A preparation process for extracting stevioside and fermented feed through steam explosion treatment of stevia rebaudiana

A technology of stevioside and stevia, which is applied in the field of extracting stevioside by steam explosion treatment of stevia and the preparation of fermented feed, can solve the problems of inapplicable stevioside extraction and quality assurance, product quality and yield impact, and product purity Not high problems, to achieve the effect of reducing internal diffusion resistance, reducing ash content of products, and increasing diffusion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

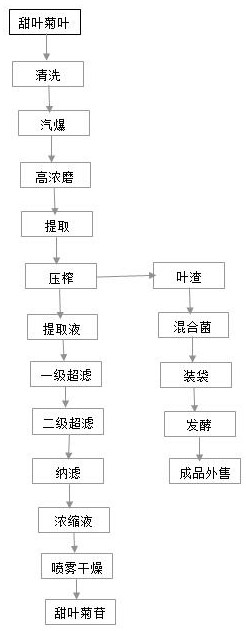

Image

Examples

Embodiment 1

[0032]After cleaning the stevia leaves (dry leaves with a water content of about 10wt%), after filtering out the water, enter the steam explosion device for steam explosion, the steam explosion conditions are temperature 150°C, pressure 1.6MPa; the washing water for cleaning the stevia leaves Reuse after settling. The steam-exploded stevia leaves are diluted with water to a concentration of 20wt% while entering the high-consistency mill for thawing. The decomposed slurry enters the continuous countercurrent extractor, and the high-consistency mill decompressed slurry is extracted with 10 times the quality of water in the countercurrent extractor, and finally the stevia rebaudiana leaf residue is squeezed to a water content of 50% for later use, to obtain Extract and leaf residue; the extract passes through the first-stage ultrafiltration membrane with a pore size of 10,000 to remove protein and other soluble impurities and smaller particles.

[0033] The permeate enters the s...

Embodiment 2

[0036] Stevia leaves after cleaning (water content is the dry leaf of about 10wt%), after filtering out moisture, enter steam explosion device and carry out steam explosion, and steam explosion condition is temperature 140 ℃, pressure 1.4MPa; Clean the washing water of stevia leaf through Reuse after settling. The steam-exploded stevia leaves are diluted with water to a concentration of 20 wt% while entering the high-consistency mill for thawing. The decomposed slurry enters the continuous countercurrent extractor, and the high-consistency mill decompressed slurry is extracted with 10 times the quality of water in the countercurrent extractor, and finally the stevia leaf residue is squeezed to a water content of 50wt% for subsequent use. The extract and leaf residue are obtained; the extract passes through the first-stage ultrafiltration membrane with a pore size of 10,000 to remove protein and other soluble impurities and smaller particles.

[0037] The permeate enters the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com