Liquid filling machine

A filling machine and liquid technology, applied in liquid bottling, liquid processing, packaging and other directions, can solve the problems of frequent start-up and easy damage, decreased measurement accuracy, and reduced concentration, etc., to simplify the control of liquid level, improve reliability, The effect of fast filling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

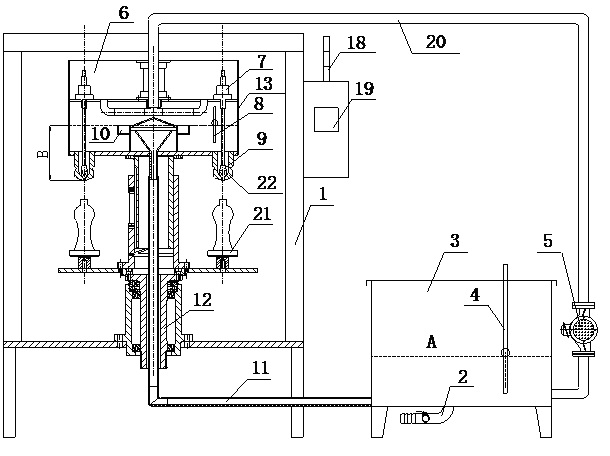

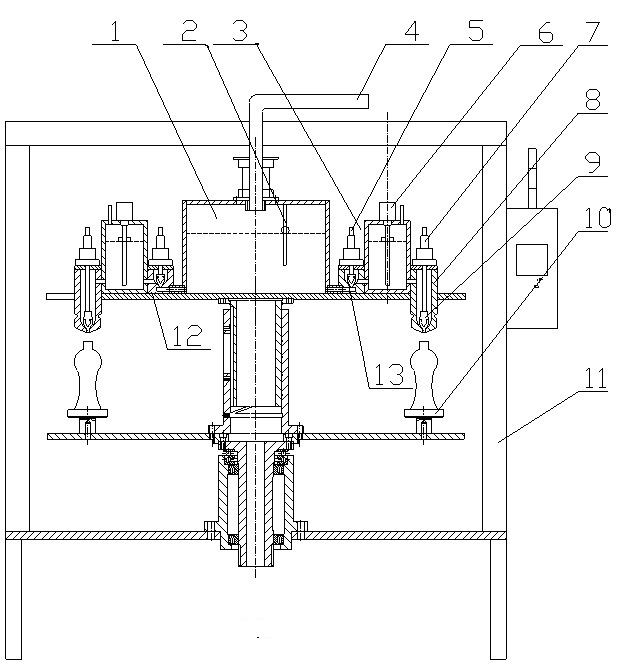

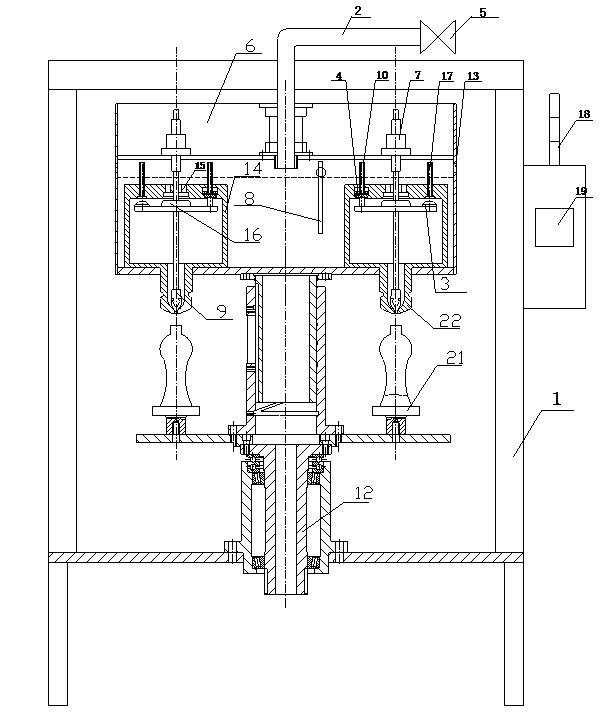

[0080] Such as image 3 As shown, a liquid filling machine includes a frame 1, a liquid inlet pipe 2, a sealing gasket 3 of the air inlet pipe before filling, a sealing gasket 4 of the air inlet pipe during filling, a liquid inlet ball valve 5, and a filling machine liquid storage tank 6 , cylinder 7, filling machine liquid storage tank float switch 8, filling valve spool 9, filling in progress vent pipe 10, main drive shaft 12, vent hole 13, constant liquid level cup 14, liquid inlet 15, Liquid inlet sealing gasket 16, vent pipe 17 before filling, warning light 18, touch screen 19, bottle tray 21 and filling head 22, wherein, liquid inlet pipe 2 passes through the upper end of frame 1 and directly stores liquid with the filling machine The upper end of the tank 6 is connected, and the liquid storage tank 6 of the filling machine is equipped with a float switch 8 of the liquid storage tank of the filling machine and multiple groups of cylinders 7. The lower end of each group o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com