Filling device and filling method for objects to be packed of filling and packing machine

A technology of filling device and filling method, which is applied to the types of packaging items, special packaging items, packaging, etc., can solve the problems of increased filling accuracy, reduced productivity, and increased productivity, and achieve the goal of improving filling accuracy, increasing productivity, and high-efficiency filling Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

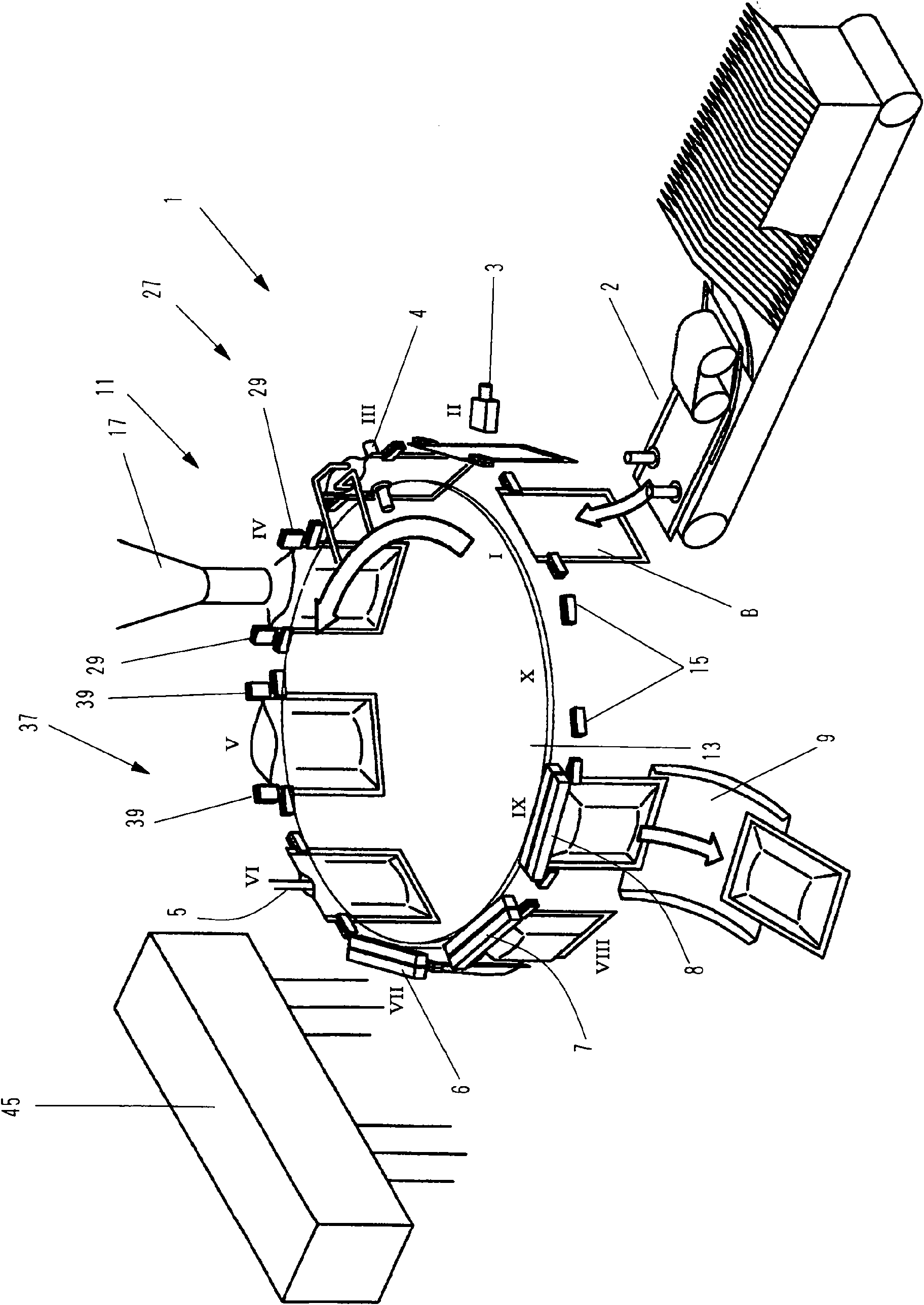

