Power rotary purification device for smoke collecting demister and purification method

A purification device, fog machine technology, applied in chemical instruments and methods, separation methods, gas treatment and other directions, can solve the problems of poor purification effect, backward technology, large volume, etc., achieve good absorption and purification effect, remove harmful components and odor effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

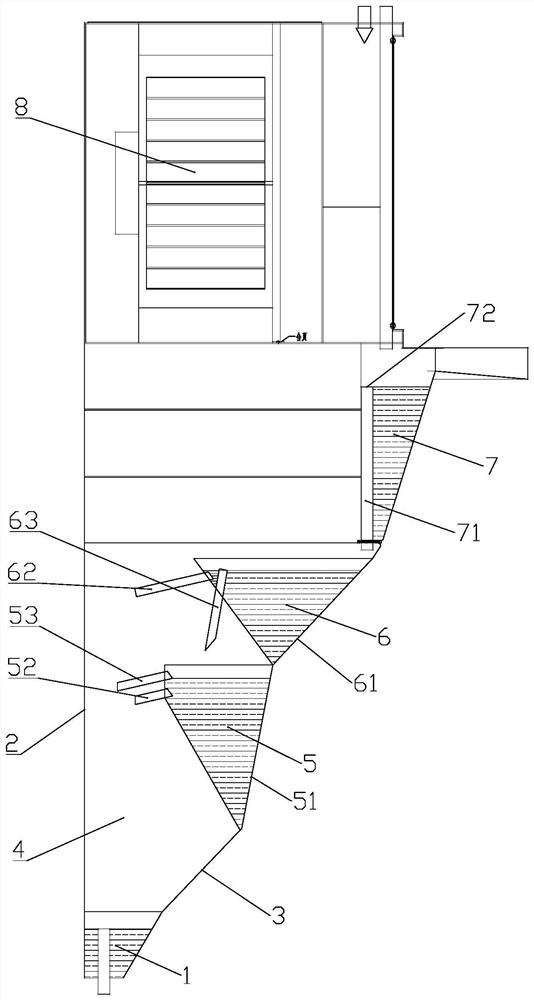

[0025] Figure 1 ~ Figure 3 It schematically shows a power rotary purification device for a smoke and mist collector according to an embodiment of the present invention.

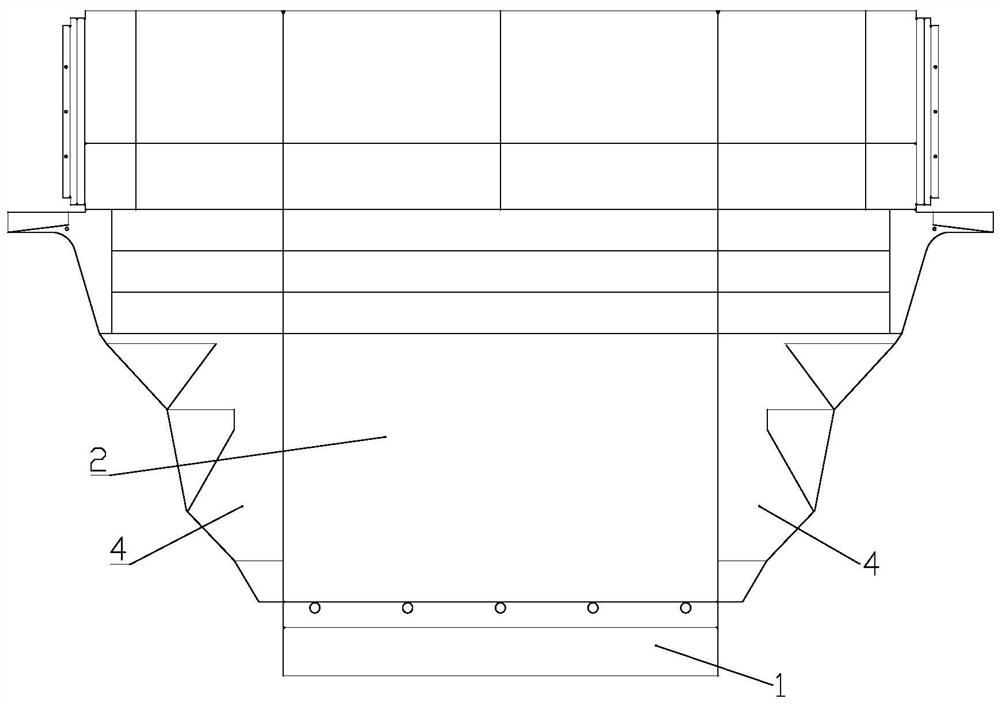

[0026] refer to figure 1 The power rotary purification device of the smoke and demist machine includes an oil collecting tank 1, a rear plate 2, an air inlet orifice plate 3, two side plates 4, a first cooling water tank 5, a second cooling water tank 6, a third cooling water tank 7, Fan 8 and plant fiber purifier 9.

[0027] The two side plates 4 are oppositely arranged and connected to both sides of the rear plate 2 and the air inlet hole plate 3, and the oil collecting tank 1 is fixedly connected to the lower side of the rear plate 2, the air inlet hole plate 3 and the two side plates 4, so as to A lower sealed warehouse body is formed. The inside of the bin body is provided with a first cooling water tank 5, a second cooling water tank 6, a third cooling water tank 7, a fan 8 and a plant fiber purifie...

Embodiment 2

[0038] This embodiment provides a power rotary purification method for a smoke collector and demist machine suitable for the aforementioned power rotary purification device for a smoke collector and demist machine, including the following steps:

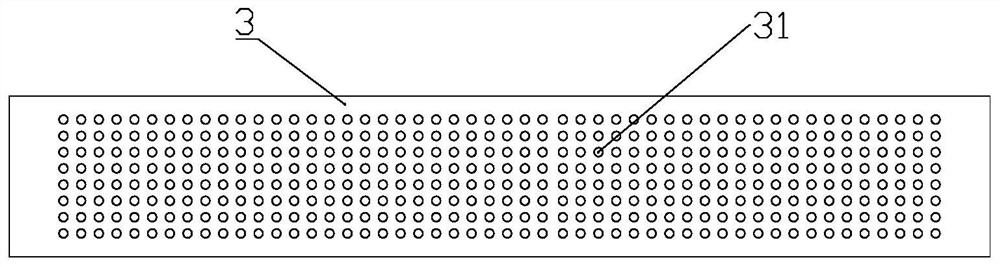

[0039] S1. Inject purified water into the third cooling water tank 7 through the water inlet, and flow downstream to the second cooling water tank 6 and the first cooling water tank 5, and then flow into the oil collecting tank 1. The purified water can be tap water or Clean water with deodorant added or other liquids that can be used for purification, etc. Turn on the blower fan 8 so that the gas that needs to be purified outside the warehouse enters the warehouse body from the air inlet 31 of the air inlet hole plate 3 .

[0040] S2. The gas continuously passes through the multiple air inlet holes 31 on the air inlet orifice plate 3 to form a plurality of wind columns, which flow upward obliquely and form a negative pressure above th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com