Liquid CO2 extinguisher filling device

A technology of fire extinguisher and CO2, which is applied in the direction of equipment loaded into pressure vessels, mechanical equipment, container filling methods, etc., can solve the problems of affecting measurement accuracy, low measurement accuracy, poor efficiency, etc., and achieve safe and convenient operation and high filling accuracy High and efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

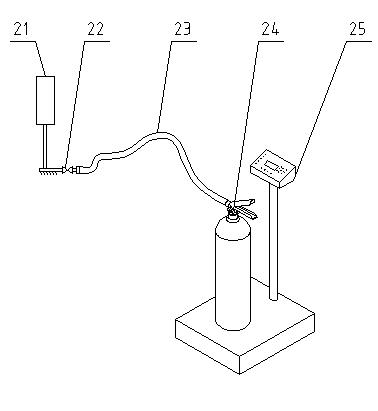

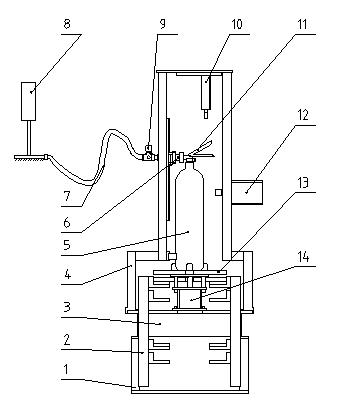

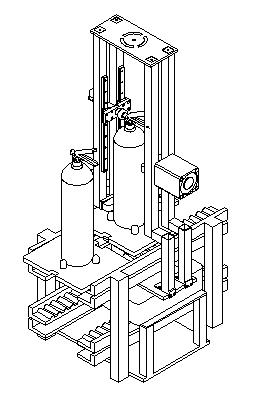

[0027] Such as Figure 2-Figure 3 The liquid CO2 fire extinguisher filling equipment shown has a production line 2 passing through the main body 4 of the equipment, the weighing sensor 3 is installed on the base 1, the equipment main body 4 is installed on the weighing sensor 3, and is in the middle of the equipment main body. The heavy sensor 3 is equipped with a bottle supporting cylinder 14, and the bottle supporting cylinder 14 supports the tooling plate 13 and the 2 fire extinguisher cylinders 5. On the right side of the frame of the equipment main body 4, the shoulder of the 2 fire extinguisher cylinder 5 is equipped with a clamping cylinder 12, 2 The valve port 51 of the gas cylinder 5 of the fire extinguisher is connected to the inflation port 41 of the inflatable part 6, and the inflatable part 6 is connected to the low-temperature and high-pressure pneumatic valve 9, and the inflatable part can slide up and down along the guide rail 45 and be positioned to adapt to M...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com