Full-automatic printing ink filling assembly line

An automatic filling and assembly line technology, applied in packaging, packaging machines, transportation and packaging, etc., can solve the problems of waste of human resources, low degree of automation, inconvenient adjustment of filling speed, etc., to improve production efficiency and product quality, Improve filling accuracy and efficiency, and increase the effect of automatic feeding function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings.

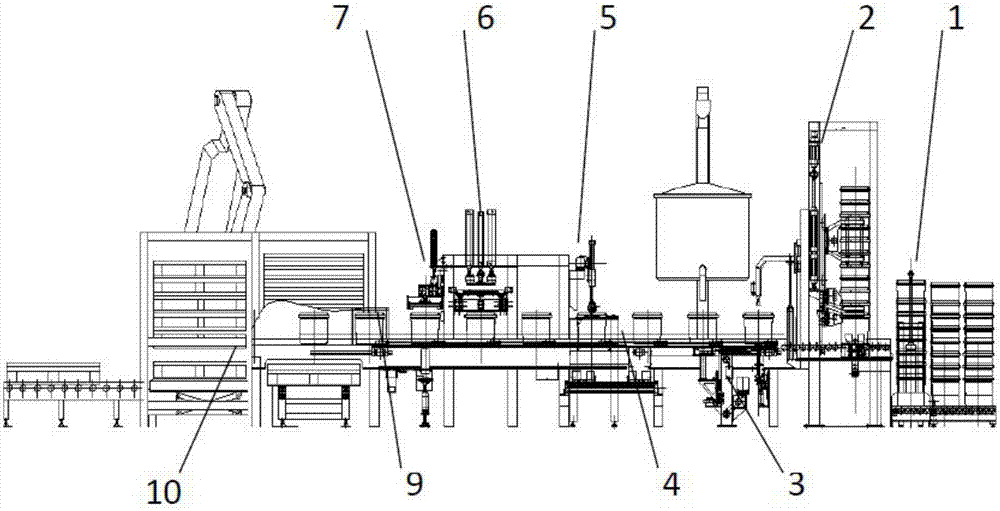

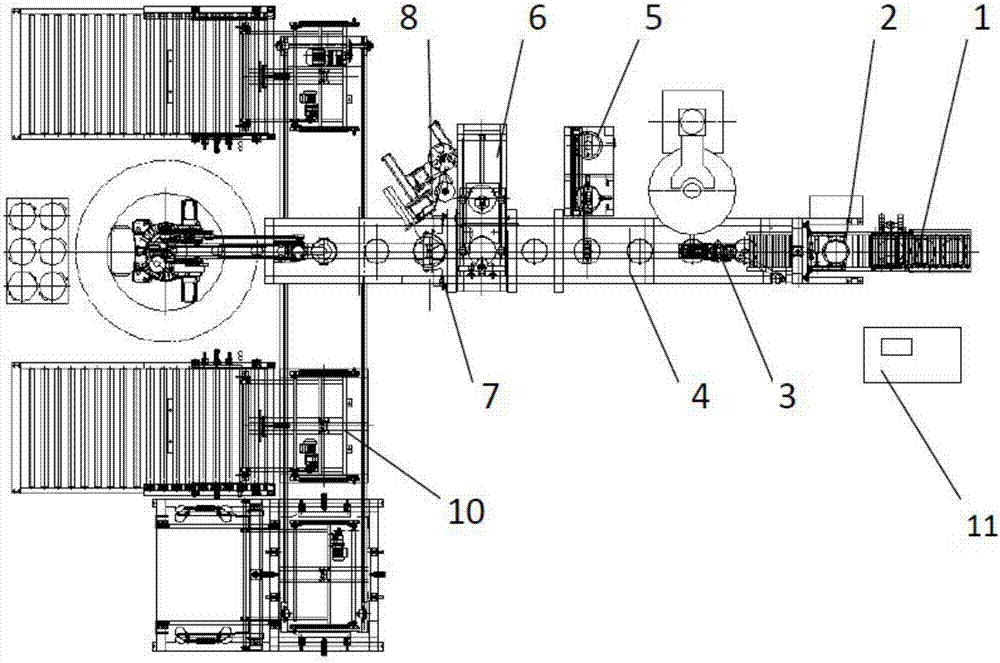

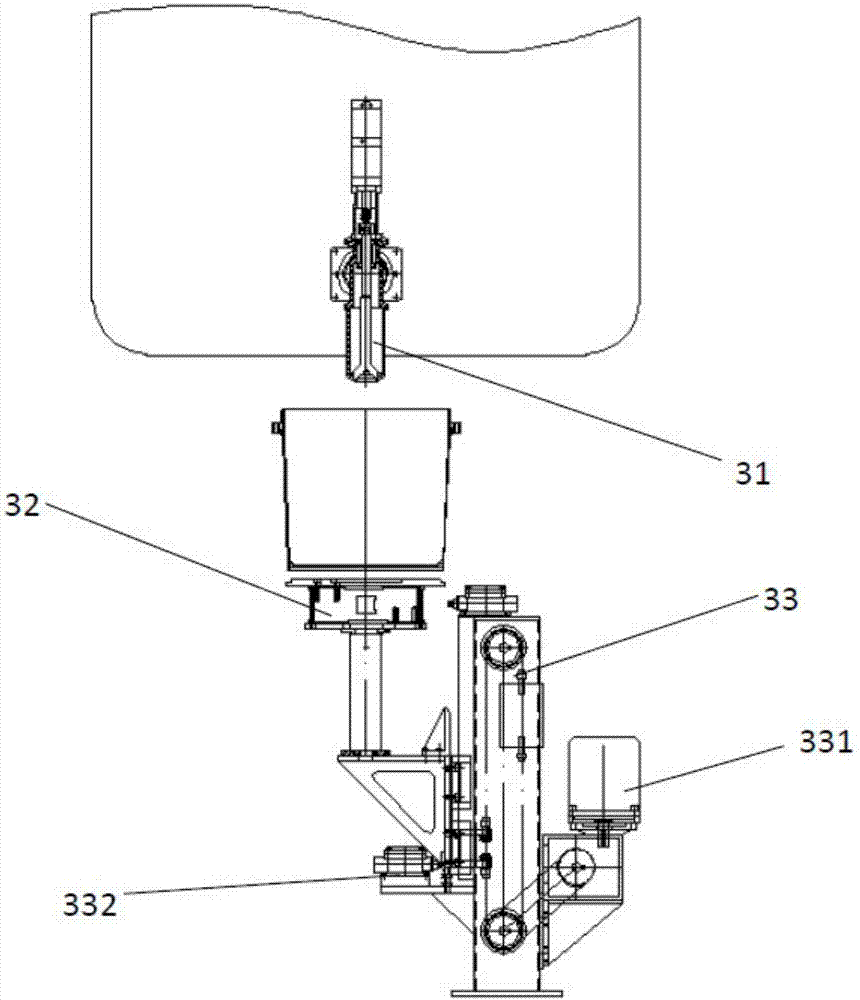

[0019] as attached figure 1 and figure 2 As shown, the ink automatic filling line of the present invention sequentially includes a barrel loading station, a barrel dividing station, a filling station, a laminating station, a capping station, a cap screwing and labeling station, and a label identification station. The station and the robot stacking station, between two adjacent stations, the material is transferred and positioned by the stepping conveying line body 4. The barrel-loading station is equipped with an automatic barrel-loading device 1, and the whole stack of barrels is transported to the automatic barrel-separating device 2 through the electric roller and the lifting cylinder, and a series of barrel-separating cylinders on the automatic barrel separating device 2 move a whole stack of barrels The plastic barrels are automatical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com