Membrane bioreactor device synergistically regulated by utilizing iron-based water treatment material

A membrane bioreactor and reactor technology, applied in water/sewage treatment, biological water/sewage treatment, oxidized water/sewage treatment, etc., can solve the problems of limited effect of enhanced bioflocculation and complex biofilm pollution process, etc. Achieve the effects of reducing membrane fouling potential, high biocompatibility, and improving effluent quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

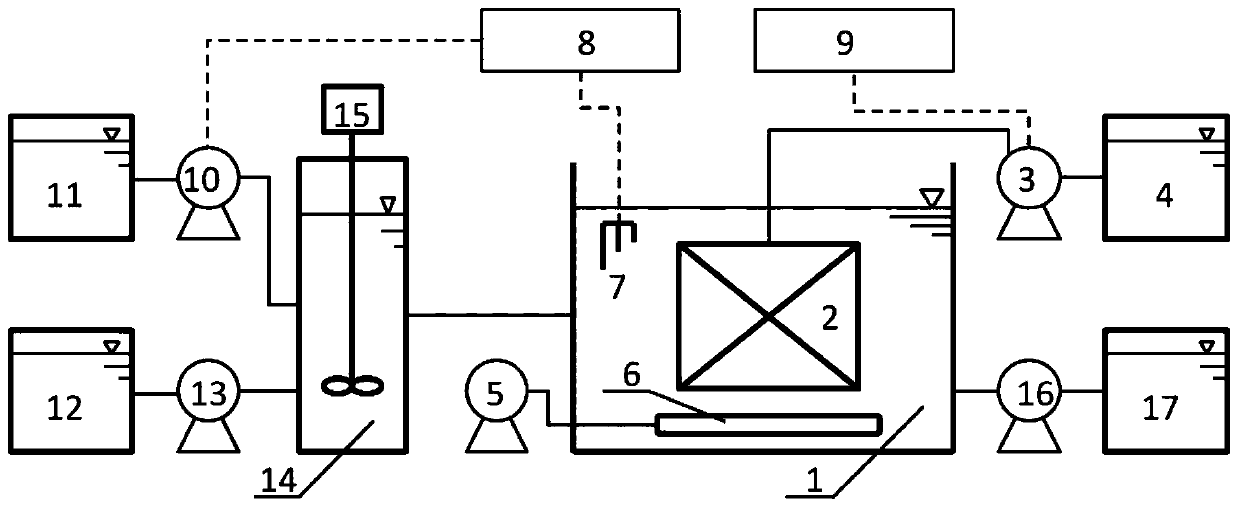

Method used

Image

Examples

Embodiment 1

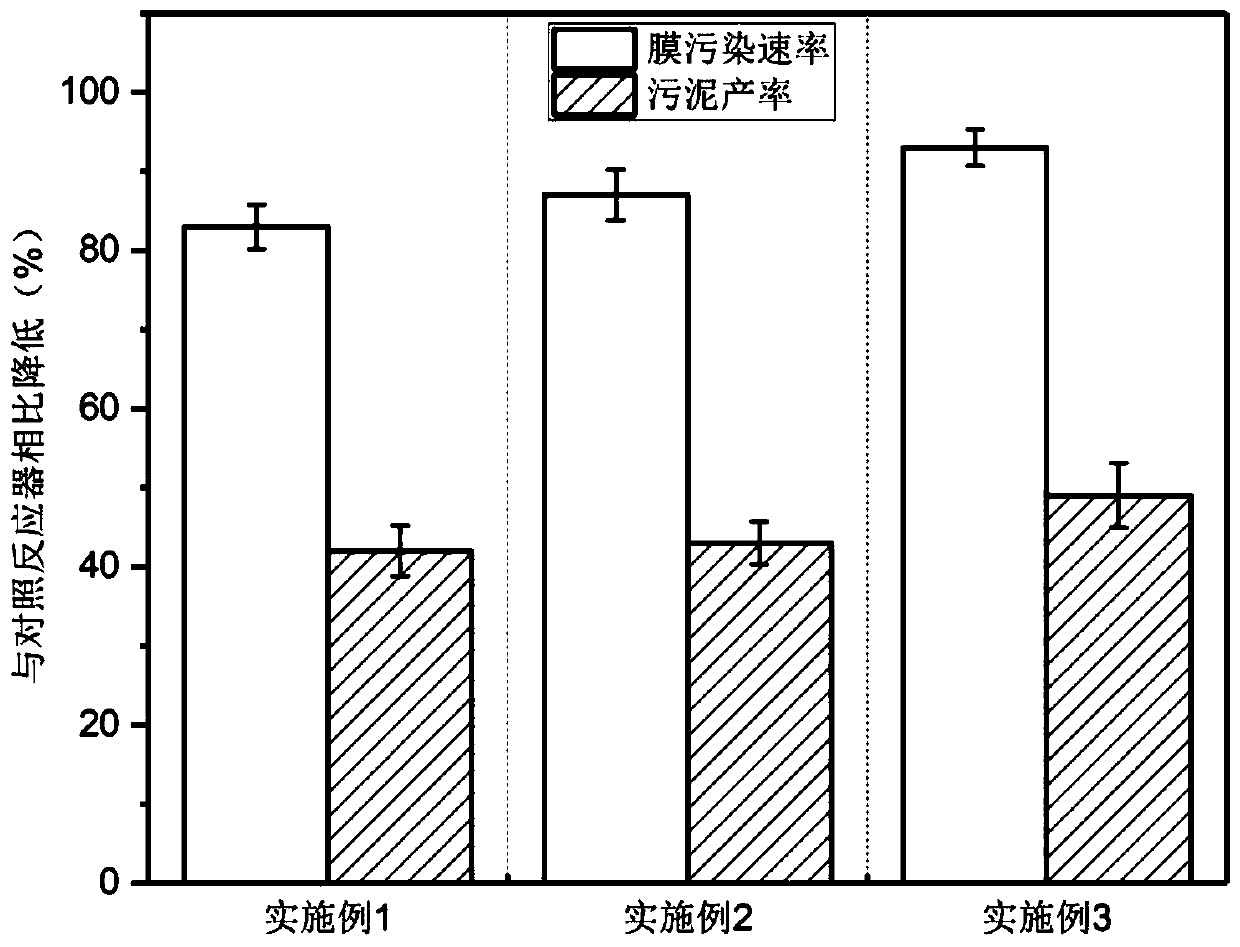

[0022] Example 1: The membrane material of the ultrafiltration membrane module in the device is polyvinylidene fluoride, the retention capacity of the membrane is 5kDa, and the membrane flux is 10L / m 2 h, the working and stopping time of the membrane were 12min and 3min respectively; the dosage of potassium ferrate was 0.01mmol / L. The operating conditions of the membrane bioreactor device: the hydraulic retention time is 12h, the sludge retention time is 30d, the air-water ratio is 20:1, the total iron content of the biopolymer iron solution is 85g / L, and the dosage is 0.04mmol / L.

[0023] The raw water is chemical wastewater, the chemical oxygen demand (COD) of the raw water is 5720-6524mg / L, and the biochemical oxygen demand (BOD 5 ) is 472-563mg / L. attached by figure 2 It can be seen that, compared with the control reactor, the membrane fouling rate of the device of the present invention is reduced by 83%, and the production rate of activated sludge is reduced by 42%. ...

Embodiment 2

