Regenerative flexible photosensitive resin plate

A photosensitive resin and flexible technology, which is applied in the field of flexible solid photosensitive resin plate and its preparation, and can solve the problems such as large environmental hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

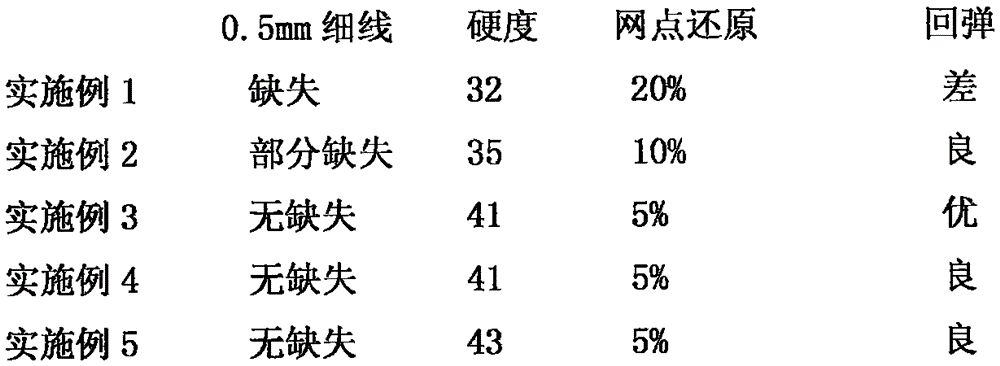

Examples

preparation example Construction

[0011] The preparation method of the regenerated flexible solid photosensitive resin plate is:

[0012] The waste resin mixed in the solvent, that is, the liquid resin, is first used to recover the solvent by a recycling machine and filter it. Carry out tests, and then carry out targeted technical treatment according to the above technical solutions, waiting to enter the forming process.

[0013] Using the existing rubber and plastic equipment such as coating, extrusion, calendering, compounding, etc. in the market, and the existing traditional processing technology to carry out the required molding, the flexible photosensitive resin plate that meets the quality requirements can be produced.

Embodiment 1

[0016] Use a recycling machine to recover the solvent from the waste resin, dry it, and completely eliminate the volatile solvent. A standard flexible solid photosensitive resin plate support film is used for the resin, and the protective film is sandwiched in the middle, put into a flat vulcanizing machine, and a 2mm thick sheet is formed at 100 degrees.

Embodiment 2

[0018] According to the test data, the harmful impurities affecting the cross-linking and curing in the waste resin exceeded the standard five times, and the corresponding liquid was used to clean and extract, and it was repeated five times. Then select and add calcium oxide, acrylate, an appropriate amount of photosensitizer, polyurethane mixture, one or more of PVA and ethylene, vinyl acetate polymer to mix and mix evenly, and form a 2mm thick sheet in the same way as in Example 1. material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com