Filling method for low-melting-point alkali metal working mediums

An alkali metal, low melting point technology, applied in lighting and heating equipment, indirect heat exchangers, etc., can solve the problems of melting, failure, high activity, etc., and achieve the effect of low oxidation tendency, less danger, and high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the above objects, features and advantages of the present invention more comprehensible, specific implementations of the present invention will be described in detail below in conjunction with the accompanying drawings.

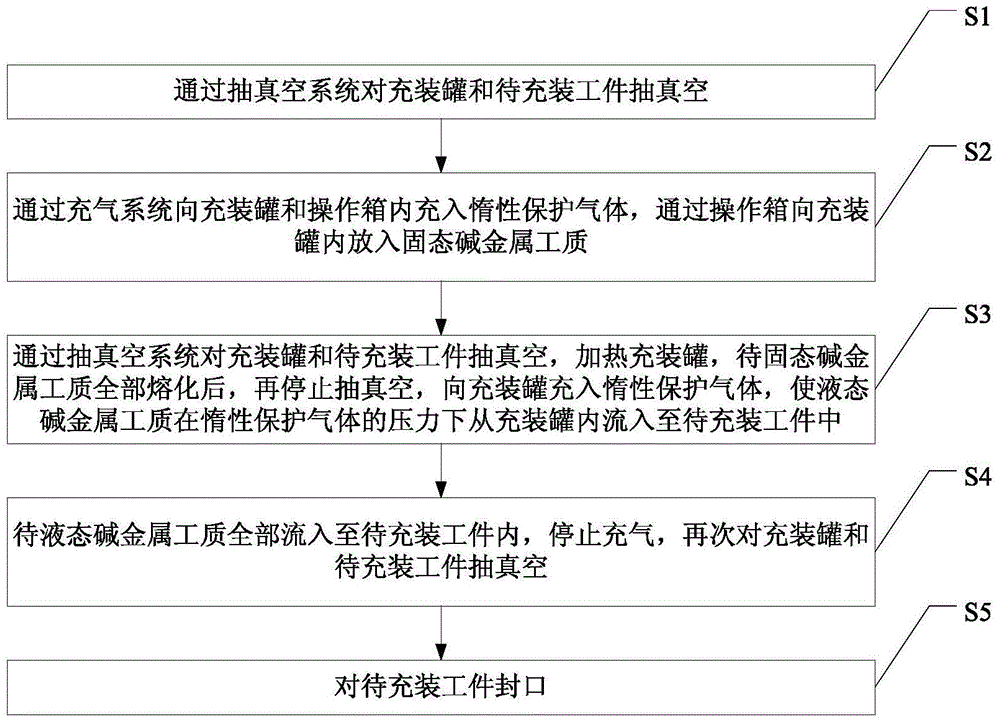

[0027] see figure 1 , figure 2 and image 3 , the invention provides a filling method of a low-melting-point alkali metal working fluid, comprising:

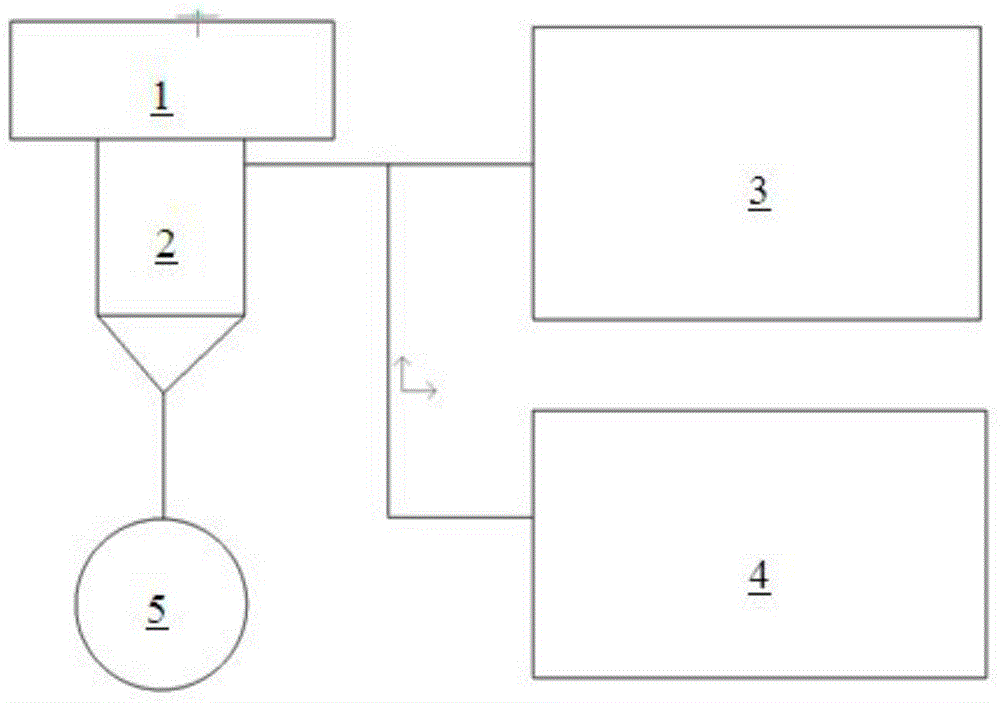

[0028] Step S1, an operation box is connected to a filling tank through a pipeline with a valve, the bottom of the filling tank is connected to a workpiece to be filled, and the filling tank is also connected to a vacuum system and an inflation system, so The operation box is connected to the inflation system; the valve is closed, and the filling tank and the workpiece to be filled are vacuumized through the vacuum pumping system;

[0029] Step S2, open the valve, fill inert protective gas into the filling tank and the operation box through the inflation system, put a certain quality...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com