Filling machine

A filling machine and filling technology, applied in the field of machinery and equipment, can solve the problems of difficult cleaning and inconvenient maintenance, and achieve the effect of improving filling accuracy and convenient cleaning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Embodiments of the present invention will now be described with reference to the drawings, in which like reference numerals represent like elements.

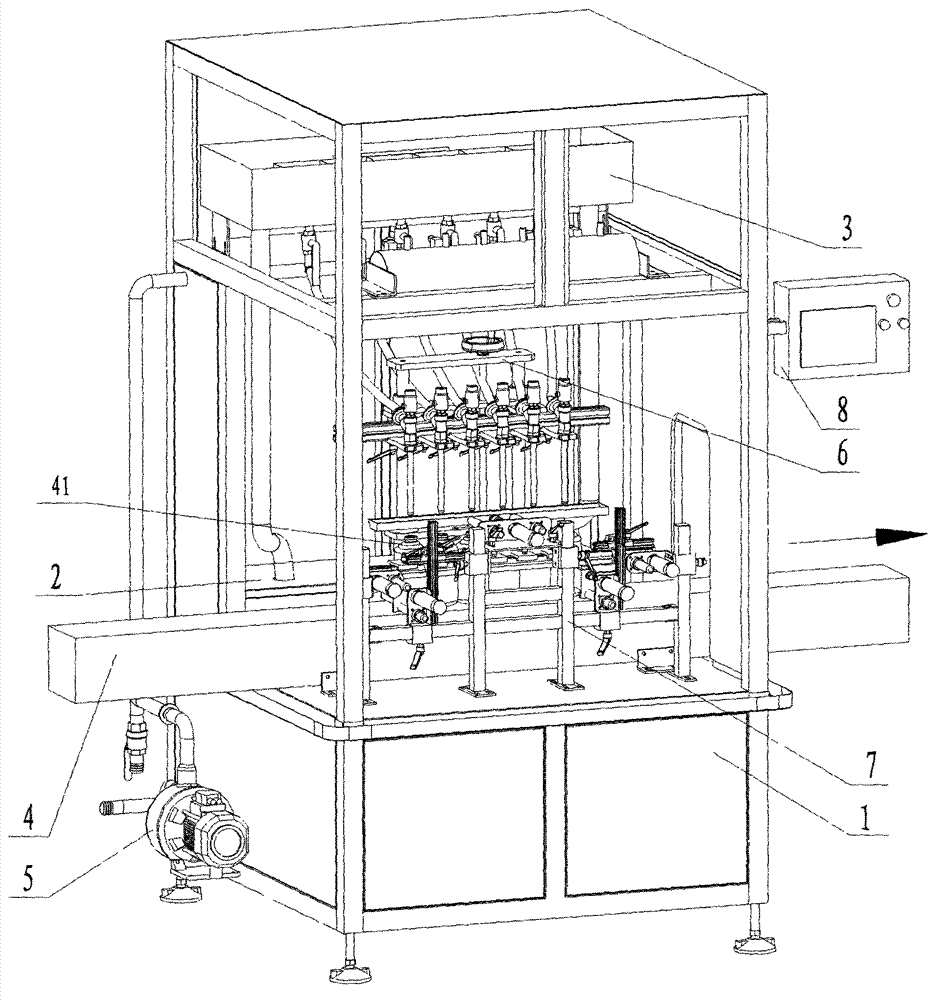

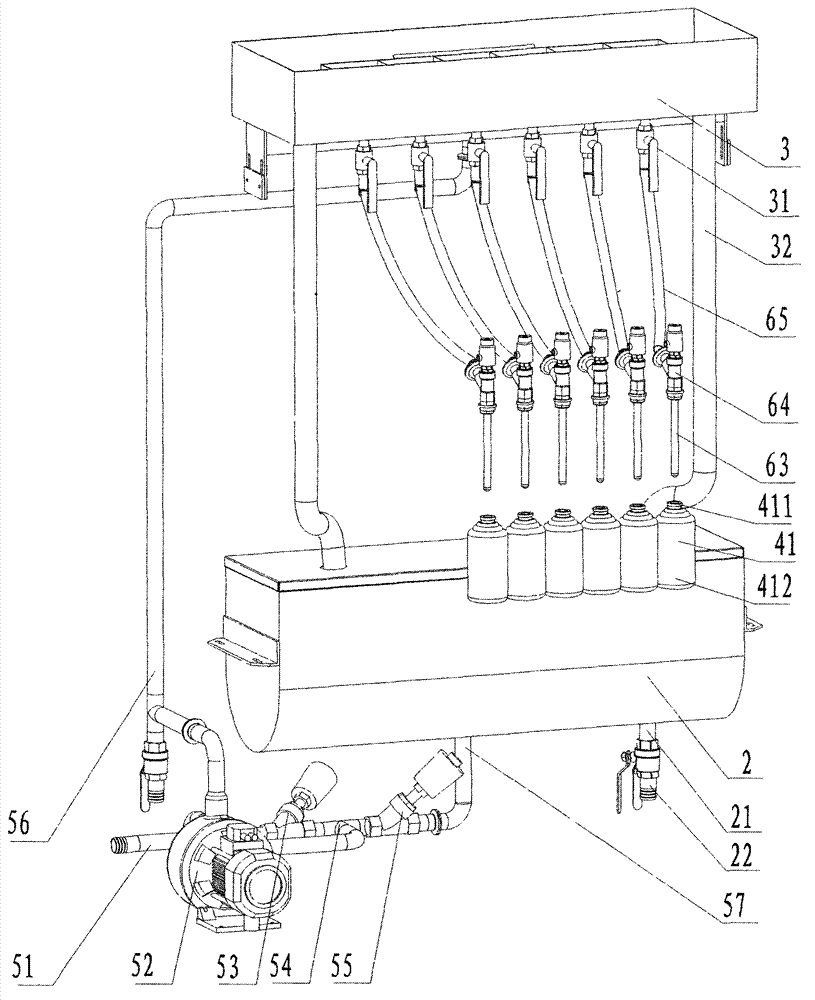

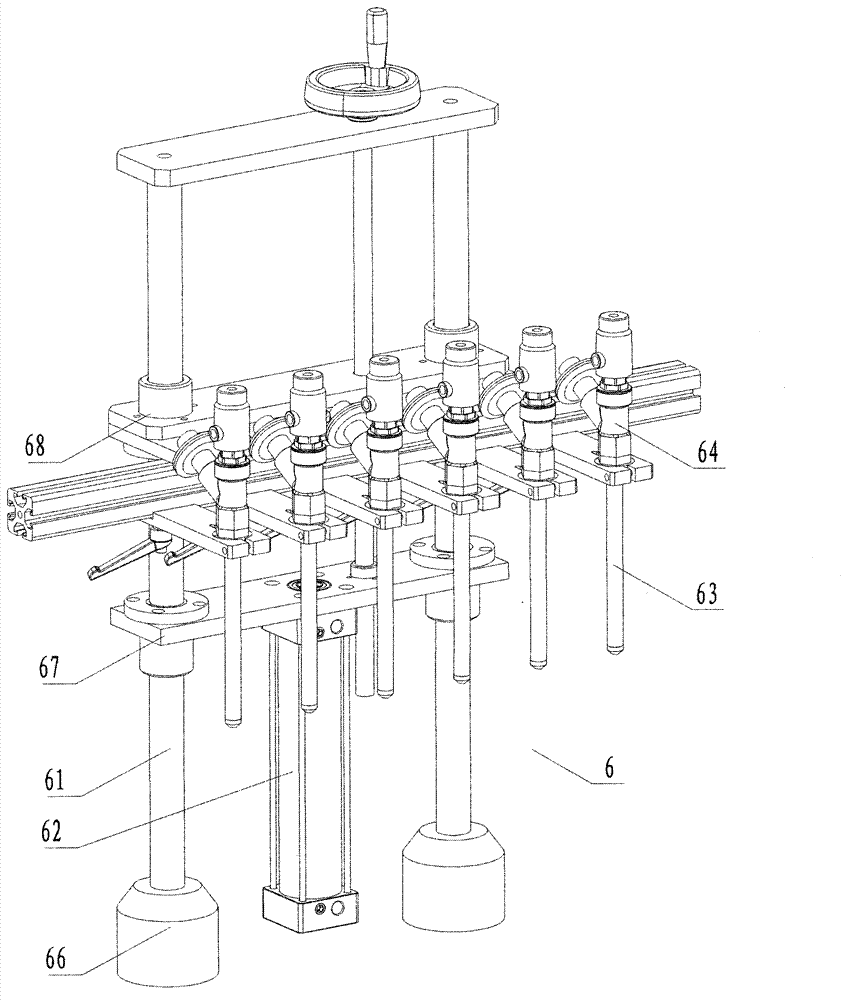

[0022] see figure 1 , the invention discloses a filling machine, which includes a frame 1, a liquid storage tank 2, an excessive liquid stabilization tank 3, a conveyor belt 4, a filling pump system 5, a filling lifting mechanism 6, an intercepting positioning mechanism 7 and a Control system 8; the frame 1 is used for fixed support, and the conveyor belt 4 is set on the frame 1 and kept parallel to the ground. It can be understood that the frame 1 and the conveyor belt 4 can be fixed as one. The conveyor belt 4 can carry, feed in and send out the containers 41 . Intercepting and positioning the excess material mechanism 7 is all arranged on the frame 1 and is positioned at both sides of the conveyor belt 4 . The liquid storage tank 2 is arranged on the frame 1 and is positioned at the rear of the filling lifting mechan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com