Oil-contained sludge pyrolysis-combustion coupled double-bed integrated treatment process system

A technology of treatment process and combustion system, applied in combustion methods, combustion types, incinerators, etc., can solve the problems of soil air pollution, atmospheric environmental pollution, occupation of large cultivated land, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The equipment and method provided by the present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited thereto.

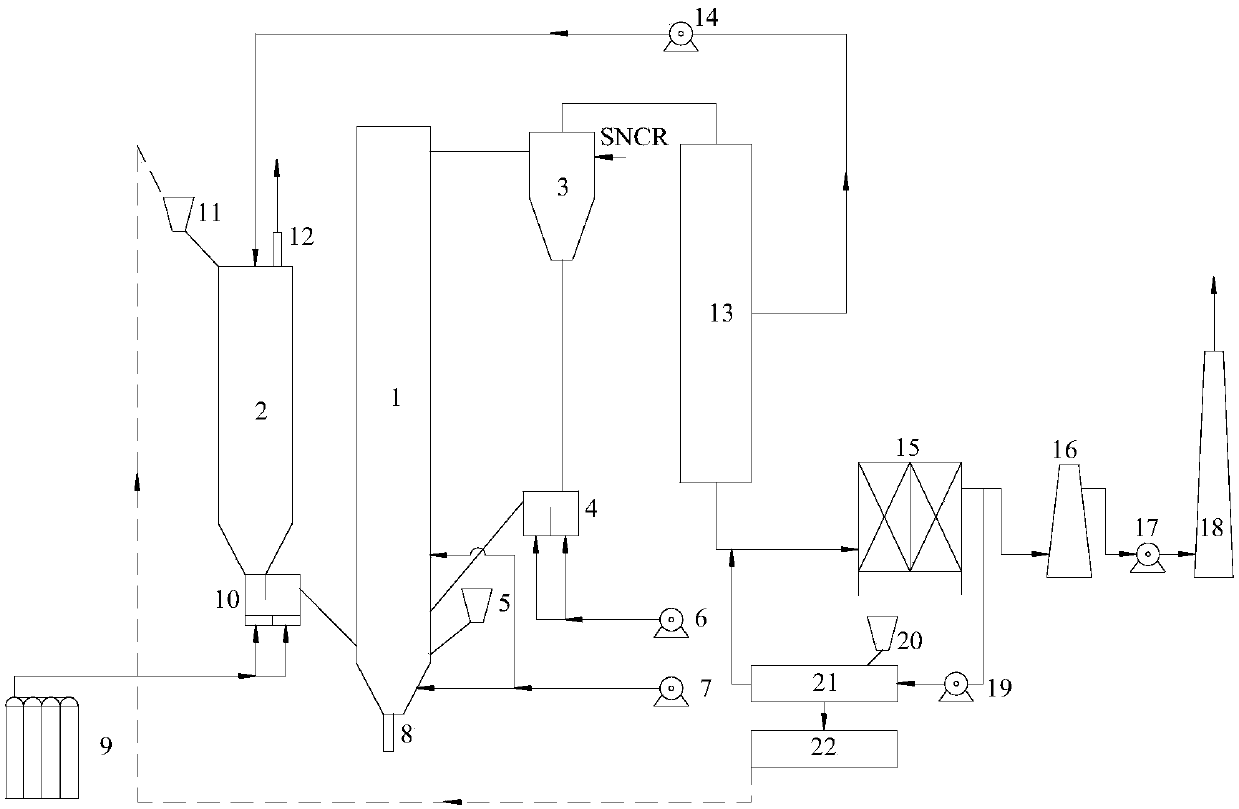

[0023] figure 1 It is a schematic diagram of the oily sludge pyrolysis-combustion coupling twin-bed integrated treatment process system of the present invention.

[0024] Such as figure 1 As shown, the oily sludge pyrolysis-combustion coupled twin-bed integrated treatment process system includes an oily sludge drying system, a combustion system and a combustion system. Among them, the oily sludge drying system includes a circulating fan 19, an oily sludge feeder 20, a drying unit 21, a dry oily sludge storage tank 22, etc.; a combustion system includes a combustion furnace 2, a flue gas recirculation fan 14, and a nitrogen cylinder Group 9, oily sludge belt conveyor 23, dry oily sludge feeder 11, combustion furnace side feeder 10, pyrolysis gas outlet 12, etc.; combustion system in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com