A filling device and method for filling solid lubricating materials in micro-textured pits

A solid lubricating material and filling device technology, which is applied in the input of lubricating oil, lubricating parts, and engine lubrication, etc., can solve the problems of complex sputter deposition current control, slow film deposition speed, and relatively high working conditions. Effects that are easy to automate, fill well, and have wide applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

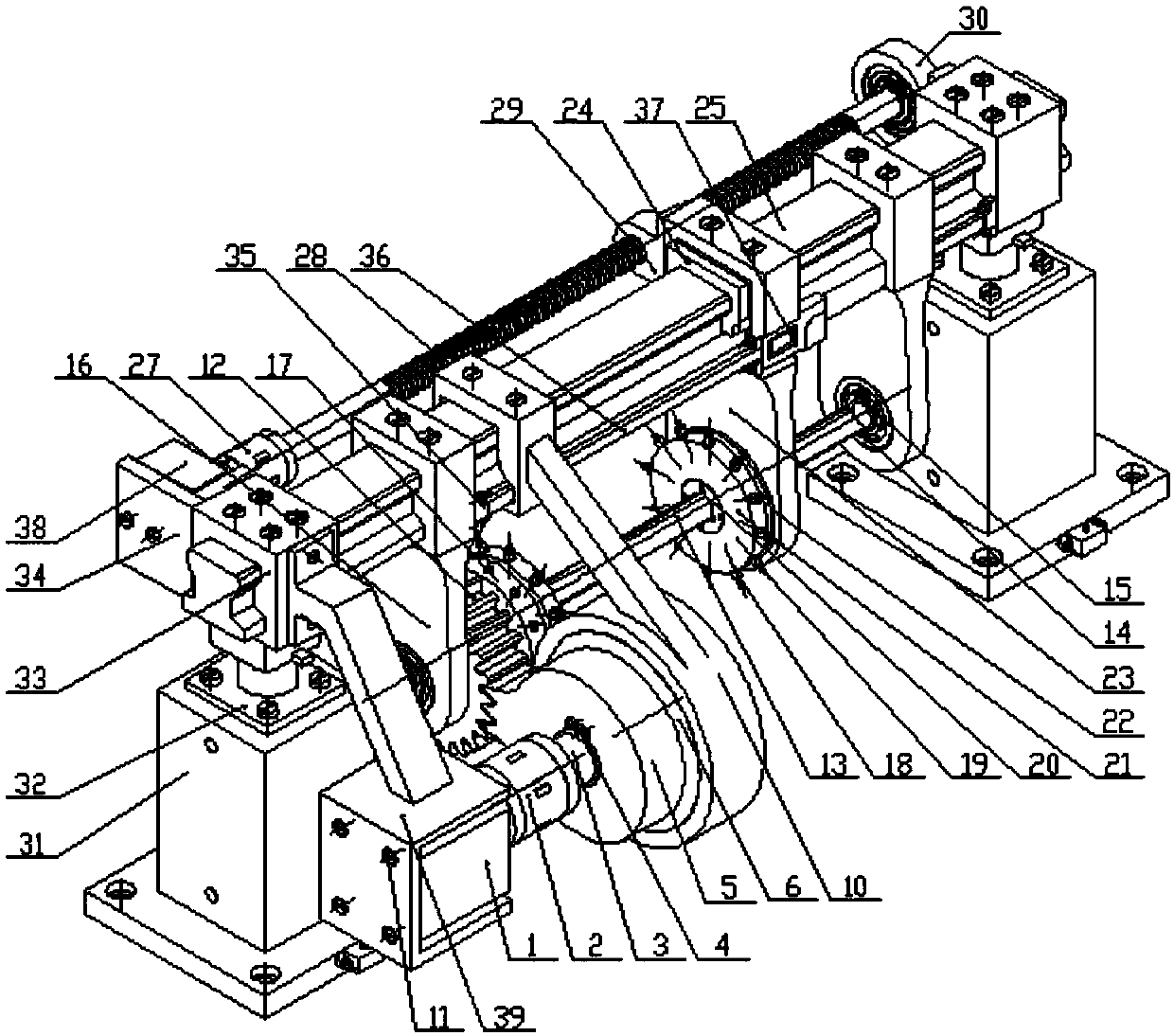

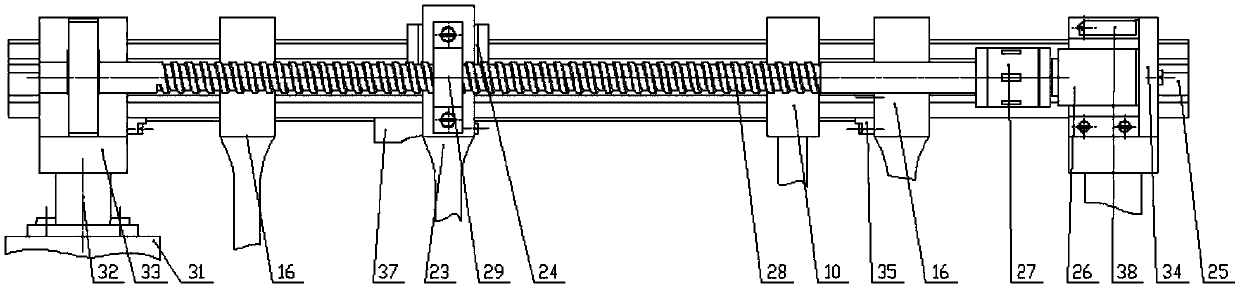

[0041] Such as figure 1 As shown, the micro-texture filling solid lubricating material filling device of the present invention is composed of