Optoelectronic components and methods for their manufacture

A component, optoelectronic technology, applied in electrical components, electro-solid devices, circuits, etc., can solve problems such as process speed reduction, achieve rapid and safe identification, and save method steps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

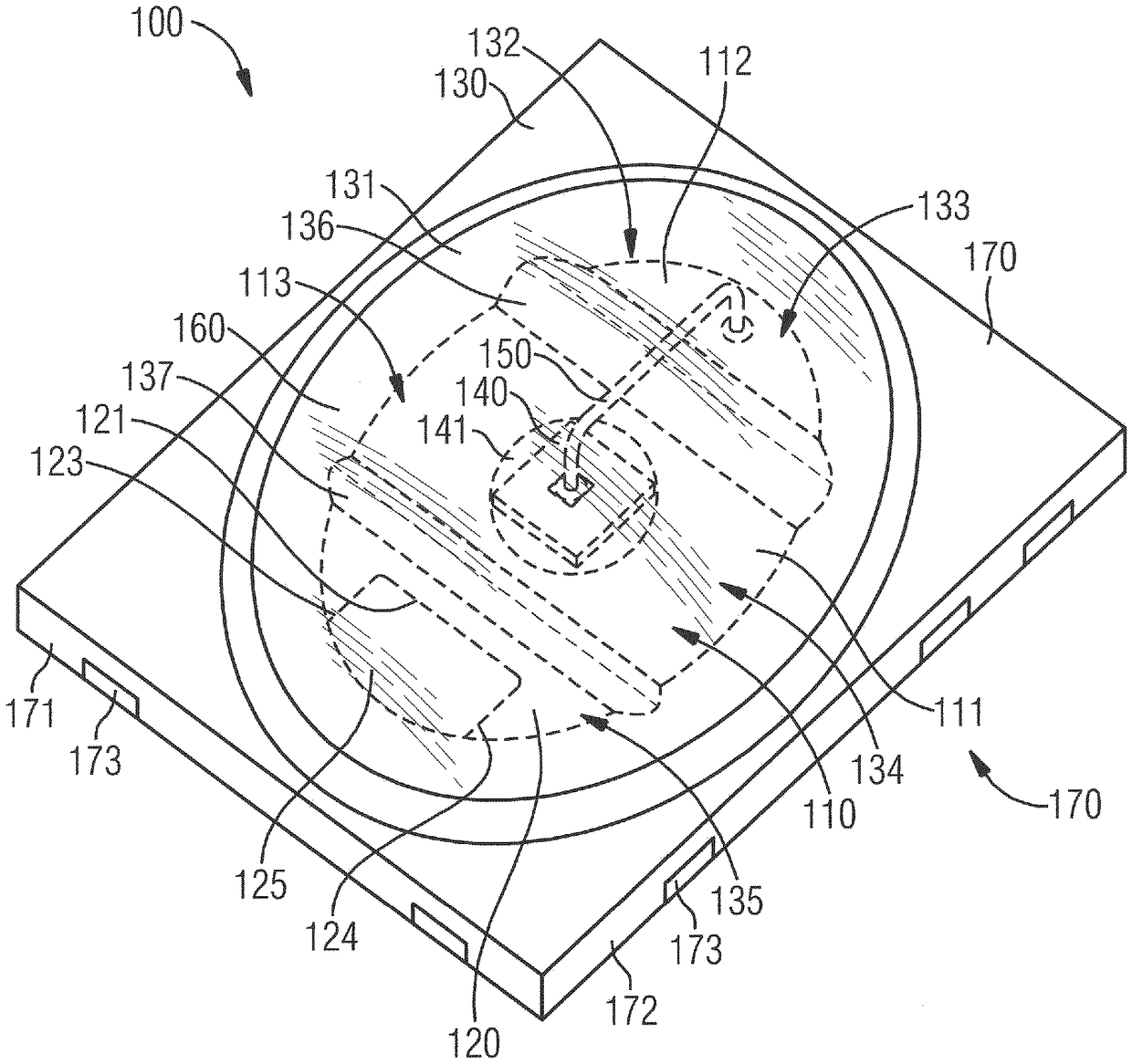

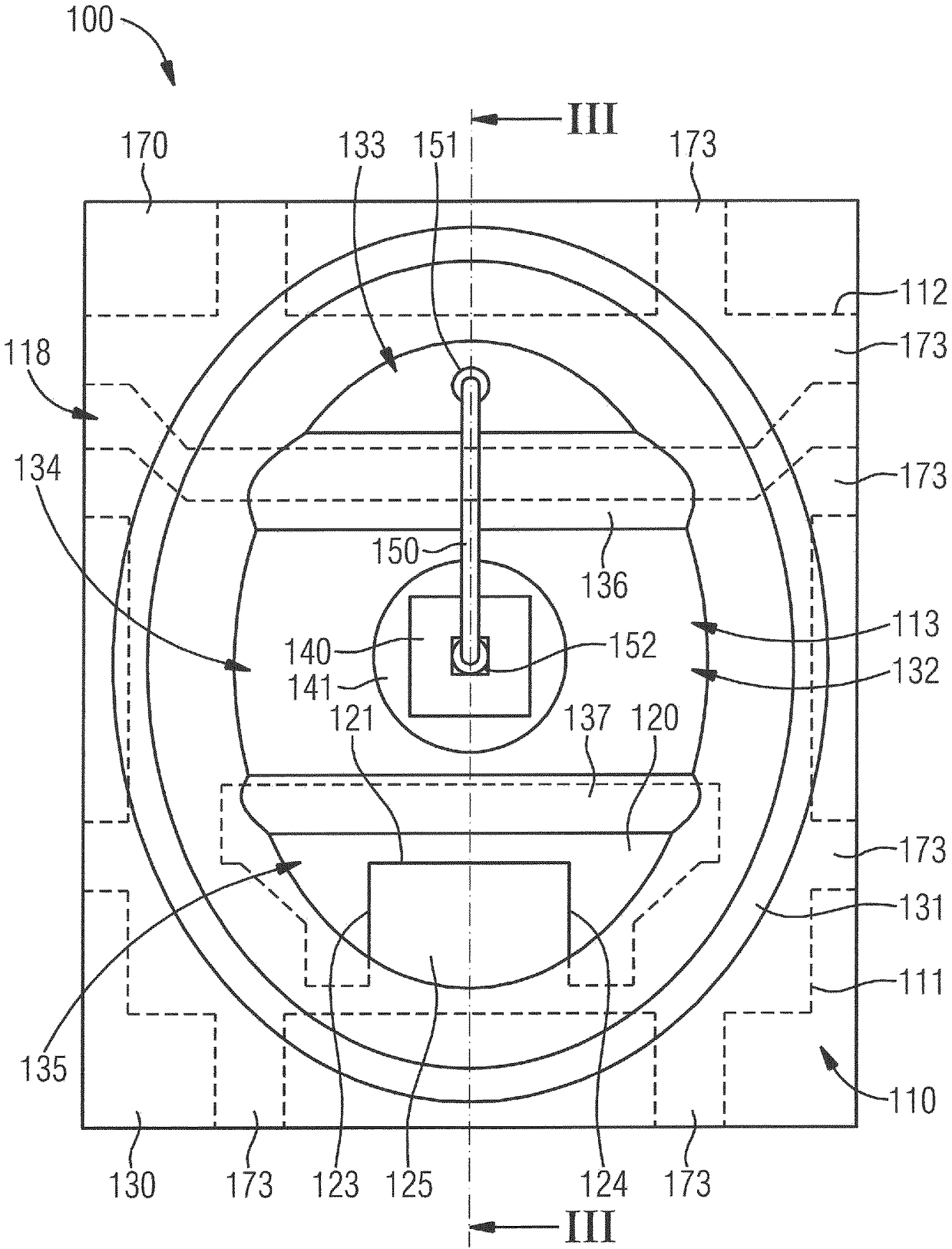

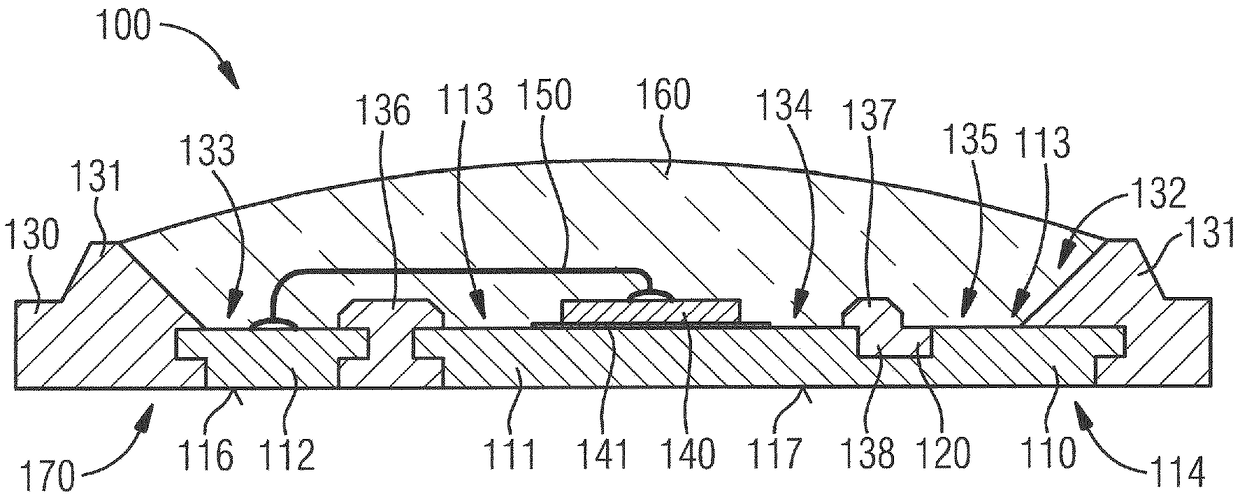

[0041] figure 1 Shows a perspective view of an optoelectronic component 100 designed according to a first embodiment of the invention, comprising a carrier 170 , an optoelectronic semiconductor chip 140 mounted on the carrier and an Housing 131. Here, used as a carrier is a lead frame 110 embedded in a molded body 130 formed of molding material. The housing 131 is designed in the present example with an elliptical contour which forms the cavity 132 for receiving the optoelectronic semiconductor chip 140 . The cavity 132 is divided into three sections 133 , 134 , 135 by two web-shaped structures extending transversely to the longitudinal axis of the elliptical housing. The optoelectronic semiconductor chip 140 is mounted directly on the surface of the frame element 110 in the central section 134 of the cavity 132 by means of solder or adhesive particles 141 . The lead frame 110 is constructed in two parts, wherein the semiconductor chip is fastened on the first lead frame pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com