Innocent treatment process of domestic garbage

A technology for harmless treatment and domestic waste, applied in the direction of machines/engines, solid waste removal, gas turbine devices, etc., can solve the problems of low rate of combustible mixed gas, generation of toxic and harmful gases, increased operating costs, etc., to eliminate secondary Secondary pollution, zero discharge and elimination of ammonia nitrogen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

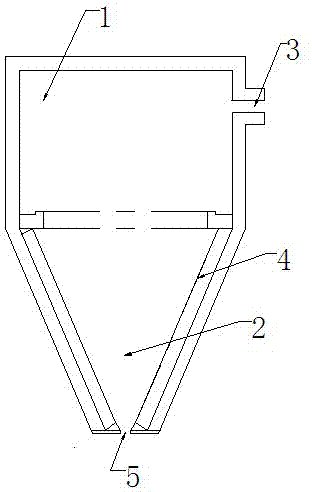

[0033] The invention relates to a harmless treatment process of domestic waste. After the domestic waste is processed through physicalization, micro-nano oxygen bubble degradation, pyrolysis gasification and gas recycling, zero discharge of domestic waste is realized.

[0034] In the physical and chemical step, the metal components and hazardous waste in the garbage are separated by garbage magnetic separation to obtain organic components, and the organic components are dehydrated by extrusion to obtain sewage and dry matter with a moisture content of 25%.

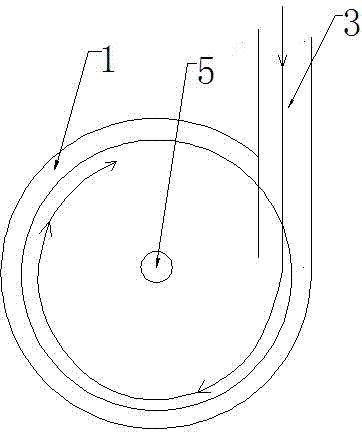

[0035] In the micro-nano oxygen bubble degradation step, the micro-nano bubbles converted from ozone are injected into the sewage, and the dissolution time in the sewage is 40 minutes, so that the organic matter in the sewage is oxidized and degraded, and part of the ammonia nitrogen is simultaneously oxidized and reduced to release nitrogen. , and then after filtration and heavy metal filtration, the organic nutrient solut...

Embodiment 2

[0044] This embodiment is basically the same as the above-mentioned embodiment, the main difference is:

[0045] In the physical and chemical step, the metal components and hazardous waste in the garbage are separated by garbage magnetic separation to obtain organic components, and the organic components are dehydrated by extrusion to obtain sewage and dry matter with a moisture content of 30%.

[0046] In the micro-nano oxygen bubble degradation step, the micro-nano bubbles transformed from ozone are injected into the sewage, and the dissolution time in the sewage is 50 minutes, so that the organic matter in the sewage is oxidized and degraded, and part of the ammonia nitrogen is simultaneously oxidized and reduced to release nitrogen. , and then after filtration and heavy metal filtration, the organic nutrient solution is obtained.

[0047] Before pyrolysis and gasification, the dry matter is dried with waste heat to remove the remaining moisture to obtain a dry matter with ...

Embodiment 3

[0051] This embodiment is basically the same as the above-mentioned embodiment, the main difference is:

[0052] In the physical and chemical step, the metal components and hazardous waste in the garbage are separated by garbage magnetic separation to obtain organic components, and the organic components are dehydrated by extrusion to obtain sewage and dry matter with a moisture content of 28%.

[0053] In the micro-nano oxygen bubble degradation step, the micro-nano bubbles converted from ozone are injected into the sewage, and the dissolution time in the sewage is 60 minutes, so that the organic matter in the sewage is oxidized and degraded, and part of the ammonia nitrogen is simultaneously oxidized and reduced to release nitrogen. , and then after filtration and heavy metal filtration, the organic nutrient solution is obtained.

[0054] Before pyrolysis and gasification, the dry matter is dried with waste heat to remove the remaining moisture to obtain a dry matter with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com