[0024] Example 2: The membrane material of the ultrafiltration membrane module in the device is polyvinylidene fluoride, the retention capacity of the membrane is 5kDa, and the membrane flux is 8.6L / m 2 h, the working and stopping time of the membrane are 12min and 3min respectively; the dosage of potassium ferrate is 0.02mmol / L. The operating conditions of the membrane bioreactor device: the hydraulic retention time is 14h, the sludge retention time is 30d, the air-water ratio is 20:1, the total iron content of the biopolymer iron solution is 93g / L, and the dosage is 0.05mmol / L.

[0025] Raw water is pharmaceutical wastewater, COD is 7540~7985mg / L, BOD 5 It is 366~428mg / L. attached by figure 2 It can be seen that, compared with the control reactor, the membrane fouling rate of the device of the present invention is reduced by 87%, and the production rate of activated sludge is reduced by 43%. The effluent of the device fully meets the secondary discharge standard of the ...

Embodiment 3

[0026] Example 3: The membrane material of the ultrafiltration membrane module in the device is polyvinylidene fluoride, the retention capacity of the membrane is 5kDa, and the membrane flux is 7.5L / m 2 h, the working and stopping time of the membrane were 12min and 3min respectively; the dosage of potassium ferrate was 0.03mmol / L. The operating conditions of the membrane bioreactor device: the hydraulic retention time is 16h, the sludge retention time is 30d, the air-water ratio is 20:1, the total iron content of the biopolymer iron solution is 97g / L, and the dosage is 0.06mmol / L.

[0027] Raw water is wastewater containing anionic surfactant, COD is 11870~14470mg / L, BOD 5 It is 675~869mg / L. attached by figure 2 It can be seen that, compared with the control reactor, the membrane fouling rate of the device of the present invention is reduced by 93%, and the production rate of activated sludge is reduced by 49%. The effluent of the device fully meets the secondary discharge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com