Method for comprehensively recovering valuable metals and arsenic trioxide from copper ash and arsenic sulfide slag

A technology of arsenic trioxide and valuable metals, applied in arsenic oxide/arsenic hydroxide/oxyacid arsenic, chemical instruments and methods, arsenic compounds, etc., can solve problems such as poisoning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

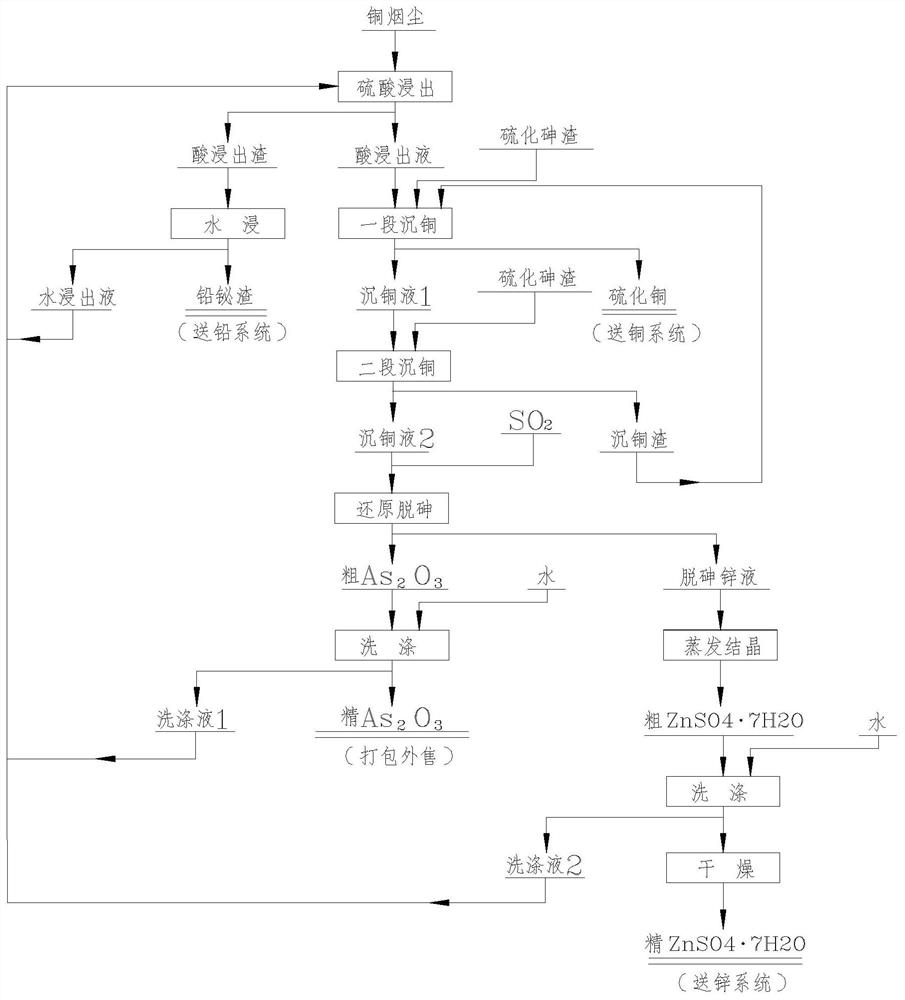

[0022] The accompanying drawings of this embodiment are shown in figure 1 .

[0023] The chemical composition of the main elements in the copper fume and arsenic sulfide slag described in the present invention is shown in the table below:

[0024] Cu As Zn Pb Bi S copper soot 4.85% 12.10% 15.26% 18.41% 2.26% 10.39% Arsenic sulfide slag 0.15% 52.97% 0.18% —— —— 37.32%

[0025] Copper soot 1kg, first use 60g / L sulfuric acid for the first stage leaching, the leaching liquid-solid ratio is 4:1mL / g, the leaching time is 2.0h, and the leaching temperature is 75°C. After filtration, 3.625L of acid leaching liquid and acid leaching residue are obtained 595.3g (wet weight); the acid leaching slag was leached in the second stage with industrial water, the leaching liquid-solid ratio was 2:1mL / g, the leaching time was 1.0h, and the leaching temperature was 75°C. After filtration, 1.075L of water leaching liquid and lead Bismuth slag 547.73...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com