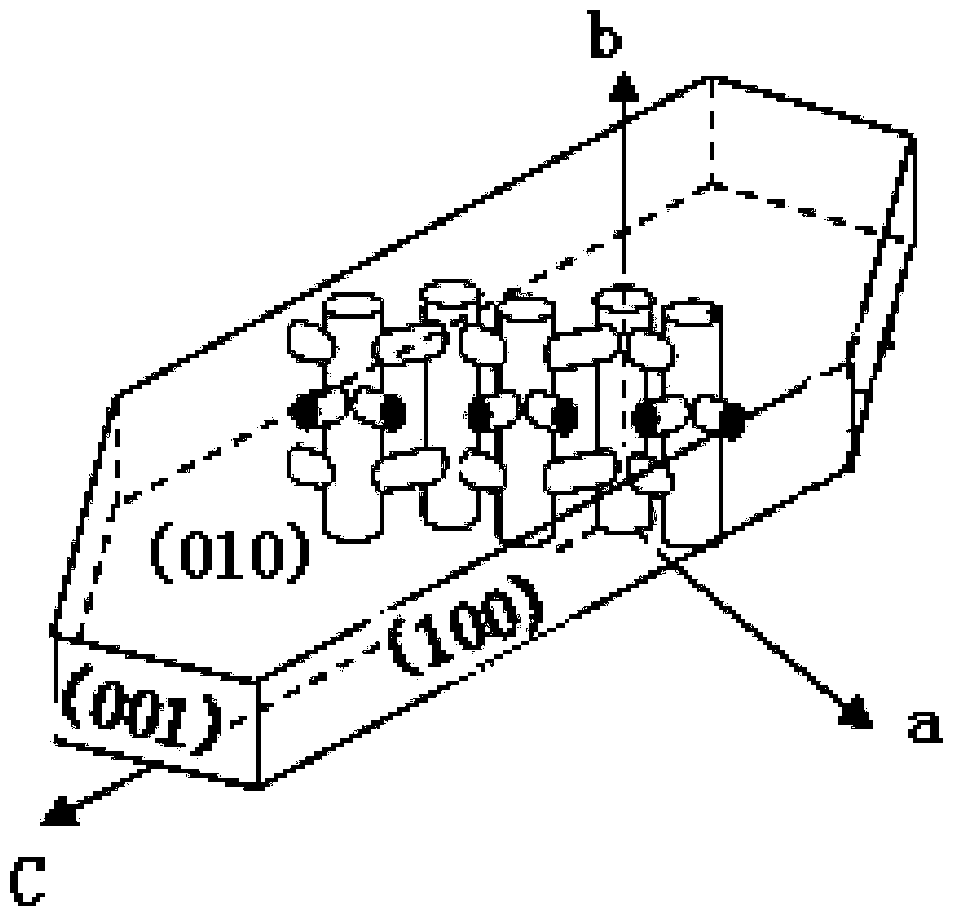

A kind of ZSM-5 molecular sieve and synthetic method thereof

A technology of ZSM-5 and synthesis method, which is applied in the direction of crystalline aluminosilicate zeolite, borocarbane silicone crystalline aluminosilicate zeolite, etc., can solve the problems of expensive and difficult to obtain template agents, achieve small internal diffusion resistance, The effect of strong adaptability of raw materials and non-agglomeration of grains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

