Filling and capping operation station for nail polish

A nail polish and filling technology, which is applied in the field of nail polish filling and capping operation stations, can solve the problems affecting the health of workers and the inability to directly use a fully automatic filling and capping production line to reduce the impact of irritating gases Hidden dangers, the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in further detail below in conjunction with the accompanying drawings.

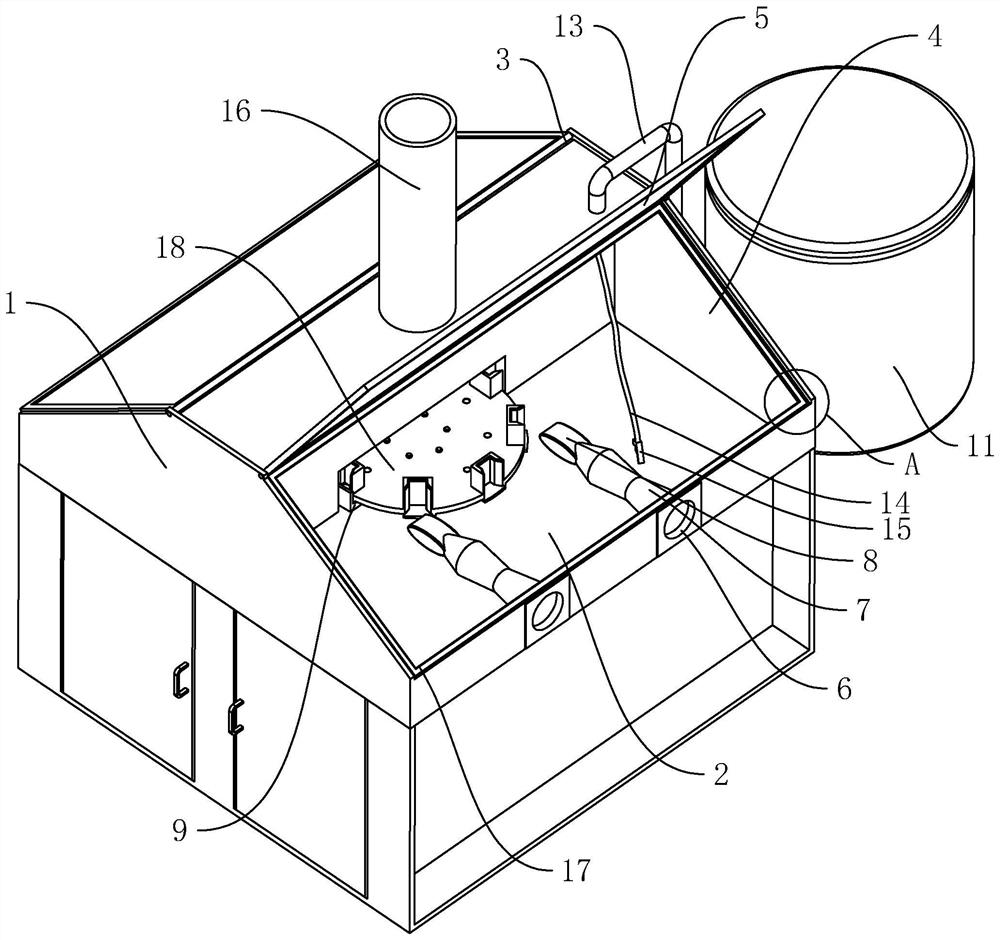

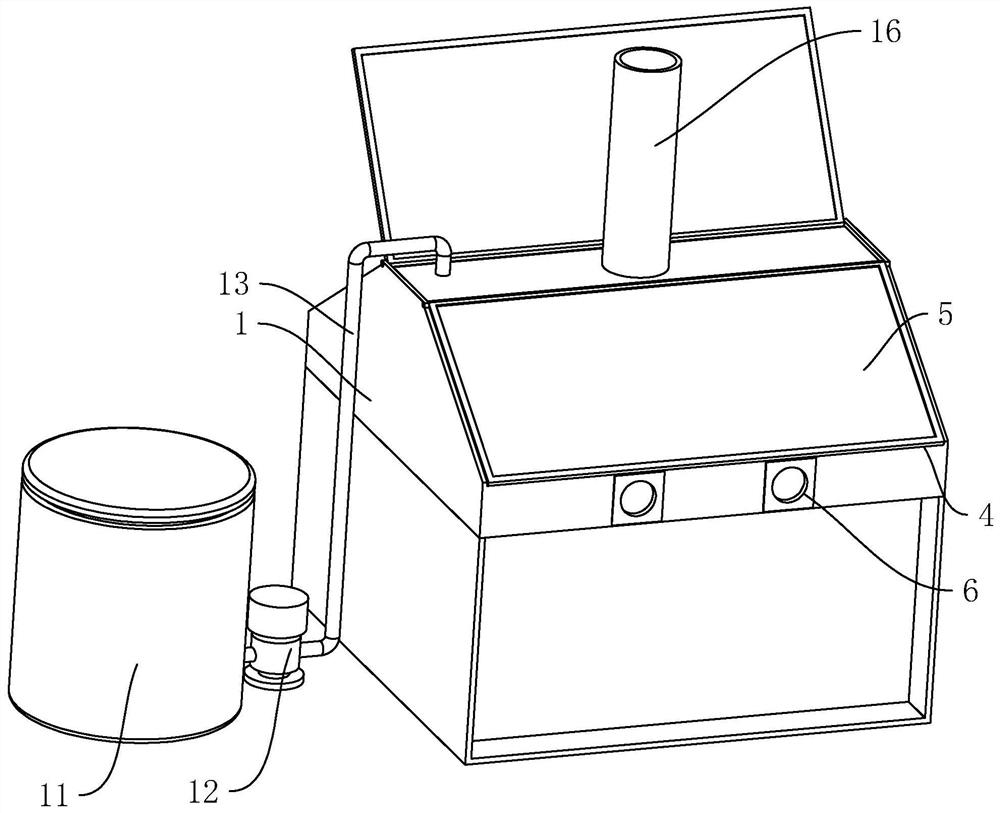

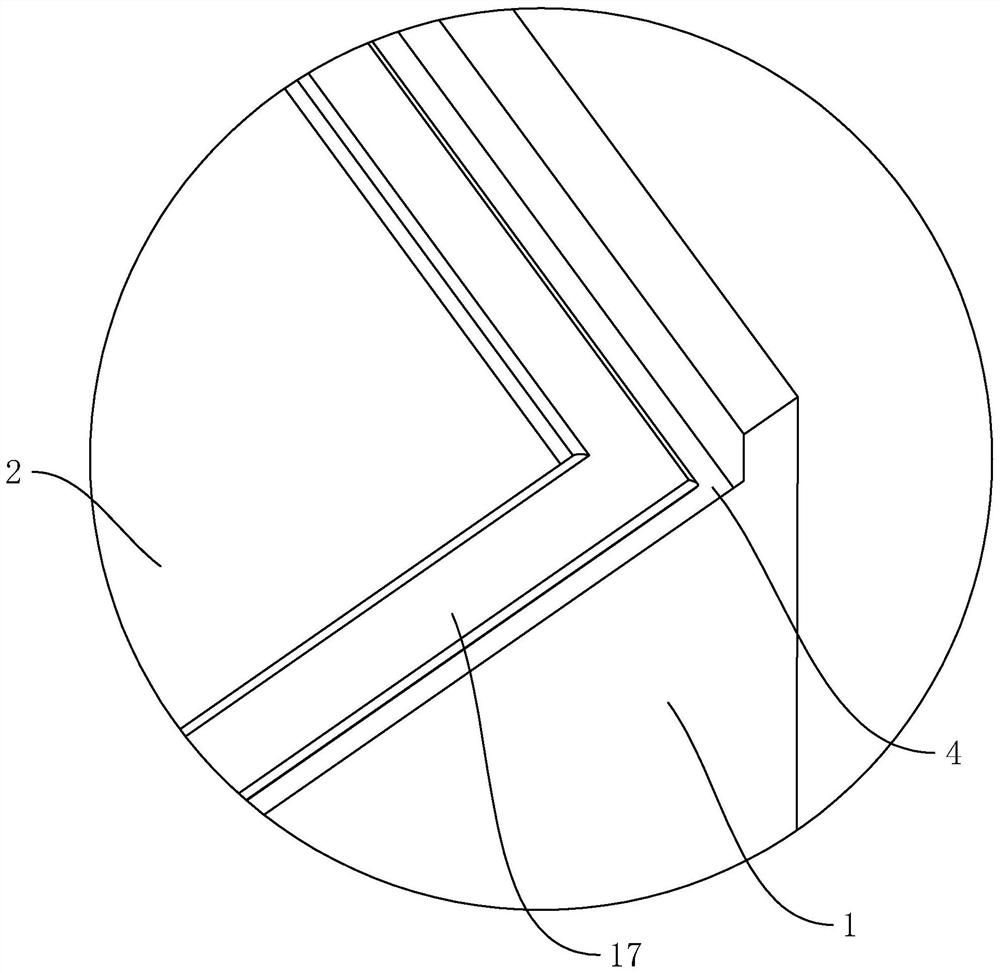

[0035] Filling and capping operation station for nail polish, such as figure 1As shown, including a cabinet body 1, the cabinet body 1 is symmetrically provided with a filling chamber 2 and a capping chamber 3, and the filling chamber 2 and the capping chamber 3 are all provided with a viewing window 4, and the viewing window 4 is provided with a transparent glass 5, and the filling chamber 2 and the capping chamber 3 are equipped with a transparent glass 5. Both the filling chamber 2 and the capping chamber 3 are provided with two hand holes 6, the hand holes 6 are glued to the sleeve 7, the end of the sleeve 7 is integrally woven with gloves 8, and the cabinet body 1 is provided with a connection filling chamber 2 and the alternate mechanism of the capping chamber 3, the cabinet body 1 is provided with a discharge channel 9 communicating with the alternate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com