Quantitative filling device for blend oil packing

A filling device and a technology for blending oil, which is applied in the directions of transportation and packaging, packaging, and the type of packaged items, and can solve problems such as reduced fluidity, oil volume error, and high viscosity of blended oil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

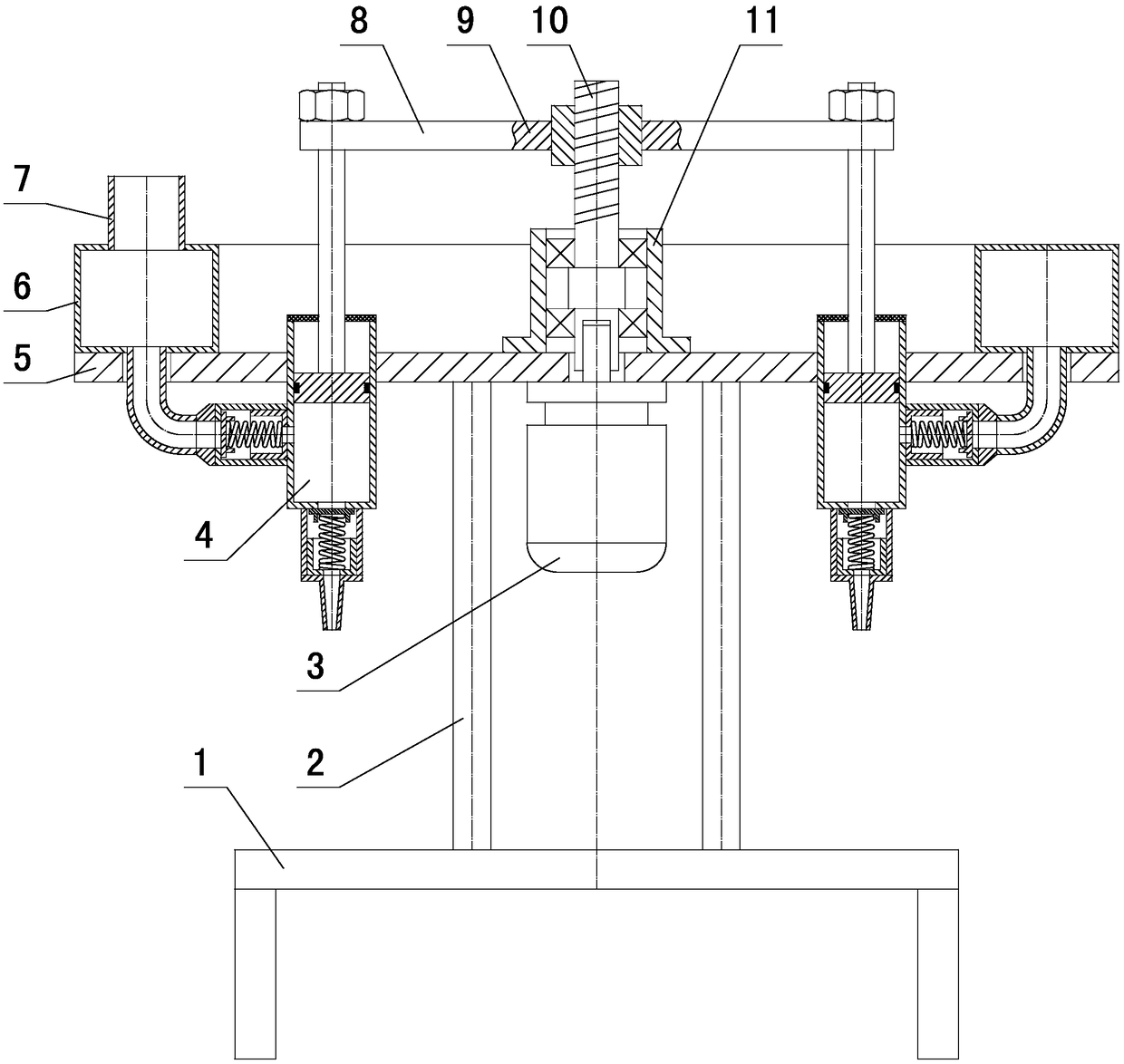

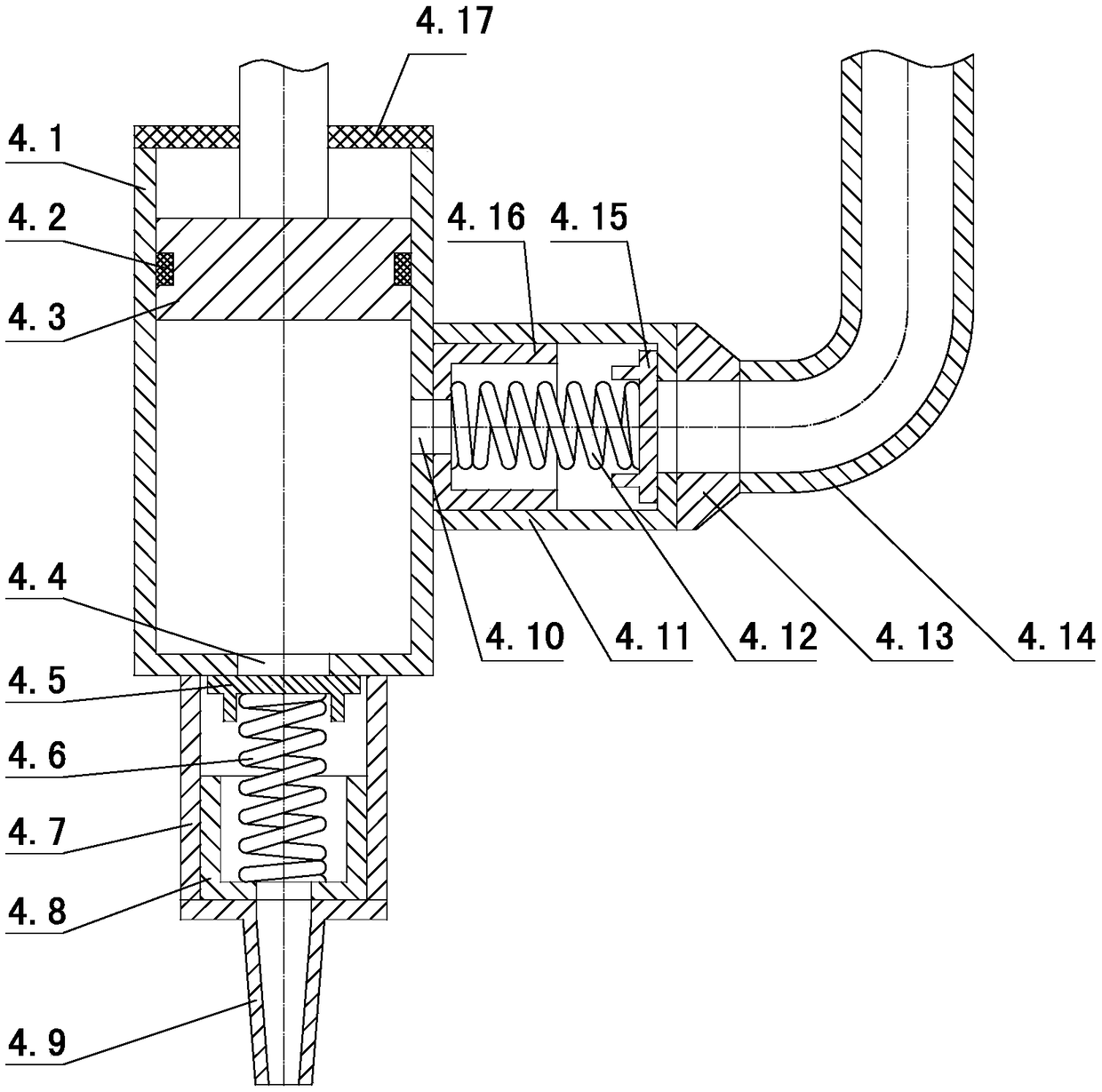

[0018] Such as figure 1 , figure 2 As shown, the quantitative filling device for blending oil packaging includes a horizontally arranged workbench 1, a mounting plate 5 is horizontally arranged above the workbench 1, and a vertically installed Support bar 2, mounting plate 5 is fixed on the workbench 1 by support bar 2, and bearing box 11 is vertically installed on mounting plate 5, and adjusting screw rod 10 is vertically worn in bearing box 11, and on mounting plate 5 An adjustment plate 8 is arranged horizontally above the adjustment plate 8, and an adjustment sleeve 9 is vertically worn on the adjustment plate 8. The upper end of the adjustment screw rod 10 is installed in the adjustment sleeve 9 through threads, and the lower end of the adjustment screw rod 10 is installed in the bearing box 11 through a bearing. Inside, an annular oil pool 6 is horizontally arranged on the mounting plate 5, and an oil supply pipe 7 connected to it is vertically provided on the annular ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com