Orthopaedic removed waste gypsum refining treatment device

A processing device and gypsum technology, applied in grain processing, incinerators, combustion methods, etc., can solve problems such as inability to remove combustible impurities and harmful components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

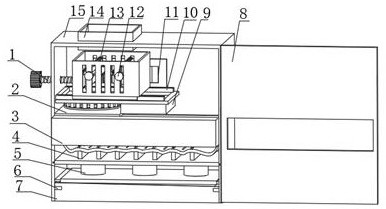

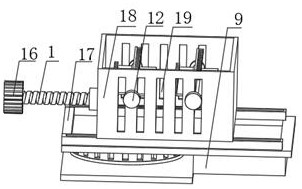

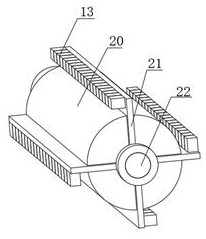

[0031] refer to Figure 1-6 , a kind of orthopedic removal waste gypsum thinning treatment device, comprising a working box 15, the front of the working box 15 is connected with a cover 8 through a rotating shaft, and the top of the working box 15 is provided with a material inlet 14, and the inside of the working box 15 is located A heating plate 17 is fixedly installed directly below the material inlet 14, and a heating box is fixedly installed at the bottom of the heating plate 17, and slide rails 10 are fixedly installed on both sides of the top of the heating plate 17, and the inside of the slide rail 10 is slidably connected with a combustion chamber. Box 18, the surface of the combustion box 18 is provided with an air outlet 19, and one side of the combustion box 18 is fixedly installed with an adjustment rod 1 through a bearing, and the outside of the air outlet 19 is fixedly installed with a blower box, and the air outlet of the blower box is fixedly installed There i...

Embodiment 2

[0042] refer to figure 1 and Figure 6 , a device for thinning waste gypsum removed from orthopedics. Compared with Embodiment 1, the two sides of the collection box 7 correspond to the inside of the work box 15. Stakes 6 are arranged, and the top of the collection box 7 is fixed and installed by bolts. Filter screen 32 is arranged, and the length of filter screen 32 is less than the length of collection box 7 tops.

[0043] During use, the collection box 7 is slid into the inside of the device by the stake 6 to collect, and the filter screen 32 on the top filters and blocks the granular debris. Since the length of the filter screen 32 is less than the length of the collection box 7 top, this makes the collection box 7 There is a gap between the top of the top and the filter screen 32 to facilitate the discharge of the collection in the collection box 7.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com