A method for adding mold slag for casting centrifugal rolls

A technology of mold slag and rolls, which is applied in the field of roll manufacturing, can solve the problems of potential safety hazards for operators, difficulty in ensuring uniformity of mold slag, and poor uniformity of temperature field, etc., to avoid safety hazards, good slag discharge, and reduce inclusions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The composition and weight percentage of mold flux in this embodiment are Na 2 O 35.6% MgO 1.6% Al 2 o 3 7.2%SiO2 2 41.5%SO 3 0.3%P 2 o 5 1.1%K 2 O 0.8% CaO 2.5% Fe 2 o 3 4.2%Cl 0.21%, the rest are impurities.

[0027] In this embodiment, the solid mold powder is added into the centrifugal roll in a liquid form, and the specific method includes the following steps,

[0028] 1) Put the solid mold slag into the heating furnace 1, set the heating temperature to 1200°C through the control system of the heating furnace 1, and heat the solid mold slag to the specified temperature to melt the solid mold slag into a liquid state;

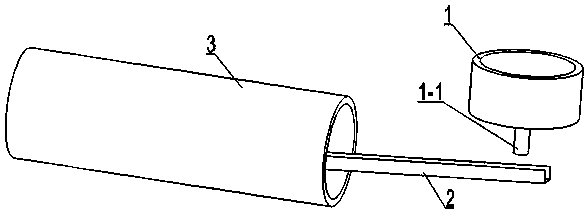

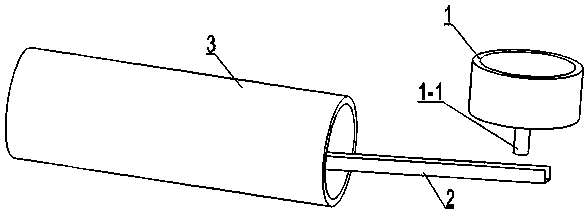

[0029] 2) After pouring the outer layer of molten iron on the centrifugal roll, pour the melted mold slag into the cold type 3 cavity of the centrifugal roll. The liquid mold slag in the heating furnace 1 flows into the stainless steel chute 2 through the slag pouring pipe 1 - 1 at the bottom of the heating furnace 1 , and pours into the c...

Embodiment 2

[0031] The composition and weight percentage of mold flux in this embodiment are Na 2 O 36.9% MgO 1.45% Al 2 o 3 6.8%SiO2 2 42.2% SO 3 0.15%P 2 o 5 1.2%K 2 O 0.4% CaO 2.33 % Fe 2 o 3 3.7% Cl 0.17%, the rest are impurities.

[0032] In this embodiment, the solid mold powder is added into the centrifugal roll in a liquid form, and the specific method includes the following steps,

[0033] 1) Put the solid mold slag into the heating furnace 1, set the heating temperature to 1300°C through the control system of the heating furnace 1, and heat the solid mold slag to the specified temperature to melt the solid mold slag into a liquid state;

[0034] 2) After pouring the outer layer of molten iron on the centrifugal roll, pour the melted mold slag into the cold type 3 cavity of the centrifugal roll. The liquid mold slag in the heating furnace 1 flows into the stainless steel chute 2 through the slag pouring pipe 1 - 1 at the bottom of the heating furnace 1 , and pours into...

Embodiment 3

[0036] The composition and weight percentage of mold flux in this embodiment are Na 2 O 38.9% MgO 1.2% Al 2 o 3 6.3%SiO2 2 40.2% SO 3 0.22%P 2 o 5 1.0%K 2 O 0.65% CaO 2.2% Fe 2 o 3 4.5% Cl 0.12%, the rest are impurities.

[0037] In this embodiment, the solid mold powder is added into the centrifugal roll in a liquid form, and the specific method includes the following steps,

[0038] 1) Put the solid mold slag into the heating furnace 1, set the heating temperature to 1400°C through the control system of the heating furnace 1, and heat the solid mold slag to the specified temperature to melt the solid mold slag into a liquid state;

[0039]2) After pouring the outer layer of molten iron on the centrifugal roll, pour the melted mold slag into the cold type 3 cavity of the centrifugal roll. The liquid mold slag in the heating furnace 1 flows into the stainless steel chute 2 through the slag pouring pipe 1 - 1 at the bottom of the heating furnace 1 , and pours into th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com