Heat-resistant steel for automobile turbine shell and exhaust pipe and preparation method of heat-resistant steel

A technology of automobile turbine shell and heat-resistant steel, which is applied in the field of mechanical casting, can solve the problems of increased difficulty of turbine shell and exhaust pipe, increased cost of processing tools, and increased manufacturing cost, so as to reduce the defective rate of slag holes and reduce processing costs , the effect of increasing the fluidity of molten steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 2 Embodiment

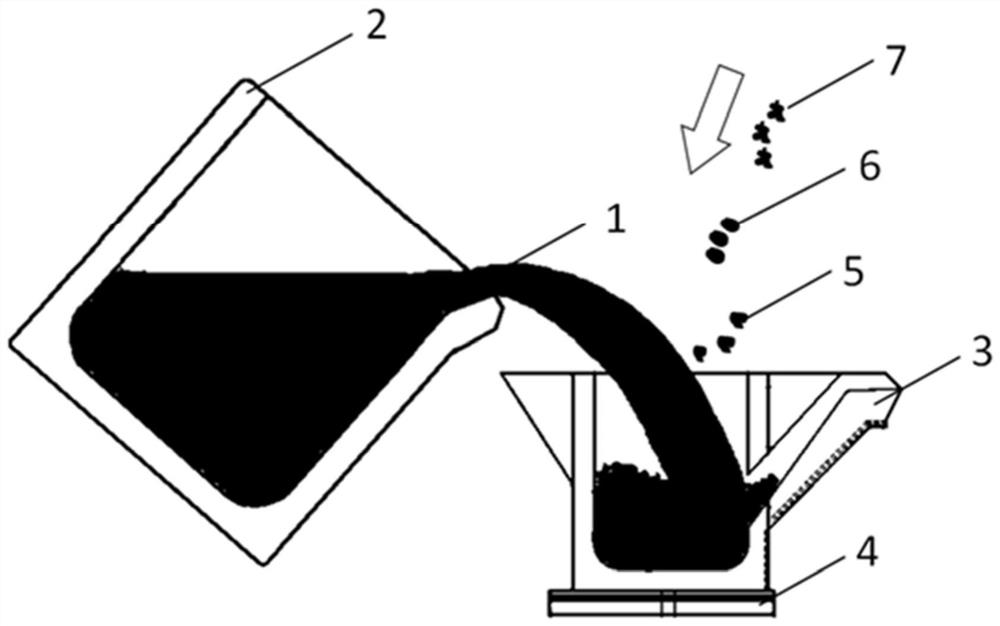

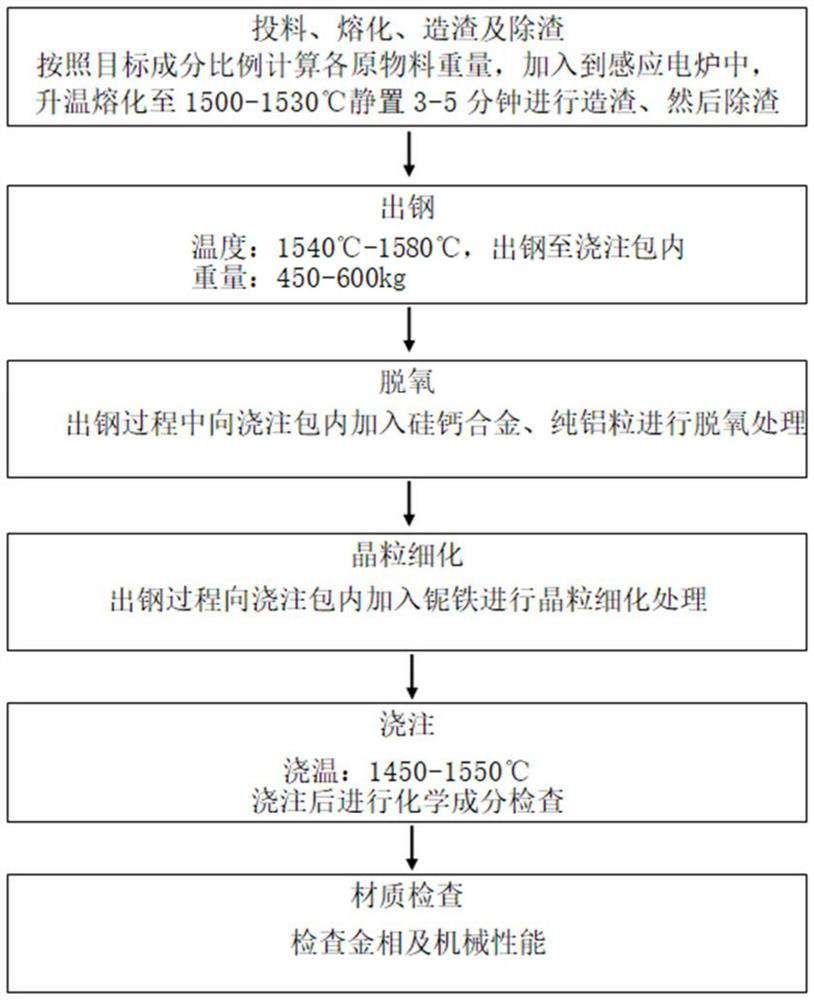

[0048] Put the raw material of heat-resistant steel 1 into the induction furnace 2 (the present embodiment is an intermediate frequency induction furnace) for smelting;

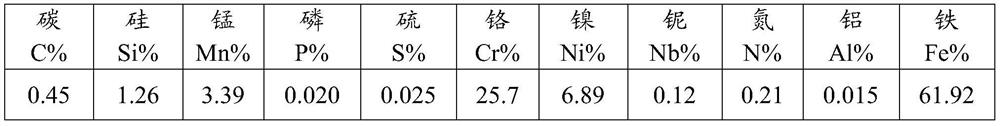

[0049] The ratio of the raw materials of the heat-resistant steel 1 is set as follows: steel accounts for 7.77% of the raw materials of the heat-resistant steel 1; 11.05% of the raw material ratio of heat-resistant steel 1, 2.4% of the raw material ratio of chromium nitride in heat-resistant steel 1, 1.9% of the raw material ratio of nickel plate in heat-resistant steel 1, and 1.9% of the raw material ratio of iron sulfide in heat-resistant steel 1 0.06% of the raw material ratio of the heat-resistant steel 1, ferroniobium accounted for 0.2%, electrolytic manganese accounted for 1.5% of the raw material ratio of the heat-resistant steel 1, and ferrosilicon accounted for 0.12% of the raw material ratio of the heat-resistant steel 1.

[0050] The specific steps of gradually melting raw materials into molten ste...

no. 3 Embodiment

[0065] Put the raw material of heat-resistant steel 1 into the induction furnace 2 (the present embodiment is an intermediate frequency induction furnace) for smelting;

