High heat-resistant waterborne coating

A high hot water resistance, coating technology, applied in fireproof coatings, polyester coatings, polyurea/polyurethane coatings, etc., can solve the problem of poor heat resistance, poor heat resistance and weather resistance of water-based environmental protection coatings, complex extract extraction process, etc. problem, achieve good heat resistance, strong scratch resistance, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] Embodiment 1 A kind of high hot water resistance coating

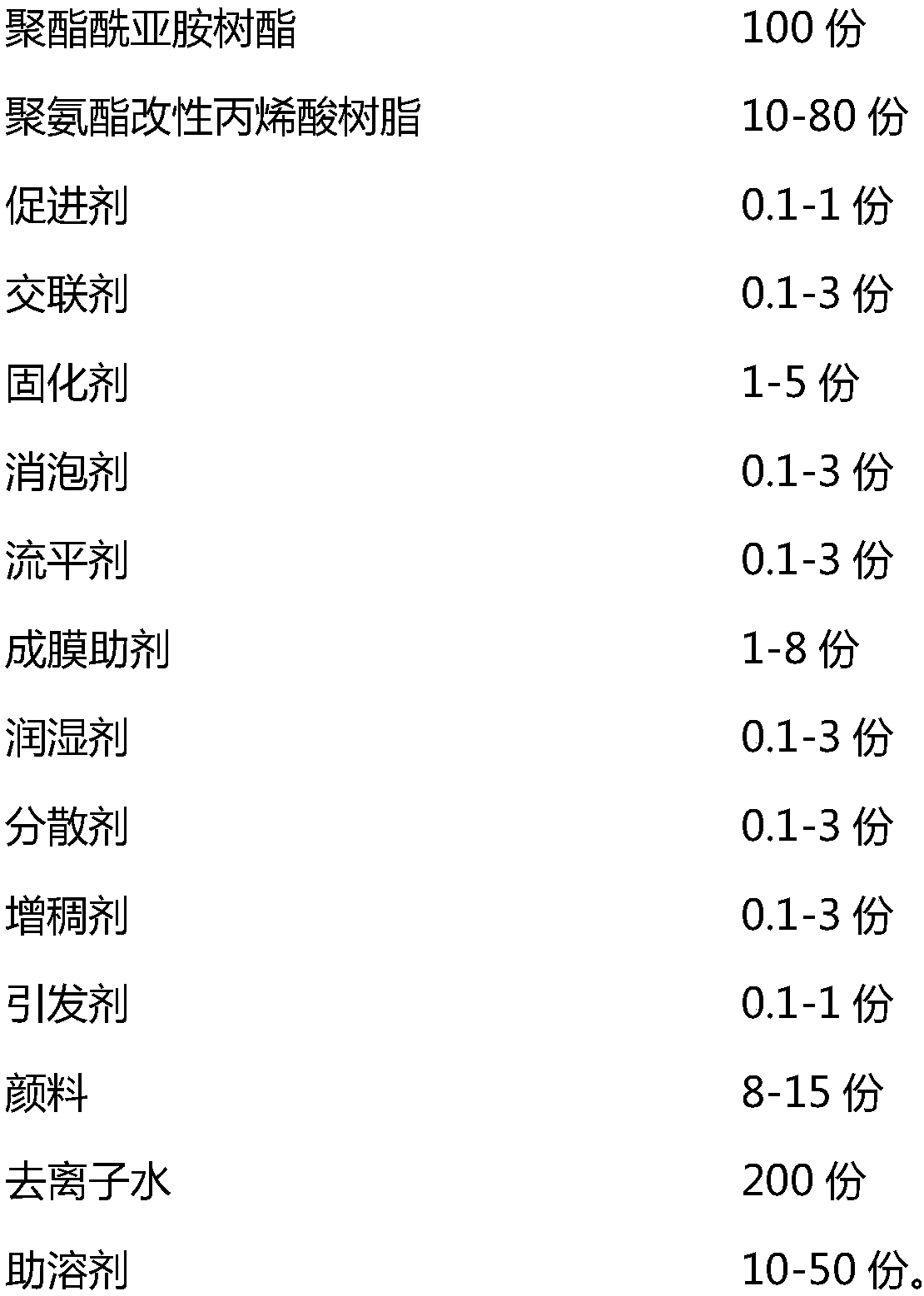

[0061] Components: parts by weight

[0062]

[0063]

[0064] Preparation method: comprising the following steps:

[0065] 1) Put the polyester imide resin, polyurethane modified acrylic resin and azobisisobutylamidine hydrochloride into the reaction kettle in sequence, stir at a speed of 400r / min for 20min, and stir evenly; 2) Mix the amount of polydimethylsiloxane, diethylenetriamine, trimethylhexamethylenediamine, diatomaceous earth, propylene glycol butyl ether and deionized water evenly and add it to the In the reaction kettle, heat up to 50°C at a speed of 400r / min, and stir;

[0066] 3) Sequentially add aminopropylamine dioleate and polyoxyethylene dioleate into the reaction kettle, mix and heat up to 60°C at 600r / min, and stir evenly;

[0067] 4) Add the formula dosage of polyoxyethylene polyoxypropanolamine ether and aminopropylamine dioleate to the reaction kettle, stir at a speed of 900r / min ...