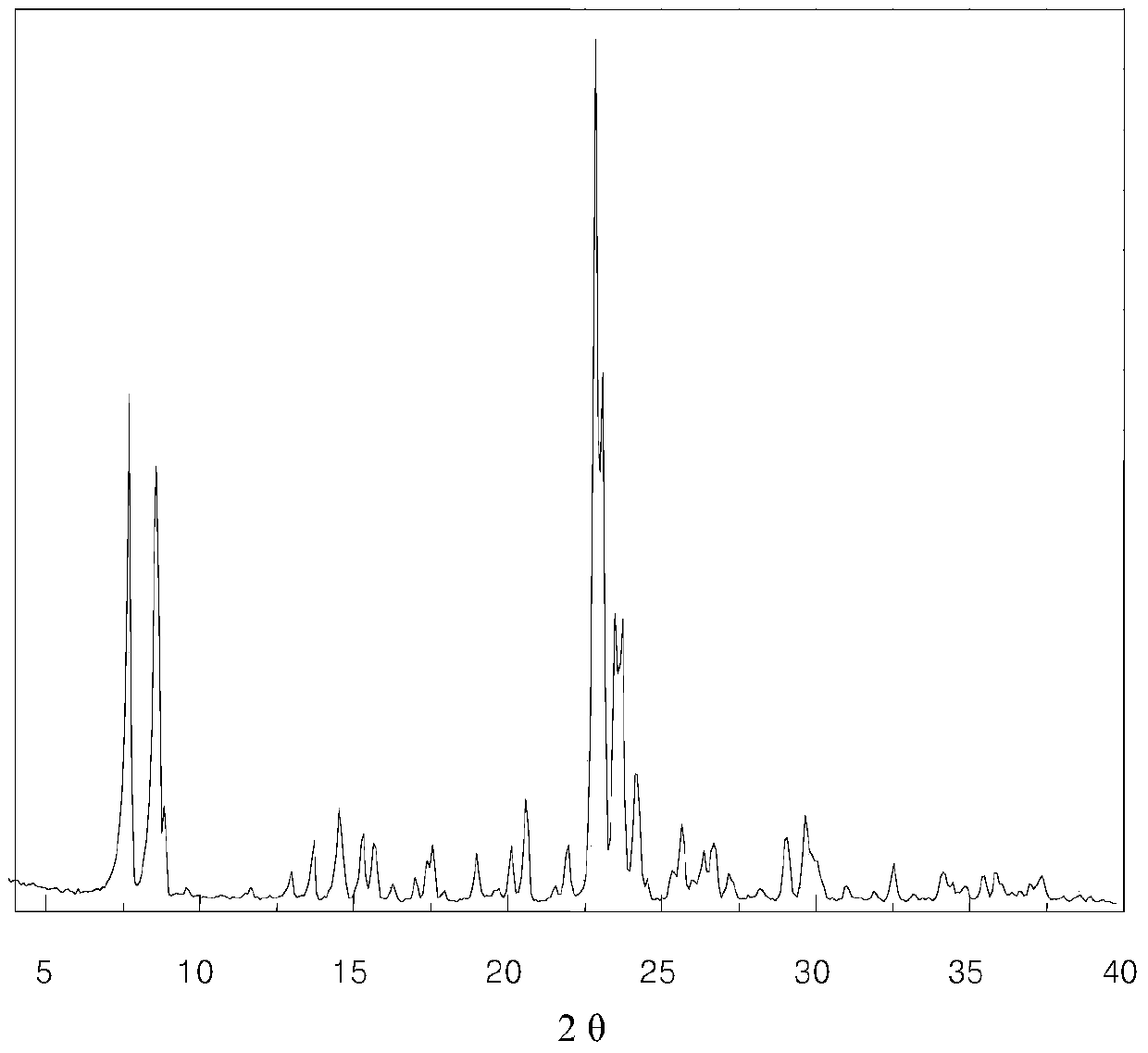

Embodiment 1

[0038] (1) Activate the aluminum source with an inorganic base.

[0039] 2gAl 2 o 3 Powder (pseudoboehmite) was dispersed in 100g deionized water, then 8g NaOH solid was added and stirred at room temperature to fully hydrolyze for 2 hours to prepare B solution;

[0040] (2) Synthesize ZSM-5 zeolite with activated aluminum source.

[0041] 100g silica sol (industrial grade, SiO 2 ≥30wt%) in 100g of deionized water, then add 18g of n-butylamine solution (industrial grade), fully stir at room temperature for 1 hour to make A solution; slowly add the activated B solution to A under stirring In the solution, a uniform gel C was made; 7.5 g of 98% concentrated sulfuric acid was added to the gel C to eliminate the influence of excess NaOH in (1) on the gel. The gel mixture has the following molar composition: SiO 2 / Al 2 o 3 =25, NaOH / SiO 2 = 0.1, NBA / SiO 2 =0.5,H 2 O / SiO 2 =30. The prepared gel was transferred to a synthesis kettle, crystallized at 170°C for about 24 hou...

