Passion fruit linear type filling machine

A linear, filling machine technology, used in packaging, bottle filling, liquid bottling, etc., can solve problems such as low production efficiency, and achieve the effects of high filling efficiency, violent relative movement, and rapid lifting and lowering.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

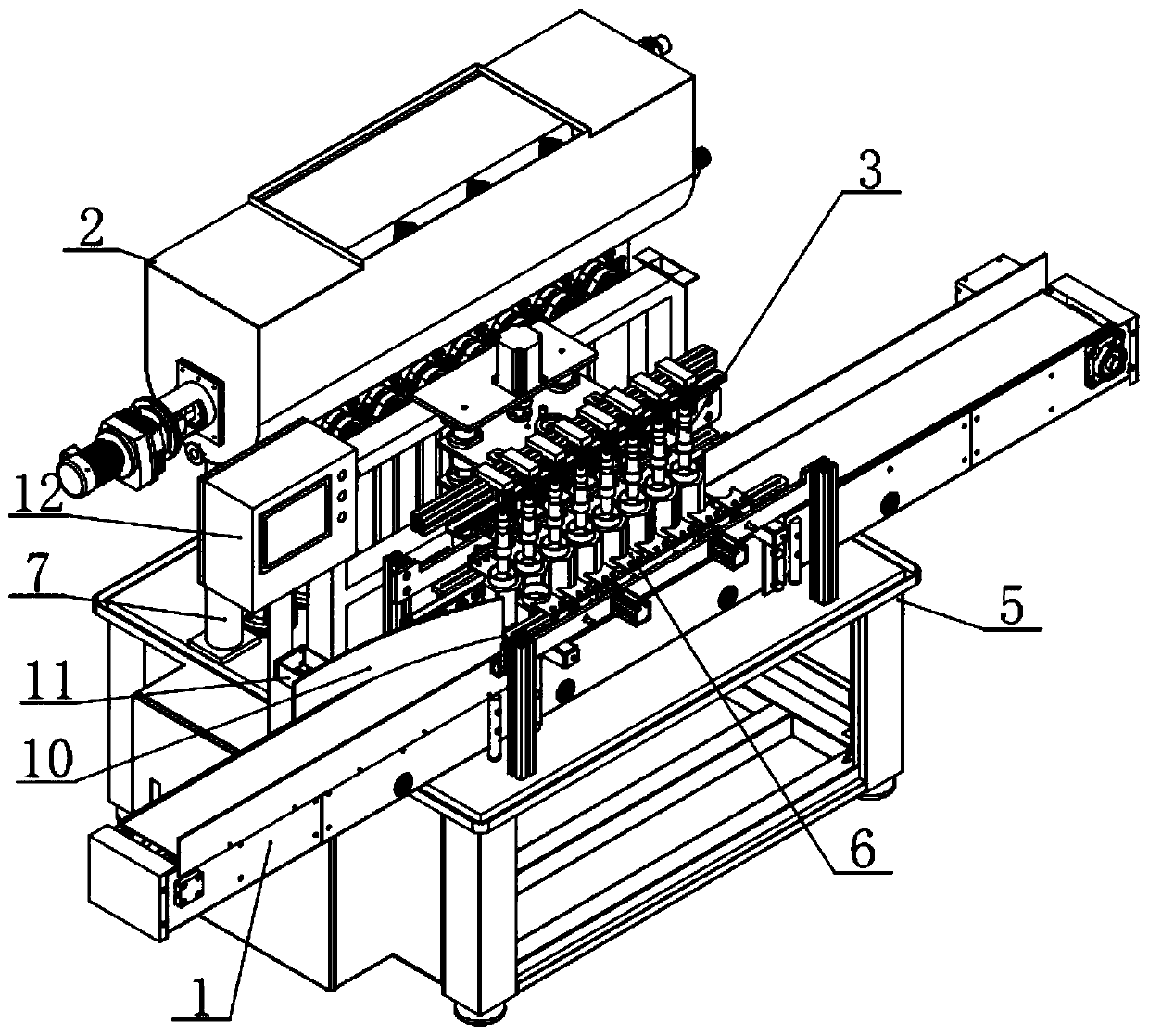

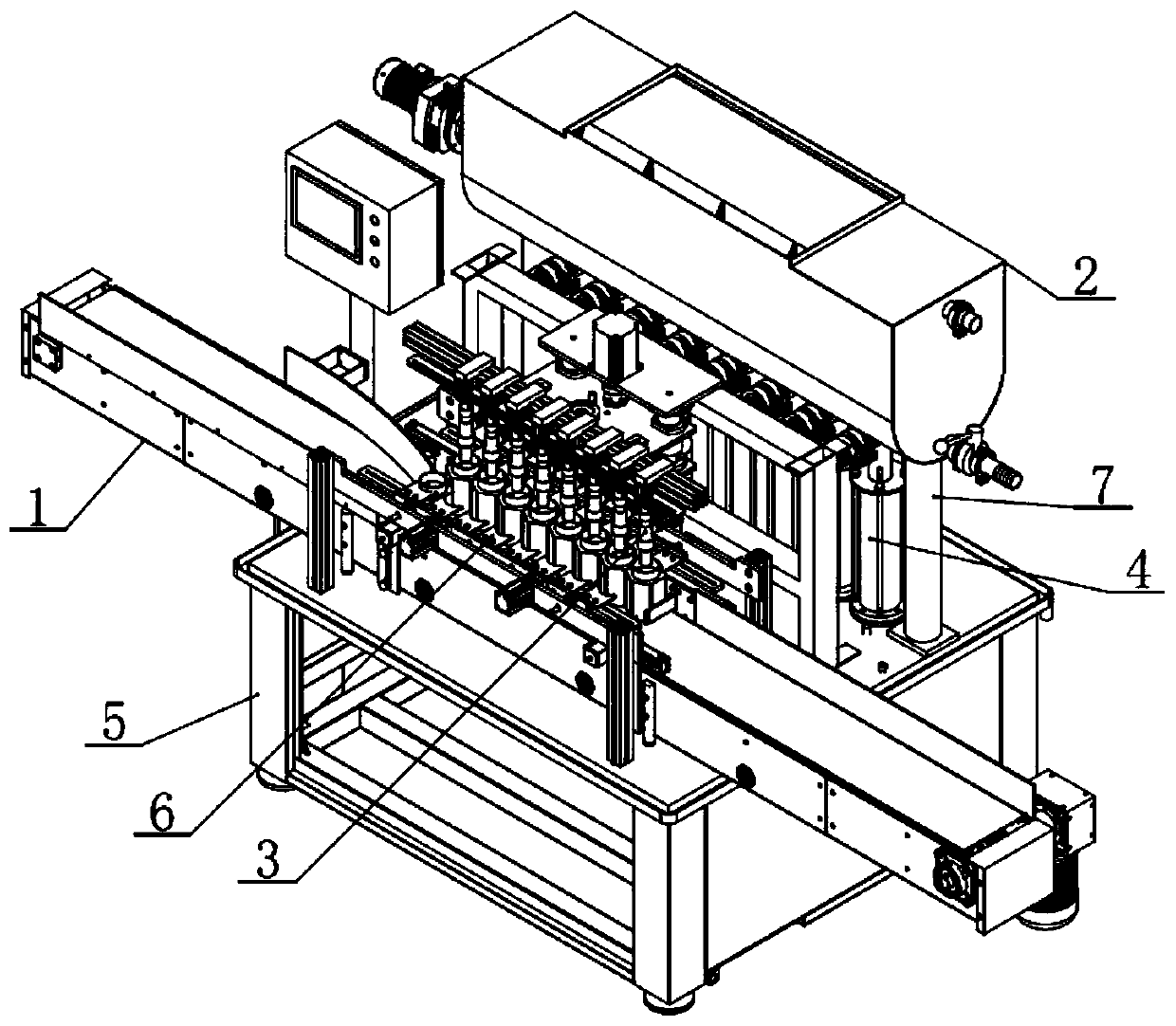

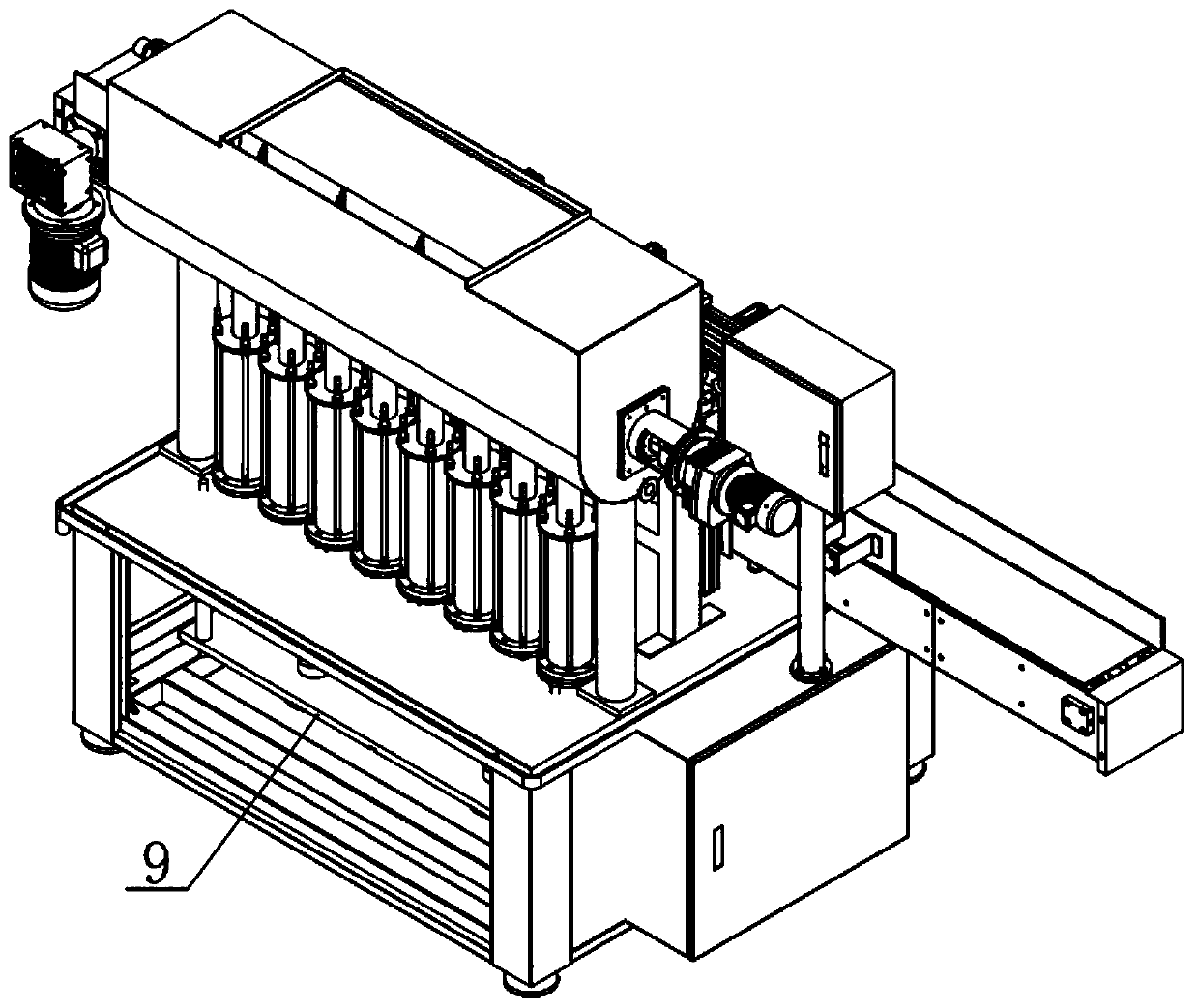

[0048] Embodiment 1: as Figure 1-Figure 23 As shown, a passion fruit linear filling machine includes a conveying mechanism 1, a mixer 2, a filling mechanism 3 and a metering cylinder 4. The conveying mechanism 1 is installed on the upper lateral front side of the base 5, and the middle part of the conveying mechanism 1 is installed on the front and rear sides. There is a bottle mouth limit mechanism 6 and a filling mechanism 3, the filling mechanism 3 is connected to the discharge end of the metering cylinder 4 through a pipe 8, the feeding end of the metering cylinder 4 is connected to the bottom of the mixer 2, and the mixer 2 is fixed by a support frame 7 Connected to the rear side of the base 5 , the piston rod 403 of the metering cylinder 4 is connected with a metering adjustment mechanism 9 , and the metering adjustment mechanism 9 is installed on the base 5 .

[0049] Preferably, the above-mentioned conveying mechanism 1 adopts a belt conveyor, and the frame of the bel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com