a support system, a filling system, a multi-station mold rotation system, a locking system, a mold head spacing adjustment system, and a control system;

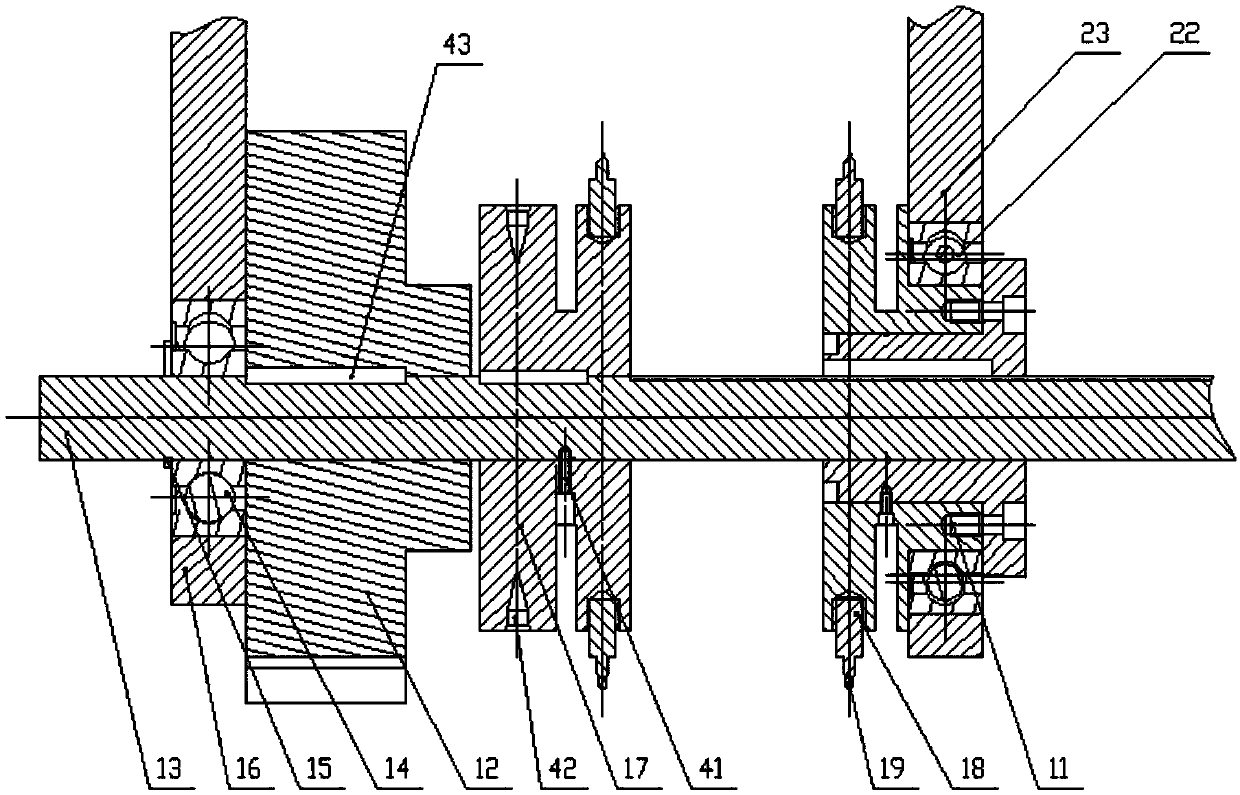

[0042] Such as figure 2 As shown, the multi-station mold rotation system includes a first stepping motor 1, a first coupling 2, a main shaft 3, a driving gear 5, a driven wheel 12, and a spline shaft 13, and the driving gear 5 is an incomplete gear, the driven wheel 12 is a complete gear, the first stepper motor 1 drives the main shaft 3 through the first coupling 2, the driving gear 5 is fixedly installed on the main shaft 3, and the driving gear 5 realizes the axis through the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com