Embodiment 2

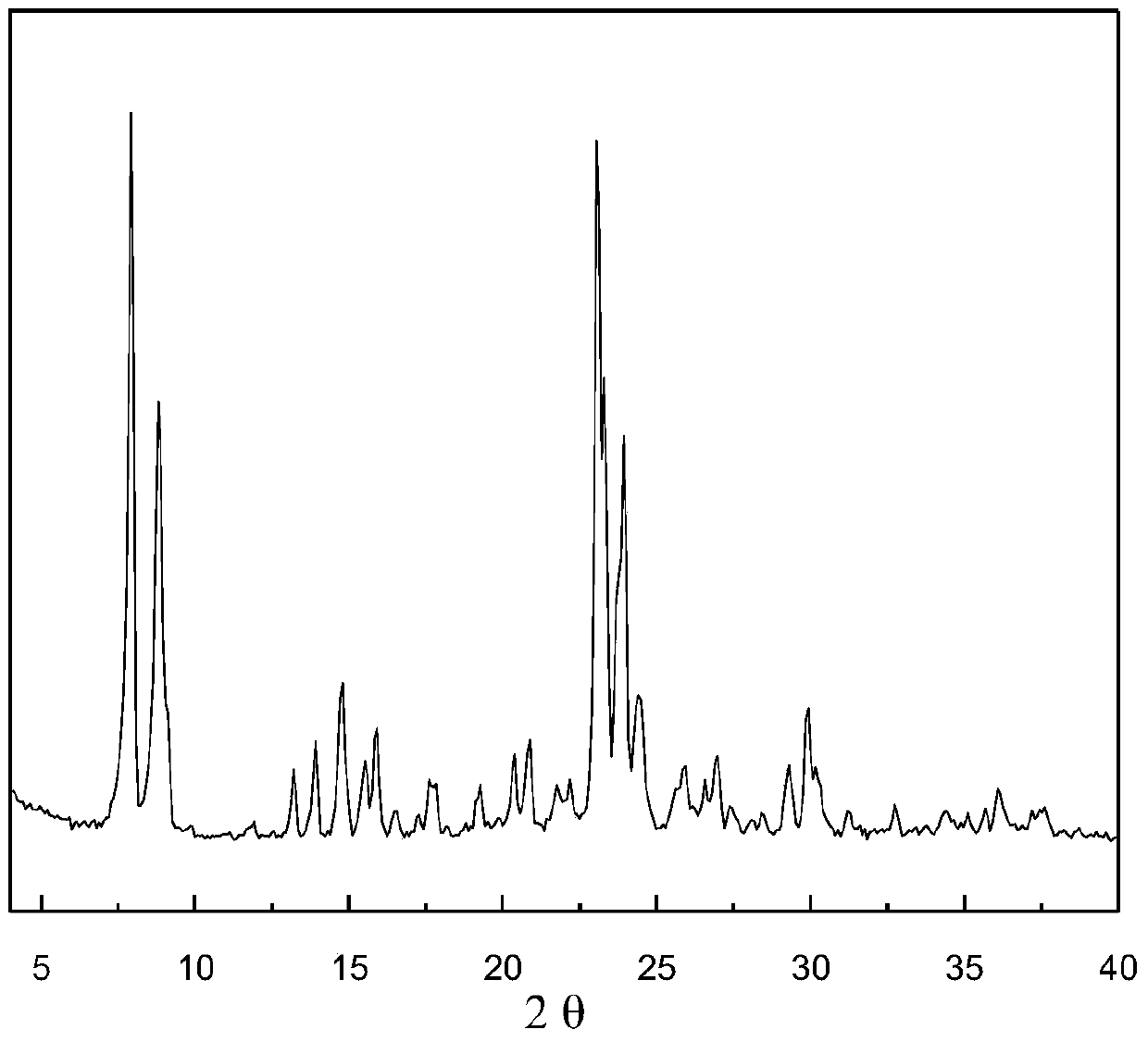

[0043] Repeat Example 1, but add 1 g of nanometer ZSM-5 zeolite crystal seeds to the gel C prepared in step (2), and the seed crystal particle size is <100 nm. A ZSM-5 zeolite product was obtained with a relative crystallinity of 80% and a particle size of 2 μm (c)×0.3 μm (b)×1.5 μm (c).

Embodiment 3

[0045] Repeat Example 1, but add 2g of nanometer ZSM-5 zeolite crystal seeds to the gel C prepared in step (2), and the seed crystal particle size is <100nm. A ZSM-5 zeolite product was obtained with a relative crystallinity of 80% and a particle size of 2 μm (c)×0.2 μm (b)×1.5 μm (c).

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystal size | aaaaa | aaaaa |

| crystallinity | aaaaa | aaaaa |

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com