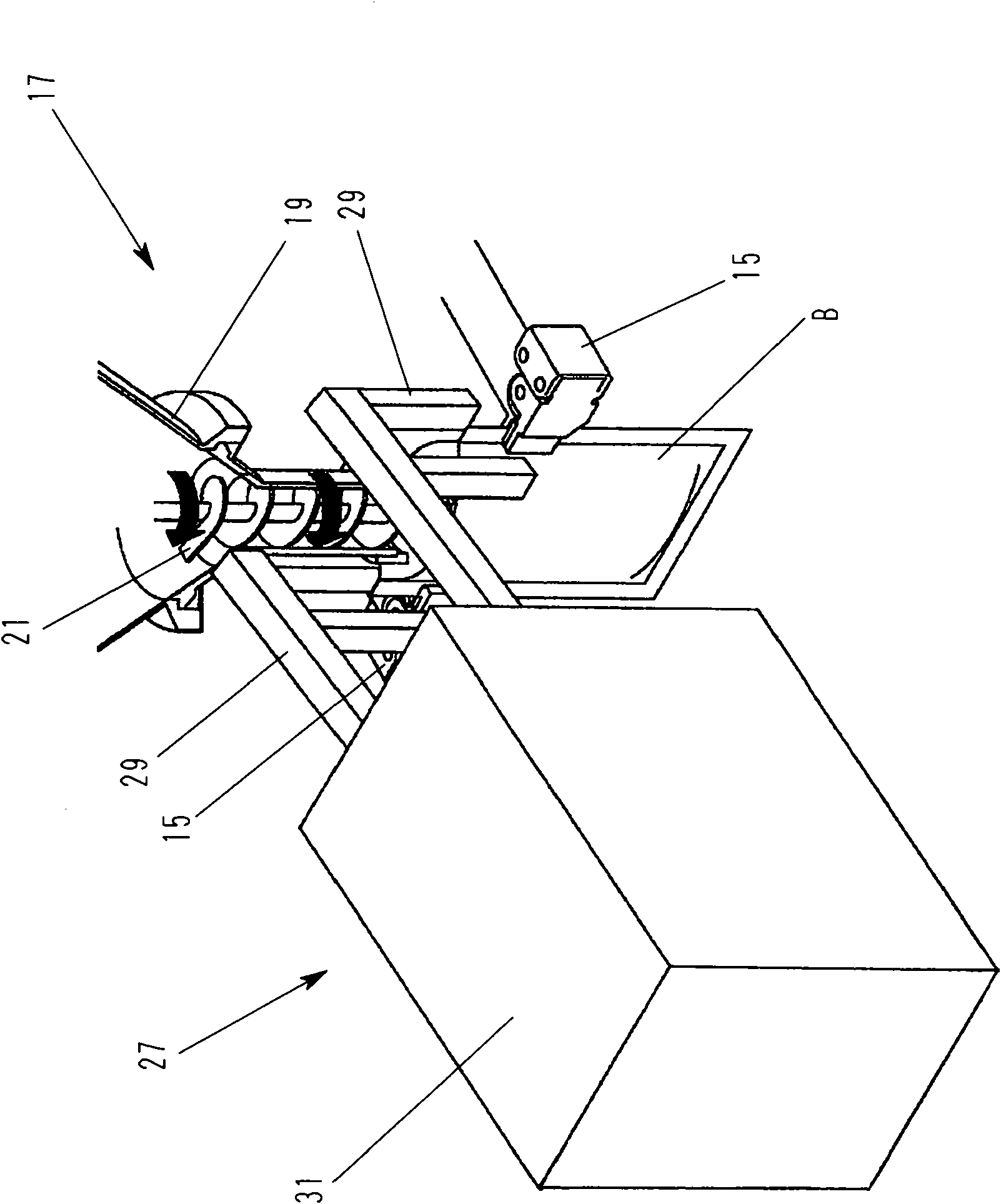

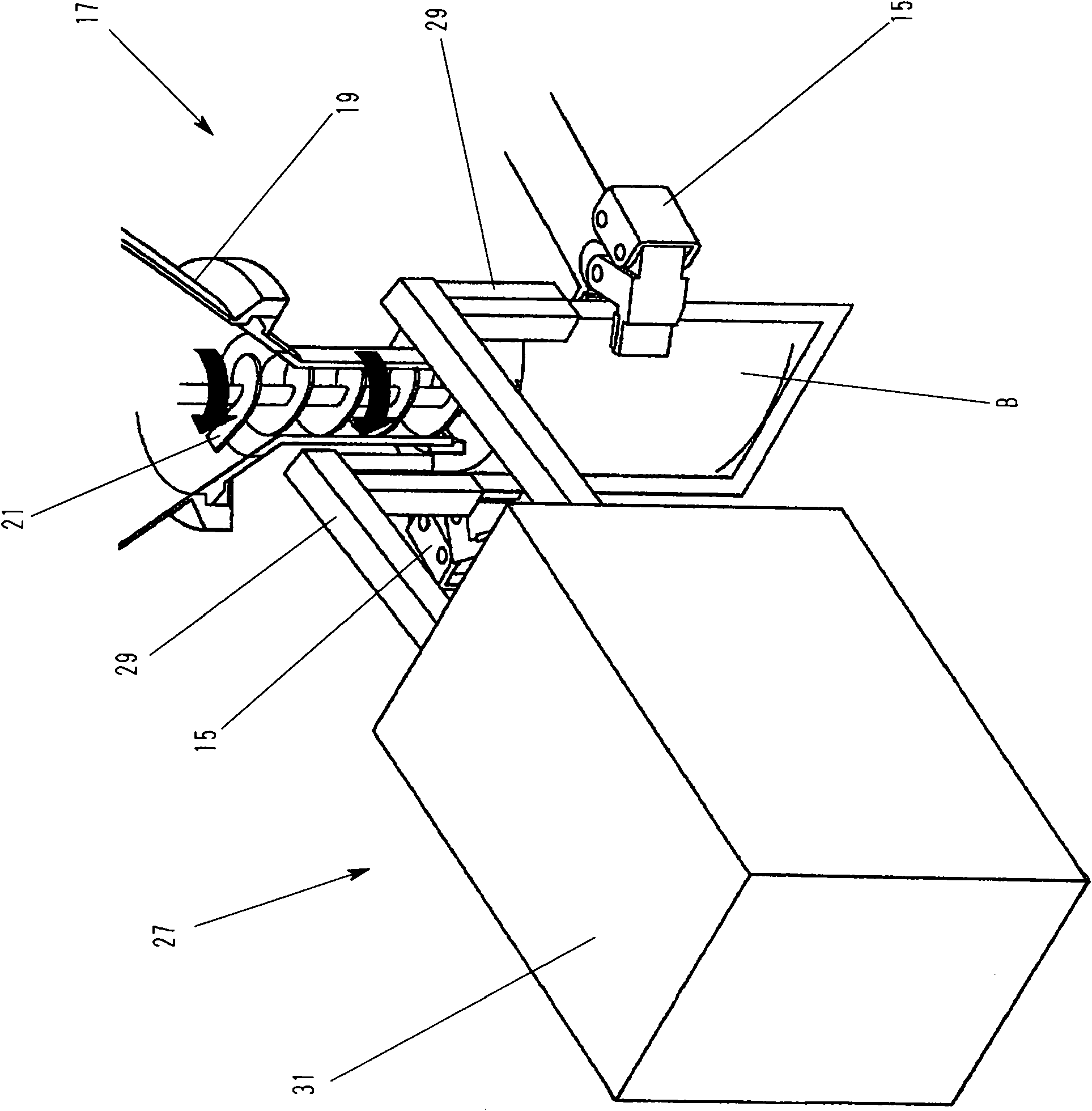

[0042] Next, a packaging object filling device (hereinafter referred to as "filling device") according to one embodiment of the present invention will be described with reference to the drawings.

[0043] figure 1 It is a schematic perspective view showing an intermittent conveyance type vertical filling and packaging machine (hereinafter referred to as "packing machine") 1 using a filling device 11 according to an embodiment of the present invention. Reference numeral 13 is a rotary table, which is connected to an index unit (not shown) and a motor, is determined by the index unit, and moves and stops intermittently and repeatedly in accordance with the rotation angle of the motor. Therefore, when the rotation speed of the motor changes, its moving speed and stop time change, but the corresponding relationship between the stop timing and the rotation angle of the motor does not change. In addition, in this embodiment, the moving track of the bag is a circle, but it is not li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com