Embodiment 2

[0068] Embodiment 2 A kind of high hot water resistance coating

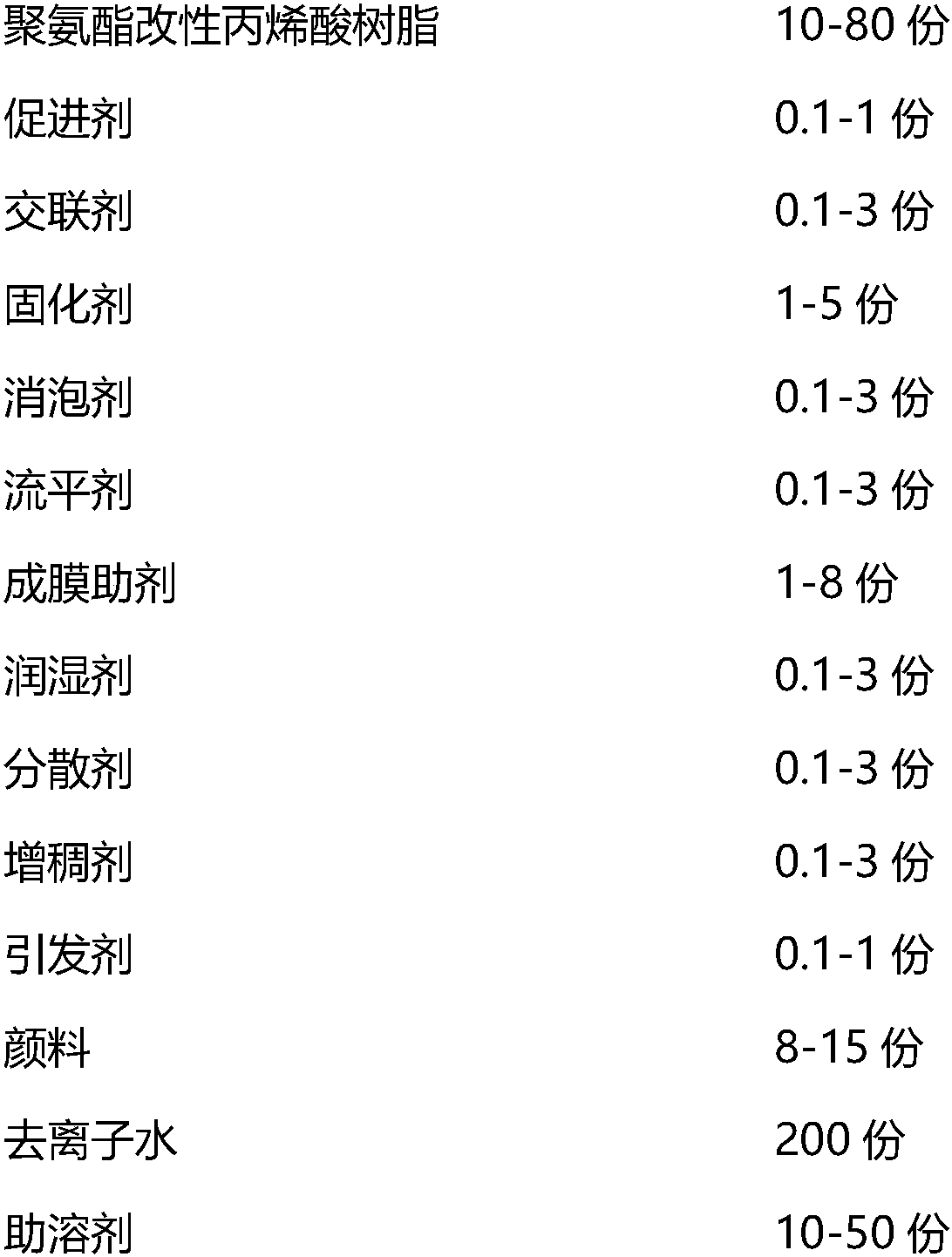

[0069] Components: parts by weight

[0070]

[0071] Preparation method: except that the components are different, other steps and methods are the same as in Example 1.

Embodiment 3

[0072] Embodiment 3 A kind of high hot water resistance coating

[0073] Components: parts by weight

[0074]

[0075]

[0076] Preparation method: except that the components are different, other steps and methods are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com