Method and equipment for filling liquid in temperature sensing bulb of thermostatic expansion valve

A thermal expansion valve and temperature-sensing bulb technology, which is applied in lighting and heating equipment, refrigeration and liquefaction, and fluid circulation arrangements, can solve the problems of short service life of thermal expansion valves, poor filling quality of temperature-sensing bulbs, and uneven product quality. Qi and other problems, to achieve the effect of reliable sealing performance, long service life and simple equipment structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

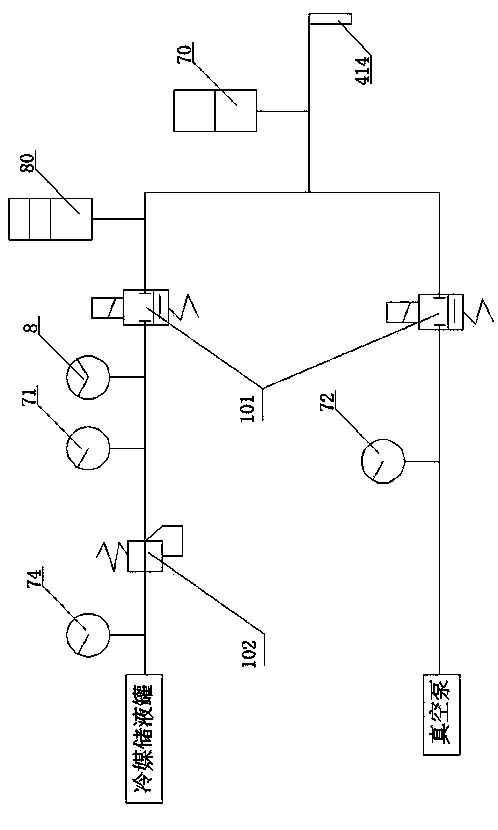

[0027] A liquid filling method for a temperature sensing bulb of a thermal expansion valve in this embodiment includes the following steps:

[0028] Step a: Vacuumize the inside of the thermal expansion valve temperature sensing bulb to -1MPa;

[0029] Step b: Fill 0.5 MPa of refrigerant into the temperature sensing bulb of the thermal expansion valve;

[0030] Step c: Flatten the capillary filling end of the thermal expansion valve about 1 cm from the mouth of the tube to seal it;

[0031] Step d: welding and sealing the nozzle of the capillary filling end of the thermal expansion valve.

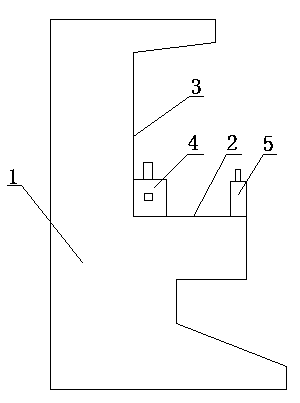

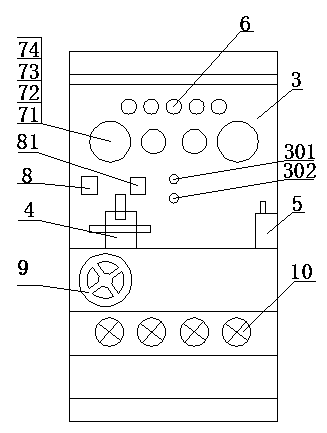

[0032] The equipment used in the above charging method, such as figure 1 , figure 2 As shown, the device body 1 is included, the front side of the device body 1 is provided with a horizontal workbench 2, a control panel 3 vertically arranged with the workbench 2, and a filling tool 4 is fixedly arranged on one side of the workbench 2, and another A welding station 5 is arranged on one ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com