A graphite/metal matrix self-lubricating composite material and its 3D printing preparation method

A 3D printing and composite material technology, which is applied in the field of graphite/metal-based self-lubricating composite materials and their 3D printing preparation, can solve the problem that graphite cannot be prepared with gradient distribution and local distribution composite materials, it is difficult to increase the amount of graphite added, and it is difficult to control graphite Distribution and other issues, to achieve the effect of controllable graphite distribution, good self-lubricating and anti-friction performance, and controllable graphite content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] The 3D printing preparation method of the above-mentioned graphite / metal-based self-lubricating composite material comprises the following steps:

[0024] (1) Prepare flake graphite powder and metal powder according to the performance index requirements, and dry the powder;

[0025] (2) Prepare the mixed powder of flake graphite powder and metal powder according to the ratio;

[0026] (3) Graphite / metal composites were directly prepared by selective laser sintering (SLS) or selective laser melting (SLM).

[0027] In step (1), the drying treatment process of flake graphite powder and metal powder is as follows: drying temperature is 100-150°C, and drying time is 0.5h-24h.

[0028] In the step (2), in the prepared mixed powder, the volume ratio of flake graphite powder to metal powder is 1:99˜50:50. The larger the proportion of graphite powder, the better the self-lubricating and anti-friction performance, thermal conductivity, and corrosion resistance of the composite ...

Embodiment 1

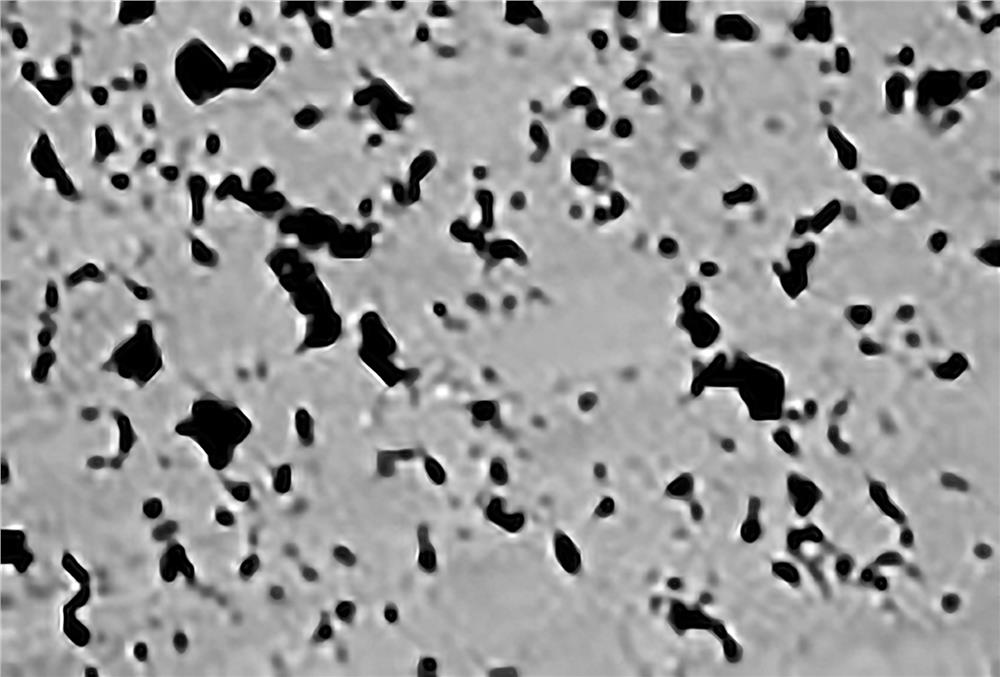

[0031] Example 1: Preparation of graphite / stainless steel self-lubricating composite material by using mixed powder of graphite and stainless steel and selective laser sintering (SLS method)

[0032] (1) Prepare flake graphite powder and stainless steel powder according to the requirements of performance indicators, both of which are screened for spherical or nearly spherical particles, with an average particle size of 38 μm. The two powders were dried separately at a drying temperature of 120° C. and a drying time of 5 hours.

