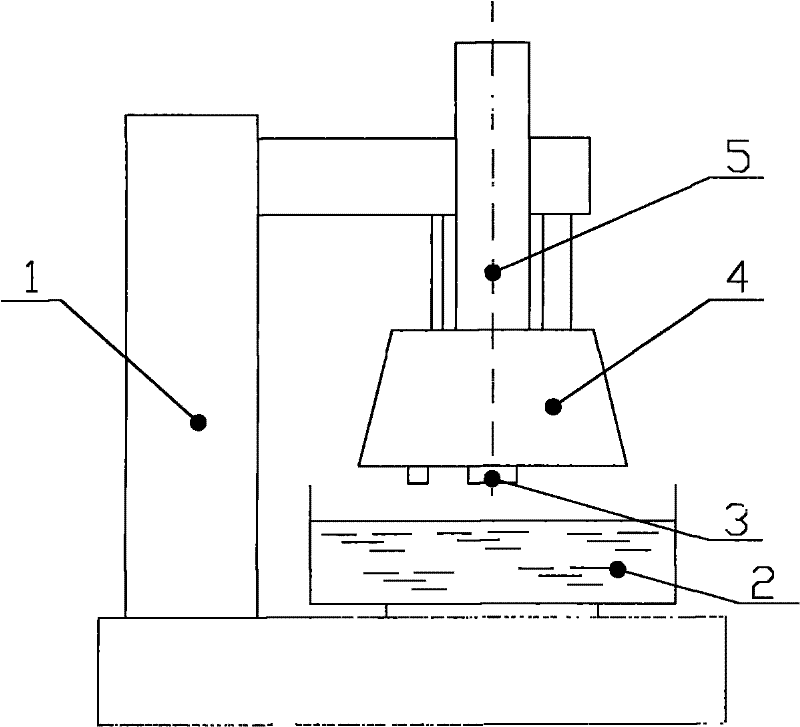

[0017] Such as figure 1 As shown, the main shaft cover body 4 of the EDM machine of the present invention is installed on the EDM machine 1 in the middle of the main shaft 5 and above the main shaft tool electrode 3.

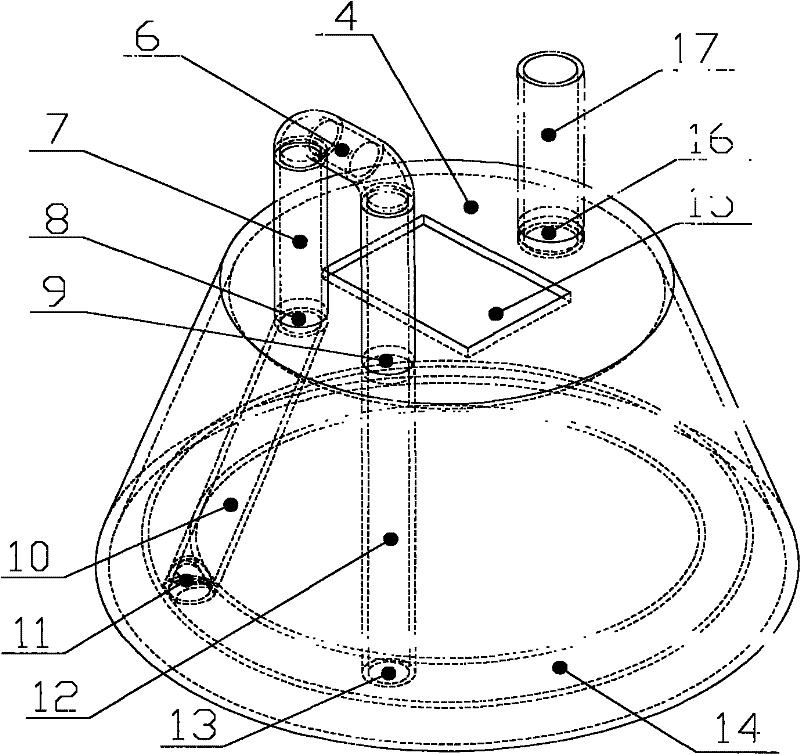

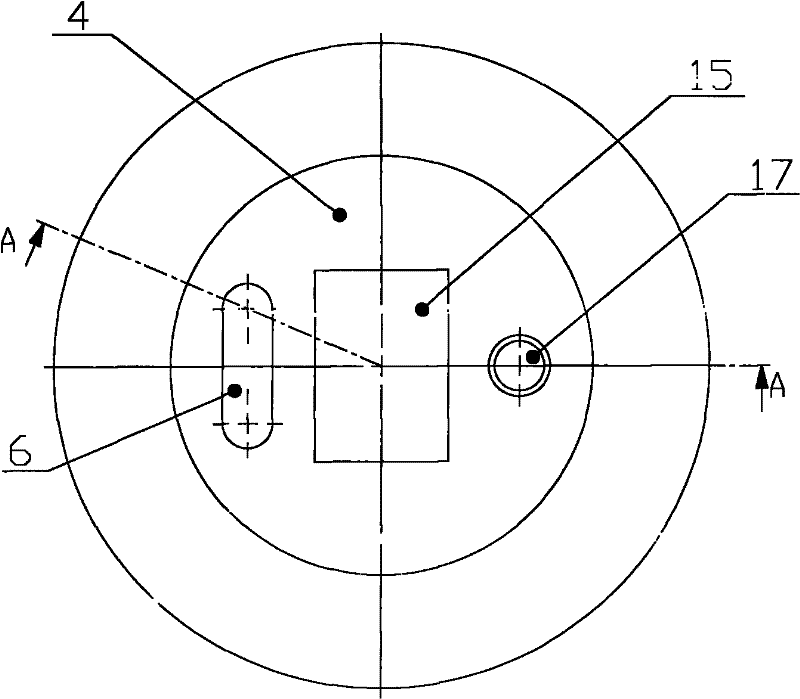

[0018] Such as Figure 2-Figure 4 As shown, the main shaft hood of the EDM machine of the present invention includes: main shaft hood body 4, connecting pipe 6, medium purification channel 7, medium downward passage upper port 8, medium upward passage upper port 9, medium downward passage 10, medium lower The underpass 11, the medium upward passage 12, the downward medium upward passage 13, the annular oil curtain spray channel 14, the main shaft connection hole 15, the smoke purification crossing 16, the smoke purification channel 17.

[0019] The main shaft hood body 4 is in the shape of a cone; the main shaft connection hole 15 penetra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com