Sealing device for expansion joint of clean workshop

A technology for clean workshops and expansion joints, applied to building components, building insulation materials, buildings, etc., can solve the problems that the device cannot produce resistance effects, and achieve the effects of simple structure, reduced environmental pollution, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

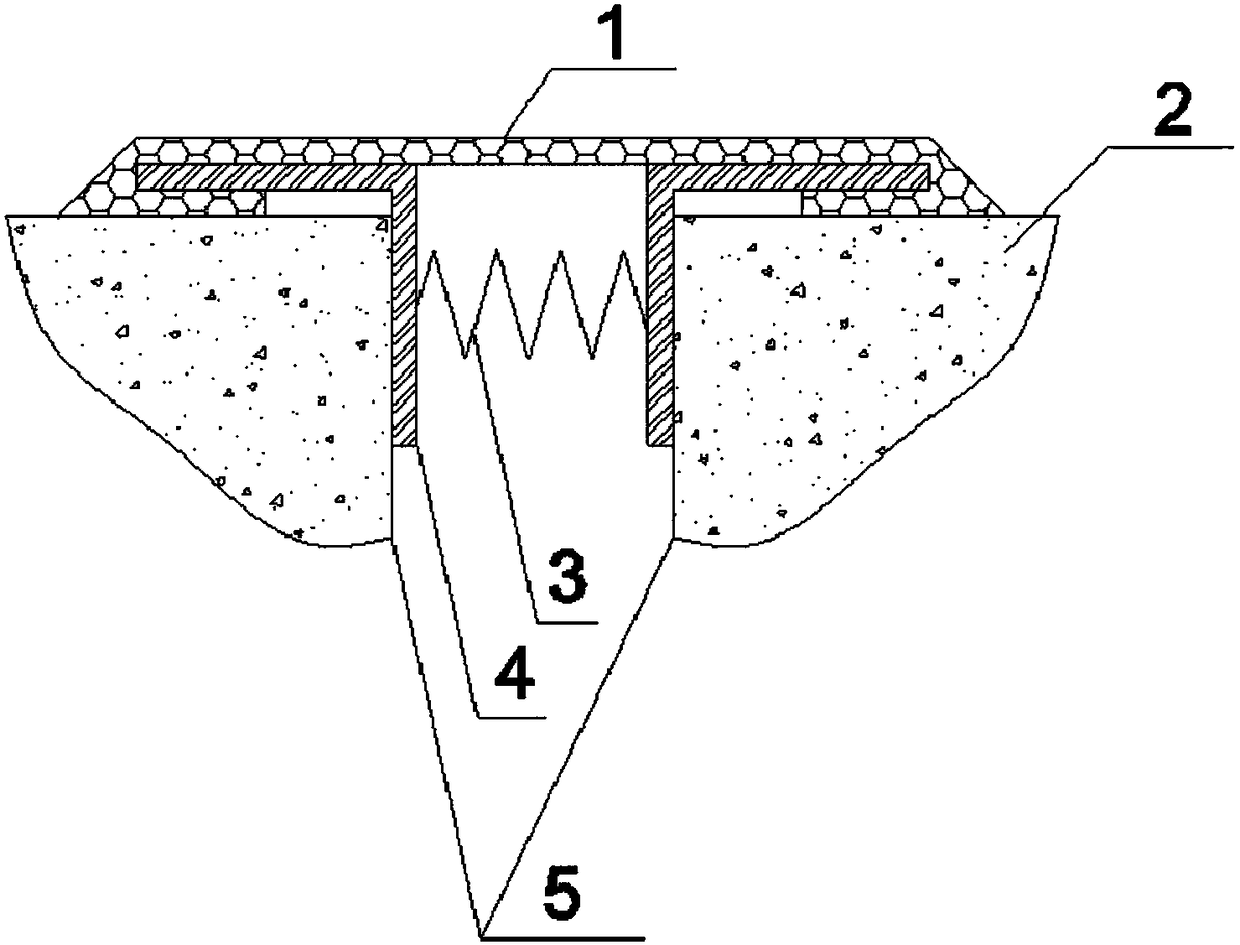

[0018] combined with figure 1 as shown,

[0019] Shown is a clean workshop expansion joint sealing device provided by the present invention, including wear-resistant elastic soft material 1, elastic material 3, and steel frame 4; the steel frame 4 is close to the floor of the adjacent clean workshop on both sides of the expansion joint 5 2. Embed the expansion joint 5 by pressing it inwardly, and seal it with the wear-resistant elastic soft material 1 in the horizontal direction after the embedding; the elastic material 3 is placed in the middle of the expansion joint 5 . The steel skeleton 4 is a "7"-shaped structure, and the elastic material 3 is a spring; the steel skeleton 4 is sealed and embedded with a wear-resistant elastic soft material in the horizontal direction, and it is seamlessly attached to the floor in the vertical direction, that is, steel The horizontal part of the framework 4 is wrapped in the wear-resistant elastic soft material 1 . The wear-resistant ela...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com