[0066] The ratio of the raw materials of the heat-resistant steel 1 is set as follows: steel accounts for 11.42% of the raw materials of the heat-resistant steel 1, recycled materials account for 70% of the raw materials of the heat-resistant steel 1, and micro-carbon ferrochrome accounts for 11.42% of the raw materials of the heat-resistant steel 1. 8.54% of the raw material ratio of heat-resistant steel 1, 1.8% of the raw material ratio of chromium nitride in heat-resistant steel 1, 3.15% of the raw material ratio of nickel plate in heat-resistant steel 1, 3.15% of the raw material ratio of iron sulfide in heat-resistant steel 1 0.22% of the raw material ratio of the heat-resistant steel 1, ferroniobium accounted for 0.35%, electrolytic manganese accounted for 3.1% of the raw material ratio of the heat-resis...

no. 4 Embodiment

[0082] Put the raw material of heat-resistant steel 1 into the induction furnace 2 (the present embodiment is an intermediate frequency induction furnace) for smelting;

[0083] The ratio of the raw materials of the above-mentioned heat-resistant steel 1 is set as steel accounts for 3.2% of the raw materials of the heat-resistant steel 1, the recycled charge accounts for 65% of the raw materials of the heat-resistant steel 1, and the micro-carbon ferrochrome accounts for 1% of the heat-resistant steel 1. 15.71% of the raw material ratio of heat-resistant steel 1, 3.6% of the raw material ratio of chromium nitride in heat-resistant steel 1, 4.63% of the raw material ratio of nickel plate in heat-resistant steel 1, and 4.63% of the raw material ratio of iron sulfide in heat-resistant steel 1 0.30% of the raw material ratio of heat-resistant steel 1, ferroniobium accounted for 0.45%, electrolytic manganese accounted for 5.0% of the raw material ratio of heat-resistant steel 1, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com