Activated carbon-based air conditioner filter cartridge and preparation process thereof

A technology of activated carbon and air conditioning, applied in the direction of filtration and separation, dispersed particle filtration, and dispersed particle separation, etc., can solve the problems of limited discharge methods, troubles, etc., and achieve the effects of eliminating harmful components, low preparation cost, and wide sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

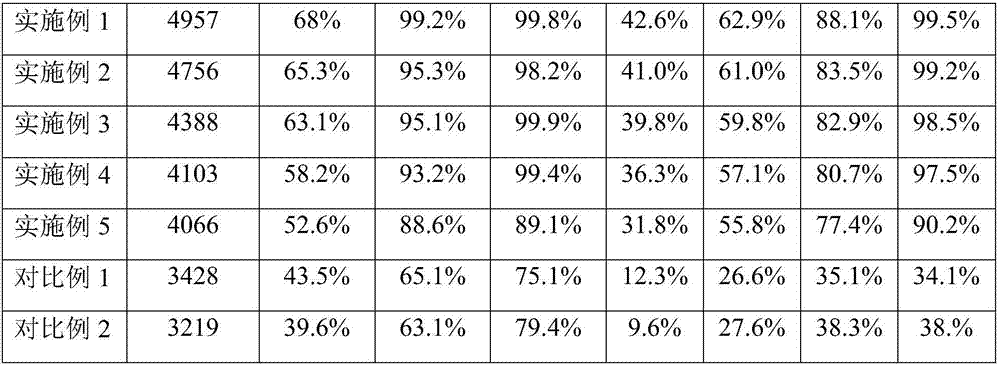

Embodiment 1

[0032] Put 1000g of lily rods into a muffle furnace, pass in argon, dry at 140°C for 10h, then raise the temperature to 500°C, calcinate for 4h, and then place in 130°C for 2.5h to obtain activated carbon;

[0033] Grind 10g of Evodia rutaecarpa, 3g of Clematis, 8g of Sanbaicao, 15g of lavender, 6g of Chuanxiong, 5g of white fresh skin, and 10g of Fritillaria into powder, pass through a 200-mesh sieve, and then put it under steam with a vapor pressure of 230KPa and a temperature of 120°C. placed in the middle for 60min to obtain Chinese herbal medicine powder;

[0034] Mix 240g of activated carbon and 40g of Chinese herbal medicine powder in water to obtain mixture 1;

[0035] Add the mixture 1 and 10kg phenolic resin into the twin-screw extruder, wherein the temperature of the extruder is set as follows: zone 1: 210°C; zone 2: 240°C; zone 3-9: 265°C; : 265° C.; the screw speed of the extruder is 125 r / min.

[0036] After melting, kneading, extruding, cooling, pelletizing an...

Embodiment 2

[0038] Put 500g of tulip rods into a muffle furnace, pass in argon, dry at 150°C for 18h, then raise the temperature to 400°C, calcinate for 6h, and then place in 120°C water vapor for 2.5h to obtain activated carbon;

[0039] Grind 5g of Evodia rutaecarpa, 16g of lavender, 18g of lemon, and 6g of Pteris cerevisiae into powder, pass through a 200-mesh sieve, and then place it in steam with a vapor pressure of 320KPa and a temperature of 120°C for 90 minutes to obtain a Chinese herbal medicine powder;

[0040] Mix 80g of activated carbon and 40g of Chinese herbal medicine powder in water to obtain mixture 1;

[0041] Add the mixture 1 and 10kg of melamine-formaldehyde resin into the twin-screw extruder. The temperature of the extruder is set as follows: zone 1: 205°C; zone 2: 240°C; zone 3-9: 255°C; : 255°C; the screw speed of the extruder is 120r / min.

[0042] After melting, kneading, extruding, cooling, pelletizing and drying, and then solidifying and forming, the activated ...

Embodiment 3

[0044] Put 1500g of Fritillaria sichuanensis into a muffle furnace, pass in argon, dry at 120°C for 5h, then raise the temperature to 600°C, calcinate for 2h, and then place it in water vapor at 150°C for 2.5h to obtain activated carbon;

[0045] Grind 15g mugwort leaves, 10g magnolia officinalis, 10g cassia seeds, 6g fennel, and 20g lemon into powder, pass through a 200-mesh sieve, and then place it in steam with a vapor pressure of 150KPa and a temperature of 140°C for 45min to obtain a Chinese herbal medicine powder;

[0046] Mix 400g of activated carbon and 50g of Chinese herbal medicine powder in water to obtain mixture 1;

[0047] Add the mixture 1 and 10kg of silicone resin into the twin-screw extruder. The temperature of the extruder is set as follows: zone 1: 215°C; zone 2: 240°C; zone 3-9: 260°C; machine head: 260° C.; the screw speed of the extruder is 120 r / min.

[0048]After melting, kneading, extruding, cooling, pelletizing and drying, and then solidifying and f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| antibacterial rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com