[0033] (2) Put the prepared graphite powder and stainless steel powder into the ball mill according to the proportion, mix and ball mill for 2 hours and take out. Wherein the volume ratio of graphite powder input is 25%.

[0034](3) The graphite / stainless steel self-lubricating composite material is prepared by the laser selective sintering method (SLS method). At this time, the thickness of the powder layer is 40 μm, and the laser power is 80 KW to 1...

Embodiment 2

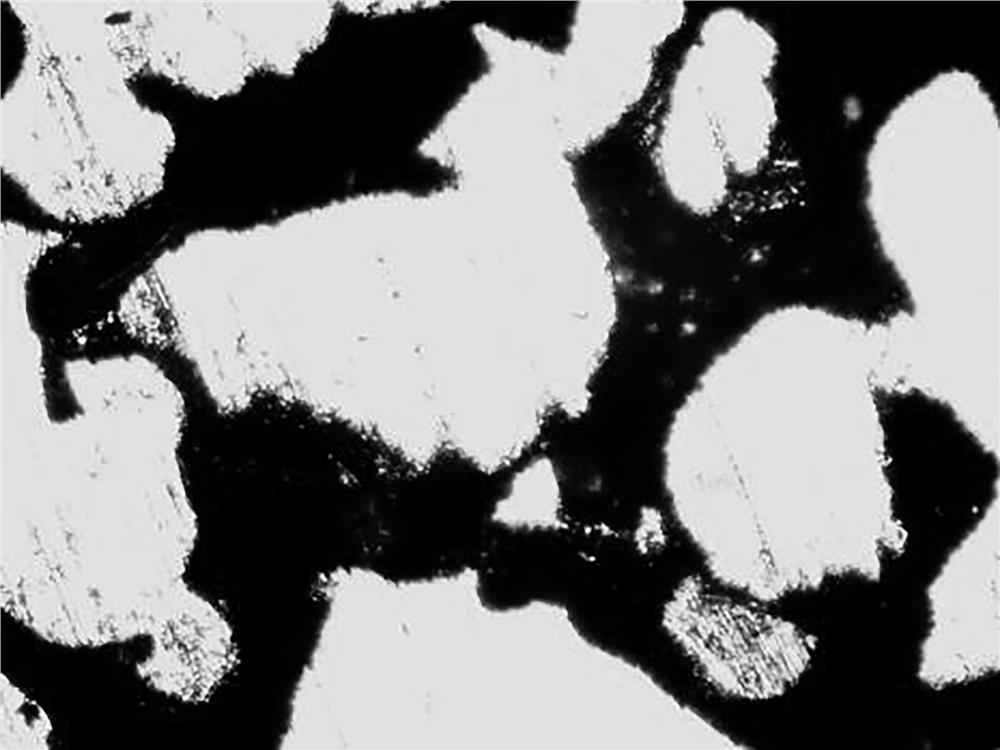

[0036] Embodiment 2: Prepare graphite / stainless steel self-lubricating composite material by using mixed powder of graphite and stainless steel and selective laser melting method (SLM method)

[0037] (1) Prepare flake graphite powder and stainless steel powder according to the requirements of performance indicators, both of which are screened for spherical or nearly spherical particles, with an average particle size of 48 μm. These two kinds of powders were dried separately at a drying temperature of 150° C. and a drying time of 12 hours.

[0038] (2) Put the prepared graphite powder and stainless steel powder into the rod mill according to the proportion, mix and ball mill for 3 hours and take it out. Wherein the volume ratio of graphite powder input is 50%.

[0039] (3) Graphite / stainless steel self-lubricating composite materials are prepared by laser selective melting method (SLM method). At this time, the thickness of the powder layer is 50 μm, and the laser power is 14...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com