A kind of combined treatment method of arsenic-containing acid wastewater, red mud and carbide slag

An arsenic-containing acid, combined treatment technology, used in chemical instruments and methods, solid waste removal, fertilizer mixtures, etc. The effect of removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

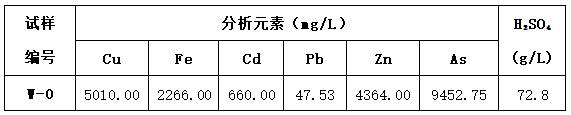

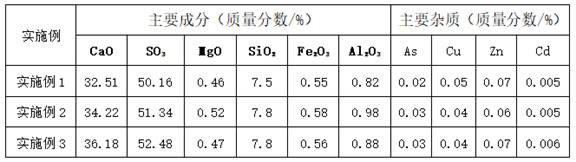

[0029] Step 1: In the primary reaction tank of a copper smelter, add arsenic-containing wastewater and red mud according to the weight ratio of 1:0.2, stir and leach at 20°C for 60 minutes to obtain a slurry liquid, and when the reaction is completed, the slurry liquid The mass fraction of free acid is 2.3%. Then the slurry is sent to the primary sedimentation tank for static settlement, the supernatant of the sedimentation tank is filtered by a filter press to obtain filtrate A, and the filtrate A flows into the secondary reaction tank by itself; the sediment at the bottom of the sedimentation tank is washed with water to become neutral , storage and stacking after filter press dehydration, analysis of its main component content is shown in Table 4. The sediment can be used as building material and soil conditioner after being dried naturally or in a rotary kiln.

[0030] Step 2: In the secondary reaction tank, adjust the flow rate of filtrate A to 120m³ / h, add carbide slag ...

Embodiment 2

[0033]Step 1: In the primary reaction tank of a copper smelter, add arsenic-containing wastewater and red mud according to the weight ratio of 1:0.4, stir and leach at 20°C for 90 minutes to obtain a slurry liquid, and when the reaction ends, the slurry liquid The mass fraction of free acid is 3.1%. Then the slurry is sent to the primary sedimentation tank for static settlement, the supernatant of the sedimentation tank is filtered by a filter press to obtain filtrate A, and the filtrate A flows into the secondary reaction tank by itself; the sediment at the bottom of the sedimentation tank is washed with water to become neutral , storage and stacking after filter press dehydration, analysis of its main component content is shown in Table 4. The sediment can be used as building material and soil conditioner after being dried naturally or in a rotary kiln.

[0034] Step 2: In the secondary reaction tank, adjust the flow rate of filtrate A to 100m³ / h, add carbide slag according...

Embodiment 3

[0037] Step 1: In the primary reaction tank of a copper smelter, add arsenic-containing waste water and red mud according to the weight ratio of 1:0.4, stir and leach at 20°C for 120 minutes to obtain a slurry liquid, and when the reaction is completed, the slurry liquid The mass fraction of free acid is 1.8%. Then the slurry is sent to the primary sedimentation tank for static settlement, the supernatant of the sedimentation tank is filtered by a filter press to obtain filtrate A, and the filtrate A flows into the secondary reaction tank by itself; the sediment at the bottom of the sedimentation tank is washed with water to become neutral , storage and stacking after filter press dehydration, analysis of its main component content is shown in Table 4. The sediment can be used as building material and soil conditioner after being dried naturally or in a rotary kiln.

[0038] Step 2: In the secondary reaction tank, adjust the flow rate of filtrate A to 180m³ / h, add carbide sla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com